Market Overview:

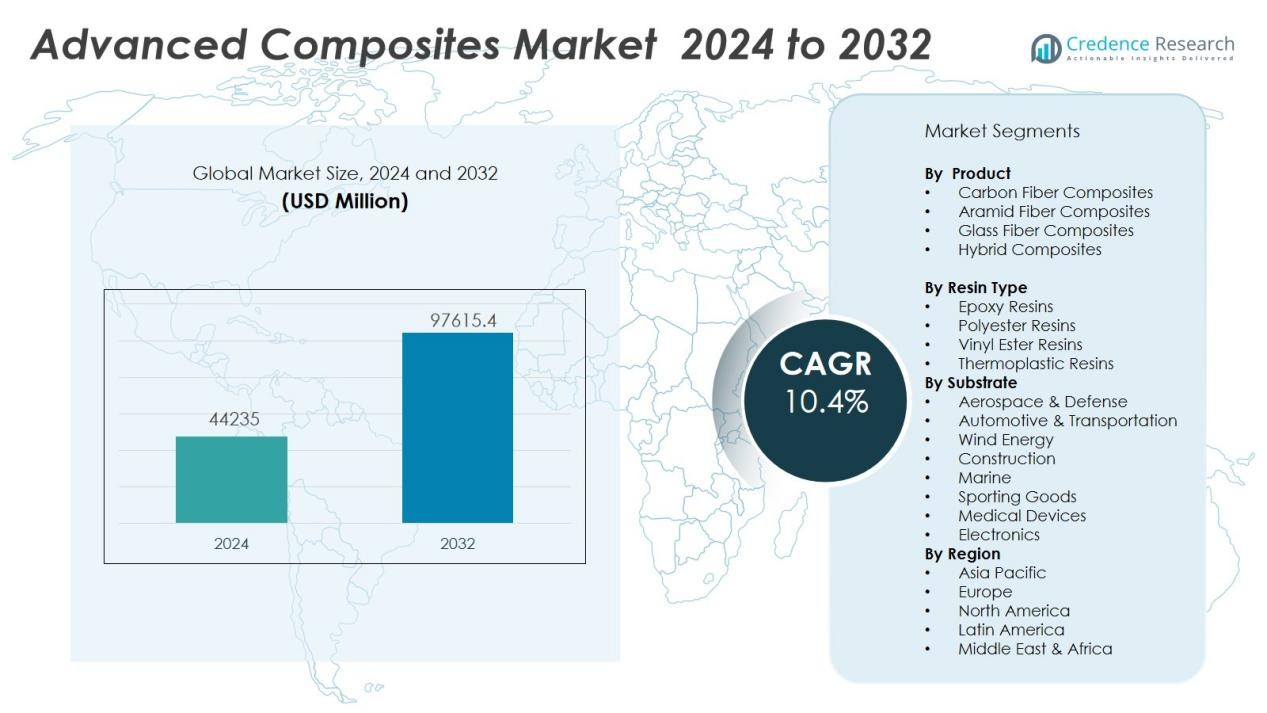

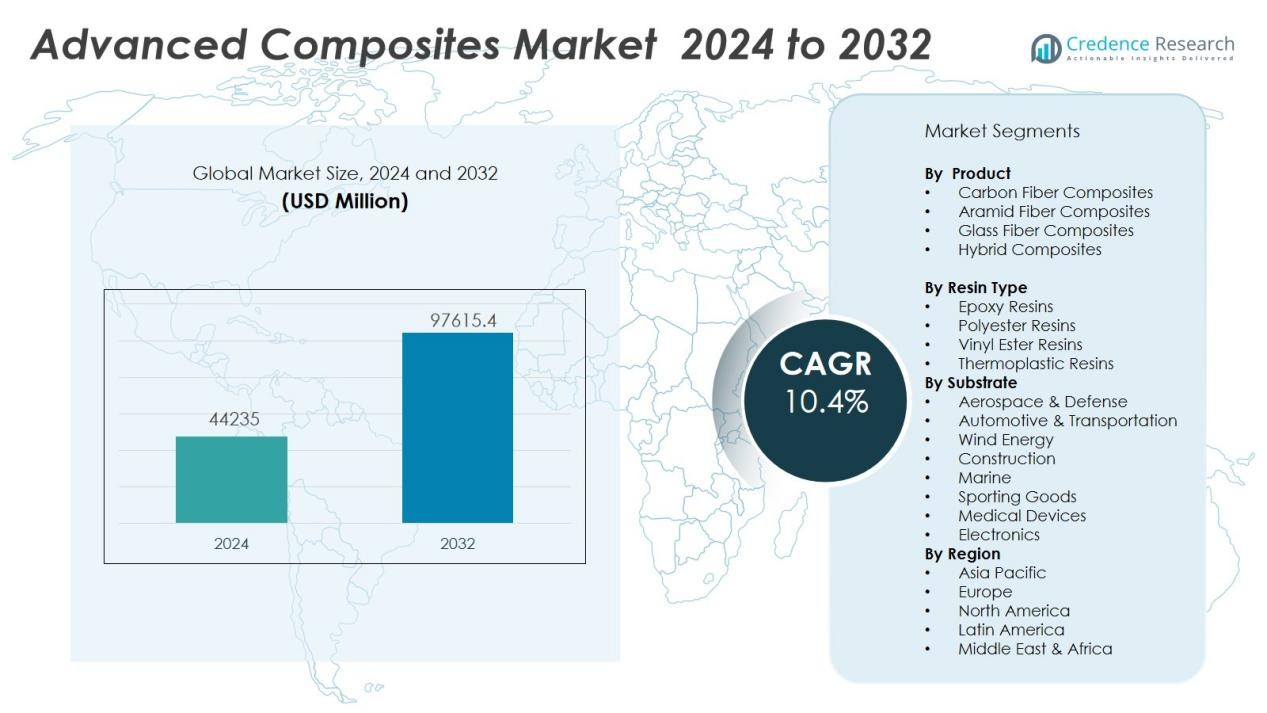

The advanced composites market size was valued at USD 44235 million in 2024 and is anticipated to reach USD 97615.4 million by 2032, at a CAGR of 10.4 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Advanced Composites Market Size 2024 |

USD 44235 Million |

| Advanced Composites Market, CAGR |

10.4 % |

| Advanced Composites Market Size 2032 |

USD 97615.4 Million |

Market drivers for advanced composites center on the need for superior mechanical properties, such as durability, corrosion resistance, and thermal stability. Industries are shifting toward advanced composites to meet stringent regulatory requirements for emissions reduction and energy efficiency. Rapid advancements in manufacturing technologies, including automation and additive manufacturing, further boost adoption by reducing production costs and enabling complex design capabilities. The growing focus on renewable energy infrastructure, particularly wind turbine blades and electric vehicle components, provides significant opportunities for market players.

Regional analysis reveals that North America and Europe hold leading positions, attributed to strong aerospace and automotive manufacturing bases, as well as robust investments in R&D. The Asia-Pacific region is experiencing the fastest growth rate, propelled by expanding industrial bases, rising infrastructure projects, and increased penetration of composites in automotive and electronics manufacturing, especially in China, India, and Japan.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The advanced composites market was valued at USD 44,235 million in 2024 and is projected to reach USD 97,615.4 million by 2032, with a CAGR of 10.4% during the forecast period.

