Market Overview:

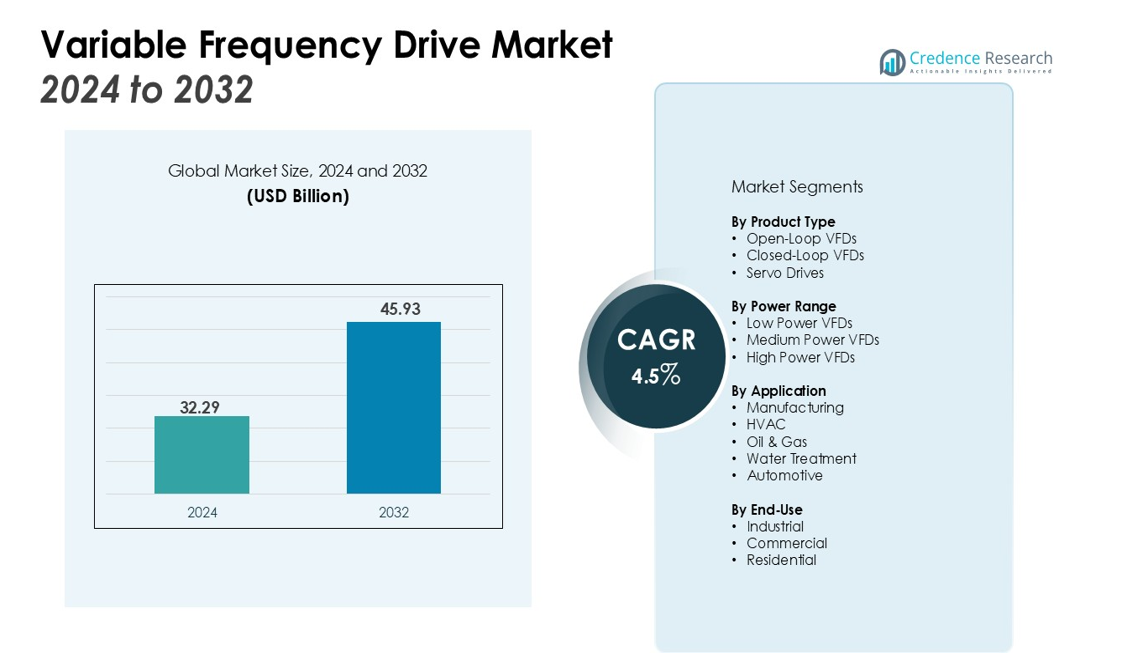

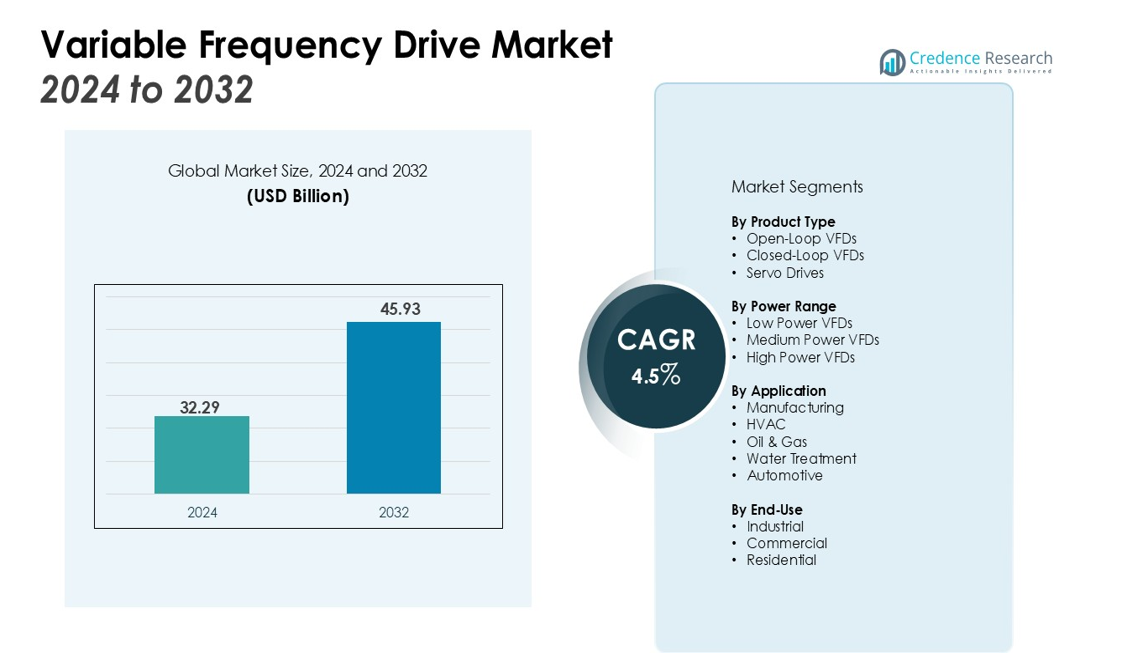

The Variable Frequency Drive Market size was valued at USD 32.29 billion in 2024 and is anticipated to reach USD 45.93 billion by 2032, at a CAGR of 4.5% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Variable Frequency Drive Market Size 2024 |

USD 32.29 billion |

| Variable Frequency Drive Market, CAGR |

4.5% |

| Variable Frequency Drive Market Size 2032 |

USD 45.93 billion |

The market is primarily driven by the rising demand for energy-efficient technologies across sectors such as manufacturing, HVAC, automotive, and oil & gas. VFDs help optimize energy consumption, reduce operational costs, and improve the lifespan of motors, making them a preferred choice for industries focused on sustainability. Additionally, the growing trend of industrial automation, coupled with advancements in smart grid technologies and renewable energy integration, further propels the market’s growth. The need for reducing carbon footprints is also contributing to the adoption of VFDs in various applications.

Regionally, North America holds a significant share of the market due to high demand from industrial automation and energy management applications. Europe follows with considerable growth prospects driven by stringent environmental regulations and the shift towards energy-efficient systems. The Asia-Pacific region, particularly China and India, is expected to witness the highest growth during the forecast period, driven by rapid industrialization, urbanization, and increasing demand for energy-efficient solutions in emerging economies.

Market Insights:

