Market Overview

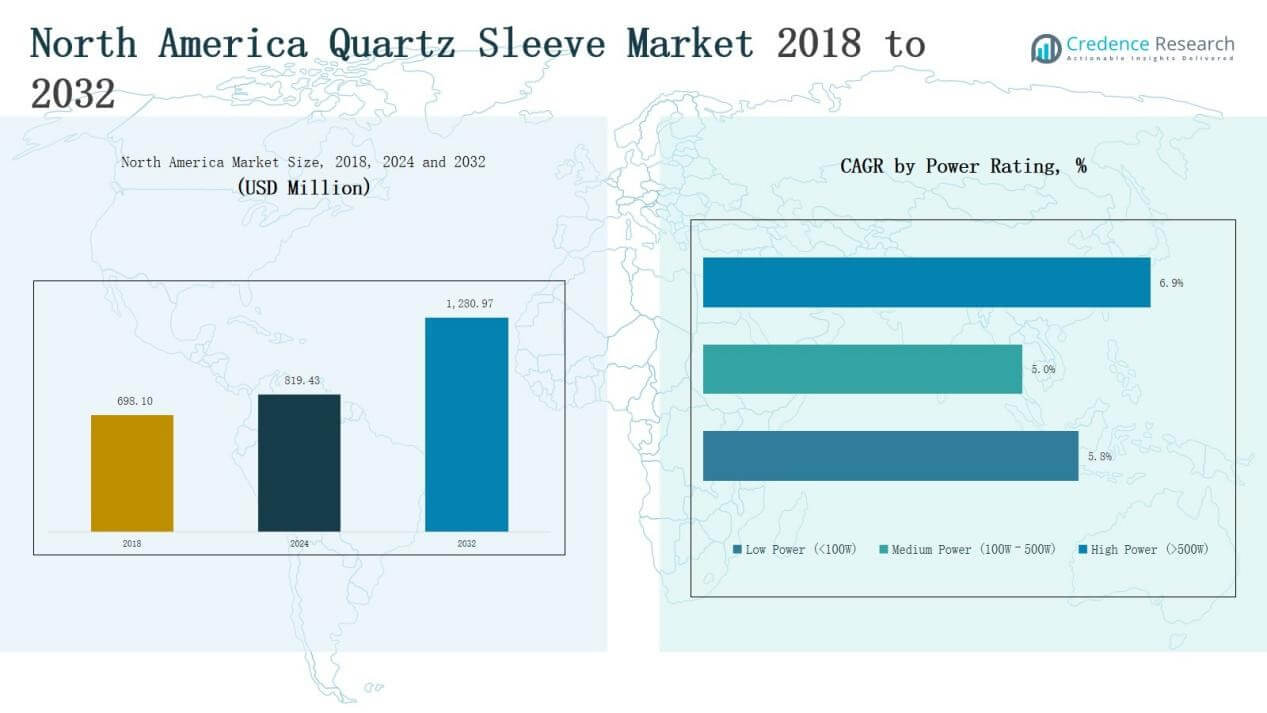

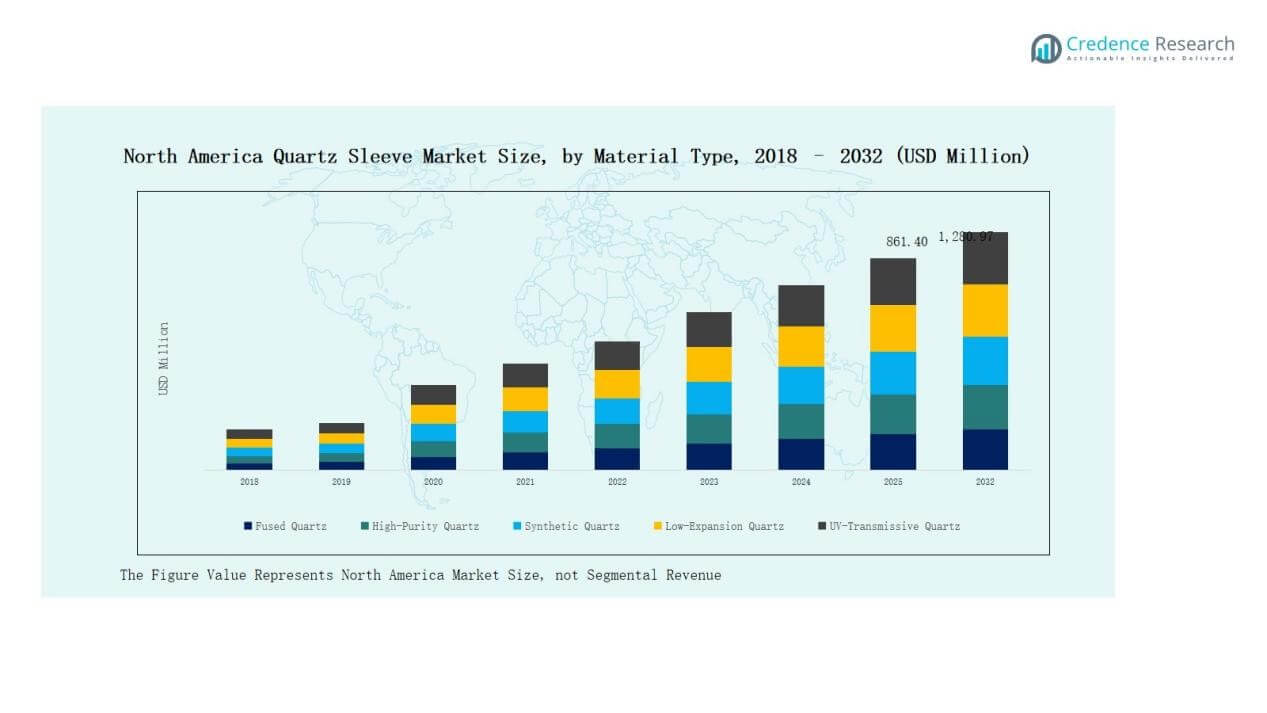

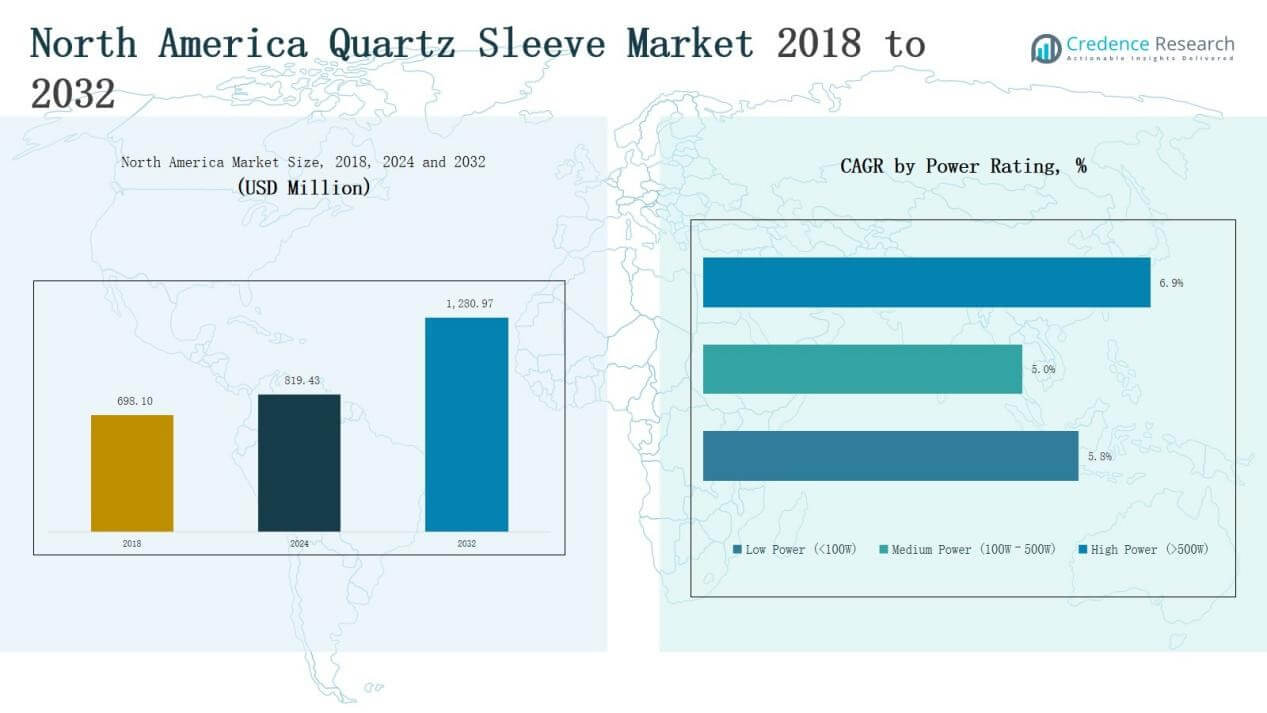

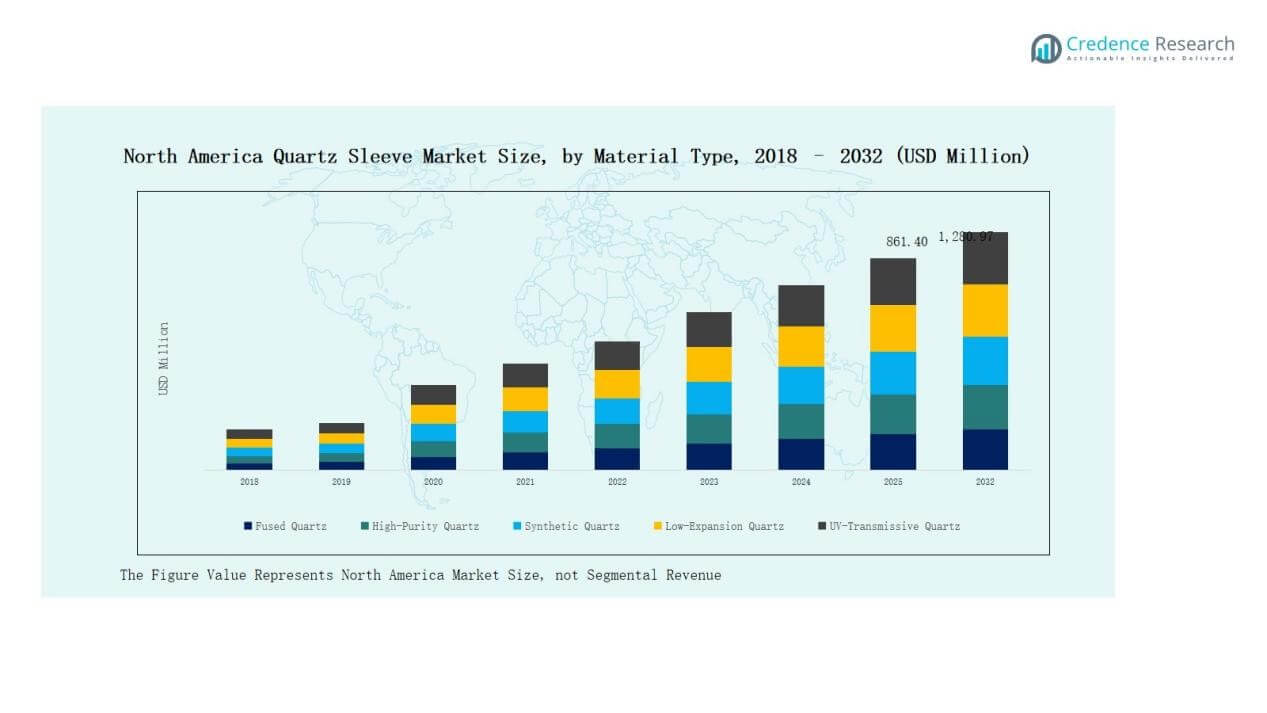

North America Quartz Sleeve Market size was valued at USD 698.10 million in 2018, reached USD 819.43 million in 2024, and is anticipated to reach USD 1,280.97 million by 2032, at a CAGR of 5.74% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| North America Quartz Sleeve Market Size 2024 |

USD 819.43 Million |

| North America Quartz Sleeve Market, CAGR |

5.74% |

| North America Quartz Sleeve Market Size 2032 |

USD 1,280.97 Million |

The North America Quartz Sleeve Market features strong competition led by global and regional players focusing on innovation, quality, and specialized applications. Key companies include Heraeus, Saint-Gobain, Momentive Performance Materials, Wacker Chemie AG, Tosoh Corporation, Quartz Scientific, QSI Quartz, Maxsil, Mondi Group, SGL Carbon, and Vesuvius. These firms drive growth through advanced fused and high-purity quartz solutions serving water treatment, semiconductors, pharmaceuticals, and food processing industries. The U.S. emerged as the leading region in 2024 with a 62% share, supported by robust industrial infrastructure, strict regulatory frameworks, and heavy investments in semiconductor and water treatment projects.

