Market Overview:

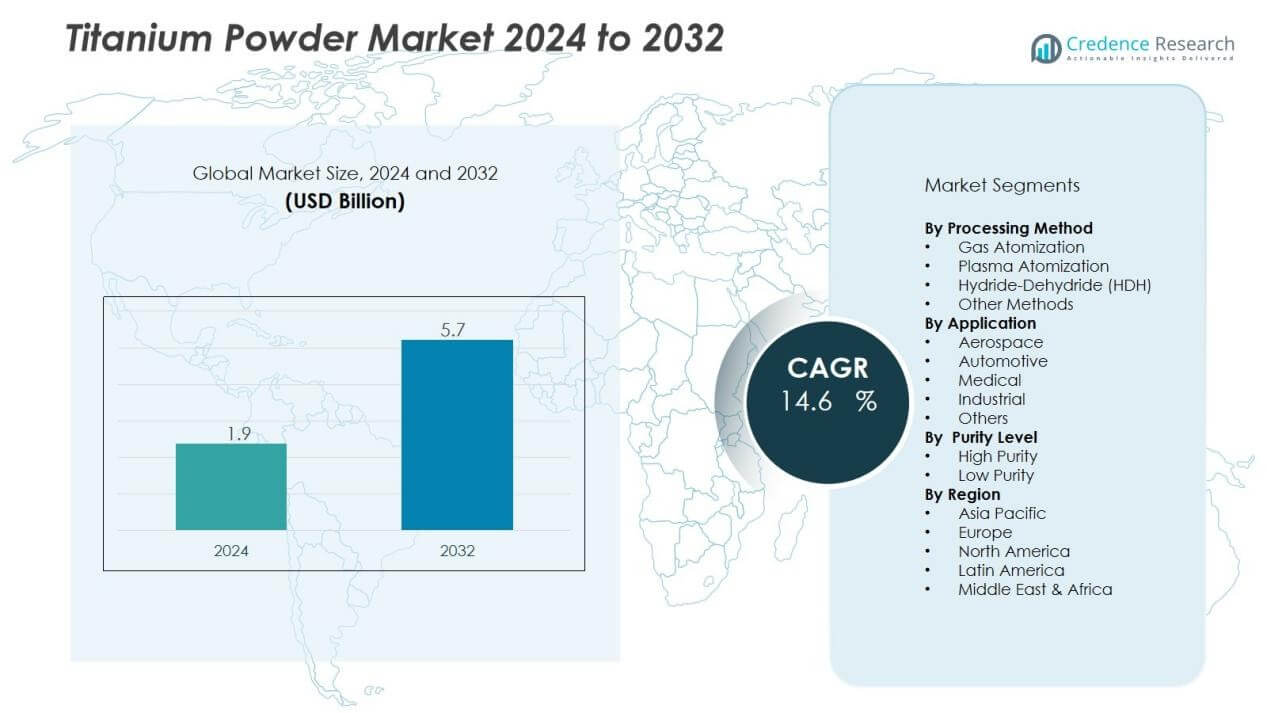

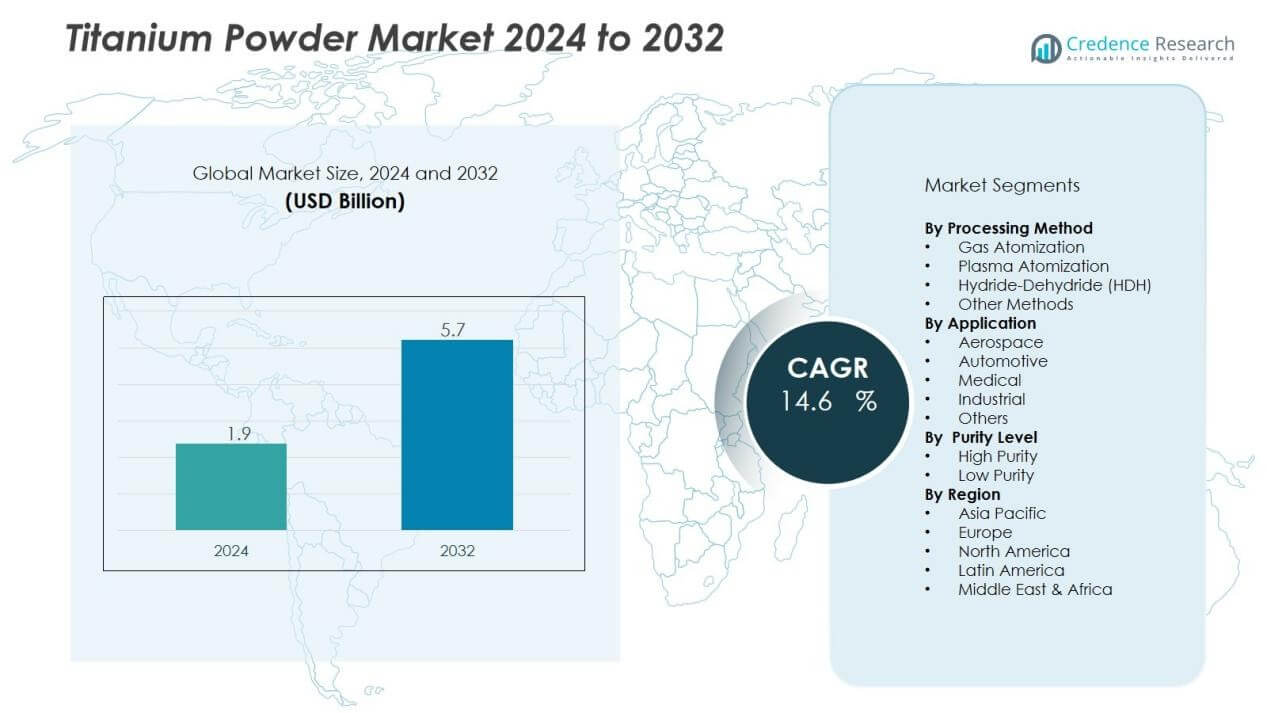

The titanium powder market size was valued at USD 1.9 billion in 2024 and is anticipated to reach USD 5.7 billion by 2032, at a CAGR of 14.6 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Titanium Powder Market Size 2024 |

USD 1.9 Billion |

| Titanium Powder Market, CAGR |

14.6% |

| Titanium Powder Market Size 2032 |

USD 5.7 Billion |

Key drivers include the growing adoption of 3D printing in aerospace and healthcare, where titanium powder enables precise, durable, and biocompatible components. Expanding use in the automotive sector for lightweight parts also boosts demand, as manufacturers seek to meet fuel efficiency and emission standards. Increasing investments in advanced powder metallurgy, alongside continuous innovations in atomization techniques, further enhance quality and production efficiency, making titanium powder more accessible across industries.

Regionally, North America holds a dominant share due to strong aerospace and defense manufacturing bases. Europe follows, supported by advanced medical device production and strict sustainability initiatives in automotive. Asia-Pacific is projected to record the fastest growth, driven by rapid industrialization, expansion of additive manufacturing, and growing medical tourism. Meanwhile, Latin America and the Middle East & Africa are emerging markets, supported by infrastructure development and increasing investment in advanced materials.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The titanium powder market was valued at USD 1.9 billion in 2024 and is projected to reach USD 5.7 billion by 2032 at a CAGR of 14.6%.

- Rising demand from aerospace and defense applications drives growth, supported by lightweight and heat-resistant properties for engines, airframes, and military equipment.

- Expanding role of additive manufacturing and 3D printing boosts adoption across medical, aerospace, and industrial sectors with titanium enabling precise and durable components.

- Increasing use in automotive lightweighting strategies supports emission compliance and electric vehicle innovation with titanium parts for safety and efficiency.

- Advancements in powder metallurgy and atomization processes improve uniformity, reduce costs, and enhance large-scale production reliability.

- High production costs and limited raw material availability remain a challenge, restricting scalability in price-sensitive industries.

- North America leads with 38% share due to aerospace, defense, and medical adoption, while Asia-Pacific records the fastest growth at 24% share driven by industrial expansion and electric vehicle demand.