- The Variable Frequency Drive (VFD) market is valued at USD 32.29 billion in 2024 and will reach USD 45.93 billion by 2032, growing at a CAGR of 4.5%.

- The rising demand for energy-efficient solutions across sectors like manufacturing, HVAC, and oil & gas is driving the VFD market growth.

- Industrial automation’s rapid growth is boosting the VFD market as it enhances motor speed control, improving operational efficiency.

- Stringent government regulations for sustainability and energy conservation are encouraging industries to adopt VFDs to meet compliance standards.

- The integration of VFDs with smart grids and renewable energy systems offers opportunities for enhanced energy distribution and efficiency.

- North America holds a 30% market share, with high demand driven by energy efficiency needs in manufacturing, HVAC, and oil & gas.

- The Asia-Pacific region leads the market with a 35% share, driven by industrialization, energy efficiency needs, and automation in China and India.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for Energy Efficiency in Industries

The increasing emphasis on energy conservation across industries drives the demand for Variable Frequency Drives (VFDs). Industries such as manufacturing, HVAC, and oil & gas require energy-efficient solutions to reduce operational costs and minimize energy wastage. VFDs play a key role by optimizing motor speed, which directly leads to energy savings and better resource management. As energy costs continue to rise, the focus on improving energy efficiency becomes more pronounced, making VFDs a crucial investment.

- For instance, Siemens’ SINAMICS G120X series is equipped with a Class 3C3 coating, ensuring the drive’s durability and sustained efficient performance in challenging industrial environments.