- Demand for lightweight and high-strength materials in sectors such as aerospace, automotive, and wind energy drives strong market momentum and supports fuel efficiency goals.

- Regulatory pressure to lower emissions and improve energy efficiency accelerates the shift to advanced composites, with industries investing in sustainable and recyclable solutions.

- Technological advancements in manufacturing, including automation and additive manufacturing, lower production costs and enable innovative product designs for various applications.

- High raw material costs and complex manufacturing requirements remain key challenges, limiting broader adoption in cost-sensitive and emerging markets.

- North America leads the market with a 38% share, backed by strong aerospace and automotive industries, while Europe follows with 31% due to sustainability initiatives and advanced engineering.

- Asia-Pacific holds a 22% share and records the fastest growth, fueled by rapid industrialization, infrastructure projects, and expanding automotive and electronics sectors.

Market Drivers:

Rising Demand for Lightweight and High-Strength Materials in End-Use Industries:

The advanced composites market is experiencing strong momentum due to heightened demand from sectors such as aerospace, automotive, and wind energy. Manufacturers require materials that offer reduced weight and increased strength, helping to improve fuel efficiency and overall product performance. The shift toward electric vehicles and energy-efficient aircraft has further intensified the need for advanced composites. It plays a crucial role in reducing operational costs and meeting industry-specific technical requirements.

- For instance, Boeing’s 787 Dreamliner incorporates composite materials comprising 50 percent of its structural weight, resulting in a 20 percent weight reduction compared to conventional aluminum designs.

