Market Overview:

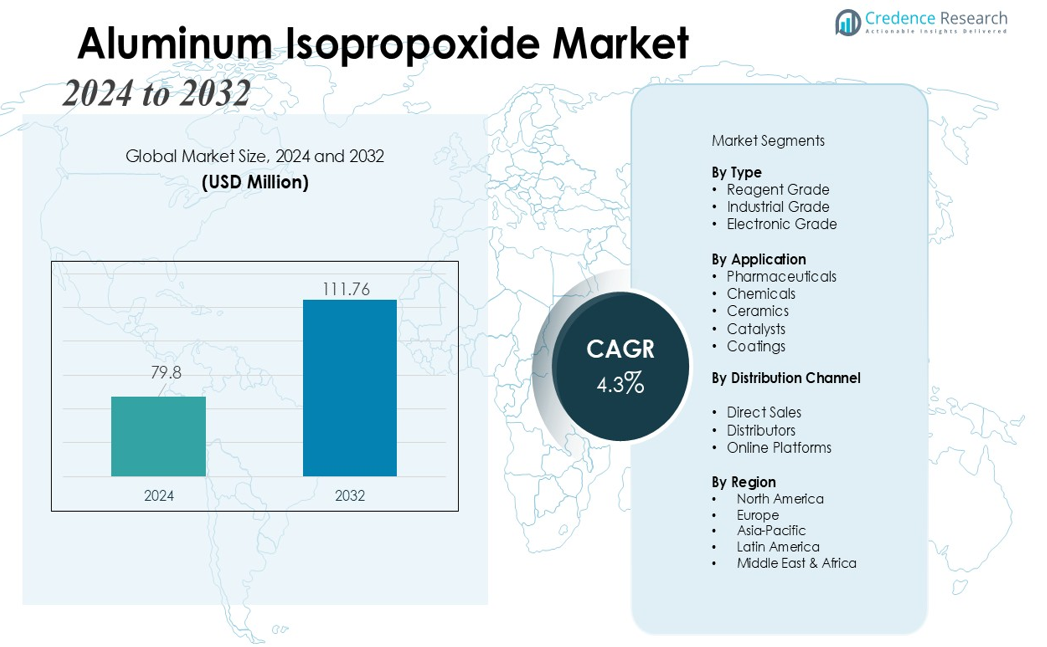

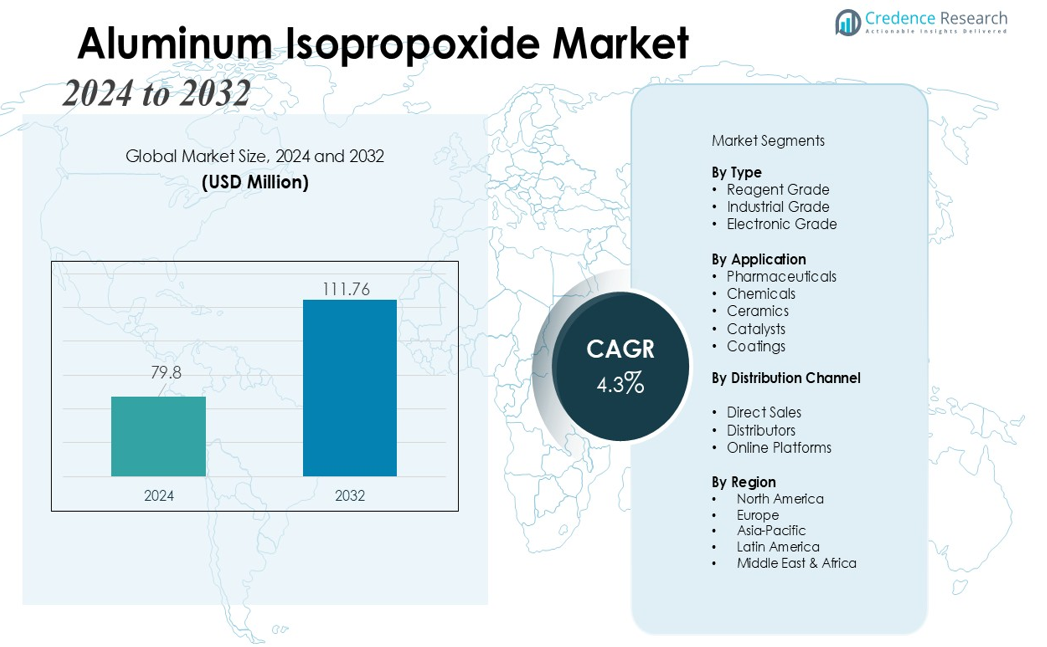

The Aluminum Isopropoxide Market size was valued at USD 79.8 million in 2024 and is anticipated to reach USD 111.76 million by 2032, at a CAGR of 4.3% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Aluminum Isopropoxide Market Size 2024 |

USD 79.8 million |

| Aluminum Isopropoxide Market, CAGR |

4.3% |

| Aluminum Isopropoxide Market Size 2032 |

USD 111.76 million |

Key drivers include increasing utilization of aluminum isopropoxide in the production of active pharmaceutical ingredients (APIs) and the growing adoption of advanced catalytic processes in polymer and material engineering. Expanding research activities in nanomaterial development further support market growth. Additionally, industries are prioritizing high-quality reagents to achieve precision in synthesis, reinforcing demand across chemical laboratories and industrial production units.