Growth of Industrial Automation

The rapid adoption of industrial automation is fueling the market for VFDs. Automated systems rely on precise motor control for optimal performance, and VFDs provide an effective solution for controlling motor speed and torque. By offering smooth and accurate control, VFDs help improve operational efficiency and reduce downtime in automated processes. Their integration in robotics, conveyors, and other automated machinery is essential for enhancing productivity in various industries.

- For instance, Honeywell’s DEV200 VFD line is engineered for robust industrial automation applications, supporting an extensive power range of up to 75 kW to drive heavy-duty machinery.

Government Regulations and Sustainability Initiatives

Government regulations focused on sustainability and energy conservation are significantly influencing the VFD market. Many countries have implemented stringent energy efficiency standards and regulations for industries, which push businesses to adopt technologies that reduce energy consumption. VFDs, by improving system efficiency and reducing energy usage, support compliance with these regulations. This creates a strong incentive for companies to adopt VFD solutions as part of their sustainability initiatives.

Advancements in Smart Grid and Renewable Energy Integration

The integration of VFDs with smart grid systems and renewable energy technologies offers considerable growth potential. Smart grids rely on variable speed control to maintain grid stability and optimize energy distribution. VFDs can enhance the efficiency of renewable energy systems, such as wind and solar, by providing flexible control over variable motor speeds. As the push for renewable energy sources intensifies globally, the demand for VFDs is expected to rise.

Market Trends:

Increasing Integration of IoT and Automation with VFDs

The integration of the Internet of Things (IoT) and automation with Variable Frequency Drives (VFDs) is becoming a significant trend in the market. IoT-enabled VFDs provide enhanced monitoring and control, allowing real-time data analysis to optimize motor performance and energy consumption. These advancements enable predictive maintenance, where potential issues can be identified before they lead to system failures, reducing downtime and maintenance costs. Industries such as manufacturing and HVAC benefit from this integration by improving operational efficiency and ensuring systems run optimally. Automation, powered by IoT, is helping industries achieve more precise and intelligent control over processes, further driving the demand for VFDs.

- For instance, Siemens AG exemplifies this trend with its SIMATIC MICRO-DRIVE system. This compact servo drive represents a key technological achievement by operating at a safety extra-low voltage of just 48 V, enabling precise motion control for advanced automation applications like autonomous guided vehicles and robotics.

Shift Toward Eco-Friendly and Sustainable Solutions

A notable trend in the Variable Frequency Drive market is the growing shift toward eco-friendly and sustainable solutions. With increasing global awareness of environmental impact, industries are seeking ways to reduce their carbon footprint. VFDs support these efforts by improving energy efficiency, reducing emissions, and contributing to greener operations. The push for sustainability is evident in sectors like manufacturing, agriculture, and transportation, where energy savings from VFDs lead to significant reductions in overall environmental impact. The demand for eco-efficient technologies is likely to grow as companies strive to meet sustainability targets and comply with government regulations regarding energy usage and emissions.

- For instance, ABB recently set a new world record with a synchronous motor developed for a steel plant in India. This technological achievement is projected to save approximately 61 GWh of electricity over its 25-year operational lifespan, preventing about 45,000 tonnes of CO₂ emissions.

Market Challenges Analysis:

High Initial Cost and Installation Complexity

One of the primary challenges in the Variable Frequency Drive (VFD) market is the high initial cost and complexity of installation. The upfront investment for purchasing and installing VFD systems can be substantial, especially for small and medium-sized enterprises. This high capital expenditure often deters companies from adopting VFDs, despite their long-term energy-saving benefits. The installation process can also be complex, requiring specialized expertise to ensure optimal performance. As a result, many businesses hesitate to make the switch, despite the potential for significant operational savings over time.

Compatibility and Integration with Existing Systems

Another significant challenge is the compatibility and integration of Variable Frequency Drives with existing systems. Many industries use legacy equipment that may not easily support modern VFD technologies. Retrofitting old systems to accommodate VFDs can be time-consuming and costly. Furthermore, the integration of VFDs with other automation and control systems often requires extensive adjustments to software and hardware infrastructure. This can increase operational disruptions and lead to additional costs. Consequently, businesses may face difficulties in fully optimizing VFD benefits if their systems are not easily adaptable.