Increasing Regulatory Pressure and Focus on Sustainability:

Stringent government regulations targeting emission reductions and energy efficiency support the adoption of advanced composites. Industries are under growing pressure to comply with evolving standards, particularly in transportation and infrastructure. The advanced composites market benefits from the move toward sustainable and recyclable materials, with companies investing in eco-friendly solutions to enhance compliance. It enables manufacturers to address both environmental mandates and customer expectations.

- For instance, SGL Carbon has implemented renewable energy-based carbon fiber manufacturing processes, achieving 50% reduction in carbon footprint compared to conventional production methods by utilizing hydropower at their Moses Lake facility, saving approximately 75,000 tonnes of CO2 annually.

Technological Advancements and Improved Manufacturing Processes:

Recent progress in manufacturing technologies, such as automation, resin transfer molding, and additive manufacturing, accelerates the use of advanced composites. Improved processing methods lower production costs, increase output efficiency, and enable more complex product designs. The advanced composites market leverages these advancements to offer innovative solutions that meet the unique needs of various applications. It supports the development of next-generation materials with improved performance characteristics.

Expansion of Renewable Energy and Infrastructure Projects:

The global push for renewable energy infrastructure, particularly wind and solar power, drives greater consumption of advanced composites. Growth in wind turbine installations and large-scale infrastructure projects creates new opportunities for material suppliers. The advanced composites market is further strengthened by the adoption of composites in bridges, pipelines, and construction applications where strength, durability, and weight reduction are critical. It positions the sector as a key enabler of future infrastructure development.

Market Trends:

Wider Integration of Automation, Digitalization, and Smart Manufacturing:

Automation and digitalization trends are reshaping production methods in the advanced composites market, leading to increased efficiency and precision. Automated fiber placement, robotic assembly, and data-driven process control now play prominent roles in composite manufacturing facilities. It enables manufacturers to optimize material usage, reduce waste, and ensure consistent product quality at scale. Integration of digital twin technology and advanced simulation tools streamlines the design and prototyping process, helping companies shorten time to market. The adoption of Industry 4.0 frameworks supports real-time monitoring and predictive maintenance, further driving operational improvements. Advanced analytics and digital supply chain solutions also facilitate better inventory and resource management.

- For instance, Boeing has implemented automated fiber placement (AFP) systems in their 787 Dreamliner production, achieving 50 times higher material deposition rates compared to manual layup methods, reducing production from 2.5 lbs per hour manually to over 50 lbs per hour with AFP technology.

Expansion of Application Scope and Development of Next-Generation Materials:

The advanced composites market is witnessing strong diversification in end-use applications, moving beyond traditional aerospace and automotive segments into wind energy, construction, electronics, and medical devices. It benefits from ongoing innovation in material chemistries, such as thermoplastic composites, nanocomposites, and bio-based composites, which offer enhanced performance and sustainability. The demand for multifunctional materials with properties like fire resistance, electrical conductivity, and self-healing capabilities continues to increase. Partnerships between material scientists, manufacturers, and end users are accelerating product development and commercialization. Growing interest in circular economy principles also drives the creation of recyclable and reprocessable composites, aligning with broader sustainability goals across industries.

- For instance, LM Wind Power has developed an innovative two-piece carbon blade design for GE Renewable Energy’s Cypress onshore wind turbine platform, enabling 5.3 MW capacity turbines with enhanced logistics flexibility and reduced transportation costs.

Market Challenges Analysis:

High Production Costs and Complex Manufacturing Processes:

The advanced composites market faces significant challenges related to high raw material costs and complex manufacturing requirements. Specialized equipment and skilled labor remain essential for producing consistent, high-quality composite parts. It often leads to elevated production expenses, limiting widespread adoption in cost-sensitive industries. Achieving large-scale automation and process standardization also remains difficult, which impacts lead times and scalability. These cost-related barriers can restrict market penetration, particularly in emerging economies.

Limited Recycling Infrastructure and Technical Barriers to Recyclability:

Sustainability expectations are rising, yet the advanced composites market must address the lack of robust recycling infrastructure. Most composite materials present technical difficulties during recycling or repurposing, especially thermoset-based products. It creates challenges for manufacturers under pressure to improve environmental footprints and comply with circular economy standards. The absence of standardized recycling solutions hampers industry-wide efforts to enhance end-of-life management for composite components. Overcoming these technical and regulatory hurdles remains crucial for long-term market growth.

