Market Overview:

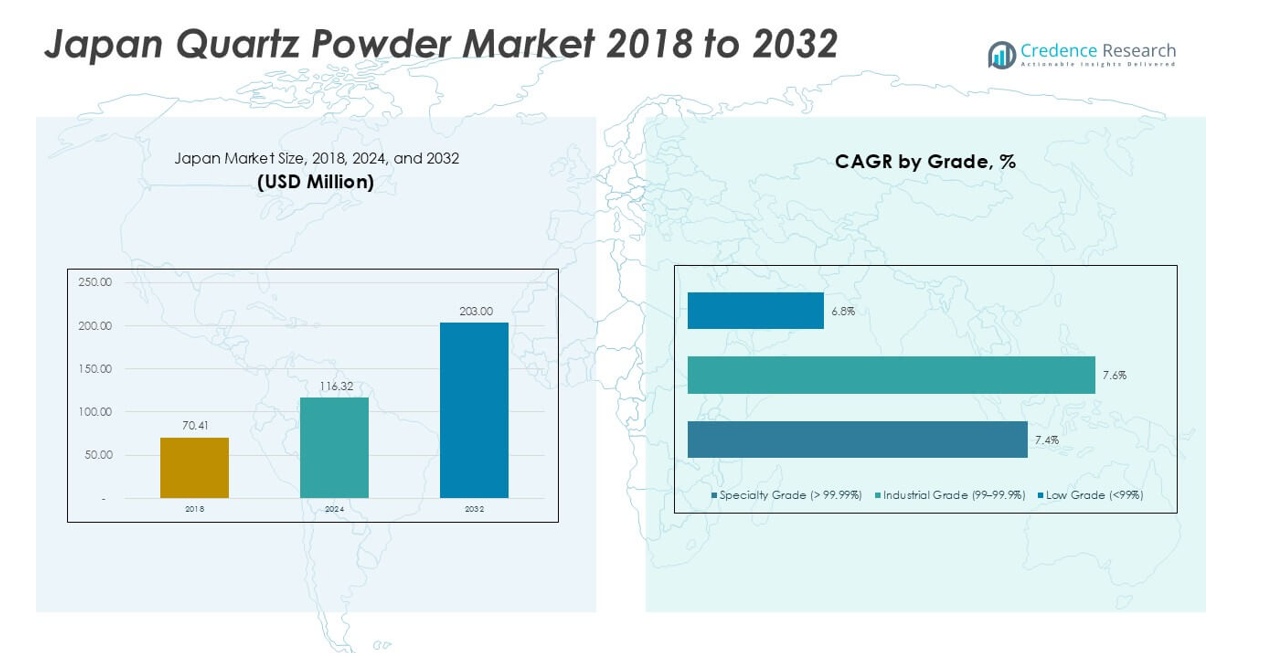

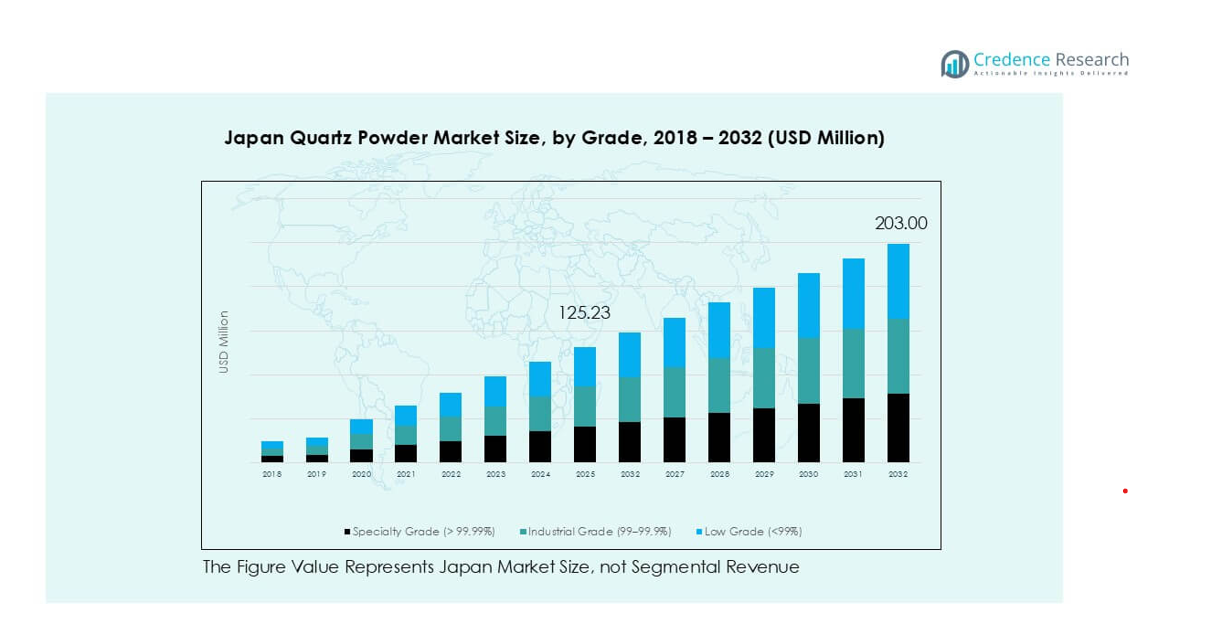

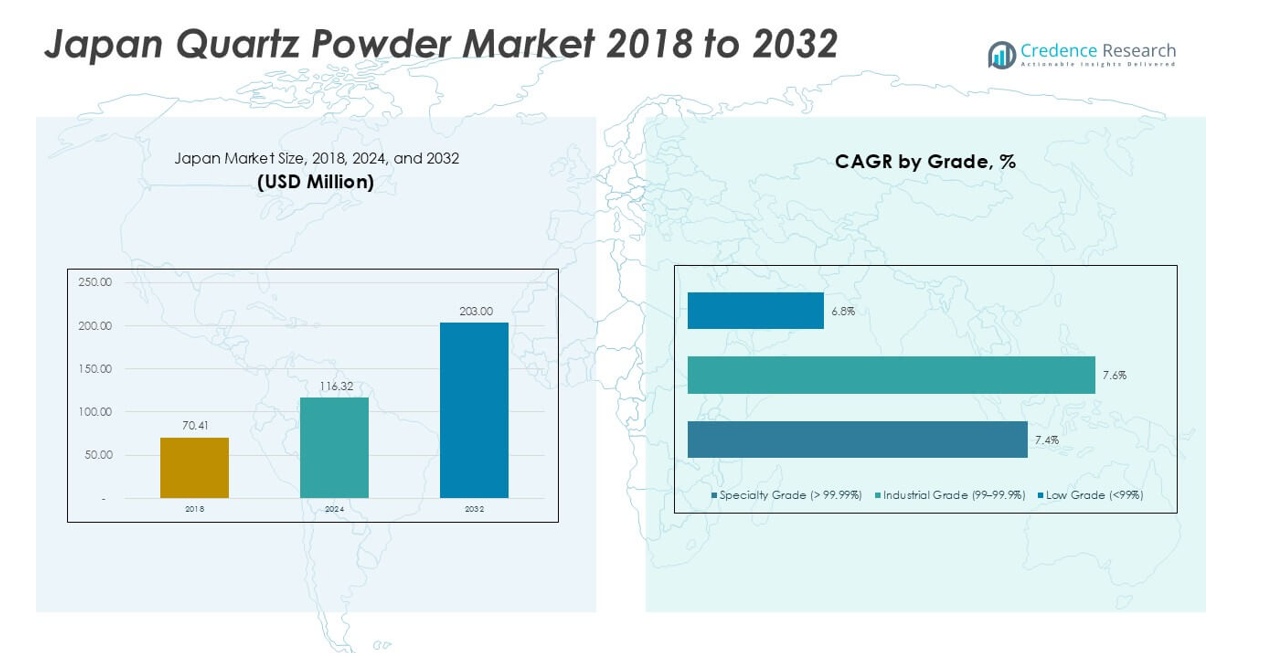

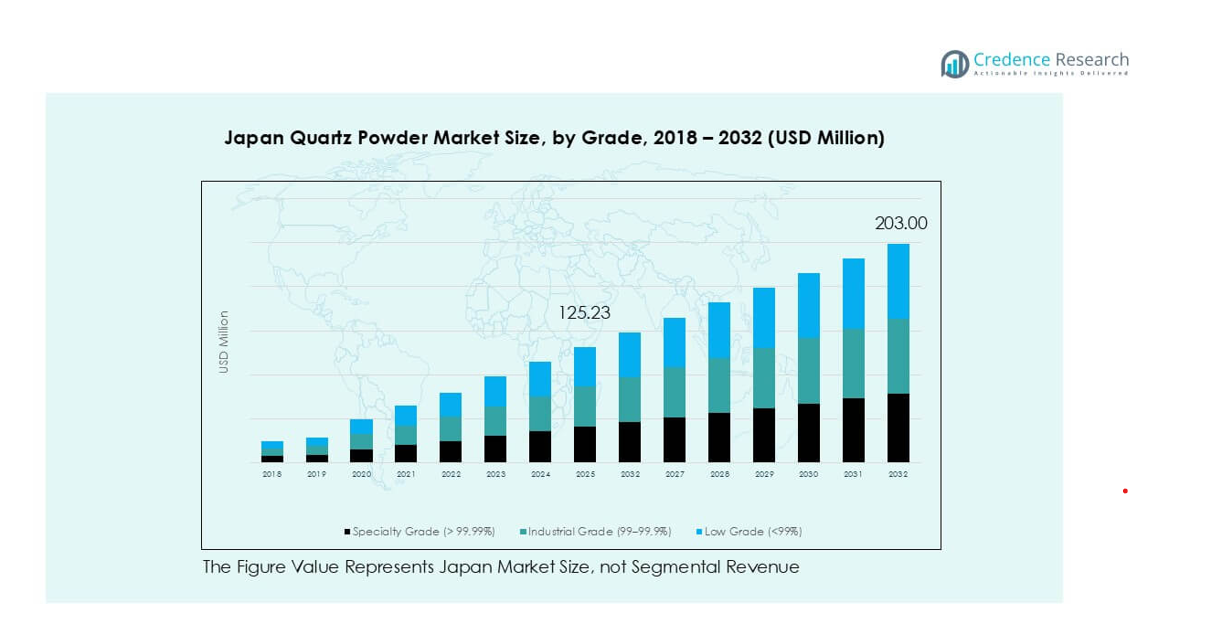

Japan Quartz Powder market size was valued at USD 70.41 million in 2018, increased to USD 116.32 million in 2024, and is anticipated to reach USD 203.00 million by 2032, at a CAGR of 7.1% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Japan Quartz Powder MarketSize 2024 |

USD 116.32 million |

| Japan Quartz Powder Market, CAGR |

7.1% |

| Japan Quartz Powder Market Size 2032 |

USD 203.00 million |

The Japan quartz powder market is led by major players such as Fumitec Minerals Private Limited, Sibelco, Imerys S.A., Momentive Technologies, and Quarzwerke Group. These companies maintain dominance through advanced purification processes, precise particle control, and strong supply reliability. Domestic firms like Speciality Geochem and The Sharad Group support industrial-grade applications in ceramics, construction, and glass sectors. Among regions, the Kanto region leads with a 36% market share in 2024, driven by its concentration of semiconductor and electronics manufacturers. Kansai and Chubu follow, supported by strong glass, ceramics, and automotive component production bases.

Market Insights

- Japan quartz powder market was valued at USD 116.32 million in 2024 and is projected to reach USD 203.00 million by 2032, registering a CAGR of 7.1% during the forecast period.

- Rising demand from semiconductor and electronics industries drives market growth, with specialty-grade quartz holding a 52% share due to its ultra-high purity for chip and wafer manufacturing.

- The market trend focuses on ultra-pure and micro-processed quartz materials, supporting Japan’s growing semiconductor and photovoltaic sectors.

- Competition remains strong among key players such as Fumitec Minerals, Sibelco, Imerys S.A., and Momentive Technologies, emphasizing quality, technology, and sustainability.