Market Opportunities:

Growing Demand for Energy Efficiency and Sustainability

The rising global demand for energy efficiency and sustainability presents a significant opportunity for the Variable Frequency Drive (VFD) market. Industries across the world are seeking solutions to reduce energy consumption and lower operational costs while meeting stricter environmental regulations. VFDs offer a practical solution by optimizing motor speed and reducing energy waste. As companies push for greener operations and improved efficiency, the adoption of VFDs is expected to rise. This trend is particularly evident in sectors like manufacturing, HVAC, and transportation, where energy-efficient systems can lead to substantial cost savings over time.

Expansion of Industrial Automation and Smart Technologies

The rapid expansion of industrial automation and smart technologies offers another opportunity for growth in the VFD market. With industries increasingly embracing automation, the need for precise motor control and integration with smart systems is growing. VFDs can enhance automation processes by providing accurate speed and torque control, improving system performance and minimizing downtime. The integration of VFDs with IoT technologies further strengthens their capabilities, allowing for real-time monitoring and predictive maintenance. As automation becomes more widespread, the demand for VFDs is likely to increase, driven by the need for advanced control and monitoring in complex industrial systems.

Market Segmentation Analysis:

By Product Type

The Variable Frequency Drive (VFD) market is segmented by product type into open-loop VFDs, closed-loop VFDs, and servo drives. Open-loop VFDs dominate the market due to their cost-effectiveness and suitability for applications that do not require high precision in speed control. Closed-loop VFDs offer higher accuracy and feedback control, making them ideal for industries where precision is essential, such as robotics and automated systems. Servo drives, known for their high torque and speed control, are increasingly used in applications requiring dynamic performance, such as CNC machines and high-precision manufacturing.

- For instance, Rockwell Automation’s PowerFlex 527 AC drive is engineered to integrate exclusively with Allen-Bradley Logix PACs, unifying variable frequency and servo technology within 1 programming environment, Studio 5000 Logix Designer.

By Power Range

The VFD market is divided into low-power, medium-power, and high-power segments based on the power range. Low-power VFDs, typically used in applications with less demanding energy needs, are commonly employed in HVAC systems, pumps, and small motors. Medium-power VFDs are widely used in industrial applications such as conveyors and compressors, where energy savings and operational efficiency are important. High-power VFDs cater to heavy industries, including oil & gas, mining, and large-scale manufacturing, where high-performance motor control is critical for large motors and high-load operations.

- For instance, GE’s Oil & Gas business developed the Steadfast System, a high-power variable frequency drive system specifically for centrifugal compressors that can deliver up to 35 megawatts of power for natural gas and LNG applications.

By Application

VFDs find applications across several industries, including manufacturing, HVAC, oil & gas, water treatment, and automotive. In manufacturing, they optimize motor performance and energy use, enhancing overall productivity. The HVAC sector benefits from VFDs by regulating fan and pump speeds, improving energy efficiency. In oil & gas, VFDs are essential for controlling pumps and compressors, ensuring consistent performance while reducing energy costs. The automotive sector uses VFDs in conveyor systems and robotic applications, driving automation and improving production efficiency.

Segmentations:

By Product Type

- Open-Loop VFDs

- Closed-Loop VFDs

- Servo Drives

By Power Range

- Low Power VFDs

- Medium Power VFDs

- High Power VFDs

By Application

- Manufacturing

- HVAC

- Oil & Gas

- Water Treatment

- Automotive

By End-Use

- Industrial

- Commercial

- Residential

By Region

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

North America

North America holds a dominant share of 30% in the Variable Frequency Drive (VFD) market. The region’s high demand for energy-efficient solutions across manufacturing, HVAC, and oil & gas industries fosters significant adoption. The focus on sustainability and energy conservation, coupled with stringent environmental regulations, drives the adoption of VFDs. Both the U.S. and Canada are investing heavily in infrastructure and green technologies, further enhancing market growth. Additionally, the rise of industrial automation and smart grid systems supports the increasing deployment of VFDs. These factors collectively strengthen North America’s market position, ensuring its continued dominance.