Regionally, Asia-Pacific dominates the Aluminum Isopropoxide Market, driven by strong chemical manufacturing bases in China, India, and Japan. North America and Europe follow, supported by well-established pharmaceutical and research sectors. Rising investments in specialty chemicals and innovation in material sciences foster growth across these regions. Emerging markets in Latin America and the Middle East also show increasing adoption, supported by expanding industrial capability and growing focus on high-performance chemical intermediates.

Market Insights:

- The Aluminum Isopropoxide Market was valued at USD 79.8 million in 2024 and is projected to reach USD 111.76 million by 2032, growing at a CAGR of 4.3%.

- Rising utilization in active pharmaceutical ingredient (API) production and adoption in advanced catalytic processes drive market growth.

- High demand for high-purity intermediates supports controlled chemical reactions such as reduction, oxidation, and esterification.

- Expanding use in advanced materials, specialty coatings, and alumina-based products strengthens the market’s long-term adoption.

- Research institutions and industrial labs invest in process optimization, catalyst systems, and high-performance ceramics, enhancing market potential.

- Asia-Pacific holds 45% share, driven by strong chemical and pharmaceutical production in China, India, Japan, and South Korea.

- North America and Europe hold 25% and 20% shares respectively, supported by robust R&D infrastructure, strict quality standards, and regulated manufacturing environments.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for High-Purity Chemical Intermediates

The Aluminum Isopropoxide Market benefits from higher demand for high-purity intermediates used in controlled chemical reactions. It supports essential processes such as reduction, oxidation, and esterification, which require consistent performance and reproducibility. Industries prioritize reagents that improve precision in synthesis workflows. The growing emphasis on reaction efficiency strengthens the compound’s market relevance.

- For instance, a patented preparation method involving the addition of specific amounts of tri-n-propyl aluminum and aluminum isopropoxide as initiators has achieved a yield of 95.8% (or higher, up to 96.5%) in synthesizing high-purity aluminum isopropoxide, optimizing reaction initiation and purity without traditional metal salt catalysts

Expansion of Pharmaceutical and API Manufacturing

Pharmaceutical producers increasingly adopt aluminum isopropoxide for active ingredient synthesis due to its reliability in complex reactions. It aligns with rising requirements for purity and compliance across regulated manufacturing environments. The compound supports efficient production of intermediates essential for therapeutic formulations. The sector’s push toward scalable and high-quality output elevates market demand.

- For instance, commercial and laboratory specifications from chemical suppliers such as Sigma-Aldrich and Tradeindia indicate that aluminum isopropoxide often meets a $\ge$98% purity specification for general use in organic synthesis and various industrial applications, including pharmaceuticals.

Growing Use in Advanced Materials and Coating Applications

The Aluminum Isopropoxide Market gains traction from wider application in advanced materials and specialty coatings. It contributes to the development of alumina-based materials with improved performance characteristics. Manufacturers use the compound to enhance thermal stability, surface quality, and structural consistency. The trend toward high-value engineered materials reinforces long-term adoption.

Increasing R&D Efforts Focused on Process Optimization

Research institutions and industrial laboratories invest in process improvements that elevate the utility of aluminum isopropoxide. It supports innovation in catalyst systems, high-performance ceramics, and next-generation chemical processes. Efforts to refine synthesis pathways drive interest in materials that deliver predictable chemical behavior. The emphasis on optimizing reaction outcomes continues to expand market potential.

Market Trends:

Increasing Integration of High-Purity Reagents Across Industrial Synthesis

The Aluminum Isopropoxide Market reflects a steady shift toward high-purity reagents that support precision-driven chemical synthesis. It plays a critical role in oxidation, reduction, and esterification reactions that demand predictable performance. Manufacturers emphasize materials that enhance reaction control and reduce variability in production environments. Industries focused on fine chemicals, polymers, and specialty additives adopt the compound to strengthen product quality. Global producers invest in improved purification technologies to meet rising quality benchmarks. Regulatory frameworks encouraging cleaner processes further accelerate the adoption of reliable intermediates.