- Regionally, Kanto dominates with a 36% share, followed by Kansai at 22% and Chubu at 19%, reflecting strong demand from high-tech manufacturing and glass production hubs across Japan.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segmentation Analysis:

By Grade

The specialty grade segment dominated the Japan quartz powder market with a 52% share in 2024. Its leadership stems from demand in high-purity applications such as semiconductors, fiber optics, and solar photovoltaic manufacturing. Specialty grade (>99.99%) quartz offers exceptional chemical stability and low thermal expansion, making it essential for silicon wafer production. Growth is driven by Japan’s strong electronics base and continuous expansion in chip fabrication. The industrial grade segment follows, used widely in glass and ceramic production due to its cost efficiency and consistent quality for industrial processing.

- For instance, Tosoh Corporation achieved a purity level of 99.999% SiO₂ in its high-purity quartz products used for semiconductor crucibles.

By Application

The electronics and semiconductors segment held the largest share of 47% in 2024, supported by Japan’s advanced semiconductor ecosystem and rising need for ultrapure quartz in wafer and crucible manufacturing. The segment benefits from precision optical properties and high melting points of quartz powder, essential for microelectronics. The glass and ceramics segment ranked second, driven by demand for high-transparency and durable glass products. Expanding construction and automotive industries also support use in paints, coatings, and adhesives applications, reflecting quartz powder’s versatile industrial adoption.

- For instance, AGC Inc. manufactures quartz glass tubing with over 99.995% purity for photolithography and optical fiber applications, supplying more than 8,000 tons annually to domestic chip foundries.

Key Growth Drivers

Rising Demand from Semiconductor and Electronics Manufacturing

Japan’s strong semiconductor ecosystem continues to drive quartz powder consumption. High-purity quartz is essential for producing crucibles, wafer tubes, and photomasks used in chip fabrication. Increasing investments by domestic firms such as Tokyo Electron and global players like TSMC Japan boost demand for specialty-grade quartz with purity levels exceeding 99.99%. The growing adoption of advanced nodes, 5G chips, and electric vehicle power electronics enhances quartz utilization in wafer processing. Continuous expansion of cleanroom infrastructure and photolithography applications further reinforces market growth in this segment.

- For instance, TSMC Japan’s Kumamoto plant integrates advanced 7 nm and 16 nm process nodes that rely on quartz crucibles with 99.999% SiO₂ purity for wafer crystal growth.

Growing Use in Glass and Ceramics Production

The expanding glass and ceramics sector is a major growth contributor to the Japan quartz powder market. High-quality quartz powder offers durability, transparency, and heat resistance required for optical glass, display panels, and high-performance ceramics. Increasing demand for lightweight and energy-efficient building materials further supports market adoption. Companies are developing refined quartz grades for specialty glass used in automotive displays, solar panels, and precision instruments. Japan’s focus on eco-friendly architectural materials and optical innovation enhances quartz powder consumption in both structural and decorative applications.

- For instance, Nippon Electric Glass (NEG) is a leading global manufacturer of specialized glass products for a variety of high-tech applications, including automotive parts, electronic displays (LCD and OLED), and other electronic devices.

Advancements in Solar Energy and Photovoltaic Applications

The rapid expansion of Japan’s renewable energy projects, especially solar photovoltaic installations, fuels demand for high-purity quartz powder. Quartz is vital in producing silicon for solar cells and encapsulation glass for photovoltaic modules. Government initiatives under the Green Growth Strategy aim to boost domestic renewable energy capacity, encouraging quartz suppliers to expand production. Collaborations between material producers and solar manufacturers are enhancing supply chain resilience and local availability. These developments establish quartz powder as a crucial material in supporting Japan’s clean energy transition and sustainable manufacturing ecosystem.