Europe

Europe accounts for 25% of the global Variable Frequency Drive market share, driven by strong regulatory support for energy efficiency. The European Union’s stringent energy standards incentivize industries to adopt VFDs to reduce energy consumption and meet compliance requirements. Countries such as Germany, the UK, and France are making significant investments in advanced industrial systems, creating a robust market environment. The shift toward renewable energy sources and the increased automation of industrial processes further boost demand for VFDs. As industries in Europe continue to focus on sustainability, the market for VFDs is expected to expand steadily.

Asia-Pacific

The Asia-Pacific region holds the largest share of 35% in the Variable Frequency Drive market. This growth is largely driven by rapid industrialization and urbanization, particularly in China and India. These emerging economies are heavily investing in infrastructure, creating substantial demand for VFDs. The region’s emphasis on energy efficiency and renewable energy adoption further propels market expansion. With increasing manufacturing activities and growing adoption of industrial automation, the demand for VFDs continues to rise in sectors like textiles, automotive, and chemicals. As these economies continue to develop, the VFD market in Asia-Pacific is expected to grow at the highest rate globally.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Key Player Analysis:

- WEG S.A.

- ABB

- Yaskawa Electric Corporation

- Danfoss A/S

- General Electric Company

- SIEMENS AG

- Eaton Corporation

- Hitachi, Ltd.

- Schneider Electric

- Rockwell Automation, Inc.

Competitive Analysis:

The Variable Frequency Drive (VFD) market is highly competitive, with key players like Siemens, ABB, Schneider Electric, Mitsubishi Electric, and Danfoss leading the industry. These companies offer a wide range of VFD solutions, catering to various industrial, commercial, and residential applications. Siemens and ABB dominate the market due to their comprehensive product portfolios and strong global presence, especially in energy-efficient systems. Schneider Electric focuses on smart grid integration and energy management, further strengthening its position. Mitsubishi Electric and Danfoss excel in providing customizable VFDs tailored to specific industrial needs, such as automation and HVAC. As industries continue to prioritize sustainability and energy efficiency, these companies are innovating to provide advanced features, such as IoT integration, real-time monitoring, and predictive maintenance. Competitive strategies focus on product differentiation, technological advancements, and strategic partnerships to maintain market share and meet evolving customer demands.

Recent Developments:

- In September 2025, ABB Robotics launched OmniCore EyeMotion, a system that enables robots to perceive their environment with third-party cameras and adapt in real-time.

- In September 2025, Hitachi announced its agreement to acquire synvert, a German data and AI services firm, to accelerate the company’s development of Agentic and Physical AI.

Report Coverage:

The research report offers an in-depth analysis based on Product Type, Power Range, Application, End-Use and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The demand for Variable Frequency Drives (VFDs) will continue to rise due to the increasing emphasis on energy efficiency across industries.

- Advances in automation and robotics will drive greater adoption of VFDs, as they optimize motor control in complex systems.

- The integration of VFDs with IoT technologies will expand, allowing for real-time monitoring and predictive maintenance.

- Industries focused on sustainability and reducing carbon footprints will increasingly rely on VFDs to lower energy consumption.

- The automotive sector will see growth in VFD applications, especially in manufacturing and electric vehicle production.

- The adoption of renewable energy sources, such as wind and solar, will enhance the need for VFDs to improve energy distribution and grid stability.

- Increasing urbanization and industrialization, particularly in developing economies, will create more opportunities for VFDs in manufacturing and infrastructure.

- Smart grid systems will continue to integrate VFDs for better energy management and efficiency in power distribution.

- VFDs will play a crucial role in meeting stricter environmental regulations by helping industries comply with energy-saving mandates.

- Emerging applications in industries like water treatment and food processing will expand the use of VFDs, offering new growth avenues.