| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2019-2022 |

| Base Year |

2023 |

| Forecast Period |

2024-2032 |

| 4D Printing Market Size 2024 |

USD 303.88 million |

| 4D Printing Market, CAGR |

35.14% |

| 4D Printing Market Size 2032 |

USD 3,358.15 million |

Market Overview:

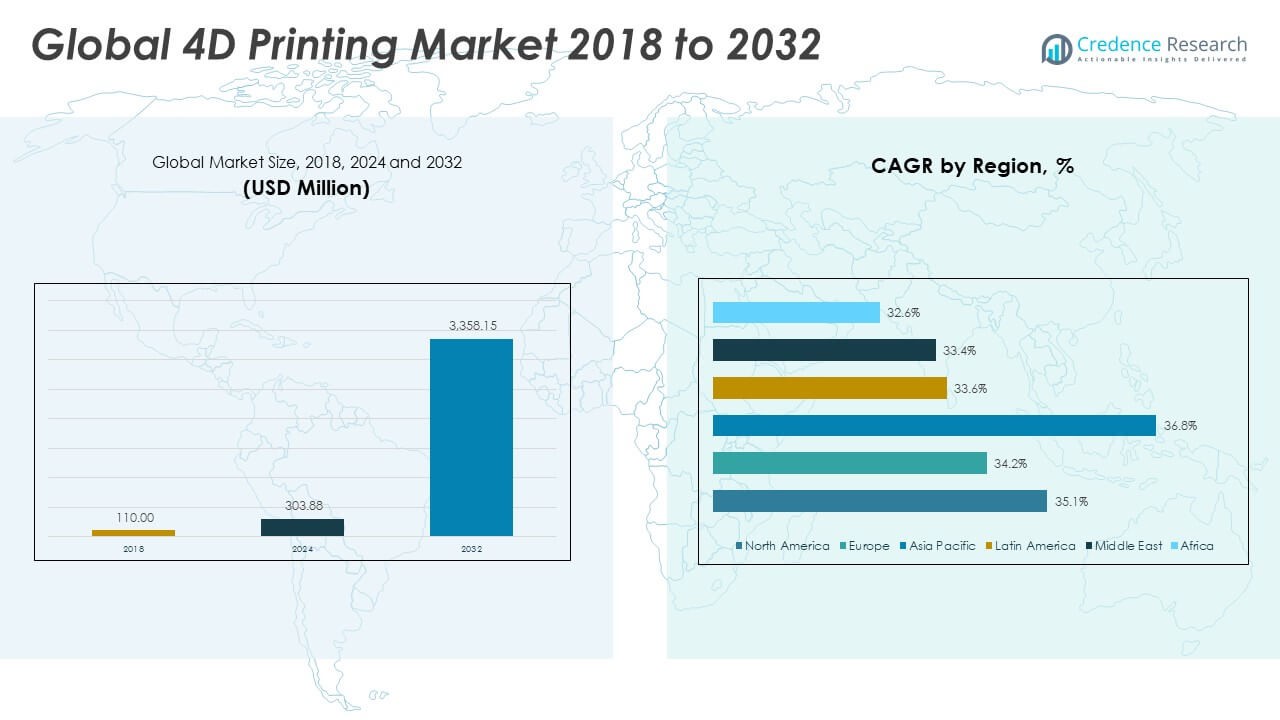

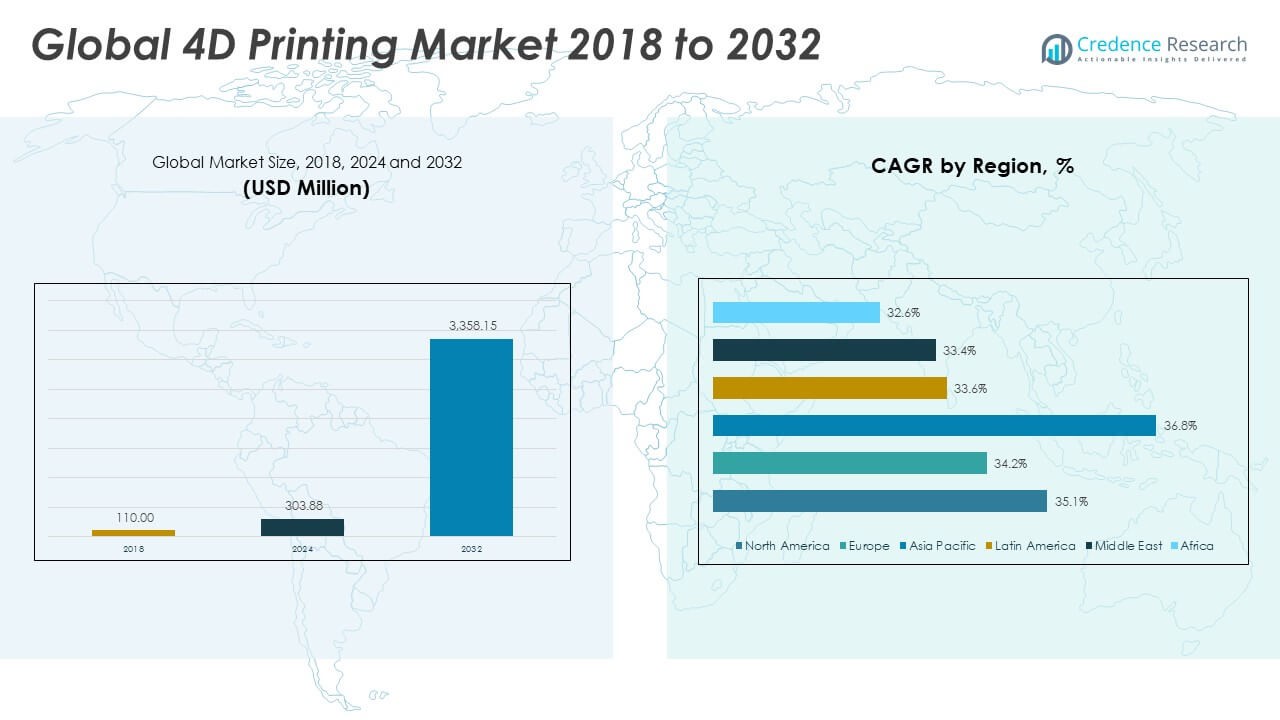

The 4D Printing Market size was valued at USD 110.00 million in 2018 to USD 303.88 million in 2024 and is anticipated to reach USD 3,358.15 million by 2032, at a CAGR of 35.14% during the forecast period.

The growth of the 4D printing market is driven by rapid advancements in programmable materials and increased adoption across diverse industries. These smart materials, which react to environmental stimuli such as heat, pressure, moisture, or light, are enabling the development of self-assembling, shape-shifting, and self-healing products. Industries such as aerospace, automotive, and healthcare are embracing 4D printing to achieve enhanced performance, adaptability, and durability in their applications. In aerospace and defense, for instance, the technology supports the creation of lightweight, deployable structures, while the medical field leverages it for customized implants and bioprinting. Additionally, the increasing focus on sustainability and resource efficiency is encouraging the shift toward additive manufacturing solutions that reduce waste and promote recyclability. Supportive government initiatives and rising R&D investments from both public and private sectors are further accelerating innovation, making 4D printing a cornerstone of next-generation digital manufacturing and Industry 5.0 ecosystems.

North America dominates the 4D printing market due to its advanced research infrastructure, strong presence of technology providers, and early adoption by major industries such as aerospace, healthcare, and defense. The region benefits from strong academic-industry collaboration, government funding for innovation, and a tech-savvy manufacturing sector that embraces next-gen technologies. Europe also shows robust activity, with several countries investing in sustainable manufacturing and digital transformation, particularly in healthcare and automotive applications. The Asia-Pacific region is emerging as the fastest-growing market, driven by rising industrialization, increased investment in smart technologies, and a growing focus on advanced manufacturing across countries like China, Japan, and South Korea. This region benefits from a large consumer base, expanding infrastructure, and government-backed innovation policies. Meanwhile, Latin America and the Middle East & Africa are gradually entering the 4D printing ecosystem, supported by rising awareness, expanding R&D capabilities, and growing demand for advanced materials across industrial and consumer applications.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The 4D Printing Market is projected to grow from USD 303.88 million in 2024 to USD 3,358.15 million by 2032, driven by a strong CAGR of 35.14%.

- Smart materials like shape-memory polymers, carbon fiber composites, and hydrogels are transforming the market by enabling products that self-adjust, self-heal, or reconfigure under environmental stimuli.

- Aerospace, automotive, and healthcare industries are leading adopters, integrating 4D printing into lightweight components, adaptive interiors, and patient-specific medical solutions.

- Rising demand for sustainable manufacturing and waste-reduction is pushing industries to shift toward 4D printing for its material efficiency and design flexibility.

- High material costs and limited commercial availability remain key challenges, restricting large-scale adoption and making the technology more suitable for high-value applications.

- Lack of standardized regulations and performance protocols slows industry-wide deployment, especially in heavily regulated sectors like healthcare and defense.

- North America leads the global market with robust research infrastructure, while Asia-Pacific emerges as the fastest-growing region, driven by smart manufacturing initiatives and industrial investment.

Market Drivers:

Emergence of Smart Materials is Transforming Product Capabilities

The 4D Printing Market is advancing due to the increasing adoption of smart materials that respond to environmental stimuli such as temperature, moisture, light, and pressure. These materials enable printed objects to change shape, function, or properties over time without external mechanical input. Shape-memory polymers, hydrogels, and carbon fiber composites have become central to 4D printing innovation. Industries now explore applications that require adaptability, self-healing, and reusability. This shift allows manufacturers to design more efficient, durable, and intelligent components across various sectors. It supports next-generation product development where form and function are no longer fixed.

Aerospace, Automotive, and Healthcare Sectors Are Driving Adoption

Industry-specific demands are playing a critical role in accelerating the 4D Printing Market. The aerospace sector prioritizes lightweight and self-deploying structures that optimize fuel efficiency and reduce payload costs. In automotive, manufacturers explore self-adaptive interiors and exterior components that enhance safety and user experience. The healthcare industry seeks patient-specific implants, biocompatible scaffolds, and responsive drug delivery systems. These applications demonstrate strong commercial value and are receiving funding and technical support. It enables these sectors to incorporate 4D printing into both prototyping and final production.

- For example, in healthcare, researchers at Queen’s University Belfast created personalized 4D printed breast implants for cancer treatment, marking the first use of 4D printing for such medical implant.

Rising Focus on Sustainable Manufacturing is Fueling Market Growth

Environmental concerns and resource constraints have intensified the shift toward sustainable manufacturing practices. 4D printing aligns with this shift by minimizing material waste, reducing energy consumption, and extending product life cycles. The use of programmable materials reduces the need for multiple components, decreasing overall assembly time and complexity. This approach lowers environmental impact while supporting design efficiency. Companies view 4D printing as a viable solution for developing eco-conscious products. It reinforces efforts to meet regulatory standards and corporate sustainability goals.

Government Initiatives and Research Investments Are Expanding Technological Boundaries

Public and private investment in research and innovation is significantly contributing to the growth of the 4D Printing Market. National governments and academic institutions are supporting advanced manufacturing through grants, innovation hubs, and collaborative projects. Startups and established firms are working with research labs to refine material science and software capabilities. These partnerships accelerate the translation of experimental concepts into commercial products. Standardization and policy frameworks are also evolving to support broader adoption across industries. It helps establish 4D printing as a scalable and economically viable manufacturing technology.

- For instance, Japan’s Ministry of Economy, Trade and Industry (METI) allocated 1.3% of its ICT budget in 2024 approximately $450 million to 4D printing R&D within smart manufacturing programs. Additionally, China’s Ministry of Industry and Information Technology increased 4D printing technology spending by 62% from 2018 to 2023, totaling ¥1.9 billion, and supported the adoption of 4D-print integrated ICT systems by 12 million enterprises in 2023.

Market Trends:

Integration with AI and Machine Learning is Enhancing Functional Customization

The 4D Printing Market is witnessing a strong trend toward the integration of artificial intelligence (AI) and machine learning in material programming and design optimization. AI helps predict how materials will behave under various stimuli and environmental conditions, improving the efficiency of design iterations. Developers now use machine learning algorithms to refine transformation sequences and reduce structural failures. This integration supports automated decision-making in design workflows and accelerates the production cycle. It also improves real-time control over functional responses in smart printed objects. The combination of 4D printing and AI is shaping the future of intelligent manufacturing systems.

- For example, IBM’s recent patent (US Patent No. 20250073998, published March 2025) demonstrates a concrete leap in integrating machine learning with 4D printing. Their process uses ML models to continuously monitor and adjust the behavior of 4D-printed smart materials in real time, ensuring microparticles (as small as 1–100 µm) are delivered precisely along programmed paths.

Expansion into Fashion, Textiles, and Consumer Goods is Creating New Demand Channels

New applications in fashion, textiles, and consumer goods are creating fresh momentum for the 4D Printing Market. Designers and brands are exploring responsive fabrics and wearable materials that can adjust to body temperature, movement, or environment. Sportswear and high-performance apparel increasingly incorporate adaptive functionality to enhance comfort and usability. Home furnishings and personal accessories are also being reimagined with embedded dynamic features. It opens up diverse revenue streams beyond industrial sectors and attracts interest from creative industries. The merging of function, form, and aesthetics is pushing boundaries in consumer product innovation.

Growing Role of Software Platforms is Simplifying Complex Design Processes

Advanced software platforms are playing a pivotal role in supporting the complex modeling and simulation requirements of the 4D Printing Market. New CAD and simulation tools allow engineers to visualize multi-state transformations and test functional transitions virtually. These tools integrate material science data, predictive modeling, and mechanical properties into the design environment. It makes multi-material and multi-layer printing more accessible to developers across disciplines. Streamlined interfaces and modular toolkits are reducing the learning curve for new users. Software innovations are transforming 4D printing from an experimental capability into a more user-friendly and scalable process.

Rise of Decentralized and On-Demand Manufacturing Models is Accelerating Adoption

Decentralized manufacturing and on-demand production models are gaining traction, with the 4D Printing Market benefiting from this shift. Organizations are setting up smaller, localized production hubs equipped with 4D printing systems to respond faster to changing customer needs. These models reduce dependency on large-scale facilities and long supply chains, allowing for real-time customization and reduced inventory costs. Rapid production close to end users shortens lead times and enhances responsiveness. It encourages a flexible approach to product development in sectors requiring frequent design updates. This trend aligns with the broader shift toward agile and distributed manufacturing strategies.

- For example, Stratasys has enabled localized production of dynamic, patient-specific medical devices in hospital-based micro-factories, reducing lead times from weeks to less than 48 hours for certain prosthetics and surgical models.

Market Challenges Analysis:

High Material Costs and Limited Commercial Availability Are Restricting Scale

One of the key challenges facing the 4D Printing Market is the high cost and limited availability of smart materials required for adaptive functions. Most of these advanced materials, such as shape-memory polymers and programmable composites, are still in the early stages of commercial development. Production of these materials remains expensive, which limits adoption across cost-sensitive industries. Many potential users struggle to justify investment without proven large-scale manufacturing outcomes. It makes the technology more viable for specialized applications rather than broad industrial use. Limited suppliers and fragmented sourcing further complicate procurement and increase supply chain risks.

Lack of Standardization and Regulatory Uncertainty Slows Adoption

Another major obstacle for the 4D Printing Market is the absence of clear industry standards and regulatory frameworks. Without universally accepted protocols for performance validation, safety testing, and compliance, companies face delays in bringing products to market. This creates uncertainty for stakeholders in regulated industries such as healthcare, aerospace, and automotive. It also slows investment from conservative sectors that require robust validation. Developers must spend significant resources on custom testing and approvals, which adds time and cost to deployment. The absence of harmonized standards restricts collaboration and cross-sector scalability.

Market Opportunities:

Emerging Applications in Medical Devices and Bioprinting Open New Revenue Streams

The 4D Printing Market holds strong potential in the development of next-generation medical devices, tissue engineering scaffolds, and drug delivery systems. The ability to create patient-specific implants that adjust to physiological conditions offers a distinct advantage in personalized medicine. Biocompatible smart materials can enable structures that evolve within the body to improve healing and integration. Healthcare institutions are exploring dynamic stents, self-deploying devices, and responsive prosthetics. It positions 4D printing as a key enabler in advanced biomedical solutions. This growing interest from the medical sector presents significant commercial and clinical opportunities.

Expansion into Infrastructure and Smart Construction Materials Supports Long-Term Growth

Infrastructure and construction represent untapped opportunities for the 4D Printing Market. Researchers and developers are working on materials that respond to environmental stress, temperature fluctuations, or mechanical strain. These innovations can enable adaptive building components, such as shape-shifting façades or self-repairing structural elements. It enhances resilience in architecture and supports sustainable urban development. Construction companies and civil engineers are beginning to evaluate pilot projects using programmable concrete and flexible reinforcement systems. Broader application across public and private infrastructure projects could drive large-scale adoption over the next decade.

Market Segmentation Analysis:

The 4D Printing Market is segmented by material and end use, reflecting diverse industrial demand and evolving application areas.

By material, programmable carbon fiber leads due to its lightweight strength and responsiveness, making it ideal for aerospace and defense applications. Programmable wood, with its custom printed grain structure, offers adaptive behavior for sustainable design, attracting interest in architecture and consumer goods. Programmable textiles support wearable technology and smart clothing innovations, especially in the healthcare and fashion sectors. Each material type brings unique transformation capabilities under specific environmental stimuli, expanding use-case possibilities.

- For example, MXene-reinforced nanocellulose fiberswere 4D-printed to create smart fabrics with controlled photothermal and electrothermal responses. These fabrics enable real-time monitoring of human motion (e.g., finger flexion, wrist movement) and are being prototyped for medical sensors and rehabilitation aids.

By end use, military and defense dominate due to the demand for deployable structures, self-repairing components, and adaptable gear. Aerospace follows closely, leveraging 4D printing for lightweight, reconfigurable components that reduce operational risk and cost. The automotive sector applies it to interior systems and smart assemblies. Healthcare is adopting 4D printing for patient-specific implants and bioprinted structures. Textile applications are emerging through responsive garments and performance fabrics. It continues to evolve across diverse industries seeking smart, sustainable, and adaptive manufacturing solutions.

- For example, 4D-printed components are being researched for deployable satellite antennas and solar panels that can be compactly stowed and reconfigured in orbit, reducing launch mass and increasing reliability.

Segmentation:

By Material:

- Programmable Carbon Fiber

- Programmable Wood (Custom Printed Wood Grain)

- Programmable Textiles

By End Use:

- Military & Defense

- Aerospace

- Automotive

- Healthcare

- Textile

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Regional Analysis:

North America

The North America 4D Printing Market size was valued at USD 41.27 million in 2018 to USD 112.68 million in 2024 and is anticipated to reach USD 1,243.53 million by 2032, at a CAGR of 35.1% during the forecast period. North America dominates the global 4D printing landscape with the highest market share, driven by strong research infrastructure, early technology adoption, and significant investment from aerospace and healthcare sectors. Key players and research institutions in the U.S. and Canada are collaborating to advance material science and additive manufacturing. Government-backed initiatives and private R&D funding support rapid prototyping and commercialization. It benefits from established regulatory frameworks and a mature industrial base. North America continues to lead in patent filings and industrial applications, reinforcing its position at the forefront of innovation. The region remains a hub for early-stage pilots and advanced manufacturing capabilities.

Europe

The Europe 4D Printing Market size was valued at USD 29.59 million in 2018 to USD 78.64 million in 2024 and is anticipated to reach USD 821.91 million by 2032, at a CAGR of 34.2% during the forecast period. Europe holds a significant share of the global market, with strong demand coming from automotive, aerospace, and medical sectors. Countries such as Germany, France, and the U.K. invest heavily in sustainable manufacturing technologies. It benefits from a well-developed industrial base and robust university-industry partnerships. European regulatory bodies are also shaping standards for adaptive materials and medical-grade applications. The region focuses on integrating 4D printing with sustainability goals and circular economy frameworks. Continued R&D support and cross-border collaborations are expected to strengthen its competitive edge.

Asia Pacific

The Asia Pacific 4D Printing Market size was valued at USD 26.40 million in 2018 to USD 76.23 million in 2024 and is anticipated to reach USD 931.22 million by 2032, at a CAGR of 36.8% during the forecast period. Asia Pacific is the fastest-growing region in the global market, supported by expanding industrial capabilities and rising investment in smart manufacturing. Countries such as China, Japan, and South Korea lead in R&D and consumer electronics innovation. Government initiatives to promote advanced technologies in manufacturing contribute to rapid regional growth. It benefits from lower production costs and a vast manufacturing ecosystem. The region also shows strong momentum in smart textiles, healthcare, and automotive applications. Asia Pacific continues to attract global players seeking scalable deployment opportunities.

Latin America

The Latin America 4D Printing Market size was valued at USD 5.63 million in 2018 to USD 15.37 million in 2024 and is anticipated to reach USD 154.71 million by 2032, at a CAGR of 33.6% during the forecast period. Latin America shows promising growth potential, driven by rising awareness and expanding access to digital manufacturing technologies. Countries like Brazil and Mexico are witnessing increased investment in industrial automation and research initiatives. Academic institutions and tech incubators are beginning to explore programmable materials and adaptive structures. It remains a nascent market with limited large-scale deployments. However, growing interest from medical and consumer goods industries suggests a positive trajectory. Public-private partnerships may accelerate regional expansion over the next decade.