Market Drivers:

Rising Demand from Aerospace and Defense Applications:

The titanium powder market benefits from strong adoption in aerospace and defense sectors. Titanium’s lightweight properties and resistance to high temperatures make it vital for aircraft engines, airframes, and spacecraft parts. Military programs also use titanium powder for advanced weapons and protective gear. Growing global defense budgets and rising aircraft production directly increase demand. It supports the development of lighter and more fuel-efficient systems.

- For instance, Boeing works with Oerlikon to industrialize titanium powder bed fusion additive manufacturing for aerospace structural components, aiming to meet FAA flight requirements with titanium powders sized between 45µm to 150µm, enhancing production reliability and cost-effectiveness.

Expanding Role of Additive Manufacturing and 3D Printing:

Titanium powder plays a critical role in additive manufacturing and 3D printing technologies. Its ability to create complex, durable, and precise components supports medical implants, aerospace parts, and industrial equipment. The healthcare sector, in particular, benefits from custom implants tailored to patient needs. Rising adoption of metal 3D printing across industries continues to drive consumption. It positions titanium powder as a core material in advanced production methods.

- For instance, AP&C, a GE Additive company, supplies aerospace-grade Ti-6Al-4V titanium powders with a production capacity exceeding 1,000 tons annually, supporting aerospace leaders like Airbus in metal additive manufacturing applications.

Increasing Use in Automotive Lightweighting Strategies:

The titanium powder market sees growing demand from the automotive sector. Automakers use titanium-based components to meet emission standards and improve fuel efficiency. Lightweight structures enhance vehicle performance and safety while reducing environmental impact. Electric vehicle makers also incorporate titanium for stronger, lighter battery casings and structural parts. It aligns with industry goals to balance sustainability with performance.

Advancements in Powder Metallurgy and Production Technologies:

Continuous improvements in powder metallurgy and atomization techniques strengthen titanium powder supply. Modern processes produce finer, more uniform powders suitable for critical applications. These advancements reduce costs and enhance product quality, expanding adoption across multiple industries. Growing investments in large-scale production facilities ensure consistent availability. It enables manufacturers to scale operations and meet rising global demand.

Market Trends:

Growing Integration of Titanium Powder in Additive Manufacturing Ecosystems:

The titanium powder market is witnessing strong growth through its integration into additive manufacturing ecosystems. Industries such as aerospace, medical, and automotive are increasingly relying on 3D printing to produce lightweight and durable parts with complex geometries. Titanium powder provides the necessary strength, corrosion resistance, and biocompatibility required in these applications. Healthcare providers are adopting it for patient-specific implants, while aerospace companies focus on weight reduction to improve fuel efficiency. Automotive manufacturers also explore titanium powder to achieve lightweighting goals without compromising safety. Continuous R&D investments by equipment makers and material suppliers strengthen its role in the additive manufacturing supply chain.

- For Instance, EOS’s Ti6Al4V Grade 23 powder can produce parts with ultimate tensile strengths typically ranging from around 1000 MPa to over 1100 MPa, depending on the manufacturing process (like Laser Powder Bed Fusion), build direction, and post-processing treatments

Rising Focus on Sustainable and Cost-Efficient Production Techniques:

The titanium powder market is also shaped by trends emphasizing sustainable and cost-efficient production. Companies invest in advanced atomization processes to improve powder quality while minimizing material waste. Recycling initiatives gain momentum, with efforts to reclaim titanium scrap and convert it into usable powder. This reduces production costs and aligns with environmental targets. Governments encourage sustainable manufacturing practices, prompting producers to adopt energy-efficient technologies. Expansion of large-scale powder production facilities ensures stable supply while meeting global demand. It positions titanium powder as a strategic material supporting both technological innovation and sustainability goals.

- For instance, PyroGenesis Canada launched its NexGen plasma atomization line capable of producing titanium powder at a rate exceeding 25 kg per hour, significantly enhancing production efficiency and powder quality with narrower particle size distribution.