Market Insights

Market Insights

- The North America Quartz Sleeve Market reached USD 819.43 million in 2024 and is projected to hit USD 1,280.97 million by 2032, growing at 5.74%.

- Fused quartz led material types with 37% share in 2024, driven by superior thermal stability, durability, and extensive adoption in water treatment and semiconductor applications.

- UV water disinfection dominated applications with 42% share in 2024, supported by strict municipal water regulations and growing residential system adoption across the region.

- Water treatment was the top end-user, holding 39% share in 2024, fueled by investments in municipal infrastructure and widespread adoption of UV-based purification technologies.

- The U.S. commanded 62% of the regional market in 2024, supported by advanced semiconductor facilities, strict sanitation standards, and rising smart infrastructure investments.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segment Insights

By Material Type

Fused quartz dominated the North America quartz sleeve market in 2024, holding a 37% revenue share. Its superior thermal stability, durability, and high UV transmission make it the preferred choice in water treatment and semiconductor applications. High-purity quartz followed, driven by demand from pharmaceutical and electronics industries. Synthetic and low-expansion quartz serve niche uses where dimensional precision matters, while UV-transmissive quartz is gaining traction in advanced disinfection systems, supported by rising regulatory focus on sanitation and safety.

For instance, Momentive launched a high-purity quartz solution targeting semiconductor fabrication, enabling improved production efficiency in wafer processing.

By Application

UV water disinfection led the application segment with a 42% share in 2024, fueled by stringent municipal water treatment regulations and growing adoption in residential systems. UV air and surface disinfection also expanded rapidly, supported by heightened hygiene awareness in healthcare and commercial settings. Chemical processing applications contributed steadily due to quartz’s chemical resistance. Other uses, including niche industrial setups, provided incremental growth. Market expansion is strongly tied to public health initiatives and sustainable treatment technologies across North America.

For instance, Atlantium Technologies supplied its Hydro-Optic UV system to a Canadian food and beverage facility, showcasing the growing role of UV disinfection in industrial processing.

By End-User

Water treatment emerged as the leading end-user, accounting for a 39% market share in 2024. The segment benefits from rising investments in municipal water infrastructure and widespread adoption of UV-based purification technologies. The food and beverage industry follows closely, emphasizing hygienic processing environments. Pharmaceuticals and semiconductor & electronics sectors also contribute significantly, relying on quartz for high-purity and precise UV transmission. Oil & gas and other industries drive specialized demand, reinforcing quartz sleeves as a versatile solution across sectors.

Key Growth Drivers

Rising Demand for UV Disinfection Technologies

The growing emphasis on safe water, air, and surface treatment is a major driver. Strict municipal water regulations and increasing adoption of UV-based disinfection systems across North America boost demand for quartz sleeves. Their durability, chemical resistance, and superior UV transmission make them essential components in disinfection units. Healthcare facilities, food processors, and commercial buildings increasingly rely on quartz sleeves for hygiene compliance. Rising urbanization and population growth further accelerate the use of advanced disinfection solutions, strengthening market expansion.

For instance, UV-Guard supplies premium 100% pure-fused silica quartz sleeves compatible with leading UV disinfection brands like Trojan and Viqua, ensuring maximum UV radiation penetration for effective microbial inactivation.

Expansion of Semiconductor and Electronics Manufacturing

North America’s semiconductor sector fuels strong demand for high-purity quartz sleeves. These materials are critical in wafer processing and precision equipment due to their purity, thermal stability, and resistance to contamination. With rising investments in domestic chip manufacturing, particularly in the U.S., quartz sleeves gain prominence in maintaining process accuracy. Electronics growth across consumer devices, automotive electronics, and 5G infrastructure continues to support long-term market demand. Government incentives to boost chip manufacturing add further momentum to the segment.

For instance, CoorsTek offers synthetic quartz ceramics with exceptional thermal shock resistance and purity that meet the high demands of rapid thermal processing and single crystal silicon pulling in chip production.