Key Trends & Opportunities

Shift Toward Ultra-High Purity and Micro-Processed Quartz Materials

A notable trend is the shift toward ultra-high purity and micro-processed quartz powder for precision electronics and optical applications. Manufacturers are investing in advanced purification and surface treatment technologies to achieve impurity levels below one part per million. Such ultra-pure grades are critical for next-generation semiconductors, fiber optics, and photonic devices. This technological progression aligns with Japan’s push toward miniaturization and high-performance materials for microelectronics and quantum computing industries. The move strengthens domestic material capabilities while supporting exports to global technology hubs.

- For instance, Heraeus Conamic supplies high-purity synthetic fused silica for various applications, including Deep Ultraviolet (DUV) lithography optics, where it enables superior transmittance.

Increasing Integration of Automation and Sustainable Processing

Another key opportunity lies in automation and eco-friendly production processes. Companies are integrating robotic systems, digital monitoring, and waste recycling technologies to enhance efficiency and reduce environmental footprint. Automated quality control ensures consistent particle size and purity, vital for high-specification applications. Growing emphasis on low-emission and circular manufacturing supports sustainable production models in line with Japan’s carbon neutrality goals. These advancements improve competitiveness and position local producers to meet global demand for responsibly manufactured quartz materials.

Key Challenges

High Production Costs and Supply Chain Constraints

One of the main challenges in Japan’s quartz powder market is the high production cost of ultra-pure materials. Purification processes require advanced technology, precision equipment, and stable energy inputs, leading to elevated costs. Dependence on imported raw quartz adds further pressure due to fluctuating global supply and logistics constraints. Rising energy and labor expenses also affect local manufacturing margins. Companies are investing in domestic mining and automated refining solutions, but scaling these operations remains complex and capital-intensive. Managing supply consistency while maintaining high purity standards remains a persistent industry challenge.

Environmental Regulations and Waste Management Issues

Strict environmental regulations in Japan present another obstacle for quartz powder manufacturers. Production processes generate silica dust and chemical effluents that require advanced filtration and disposal systems. Compliance with environmental and occupational safety laws increases operational complexity and costs. Small and mid-sized manufacturers face difficulties meeting these standards while maintaining profitability. The industry’s shift toward sustainable production and closed-loop recycling systems is helping reduce waste, but full adaptation demands long-term investment. Regulatory pressure continues to shape operational strategies and technology adoption across the market.

Regional Analysis

Kanto Region

The Kanto region dominated the Japan quartz powder market with a 36% share in 2024. Its leadership is driven by the presence of major semiconductor and electronics manufacturers concentrated around Tokyo, Kanagawa, and Saitama. The region’s advanced cleanroom infrastructure and high-tech industrial base support strong demand for specialty-grade quartz. Continuous investment in semiconductor fabs and optical component production enhances consumption. Expanding R&D facilities and collaborations between domestic and global electronics firms further strengthen Kanto’s position as Japan’s primary hub for high-purity quartz powder applications.

Kansai Region

The Kansai region accounted for about 22% of the Japan quartz powder market in 2024. Demand is driven by its established ceramics, glass, and advanced materials industries across Osaka, Kyoto, and Hyogo. The region’s focus on industrial ceramics, optical glass, and construction materials supports steady consumption of industrial-grade quartz. Increasing adoption of energy-efficient building materials and electronic ceramics further boosts market prospects. Strong academic and industrial collaboration in materials science across Kyoto University and corporate research centers continues to enhance Kansai’s technological contribution to quartz innovation.

Chubu Region

The Chubu region held a 19% share of the Japan quartz powder market in 2024, supported by its robust manufacturing and automotive industries. Major cities like Nagoya and Shizuoka contribute significantly through precision glass and coating production. The region’s quartz demand is reinforced by electronic component and solar panel manufacturing. Expanding renewable energy projects, coupled with industrial automation initiatives, are creating strong growth opportunities. Chubu’s strategic position as a key logistics and export hub also enhances material distribution efficiency across Japan’s quartz powder supply chain.

Kyushu Region

The Kyushu region captured around 14% of the Japan quartz powder market in 2024, driven by rapid semiconductor manufacturing growth. The region hosts several advanced chip fabrication facilities, particularly in Kumamoto and Fukuoka, fueling strong demand for specialty-grade quartz. Government-backed semiconductor expansion programs are enhancing Kyushu’s role as a new production center. The region’s growing renewable energy and construction sectors also contribute to quartz powder use in photovoltaic and infrastructure applications, positioning Kyushu as a dynamic and expanding market for high-purity material demand.

Hokkaido and Tohoku Region

The Hokkaido and Tohoku region accounted for about 9% of the Japan quartz powder market in 2024. Its market presence is supported by resource availability and increasing renewable energy projects. Growing solar energy and industrial glass production drive quartz powder utilization across northern Japan. The region’s focus on infrastructure development and local material sourcing contributes to moderate but consistent growth. Emerging research programs in optical materials and clean energy technologies further enhance quartz powder applications, positioning this region as a developing hub for sustainable and high-quality material production.

Market Segmentations:

By Grade

- Specialty Grade (> 99.99%)

- Industrial Grade (99–99.9%)

- Low Grade (<99%)

By Application

- Electronics & Semiconductors

- Glass & Ceramics

- Paints, Coatings & Adhesives

- Construction Materials

- Oil and Gas

- Others

By Geography

- Kanto Region

- Kansai Region

- Chubu Region

- Kyushu Region

- Hokkaido and Tohoku Region

Competitive Landscape

The Japan quartz powder market features strong competition among global and domestic producers focusing on purity, precision, and reliability. Leading companies such as Fumitec Minerals Private Limited, Sibelco, Imerys S.A., and Momentive Technologies dominate through advanced refining technologies, consistent quality, and extensive supply networks. Domestic players like Speciality Geochem and The Sharad Group cater to industrial-grade applications, supporting demand across glass, ceramics, and construction materials. Global firms including Quarzwerke Group and Lianyungang Dong Hai Bo Tech Silica Powder Co., Ltd. strengthen their presence through partnerships with Japanese electronics and solar manufacturers. Continuous R&D efforts emphasize ultra-pure grades for semiconductor and photovoltaic sectors. Market participants are adopting sustainable production techniques and automation to enhance operational efficiency and environmental compliance. Strategic mergers, capacity expansions, and long-term supply contracts with electronics and solar panel producers define the industry’s competitive landscape, ensuring Japan’s position as a high-purity quartz material hub.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Fumitec Minerals Private Limited

- Lianyungang Dong Hai Bo Tech Silica Powder Co., Ltd.

- Sibelco

- The Sharad Group

- Speciality Geochem

- Quarzwerke Group

- Imerys S.A.

- Xuzhou Sainuo Quartz Co., Ltd.

- Momentive Technologies

- Other Key Players

Recent Developments

- In August 2024, Caesarstone introduced The Time Collection, which included ten new items, seven of which were new Porcelain colors and three Mineral Surfaces. These Mineral Surfaces represent a big step forward in surface design and are a testament to Caesarstone’s latest innovation. Using its vast expertise and advanced technology, the company has developed surfaces that combine minerals like Feldspar and Quartz with recycled content to create surfaces that are better performing and better for the environment.

- In January 2023, Caesarstone Ltd. declared the launch of its line of multi-material surfaces, which includes porcelain and natural stone in addition to outdoor quartz.

- In December 2022, Kyocera Corporation announced its purpose to invest 1.3 trillion yen ($9.78 billion), or through March 2026, in novel chip component manufacturing and the evolution of other sectors of its capabilities.

Report Coverage

The research report offers an in-depth analysis based on Grade, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand for high-purity quartz will rise with semiconductor and electronics expansion.

- Local production capacity will increase to reduce dependence on imported raw materials.

- Renewable energy projects will boost quartz use in photovoltaic and solar glass manufacturing.

- Technological advancements will enhance purification and particle size control processes.

- Automation and digital monitoring will improve production efficiency and product consistency.

- Sustainable and low-emission manufacturing practices will gain wider adoption across producers.

- Strategic partnerships will grow between quartz suppliers and semiconductor manufacturers.

- The glass and ceramics industry will continue adopting fine-grade quartz for premium applications.

- Research in ultra-micro quartz processing will strengthen Japan’s export competitiveness.

- Regional hubs like Kanto and Kyushu will remain key centers for high-purity quartz consumption.