Market Overview

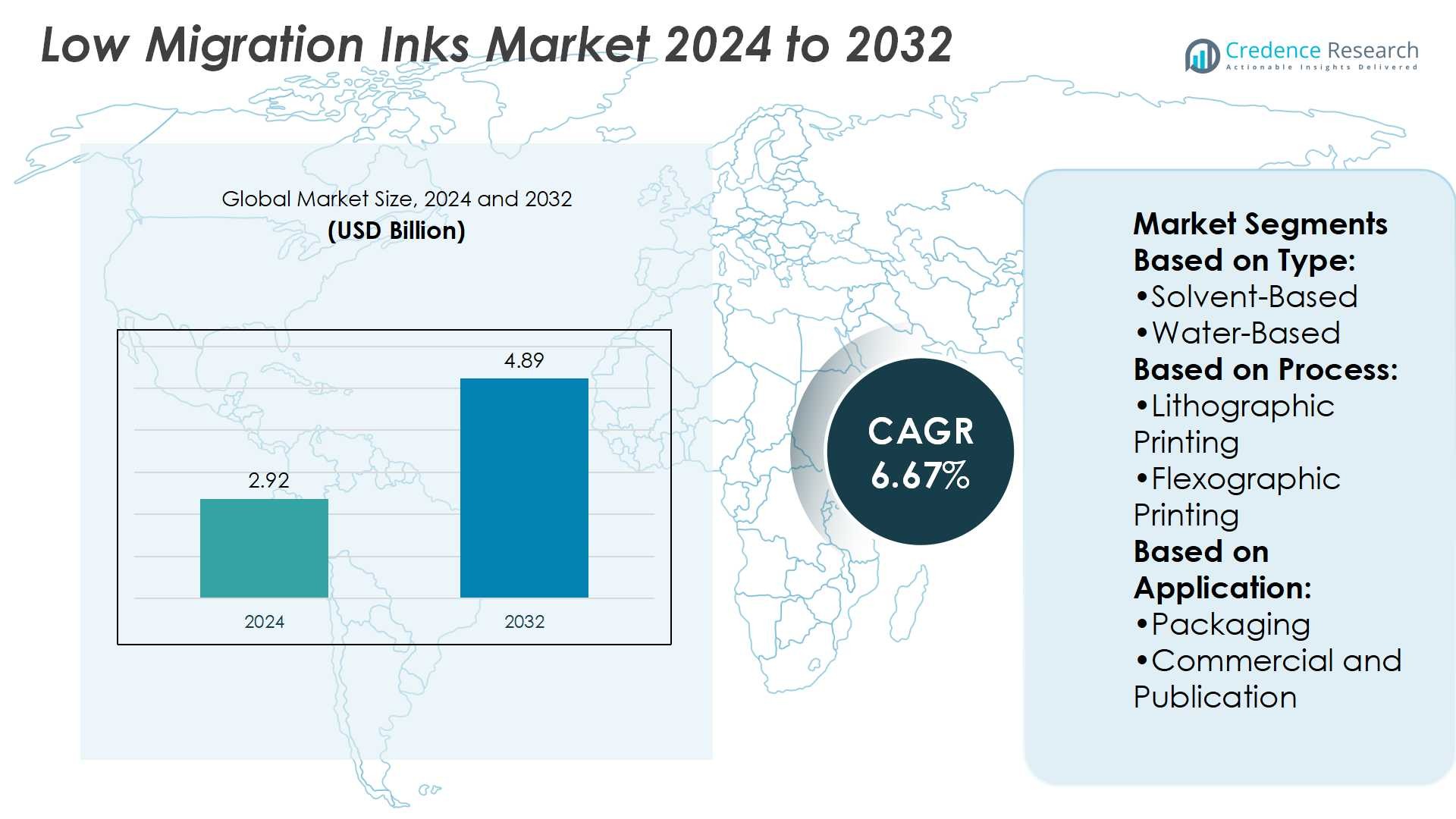

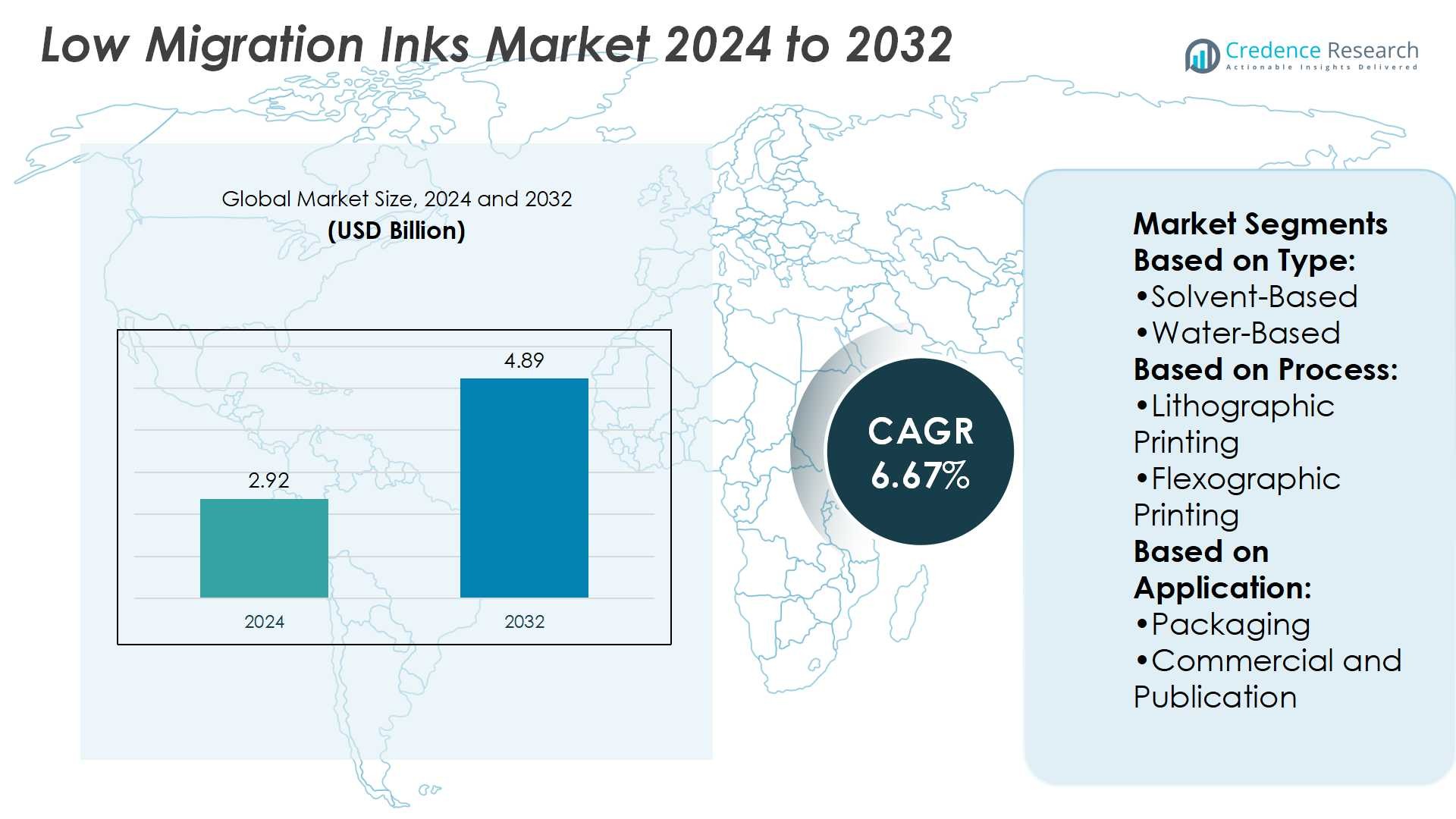

Low Migration Inks Market size was valued at USD 2.92 billion in 2024 and is anticipated to reach USD 4.89 billion by 2032, at a CAGR of 6.67% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Low Migration Inks Market Size 2024 |

USD 2.92 Billion |

| Low Migration Inks Market, CAGR |

6.67% |

| Low Migration Inks Market Size 2032 |

USD 4.89 Billion |

The Low Migration Inks Market grows with rising demand for safe packaging in food, beverage, and pharmaceutical sectors, driven by strict global regulations on chemical migration. Printers adopt UV, UV-LED, and water-based systems that ensure compliance, reduce emissions, and improve curing efficiency. The shift toward eco-friendly packaging supports innovation in bio-based and solvent-free formulations. Growing use of digital and hybrid presses further strengthens adoption, meeting the need for shorter runs and personalized packaging. Strong focus on regulatory alignment, sustainability, and performance highlights the market’s transition toward safer, greener, and more advanced printing solutions across global supply chains.

Europe holds the largest share of the Low Migration Inks Market, supported by strict EU regulations, while Asia-Pacific shows the fastest growth due to rising packaged food and pharmaceutical demand. North America maintains steady adoption through FDA compliance, whereas Latin America and the Middle East & Africa expand gradually with growing safety awareness. Key players active in this market include Sun Chemical, Flint Group, Siegwerk Druckfarben, Huber Group, Toyo Inks, INX International, Agfa-Gevaert, Altana, Marabu GmbH, and Epple Druckfarben.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- Low Migration Inks Market size was valued at USD 2.92 billion in 2024 and is anticipated to reach USD 4.89 billion by 2032, at a CAGR of 6.67%.

- Rising demand for safe packaging in food, beverage, and pharmaceutical sectors drives steady growth.

- Market trends highlight wider adoption of UV, UV-LED, and water-based inks for compliance and efficiency.

- Competitive landscape shows leading companies expanding sustainable portfolios with bio-based and solvent-free solutions.

- High production costs and complex regulatory requirements act as restraints for smaller converters.

- Europe leads the market with strict rules, while Asia-Pacific grows fastest with expanding packaged food and pharma industries.

- North America remains stable with FDA-driven demand, while Latin America and Middle East & Africa show gradual adoption supported by global suppliers.

Market Drivers

Rising Regulatory Emphasis on Food Safety and Packaging Compliance

Stringent global regulations drive the Low Migration Inks Market, as food safety remains a top priority. Packaging for food and beverages requires inks that prevent chemical transfer to consumables. Regulators in Europe and North America set strict migration limits for inks used in labels and cartons. Compliance ensures manufacturers avoid recalls and maintain brand trust. It also drives investment in safer ink formulations that reduce health risks. The trend strengthens adoption among packaging converters that operate in regulated industries.

- For instance, Toyo Printing Inks’ LP-9000 TOYO LIFE PREMIUM FOOD LO/LM ink series achieved a perfect deinkability score of 100 out of 100 in the INGEDE Method 11 test, showing it can be fully removed during paper recycling.

Growing Demand from Food, Beverage, and Pharmaceutical Packaging Applications

Food and pharmaceutical sectors rely heavily on packaging safety, fueling demand for low migration inks. The inks prevent contamination and preserve product quality across storage cycles. Rising consumption of packaged foods, ready-to-eat meals, and over-the-counter drugs increases reliance on compliant inks. It ensures packaging integrity during global trade and long-distance logistics. The Low Migration Inks Market benefits from manufacturers focusing on specialized formulations for these industries. Demand accelerates as healthcare packaging regulations tighten globally.

- For instance, Sun Chemical’s EtiJet LM UV inkjet inks for digital labels demonstrate migration levels of below 10 ppb when cured in air with standard mercury lamps, meeting strict food packaging standards.

Technological Advancements in Ink Formulations and Printing Processes

Ongoing innovations support the Low Migration Inks Market, with companies investing in UV-curable, water-based, and energy-efficient inks. Advanced curing techniques reduce volatile organic compounds and ensure durability on varied substrates. It allows faster printing speeds without compromising compliance standards. Improved formulation science supports inks that resist chemical interactions under extreme storage conditions. These technological upgrades help printers meet customer requirements for safety and sustainability. Enhanced performance also boosts competitiveness in packaging supply chains.

Sustainability Initiatives and Eco-Friendly Packaging Requirements

Sustainability drives the Low Migration Inks Market as brands adopt recyclable and bio-based packaging. Eco-friendly inks align with corporate sustainability commitments and consumer expectations for safer packaging. It reduces environmental impact while maintaining compliance with migration standards. Companies explore renewable raw materials and solvent-free ink technologies to meet green packaging goals. The shift supports circular economy initiatives in global supply chains. Growing demand for eco-conscious solutions reinforces the role of low migration inks in future packaging strategies.

Market Trends

Shift Toward UV-Curable and Water-Based Ink Technologies

The Low Migration Inks Market shows a steady move toward UV-curable and water-based solutions. These technologies reduce harmful emissions and support compliance with global safety standards. Printers favor UV-curable inks for their fast curing, high durability, and energy efficiency. Water-based inks gain traction due to their lower solvent use and eco-friendly profile. It supports safer production practices while meeting packaging demands in food and pharma. The shift underscores the industry’s focus on balancing performance with sustainability goals.

- For instance, Agfa offers UV-curable inks formulated with viscosity between 9 and 12 mPa·s, suitable for both bulb and LED curing systems. On the water-based side, Agfa has expanded production at its Mortsel (Belgium) plant, dedicated specifically to aqueous inkjet inks, supporting high print quality and long shelf life for packaging applications like décor paper and corrugated carton.

Expansion of Packaging Applications in Food and Pharmaceutical Sectors

Packaging trends in food, beverage, and pharmaceuticals accelerate the demand for low migration inks. Brands seek safer inks that maintain shelf life without compromising product integrity. Ready-to-eat meals, dietary supplements, and medical devices increase pressure for compliant solutions. The Low Migration Inks Market benefits from wider use in flexible packaging, cartons, and labels. It reinforces safety and consumer trust in highly regulated industries. Growth in healthcare and convenience foods amplifies the importance of packaging compliance.

- For instance, hubergroup’s MGA NATURA 5250 sheet-fed offset ink achieves an overall migration of less than 10 mg/dm², ensuring safe use on non-food contact surfaces in food packaging.

Integration of Sustainable Raw Materials and Circular Economy Practices

Sustainability shapes trends in the Low Migration Inks Market with focus on renewable raw materials. Ink producers experiment with bio-based pigments and solvent-free carriers. It aligns with global packaging commitments to reduce plastic and chemical waste. Circular economy initiatives encourage recyclable and compostable packaging formats that require safe ink systems. Brands highlight eco-labeling and low environmental impact to enhance consumer loyalty. The trend reflects a broader shift toward greener and safer packaging ecosystems.

Adoption of Digital Printing and High-Performance Packaging Solutions

Digital printing adoption supports customization and shorter production runs in packaging. It allows faster turnaround while ensuring compliance with migration standards. The Low Migration Inks Market leverages these advances to meet personalized packaging demands. It supports high-resolution graphics on flexible substrates used in food and pharma industries. Printers integrate low migration inks into hybrid platforms combining offset and digital systems. The trend improves efficiency while aligning packaging design with regulatory and consumer expectations.

Market Challenges Analysis

High Production Costs and Complex Formulation Requirements

The Low Migration Inks Market faces a major challenge in balancing safety with cost efficiency. Specialized formulations require expensive raw materials and advanced testing, raising production costs for suppliers. Printers operating in cost-sensitive markets hesitate to adopt these inks due to higher pricing. It creates pressure on manufacturers to justify costs while maintaining compliance. Complex formulation processes also limit scalability for smaller producers. Strict quality checks and certifications further extend development cycles, slowing adoption across regions.

Regulatory Complexity and Limited Standardization Across Markets

Compliance remains a significant barrier for the Low Migration Inks Market, with varying global regulations. Each region enforces different limits on chemical migration, forcing companies to adjust formulations for specific markets. It creates operational inefficiencies and raises costs for global suppliers. Lack of universal standards complicates cross-border packaging operations, delaying product approvals. Printers face uncertainty when navigating evolving regulations in food and pharmaceutical packaging. The challenge hinders consistent adoption, especially in emerging markets where enforcement remains uneven.

Market Opportunities

Rising Demand for Safe Packaging in Food and Pharmaceutical Industries

The Low Migration Inks Market holds strong opportunities with growing demand for safer packaging solutions. Food and pharmaceutical sectors prioritize inks that meet strict compliance while preserving product quality. It creates room for suppliers to develop advanced formulations tailored to sensitive applications. Expanding consumption of packaged foods and global trade in medical products drive consistent growth. Brands seek reliable solutions that strengthen consumer trust in safety and labeling. This demand offers long-term opportunities for manufacturers focusing on regulatory alignment and performance.

Innovation in Sustainable and Digital Printing Technologies

Technological innovation presents a major opportunity for the Low Migration Inks Market. Eco-friendly ink formulations that use renewable raw materials gain traction among global packaging brands. It supports corporate sustainability initiatives while addressing consumer preference for green packaging. Digital and hybrid printing platforms also open pathways for short runs and personalized packaging. These systems require compliant inks that ensure safety without reducing quality. The combination of sustainable formulations and advanced printing provides significant opportunities for future market expansion.

Market Segmentation Analysis:

By Type

The Low Migration Inks Market includes solvent-based, water-based, oil-based, UV, UV-LED, and other types. Water-based inks gain prominence due to lower emissions and compliance with environmental regulations. Solvent-based and oil-based inks continue to serve niche applications where durability is essential. UV and UV-LED inks expand rapidly, offering fast curing and strong adhesion across substrates. It enables packaging producers to meet high-volume needs while ensuring food safety. The diversity of ink types reflects evolving demand across different packaging formats and regulatory environments.

- For instance, INX launched INXhrc RC LM, a natural-based UV/LED dual-cure ink verified under ASTM D6866-20 for bio-content. Independent testing confirmed overall migration below 10 mg/dm² and specific migration under 60 mg/kg food.

By Process

Lithographic, flexographic, gravure, digital, and other processes define the market structure. Flexographic printing dominates packaging due to its efficiency in high-volume production. Lithographic processes remain important for labels and cartons requiring precise detail. Gravure printing is favored in long-run applications such as flexible packaging with high-quality finish. Digital printing grows steadily, supporting personalized and short-run packaging with fast turnaround. It creates opportunities for printers to integrate low migration inks across both traditional and digital workflows. This process-level diversity highlights the adaptability of the market to varied end-user needs.

- For instance, Flint Group’s Low Migration UV Flexo Silver ink (item code YFM00077) achieves migration levels below 10 ppb using 95% ethanol as a food simulant, while still delivering very good metallic performance, cure speed and adhesion on paper and synthetic substrates.

By Application

Packaging represents the largest application segment, driven by demand in food, beverages, and pharmaceuticals. The Low Migration Inks Market strengthens its position here as safety standards tighten globally. Commercial and publication printing uses low migration inks for high-quality labels and premium print products. Textiles represent a growing segment, where safety and compliance with eco-labeling regulations guide adoption. Other applications, including specialty graphics, benefit from expanding use of sustainable and compliant inks. It demonstrates the growing relevance of low migration inks beyond traditional packaging. Expanding across industries, these applications showcase the market’s long-term growth potential.

Segments:

Based on Type:

- Solvent-Based

- Water-Based

Based on Process:

- Lithographic Printing

- Flexographic Printing

Based on Application:

- Packaging

- Commercial and Publication

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America accounts for around 20% of the global market. The region benefits from strict FDA oversight on food and pharmaceutical packaging, which makes compliance a priority for converters and brand owners. Printers here invest in UV-curable and water-based inks to ensure safety and low migration performance. It gains strength from a mature packaging industry, established converter networks, and strong quality certification systems. Food and beverage companies, as well as major pharmaceutical brands, demand high-standard packaging, creating consistent opportunities. Continuous innovation in ink formulations and sustainability goals keeps North America’s market share steady and competitive.

Europe

Europe holds the largest share at about 45%, supported by its strict regulatory environment. EU rules such as Framework Regulation 1935/2004 and the Swiss Ordinance drive widespread adoption of low migration inks. Printers and converters in Germany, France, Italy, and the UK prioritize compliance with EuPIA and Nestlé guidance, making safety a non-negotiable aspect of packaging production. It benefits from a strong packaging sector that spans food, beverages, cosmetics, and pharmaceuticals. The region also shows strong innovation in bio-based formulations and solvent-free systems. Private-label retail growth further reinforces demand, making Europe the clear leader in this market.

Asia-Pacific

Asia-Pacific represents around 30% of the global share and stands out as the fastest-growing region. Rising consumption of packaged food, beverages, and medicines in China, India, and Southeast Asia drives strong demand. Global companies bring strict standards into the region, pushing local suppliers to upgrade ink technologies. It also benefits from cost-efficient manufacturing, making Asia a major hub for exports. Converters increasingly adopt digital and hybrid printing platforms to meet flexible packaging needs. The Low Migration Inks Market expands here as governments tighten food safety laws, narrowing the gap with North America and Europe. The combination of growth and compliance adoption positions Asia-Pacific as a key future leader.

Latin America

Latin America contributes roughly 3–4% of the global market share. Growth is steady, driven by the food and beverage sector and supported by exports. Mexico and Brazil are the main markets, where converters focus on compliance to meet both domestic and international standards. It develops through adoption of UV-curable and water-based inks, which reduce harmful emissions and meet safety goals. Global suppliers play a key role by providing technology, training, and certification support to local producers. Consumer awareness of food safety is rising, which creates further demand. Although smaller than Asia or Europe, the region continues to strengthen its role in packaging compliance.

Middle East & Africa

The Middle East & Africa region accounts for about 1–2% of the market share, making it the smallest region but with gradual growth. Countries in the Gulf and South Africa lead in adopting UV-LED and low-residual ink technologies for food and pharma packaging. It gains from investments in food security programs and local pharmaceutical production. Converters in the region increasingly focus on certification and testing to meet export standards. Global ink companies provide technical support and product access, which helps boost adoption. While growth is slower than other regions, steady demand in FMCG and healthcare packaging ensures progress.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Toyo Inks

- Epple Druckfarben

- Sun Chemical

- Agfa-Gevaert

- Huber Group

- Marabu GmbH

- INX International

- Flint Group

- Altana

- Siegwerk Druckfarben

Competitive Analysis

The Low Migration Inks Market players such as Agfa-Gevaert; Altana; Epple Druckfarben; Flint Group; Huber Group; INX International; Marabu GmbH; Siegwerk Druckfarben; Sun Chemical; Toyo Inks. The Low Migration Inks Market is defined by strong competition centered on compliance, innovation, and service delivery. Companies focus on expanding product lines that include UV, UV-LED, water-based, and solvent-free systems tailored for food, beverage, and pharmaceutical packaging. Market leaders prioritize regulatory alignment with frameworks such as the Swiss Ordinance and EU 1935/2004, ensuring safe use in sensitive applications. They also invest in R&D to create low-odor, photoinitiator-free, and de-inkable inks that support sustainability goals. Technical services, migration testing, and close collaboration with converters strengthen customer loyalty. Competitive advantage often comes from balancing cost efficiency with advanced performance and faster turnaround in both traditional and digital printing platforms.

Recent Developments

- In March 2025, scientists from the Bhabha Atomic Research Center (BARC) and the Institute of Nano Science and Technology launched a novel security ink. This ink is developed by using nanoparticles, known as strontium bismuth fluoride, that are helpful for detecting counterfeiting.

- In September 2024, Propper Manufacturing Company announced FDA clearance for its EO Chex Ethylene Oxide (EO) Indicator Tape, making it the only FDA-cleared ethylene oxide indicator tape available in the U.S. This innovative tape features diagonal stripes of pink chemical indicator ink that change to orange-brown upon exposure to EO sterilization, helping distinguish processed from unprocessed packages.

- In April 2023, INX International Ink Co. introduced a new sustainable low migration ink called the DuraInx HRC ink. This ink is designed with superior components and pigments. It comprises of up to 40% of renewable contents.

- In February 2023, Huber Group unveiled a new affordable series of low migration offset inks designed especially for the food packaging sector.

Report Coverage

The research report offers an in-depth analysis based on Type, Process, Application and Geography. It details leading market players, providing an overview of their business,product offerings, investments, revenue streams, and key applications. Additionally, the reportincludes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Low Migration Inks Market will grow steadily with stronger global food safety rules.

- Demand will rise from packaging in food, beverage, and pharmaceutical industries.

- Printers will adopt UV and UV-LED inks for faster curing and safer performance.

- Water-based and solvent-free inks will gain wider use for eco-friendly packaging.

- Digital and hybrid printing will create more opportunities for compliant ink systems.

- Brands will push suppliers for low-odor, photoinitiator-free, and de-inkable solutions.

- Regulatory alignment across regions will support smoother cross-border packaging operations.

- Sustainability goals will drive the shift toward bio-based and recyclable ink products.

- Partnerships with press manufacturers will speed up adoption of new ink technologies.

- Continuous R&D will enhance safety, efficiency, and reliability across global supply chains.