Market Opportunities:

Emerging Demand in Electric Vehicles and Renewable Energy Sectors:

The advanced composites market stands to benefit from rising demand in electric vehicles and renewable energy applications. Lightweight and durable composite materials help automakers improve energy efficiency and battery performance, supporting the global transition toward sustainable mobility. It also supports the production of high-performance wind turbine blades and solar panel components, aligning with ambitious renewable energy targets. Market participants can expand their portfolios by collaborating with leading automotive and energy firms. Strong investment in green infrastructure projects further fuels opportunities for innovative composite solutions.

Expansion into Medical, Electronics, and Infrastructure Applications:

Opportunities are growing for the advanced composites market within medical devices, electronics, and civil infrastructure. Composite materials offer unique combinations of biocompatibility, strength, and flexibility required for next-generation medical implants and diagnostic equipment. It enables electronics manufacturers to develop lightweight, resilient casings and internal components for smart devices. In infrastructure, composites provide corrosion resistance and durability for bridges, pipelines, and building reinforcements. These expanding end-use segments open new revenue streams and promote long-term market growth for advanced composite suppliers.

Market Segmentation Analysis:

By Product:

The advanced composites market includes carbon fiber composites, aramid fiber composites, and glass fiber composites. Carbon fiber composites lead the segment due to their exceptional strength-to-weight ratio and widespread use in aerospace and automotive applications. Aramid fiber composites follow with strong demand in defense, ballistic protection, and industrial sectors where high impact resistance is critical. Glass fiber composites hold a significant share owing to their cost-effectiveness and versatile use in wind energy, construction, and marine industries. The market continues to see innovations in hybrid composites to meet evolving performance requirements.

- For instance, DuPont’s Kevlar 49 demonstrates tensile strength of 3.0 GPa with exceptional impact resistance properties, making it ideal for ballistic applications.

By Resin Type:

Thermoset resins dominate the advanced composites market, with epoxy, polyester, and vinyl ester resins serving as primary options for structural applications. Epoxy resins remain the top choice due to superior adhesion, chemical resistance, and durability. Thermoplastic resins are gaining traction for their recyclability and ease of processing, especially in automotive and electronics manufacturing. It enables faster production cycles and supports growing interest in sustainable solutions. Market participants invest in new resin formulations to enhance toughness, fire resistance, and environmental performance.

By Application:

Aerospace and defense represent the largest application segment in the advanced composites market, driven by the need for lightweight, high-strength components. Automotive and transportation industries increasingly adopt composites for improved fuel efficiency and emission reduction. Wind energy and construction sectors utilize composites for turbine blades, bridge reinforcements, and infrastructure projects requiring durability and design flexibility. The market also sees rising use in sporting goods, marine, and medical devices, expanding opportunities for specialized composite solutions.

- In military applications, Lockheed Martin’s F-35 Lightning II features 35 percent composite materials by weight in its airframe structure, with carbon fiber reinforced polymer enabling stealth capabilities through reduced radar detectability.

Segmentations:

By Product:

- Carbon Fiber Composites

- Aramid Fiber Composites

- Glass Fiber Composites

- Hybrid Composites

By Resin Type:

- Epoxy Resins

- Polyester Resins

- Vinyl Ester Resins

- Thermoplastic Resins

By Application:

- Aerospace & Defense

- Automotive & Transportation

- Wind Energy

- Construction

- Marine

- Sporting Goods

- Medical Devices

- Electronics

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

North America :

North America commands a 38% share of the advanced composites market, supported by robust aerospace, defense, and automotive industries. The United States leads regional growth, with leading manufacturers investing heavily in R&D, advanced manufacturing, and process optimization. The region benefits from a strong ecosystem of technology innovators and partnerships between material suppliers and end users. Adoption of lightweight composites for fuel-efficient aircraft, electric vehicles, and energy applications fuels sustained demand. Government funding and regulatory incentives further encourage innovation and early adoption. North America’s established supply chain and skilled workforce strengthen its position in the global market.

Europe :

Europe captures 31% of the advanced composites market, reflecting its advanced engineering capabilities and commitment to sustainable manufacturing. Germany, France, and the United Kingdom anchor market activity with a focus on high-performance automotive, wind energy, and construction sectors. Stringent EU regulations and carbon reduction targets accelerate the use of lightweight, recyclable composites across multiple applications. Leading research institutions collaborate with industry to develop next-generation materials and recycling solutions. Europe’s strong focus on renewable energy installations drives demand for advanced composites in wind turbine blades and grid infrastructure. Investments in smart manufacturing technologies continue to shape the competitive landscape.

Asia-Pacific :

Asia-Pacific holds a 22% share of the advanced composites market and records the highest growth rate globally. China, Japan, and India emerge as key contributors, supported by rapid industrialization, expanding automotive manufacturing, and increasing electronics production. Government infrastructure initiatives drive the use of composites in bridges, buildings, and energy projects. The region’s growing middle class and urbanization boost demand for lightweight, durable materials in consumer goods and transportation. Expansion of domestic manufacturing capabilities and rising foreign investments promote further market penetration. Asia-Pacific’s focus on cost-competitive production and scaling up capacity positions it for sustained leadership in the coming years.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- SGL Group

- Toray Industries, Inc.

- Koninklijke Ten Cate NV

- AGY Holdings Corp.

- Teijin Limited

- Cytec Solvay Group

- Hexcel Corporation

- Huntsman Corporation

- Momentive Performance Materials Inc.

- Owens Corning

- E. I. Dupont De Nemours and Company

- WS Atkins plc

Competitive Analysis:

The advanced composites market features a competitive landscape shaped by innovation, strategic partnerships, and continuous investment in research and development. Key players such as SGL Group, Toray Industries, Inc., Koninklijke Ten Cate NV, AGY Holdings Corp., Teijin Limited, Cytec Solvay Group, Hexcel Corporation, Huntsman Corporation, and Momentive Performance Materials Inc. lead the industry with comprehensive product portfolios and global manufacturing footprints. It benefits from the efforts of these companies to introduce high-performance materials that address the evolving needs of aerospace, automotive, energy, and industrial sectors. Companies focus on capacity expansions, mergers, and collaborations to strengthen market share and technological expertise. The emphasis on sustainability and advanced resin systems fuels competition, prompting suppliers to differentiate through proprietary formulations, custom solutions, and integrated value chain services.

Recent Developments:

- In June 2025, SGL Carbon launched the SIGRACELL® GFX4.8 EA battery felt for redox flow batteries, targeting improved energy storage efficiency for renewable solutions.

- In April 2024, Toray Industries signed a strategic partnership with Hyundai Motor Group to innovate advanced materials and support next-generation electric mobility through lightweight solutions.

- In June 2025, TenCate Grass acquired a majority stake in Sports & Leisure Group, enhancing its market presence in the artificial grass industry.

Market Concentration & Characteristics:

The advanced composites market demonstrates moderate to high concentration, with a small number of global players controlling significant market share and influencing industry standards. Leading companies invest in R&D, strategic partnerships, and capacity expansion to maintain technological leadership and meet evolving customer requirements. It features a blend of vertically integrated giants and specialized regional manufacturers, creating a competitive landscape driven by innovation and customization. High entry barriers due to capital-intensive processes, technical expertise, and regulatory compliance contribute to the consolidated structure. The market is characterized by rapid technological advancements, strong focus on quality assurance, and active collaboration across the value chain to deliver tailored solutions for diverse end-use sectors.

Report Coverage:

The research report offers an in-depth analysis based on Segment 1, Segment 2, Segment 3, and Segment 3. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- Manufacturers adopt scalable digital manufacturing and automated production methods to reduce costs and boost throughput.

- Research teams develop next-generation material chemistries, including thermoplastic composites and nanocomposites with enhanced durability.

- Companies expand collaborations with automotive and aerospace firms to integrate composite parts in electric vehicles and lightweight aircraft.

- Tier‑1 suppliers introduce recyclable and reprocessable composites to support circular economy goals and meet regulatory pressure.

- Designers incorporate multifunctional composites with properties like fire resistance, conductivity, and self-healing into new product lines.

- Infrastructure and energy sectors deploy composite materials in bridges, pipelines, wind turbines, and solar applications seeking corrosion resistance and longevity.

- Regional markets in Asia‑Pacific attract investment in low-cost manufacturing hubs and infrastructure projects, increasing composite demand.

- Aerospace and defense industries push adoption of composites for next‑generation spacecraft and military platforms requiring high strength‑to‑weight ratios.

- Material characterization and testing capabilities improve to accelerate certification processes and enable broader industry acceptance.

- Suppliers offer modular composite systems and digital twins to support faster product customization and optimize supply chain operations.