- For example, materials science researchers have successfully demonstrated the application of heterogenization in various contexts. This involves anchoring or supporting active components onto a solid material, which allows for their efficient catalytic reuse

Growing Adoption in Advanced Materials, Catalysts, and Pharmaceutical Applications

The Aluminum Isopropoxide Market benefits from wider application in advanced ceramics, catalyst development, and pharmaceutical manufacturing. It supports the production of alumina-based materials with improved mechanical and thermal characteristics. Companies expand their R&D efforts to leverage the compound in high-value materials aligned with performance-driven industries. Pharmaceutical manufacturers prefer reagents that deliver consistency during complex synthesis stages, reinforcing long-term demand. Market participants explore optimized formulations to improve stability and handling efficiency. The trend toward high-performance materials and scalable pharmaceutical production strengthens the compound’s strategic importance across global markets.

- For instance, one research paper reported an approximately three times longer catalytic lifetime and remarkably improved selectivity for light olefins when using a specific polyacrylamide-assisted synthesis method to create hierarchical porous SAPO-34 zeolites, compared to conventional microporous analogs.

Market Challenges Analysis:

Supply Chain Vulnerabilities and Raw Material Constraints

The Aluminum Isopropoxide Market faces structural challenges linked to raw material availability and supply chain instability. It depends on consistent access to high-quality aluminum and isopropanol, which remain sensitive to price fluctuations and regional production gaps. Manufacturers address strict purity specifications that increase production complexity and operational costs. Logistics disruptions create delays that affect downstream industries relying on timely deliveries. Producers must maintain stringent storage and handling standards to prevent degradation. The need for continuous supply assurance places added pressure on procurement strategies.

Safety, Regulatory Compliance, and Production Complexity

Safety and regulatory compliance present long-term challenges for the Aluminum Isopropoxide Market. It requires controlled environments due to its sensitivity to moisture and potential for hazardous reactions during improper handling. Companies must invest in specialized equipment and monitoring systems that increase overall operational expenditure. Strict environmental rules in major markets elevate the cost of waste management and emissions control. Regulatory scrutiny in pharmaceuticals and advanced materials limits producer flexibility. The compound’s production demands high technical expertise, which restricts the number of qualified manufacturers.

Market Opportunities

Supply Chain Vulnerabilities and Raw Material Constraints

The Aluminum Isopropoxide Market faces structural challenges linked to raw material availability and supply chain instability. It depends on consistent access to high-quality aluminum and isopropanol, which remain sensitive to price fluctuations and regional production gaps. Manufacturers address strict purity specifications that increase production complexity and operational costs. Logistics disruptions create delays that affect downstream industries relying on timely deliveries. Producers must maintain stringent storage and handling standards to prevent degradation. The need for continuous supply assurance places added pressure on procurement strategies.

Safety, Regulatory Compliance, and Production Complexity

Safety and regulatory compliance present long-term challenges for the Aluminum Isopropoxide Market. It requires controlled environments due to its sensitivity to moisture and potential for hazardous reactions during improper handling. Companies must invest in specialized equipment and monitoring systems that increase overall operational expenditure. Strict environmental rules in major markets elevate the cost of waste management and emissions control. Regulatory scrutiny in pharmaceuticals and advanced materials limits producer flexibility. The compound’s production demands high technical expertise, which restricts the number of qualified manufacturers.

Market Segmentation Analysis:

By Type

The Aluminum Isopropoxide Market is segmented into reagent grade, industrial grade, and electronic grade. It fulfills varied performance requirements across synthesis and materials development. Reagent grade dominates high-purity applications in pharmaceuticals and fine chemicals due to strict quality expectations. Industrial grade supports bulk chemical processing where large-volume production is essential. Electronic grade expands with rising demand for advanced materials and precision coatings in electronics manufacturing.

- For Instance, Chemson Industrial (Shanghai) Co., Ltd. manufactures industrial grade aluminum isopropoxide and offers it in bulk quantities for various industrial applications

By Application

Key applications include pharmaceuticals, chemicals, ceramics, catalysts, and coatings. Pharmaceutical synthesis holds a leading share due to controlled reaction needs and high-purity standards. The chemical segment relies on the compound for consistent performance in oxidation and reduction processes. Ceramics and catalyst development show rising integration driven by high-performance industries. Coating applications gain momentum as it enhances thermal stability and structural properties.

- For Instance, Pharmaceutical companies, including Pfizer, consistently achieve high purity rates in their active pharmaceutical ingredients (APIs) by employing advanced manufacturing and purification processes, such as catalytic reactions and crystallization.

By Distribution Channel

The market is distributed through direct sales, distributors, and online channels. Direct sales dominate sectors requiring customized solutions and strict quality validation. Distributors serve medium-scale users that depend on reliable supply and technical support. Online platforms grow in relevance among small and emerging manufacturers due to convenient procurement and broader accessibility.

Segmentations:

By Type

- Reagent Grade

- Industrial Grade

- Electronic Grade

By Application

- Pharmaceuticals

- Chemicals

- Ceramics

- Catalysts

- Coatings

By Distribution Channel

- Direct Sales

- Distributors

- Online Platforms

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia-Pacific Strengthens its Lead with Expanding Chemical and Pharmaceutical Production

Asia-Pacific holds 45% share of the Aluminum Isopropoxide Market, driven by strong chemical and pharmaceutical production capacity. The region maintains its leadership due to high consumption across fine chemicals, intermediates, and advanced material synthesis. It benefits from major production hubs in China, India, Japan, and South Korea with a focus on high-purity output. Regional manufacturers invest in capacity upgrades to support expanding end-use sectors. Competitive operating conditions attract global buyers seeking stable and cost-efficient supply. Government-backed industrial growth continues to reinforce regional dominance.

North America Demonstrates Steady Growth with High Standards and Innovation

North America holds 25% share of the market, supported by rigorous quality standards and advanced manufacturing systems. The region records consistent demand from pharmaceutical producers, specialty chemical companies, and catalyst developers. It benefits from strong R&D infrastructure that accelerates the adoption of high-performance intermediates. Regulatory frameworks favor materials with predictable reactivity and high purity. Companies in the United States and Canada incorporate the compound across engineered coatings, ceramics, and precision synthesis processes. Innovation-driven strategies continue to strengthen regional competitiveness.

Europe Advances with Strong Regulatory Oversight and High-Value Applications

Europe holds 20% share of the market, backed by mature industrial ecosystems and strict regulatory oversight. The region maintains steady use of aluminum isopropoxide within pharmaceuticals, catalysis, and specialty chemical applications. It supports production environments requiring controlled performance and compliance with stringent environmental regulations. Producers emphasize sustainable and high-purity output aligned with regional expectations. Ongoing advancements in materials research increase demand for alumina precursors and catalytic reagents. Germany, France, and the United Kingdom maintain strong integration across high-precision industrial processes.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- BASF SE

- Merck KGaA

- Albemarle Corporation

- Evonik Industries AG

- Wacker Chemie AG

- Arkema S.A.

- Mitsubishi Chemical Corporation

- Sigma-Aldrich Corporation

- Tokyo Chemical Industry Co., Ltd.

- Honeywell International Inc.

- Anhui Jinhe Industrial Co., Ltd.

- Jiangsu Guotai International Group

Competitive Analysis:

The Aluminum Isopropoxide Market features a moderately consolidated competitive landscape with global and regional players focusing on high-purity production and reliable supply chains. Leading companies strengthen their positions through capacity expansion, advanced purification technologies, and strategic collaborations with pharmaceutical and specialty chemical manufacturers. It benefits from manufacturers that emphasize strict quality control and consistent batch performance to meet regulated industry requirements. Competitors invest in research to improve product stability and optimize synthesis pathways supporting advanced materials and catalyst applications. Market participants enhance distribution networks to serve diverse end-use industries across Asia-Pacific, North America, and Europe. Firms prioritizing cost efficiency, technological capability, and robust compliance frameworks maintain a competitive edge in this evolving market.

Recent Developments:

- In June 2025, Merck KGaA completed the acquisition of SpringWorks Therapeutics, finalizing one of the biggest M&A deals globally in biopharma for 2025, expected to boost revenues and earnings per share by 2027.

- In June 2023, Evonik Industries AG acquired Novachem Srl, an Argentinian sustainable cosmetic actives innovator.

Report Coverage:

The research report offers an in-depth analysis based on Type, Application, Distribution Channel and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and ITALY economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Aluminum Isopropoxide Market is expected to experience sustained demand driven by its expanding role in chemical synthesis and advanced material production.

- Manufacturers will focus on improving purity levels and batch consistency to support pharmaceutical and specialty chemical applications.

- It will benefit from rising adoption in catalyst development, high-performance ceramics, and engineered coatings.

- Global producers are likely to invest in automation and process optimization to strengthen operational efficiency.

- Regulatory emphasis on cleaner and safer chemical processes will encourage the use of high-quality intermediates.

- The market will see increased collaboration between chemical producers and research institutions to develop innovative synthesis pathways.

- Expansion of pharmaceutical and fine chemical manufacturing in Asia-Pacific will continue supporting regional growth.

- Supply chain enhancements will remain a priority to ensure reliable access to raw materials and mitigate production risks.

- Companies are expected to explore new application areas in electronics, energy systems, and precision manufacturing.

- Competitive intensity will increase as firms adopt advanced technologies and pursue strategic partnerships to gain market advantage.