Growing Adoption in Pharmaceutical and Food Industries

Pharmaceutical and food sectors rely heavily on UV-based sterilization for quality control and regulatory compliance. Quartz sleeves play an essential role in ensuring UV lamp efficiency and preventing contamination during sterilization processes. Rising demand for packaged foods and strict FDA regulations on hygiene enhance the importance of these products. In pharmaceuticals, quartz sleeves support sterile drug manufacturing and lab-scale applications. Increasing investments in advanced processing facilities across North America further drive adoption, positioning these industries as major growth contributors.

Key Trends & Opportunities

Key Trends & Opportunities

Shift Toward High-Purity and UV-Transmissive Quartz

Technological advancements and stricter regulations are driving adoption of high-purity and UV-transmissive quartz sleeves. These materials offer improved performance in disinfection and semiconductor applications, reducing energy use while ensuring higher efficiency. As demand for advanced UV-C systems grows in water, air, and surface disinfection, manufacturers are focusing on premium materials to meet evolving needs. This shift creates opportunities for suppliers to innovate with coatings, enhanced durability, and tailored solutions, strengthening their competitive positioning in the North American market.

For instance, QSIL Group developed high-purity fused silica components that deliver over 90% UV-C transmittance, supporting enhanced sterilization efficiency in both medical and semiconductor applications.

Expansion of Smart Infrastructure and Healthcare Applications

The rising adoption of smart cities and healthcare-focused infrastructure presents significant opportunities for quartz sleeves. Municipal water projects, hospital sanitation systems, and large commercial buildings increasingly deploy UV disinfection technologies. Quartz sleeves enhance the reliability and lifespan of these systems, making them a key enabler of safe, sustainable infrastructure. Emerging applications in air quality management, driven by public health awareness post-pandemic, further extend opportunities. Partnerships between equipment manufacturers and quartz suppliers are likely to accelerate adoption across diverse end-use sectors.

For instance, in the City of Florence, Oregon, a municipal wastewater treatment plant employs UV disinfection systems where quartz sleeves house UV bulbs to ensure effective pathogen inactivation, enhancing water safety for downstream users.

Key Challenges

High Manufacturing and Material Costs

Quartz sleeve production requires advanced processes, high-purity raw materials, and precision engineering, leading to elevated costs. These expenses often translate into higher product prices, limiting adoption among cost-sensitive industries and smaller operators. Import dependence for certain raw materials can further escalate expenses. Price competition among suppliers adds pressure to balance affordability with quality. Manufacturers face the ongoing challenge of investing in cost-reduction technologies while maintaining performance standards, as affordability remains a decisive factor for market penetration and growth.

Competition from Alternative Materials and Technologies

While quartz sleeves remain the standard in UV systems, alternative materials and disinfection technologies pose challenges. Advancements in LED-based UV systems reduce the need for quartz sleeves in certain applications, offering compact, energy-efficient solutions. Polymer-based alternatives with lower costs also gain limited traction in specific environments. As industries adopt emerging technologies, quartz sleeve manufacturers must continuously innovate to maintain relevance. Balancing traditional market strengths with the ability to compete against evolving technologies is critical for sustaining long-term growth.

Supply Chain Vulnerabilities and Regional Dependence

The quartz sleeve market faces risks from raw material supply disruptions and regional dependencies. Global supply fluctuations, shipping delays, and geopolitical uncertainties can restrict access to high-purity quartz, directly affecting production capacity. North American manufacturers often rely on imports for critical inputs, making the market sensitive to external shocks. Additionally, any delays in semiconductor or water infrastructure projects amplify these vulnerabilities. Strengthening domestic sourcing and building resilient supply chains remain crucial to ensuring stable growth and competitive advantage.

Regional Analysis

U.S.

The U.S. accounted for 62% share of the North America Quartz Sleeve Market in 2024. Strong municipal water treatment programs and strict sanitation regulations drive consistent adoption of quartz sleeves. The country’s expanding semiconductor industry increases demand for high-purity quartz solutions in wafer processing and electronics manufacturing. Healthcare and pharmaceutical sectors contribute further by using UV disinfection systems to meet compliance standards. Rising investments in smart city infrastructure also support growth. It remains the dominant regional hub due to advanced technology adoption and large-scale industrial applications.