Market Challenges Analysis:

High Production Costs and Limited Raw Material Availability:

The titanium powder market faces challenges linked to high production costs and limited raw material supply. Titanium extraction and powder production require energy-intensive processes, making the end product more expensive than alternatives such as aluminum or steel powders. Limited availability of high-grade raw materials further adds to supply chain risks. Price volatility in titanium ore impacts cost stability for powder manufacturers and end users. These factors often discourage wider adoption in price-sensitive industries. It restricts scalability despite the material’s superior properties.

Technical Barriers and Safety Concerns in Handling:

The titanium powder market is also constrained by technical barriers and safety issues. Fine titanium powders are highly reactive and pose fire and explosion risks during storage and handling. Manufacturers must invest heavily in specialized equipment, protective measures, and regulatory compliance. Processing challenges, including maintaining uniform particle size and purity, also limit broader application. End users in smaller industries often face difficulties adopting the technology due to these requirements. It increases operational complexity and slows expansion across potential markets.

Market Opportunities:

Expanding Applications in Healthcare and Biomedical Implants:

The titanium powder market presents strong opportunities in healthcare and biomedical sectors. Titanium’s biocompatibility makes it ideal for implants such as hip replacements, dental fixtures, and bone plates. Advances in 3D printing enable customized medical implants tailored to patient-specific needs. Rising demand for minimally invasive procedures and personalized healthcare boosts consumption further. Growth in medical tourism across Asia-Pacific and Latin America strengthens this opportunity. It creates long-term potential for manufacturers to expand supply chains and collaborate with healthcare providers.

Rising Demand from Emerging Economies and Advanced Manufacturing:

The titanium powder market is positioned to benefit from rising demand in emerging economies. Industrialization in Asia-Pacific, Middle East, and Latin America fuels the need for advanced materials in automotive, aerospace, and infrastructure projects. Governments invest in additive manufacturing hubs, creating strong local markets for titanium powders. Technological advancements that reduce costs improve adoption across mid-scale industries. Expanding renewable energy and electric vehicle sectors also require lightweight, durable components where titanium plays a key role. It aligns with global trends that prioritize efficiency, sustainability, and innovation.

Market Segmentation Analysis:

By Processing Method:

The titanium powder market is segmented by processing methods such as gas atomization, plasma atomization, and hydride-dehydride (HDH). Gas atomization dominates due to its ability to produce fine and uniform powders suited for aerospace and medical uses. Plasma atomization holds strong potential with high purity output ideal for additive manufacturing. The HDH method remains cost-effective, making it suitable for automotive and industrial applications. It provides flexibility for producers catering to varied end-use sectors.

- For instance, Osaka Titanium Technologies Co., Ltd. (OTC) has produced gas atomized titanium powder “TILOP” with aerospace-quality titanium, maintaining spherical particle morphology optimized for metal injection molding and additive manufacturing since 1990.

By Application:

The titanium powder market serves aerospace, automotive, medical, and industrial applications. Aerospace leads demand due to lightweight structures and high-performance parts. Medical applications grow with rising adoption of titanium-based implants and prosthetics. Automotive manufacturers increasingly use titanium for lightweighting strategies and electric vehicle components. Industrial uses span chemical processing, marine, and energy, where corrosion resistance is vital. It continues to diversify applications with advancements in powder metallurgy.

- For instance, Osaka Titanium Technologies Co., Ltd. (OTC) has produced gas atomized titanium powder “TILOP” with aerospace-quality titanium, maintaining spherical particle morphology optimized for metal injection molding and additive manufacturing since 1990.

By Purity Level:

The titanium powder market is further segmented into high purity and low purity grades. High purity powder finds significant demand in aerospace and biomedical sectors where quality standards are critical. Low purity powder caters to automotive, industrial, and general manufacturing needs. Demand for high purity powder rises with stricter performance requirements in advanced technologies. The availability of cost-effective low purity grades ensures wider adoption across mid-scale industries. It balances the market by meeting both premium and volume-driven demand.

Segmentations:

By Processing Method:

- Gas Atomization

- Plasma Atomization

- Hydride-Dehydride (HDH)

- Other Methods

By Application:

- Aerospace

- Automotive

- Medical

- Industrial

- Others

By Purity Level:

By Region:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

North America:

North America holds 38% market share in the titanium powder market, driven by a robust aerospace and defense industry. The United States leads production and consumption due to strong investments in additive manufacturing and advanced metallurgy. Healthcare applications, especially for orthopedic and dental implants, further strengthen demand. Government-backed programs supporting defense modernization expand adoption across military applications. The region benefits from established R&D centers and strong supplier networks. It remains a critical hub for innovation and large-scale industrial use.

Europe:

Europe accounts for 27% market share in the titanium powder market, supported by strong automotive, aerospace, and medical sectors. Countries such as Germany, France, and the U.K. prioritize titanium powder for lightweighting and sustainability goals. Stringent environmental policies drive manufacturers to adopt advanced, efficient production methods. Healthcare providers increase usage for customized implants, supported by advanced 3D printing technologies. The region also benefits from collaborative projects between universities and industries. It continues to expand applications through strict quality standards and innovation-driven policies.

Asia-Pacific:

Asia-Pacific captures 24% market share in the titanium powder market, with China and Japan leading adoption. The region experiences rapid growth in aerospace, automotive, and healthcare manufacturing. Expanding medical tourism and large-scale infrastructure projects drive titanium demand. Governments invest in additive manufacturing capabilities, fostering local production and reducing import dependence. Rising demand for electric vehicles also supports titanium powder usage in battery casings and lightweight components. It positions Asia-Pacific as the fastest-growing regional market during the forecast period.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Praxair Surface Technologies, Inc.

- TLS Technik GmbH Co. Spezialpulver KG

- GfE Metalle und Materialien GmbH

Competitive Analysis:

The titanium powder market is highly competitive, driven by strong demand across aerospace, medical, and automotive sectors. Key players include Oerlikon Metco, Umicore SA, Sandvik AB, Praxair Surface Technologies, Inc., Elementum 3D, Arcam AB, ATI, and TLS Technik GmbH Co. Spezialpulver KG. Companies focus on advanced atomization techniques, quality improvement, and expanding supply capacity to meet global requirements. Strategic partnerships with aerospace and medical device manufacturers strengthen market positions. Investment in additive manufacturing technologies enhances competitiveness by supporting customized, high-performance applications. Regional expansion and collaboration with research institutes further enable product innovation and broader adoption. It remains a dynamic market where players compete on technology, cost efficiency, and reliability of supply.

Recent Developments:

- In April 2025, Sandvik AB signed an agreement to acquire Osa Demolition Equipment S.r.l., an Italian manufacturer specializing in demolition tools and hydraulic hammers, with the acquisition expected to close in the third quarter of 2025.

- In April 2025, Elementum 3D was included in the $46 billion U.S. Air Force Enterprise-Wide Agile Acquisition Contract (EWAAC), enabling the company to provide metal powders and additive manufacturing expertise to support the Air Force’s modernization efforts.

- In August 2025, Praxair Surface Technologies, now rebranded as Linde Advanced Material Technologies Inc., continued its operations under the new name, aligning with the global Linde brand and focusing on surface-enhancing materials for various industries.

Report Coverage:

The research report offers an in-depth analysis based on Processing Method, Application, Purity Level and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- The titanium powder market will expand through rising adoption in aerospace and defense industries.

- It will benefit from increasing integration in additive manufacturing and 3D printing technologies.

- Medical implants and prosthetics will remain a strong demand driver due to biocompatibility.

- Automotive manufacturers will increase usage to achieve lightweighting and sustainability targets.

- Emerging economies will contribute significantly through industrialization and infrastructure development.

- Recycling initiatives and improved production methods will lower costs and enhance accessibility.

- Investments in advanced atomization techniques will ensure consistent quality and reliable supply.

- Electric vehicle growth will create new opportunities in battery casings and structural components.

- Collaborations between research institutes and manufacturers will accelerate innovation and product development.

- The market will see long-term growth supported by sustainability policies and global demand for high-performance materials.