Middle East

The Middle East 4D Printing Market size was valued at USD 4.18 million in 2018 to USD 10.82 million in 2024 and is anticipated to reach USD 107.81 million by 2032, at a CAGR of 33.4% during the forecast period. The Middle East is gradually adopting 4D printing technologies through smart city projects and sustainable infrastructure development. Countries like the UAE and Saudi Arabia are investing in innovation hubs and future-oriented manufacturing. It is exploring the integration of programmable materials in construction, energy, and defense applications. Localized production initiatives and government-led innovation drives support market visibility. Regional interest in high-performance components for extreme environments further boosts technology appeal. The Middle East is positioning itself as a strategic player in emerging advanced manufacturing trends.

Africa

The Africa 4D Printing Market size was valued at USD 2.93 million in 2018 to USD 10.15 million in 2024 and is anticipated to reach USD 98.96 million by 2032, at a CAGR of 32.6% during the forecast period. Africa represents an emerging market with untapped potential in healthcare, construction, and education. Countries like South Africa and Kenya are taking early steps to integrate digital manufacturing into national development goals. It faces challenges related to infrastructure, funding, and technical expertise. However, global partnerships and donor-supported innovation programs are fostering initial adoption. Pilot projects in healthcare and sustainable building materials are gaining interest. Africa offers long-term opportunity as infrastructure and policy frameworks evolve.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Autodesk, Inc.

- Stratasys

- HP Development Company, L.P.

- Organovo Holdings, Inc.

- Materialise

- ENVISIONTEC US LLC

- ExOne

- Dassault Systèmes

- CT Core Technologie Group

Competitive Analysis:

The 4D Printing Market features a competitive landscape defined by innovation, early-stage research, and strategic collaboration. Key players include industry giants, material science firms, and emerging startups, all focused on developing programmable materials and dynamic printing capabilities. Companies are investing in partnerships with universities and research institutions to accelerate breakthroughs in shape-memory polymers and self-transforming structures. It reflects a high level of patent activity and prototype development, particularly in aerospace, defense, and biomedical applications. Firms compete by enhancing software compatibility, reducing production complexity, and improving material responsiveness. Startups play a vital role in niche applications, while larger corporations focus on scalability and integration with existing additive manufacturing systems. The competitive environment encourages continuous experimentation, pushing boundaries in adaptive functionality and precision control. Strategic mergers, funding rounds, and joint ventures are shaping the market trajectory, positioning companies to capitalize on future demand across industrial and consumer domains.

Recent Developments:

- In March 2025, IBM obtained a U.S. patent for a machine learning‑controlled 4D‑printed smart material that can transport microparticles along predefined paths. The method uses external stimuli such as heat, light, or magnetic fields to control movement and adapts in real time via ML models monitoring any trajectory deviations.

- In May 2025, Airtech finalized the acquisition of Kimya, integrating the latter’s advanced filament portfolio into its offerings. It aims to enhance 4D printing material availability for industrial and educational users by expanding smart material compatibility. This strategic move supports broader adoption and simplifies access to programmable materials across global markets.

Market Concentration & Characteristics:

The 4D Printing Market remains moderately concentrated, with a limited number of players driving innovation and early commercialization. It is characterized by high R&D intensity, proprietary material development, and strong academic-industry collaboration. Most market participants operate in specialized segments, targeting aerospace, biomedical, automotive, and defense applications. The market favors companies with advanced material science capabilities and access to simulation and modeling technologies. It also exhibits high entry barriers due to the need for technical expertise, substantial investment, and complex regulatory compliance. Continuous innovation, intellectual property strength, and strategic partnerships define the competitive landscape and influence market dynamics.

Report Coverage:

The research report offers an in-depth analysis based on Material and End Use. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Demand for programmable and self-adaptive materials will expand across aerospace, automotive, and healthcare sectors.

- Integration with AI and digital twin technologies will improve precision and functional design.

- Commercial-scale production methods will evolve, reducing costs and improving scalability.

- Government support and funding for advanced manufacturing will stimulate regional innovation hubs.

- Adoption in smart textiles and consumer electronics will open new application areas.

- Standardization and regulatory frameworks will mature, enabling faster market entry.

- Strategic collaborations between tech firms and research institutions will accelerate innovation cycles.

- Startups will gain ground in niche applications through agile product development.

- Advancements in 4D bio-printing will drive breakthroughs in personalized medicine and regenerative therapies.

- Decentralized, on-demand manufacturing models will boost flexibility and reduce lead times globally.