Canada

Canada held a 23% share of the North America Quartz Sleeve Market in 2024. Water disinfection remains the largest application, supported by federal and provincial initiatives to secure safe drinking water in urban and rural areas. Growing pharmaceutical manufacturing and food processing industries add to demand for quartz sleeves in sterilization processes. Canada’s healthcare infrastructure continues to adopt UV-based air and surface disinfection technologies, strengthening market presence. Investment in energy-efficient solutions supports use of UV-transmissive quartz sleeves. It is emerging as a strong secondary market with steady growth potential.

Mexico

Mexico represented 15% share of the North America Quartz Sleeve Market in 2024. Rising industrialization and urbanization increase reliance on quartz sleeves in water and air treatment systems. Demand is expanding in food and beverage processing, where regulatory oversight is tightening around hygiene standards. The pharmaceutical industry also integrates UV disinfection technologies, further supporting adoption. Investments in electronics assembly and export manufacturing create additional opportunities for high-purity quartz sleeves. It is steadily strengthening its role in the regional market with improving infrastructure and manufacturing expansion.

Market Segmentations:

Market Segmentations:

By Material Type

- Fused Quartz

- High-Purity Quartz

- Synthetic Quartz

- Low-Expansion Quartz

- UV-Transmissive Quartz

By Application

- UV Water Disinfection

- UV Air Disinfection

- UV Surface Disinfection

- Chemical Processing

- Others

By End-User

- Water Treatment

- Food & Beverage

- Pharmaceutical

- Semiconductor & Electronics

- Oil & Gas

- Others

By Power Rating

- Low Power (<100W)

- Medium Power (100W–500W)

- High Power (>500W)

By Distribution Channel

- OEMs (Original Equipment Manufacturers)

- Aftermarket / Distributors

- Direct Sales

- Online / E-Commerce

- Others

By Region

Competitive Landscape

The North America Quartz Sleeve Market is highly competitive, with a mix of global leaders and regional specialists focusing on material innovation, product durability, and application-specific solutions. Companies such as Heraeus, Saint-Gobain, Momentive Performance Materials, Wacker Chemie AG, and Tosoh Corporation dominate through strong portfolios in fused and high-purity quartz. Regional players like Quartz Scientific, QSI Quartz, and Maxsil strengthen the landscape by offering customized and cost-effective products tailored for water treatment, food processing, and healthcare applications. Competition is further shaped by advancements in UV-transmissive technologies and partnerships with OEMs to enhance efficiency in disinfection and semiconductor equipment. Price competitiveness, distribution strength, and ability to meet stringent regulatory standards remain decisive factors. Leading manufacturers invest heavily in R&D to introduce sleeves with superior UV transmission and extended lifespans. Strategic collaborations, expansion of regional production, and mergers support sustained market positions and drive long-term growth across North America.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Players

- Heraeus

- Quartz Scientific, Inc.

- Saint-Gobain

- Momentive Performance Materials

- Tosoh Corporation

- Vesuvius

- Maxsil

- Mondi Group

- SGL Carbon

- Wacker Chemie AG

- QSI Quartz

Recent Developments

- In June 2025, Trojan Technologies launched the TrojanUV AOP Demonstration System to showcase advanced water disinfection.

- In September 2024, Southern Lamps acquired the medium pressure division of Superior Quartz Products.

- In 2024, Alpha-Cure Ltd. acquired the amalgam lamp technology division from Superior Quartz Products, Inc.

- In January 2023, Xylem completed the USD 7.5 billion acquisition of Evoqua Water Technologies to expand its water treatment solutions.

Report Coverage

The research report offers an in-depth analysis based on Product Type, Application, , End User, Power Rating, Distribution Channel and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand for fused quartz will continue to dominate due to its durability and UV efficiency.

- Adoption of UV disinfection systems in municipal water projects will expand steadily.

- Semiconductor manufacturing growth in the U.S. will boost high-purity quartz consumption.

- Healthcare and pharmaceutical facilities will increase reliance on UV sterilization technologies.

- Food and beverage processors will strengthen adoption for hygiene and compliance requirements.

- Canada will emerge as a stronger market with rising investments in healthcare infrastructure.

- Mexico will gain momentum from industrial expansion and rising food processing standards.

- Technological innovation will focus on UV-transmissive quartz sleeves with longer lifespans.

- Distribution through online and direct sales channels will grow with wider customer reach.

- Strategic partnerships between manufacturers and OEMs will shape competitive advantages.

Market Insights

Market Insights Key Trends & Opportunities

Key Trends & Opportunities Market Segmentations:

Market Segmentations: