Market Overview:

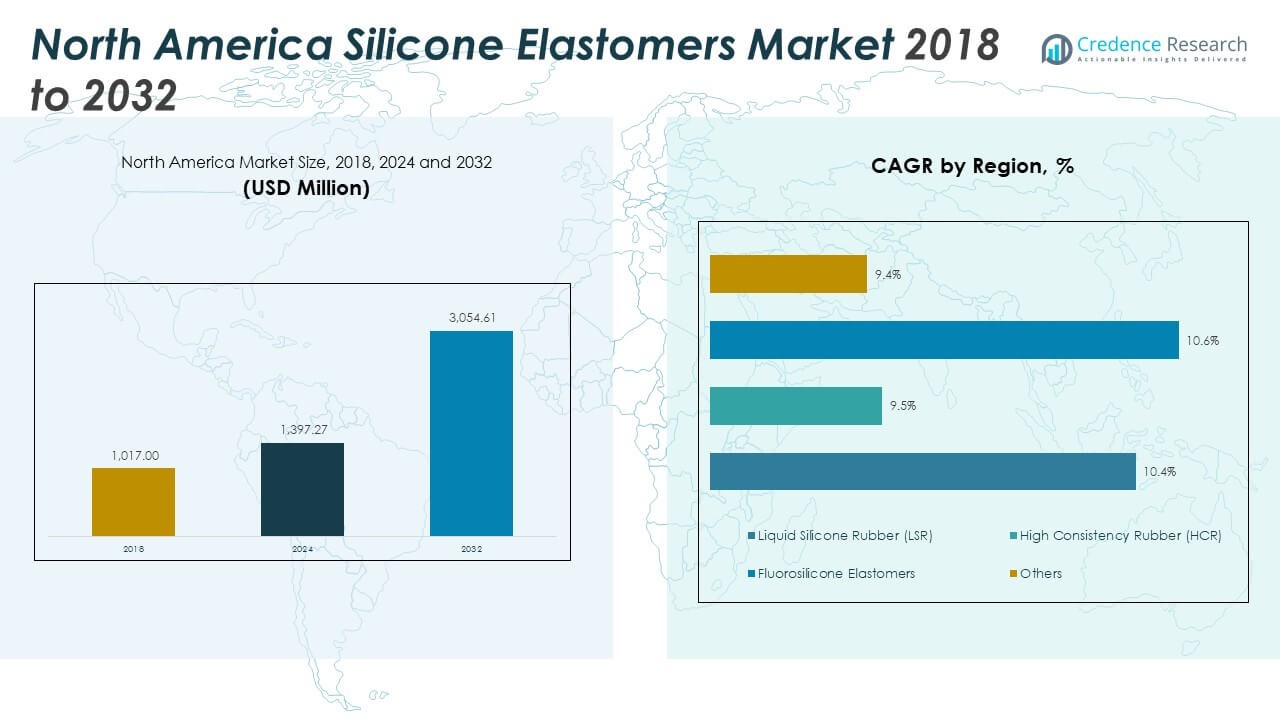

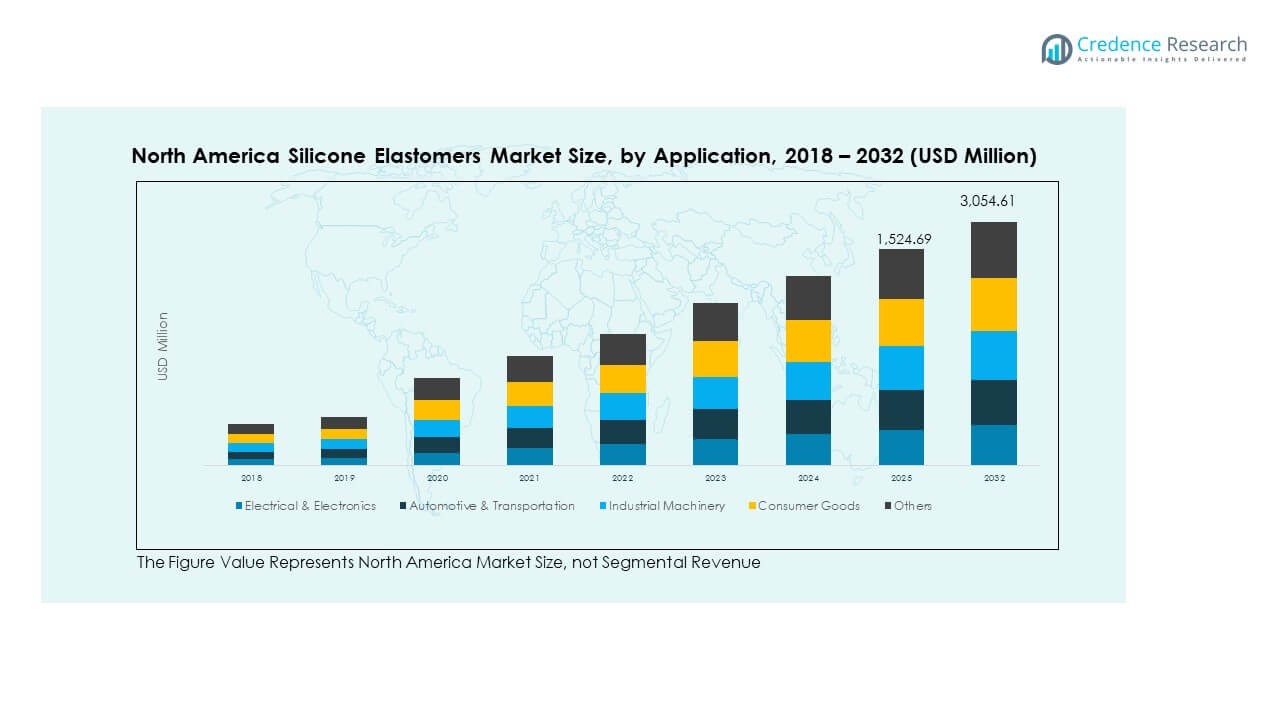

The North America Silicone Elastomers Market size was valued at USD 1,017.00 million in 2018 to USD 1,397.27 million in 2024 and is anticipated to reach USD 3,054.61 million by 2032, at a CAGR of 10.19% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| North America Silicone Elastomers Market Size 2024 |

USD 1,397.27 Million |

| North America Silicone Elastomers Market, CAGR |

10.19% |

| North America Silicone Elastomers Market Size 2032 |

USD 3,054.61 Million |

Market growth is driven by increasing demand across automotive, electronics, and healthcare sectors. Silicone elastomers are valued for their flexibility, heat resistance, and electrical insulation properties. Expanding applications in electric vehicles, medical implants, and construction sealants strengthen product adoption. Continuous innovation in liquid silicone rubber formulations and manufacturing technologies enhances performance, supporting broader use in high-precision components. Rising sustainability standards also boost demand for eco-friendly silicone-based materials across industries.

The United States leads the market due to strong industrial infrastructure, high R&D investment, and extensive end-use adoption in automotive and medical applications. Canada is growing steadily with rising healthcare manufacturing and green construction projects, while Mexico is emerging as a key hub for automotive component production and industrial exports. Robust trade relations, favorable policies, and technological advancements across these nations reinforce North America’s position as a vital region in the global silicone elastomers industry.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The North America Silicone Elastomers Market was valued at USD 1,017.00 million in 2018, reached USD 1,397.27 million in 2024, and is projected to hit USD 3,054.61 million by 2032, registering a CAGR of 10.19%.

- The United States leads with a 61% share, supported by strong manufacturing, innovation in LSR technologies, and demand across automotive and healthcare sectors.

- Canada holds a 23% share, driven by healthcare manufacturing and green infrastructure projects, while Mexico accounts for 16% due to its expanding automotive and industrial exports.

- Mexico represents the fastest-growing region in the North America Silicone Elastomers Market, supported by low production costs, foreign investment, and increasing electronics manufacturing.

- Segmentally, automotive and transportation contribute 35% of market revenue, followed by electrical and electronics at 28%, reflecting strong industrial demand and product diversification across applications.

Market Drivers

Rising Demand for Silicone Elastomers in Automotive and Transportation Applications

The automotive sector drives major growth within the North America Silicone Elastomers Market due to increasing use in high-performance parts. Silicone elastomers deliver superior resistance to heat, oil, and environmental stress, improving vehicle durability. Electric vehicles require silicone-based seals, gaskets, and insulation materials to enhance thermal stability. Automakers focus on lightweight materials to meet emission standards and boost efficiency. It supports the production of safer and more efficient electric and hybrid models. The strong presence of automotive manufacturers across the U.S. strengthens market demand. Expanding electric mobility networks further encourage wider material adoption. Innovation in silicone formulations enhances design flexibility and component longevity.

- For instance, in March 2025, Elkem Siliconeswon the Ringier Technology Innovation Award for its BLUESIL™ LSR 3935, a liquid silicone rubber designed specifically for high-voltage connectors in new energy vehicles, offering self-lubrication and thermal stability with hardness ranges from ShA20 to ShA60 for long-term waterproofing in electric mobility systems.

Expanding Use of Silicone Elastomers in Healthcare and Medical Devices

Medical applications represent another strong driver for the North America Silicone Elastomers Market due to superior biocompatibility and sterilization performance. Liquid silicone rubber is used in catheters, tubing, and implantable devices that demand high purity. Hospitals and healthcare device makers rely on its stability under extreme sterilization conditions. It ensures reliability and longevity in critical medical environments. The growing elderly population increases demand for healthcare products using silicone elastomers. Manufacturers are scaling production capacity for precision-molded medical parts. Advancements in liquid injection molding enhance customization capabilities. Regulatory approvals for medical-grade silicone further accelerate adoption across the healthcare sector.

Growth in Construction and Infrastructure Modernization Projects

The construction industry fuels significant growth in the North America Silicone Elastomers Market due to its extensive use in sealants, adhesives, and coatings. Silicone-based materials offer durability, flexibility, and resistance to weathering, making them ideal for structural applications. Infrastructure renewal and energy-efficient building designs increase silicone usage in glazing and insulation. It improves air-tightness and enhances energy conservation in commercial and residential structures. Urban expansion projects across major cities stimulate product consumption. Demand for high-performance sealants in skyscrapers and green buildings continues to rise. Construction companies prefer silicone elastomers for sustainable and low-maintenance solutions. The growing focus on long-term infrastructure sustainability drives consistent market expansion.

- For instance, Wacker Chemie AGintroduced new silane-crosslinking binders GENIOSIL® STP-E 140 and GENIOSIL® STP-E 340 in March 2025, specifically for tin-free, elastic sealants and adhesives with low modulus of elasticity. This technical innovation—the first of its kind—targets the construction sector and enables better performance in elastic recovery and durability for green buildings and large infrastructure projects.

Technological Advancements Enhancing Product Performance and Process Efficiency

Rapid innovation in processing and formulation technology drives advancements across the North America Silicone Elastomers Market. Manufacturers develop customized grades of liquid and high-consistency rubber for diverse end-use sectors. It improves thermal stability, tensile strength, and moldability. Integration of advanced curing systems enhances production speed and cost efficiency. Research initiatives focus on low-volatile formulations that meet stringent environmental standards. Industrial automation in silicone processing boosts output consistency. These technological upgrades support expanding applications across electronics, healthcare, and energy sectors. The shift toward precision manufacturing and sustainability strengthens long-term growth prospects.

Market Trends

Increasing Adoption of High-Performance Liquid Silicone Rubber in Electronics and Medical Sectors

notable trend in the North America Silicone Elastomers Market is the growing use of high-performance liquid silicone rubber (LSR). LSR provides superior precision molding and is used for complex electronic connectors and wearable sensors. Consumer electronics demand flexibility, thermal stability, and miniaturized components. It enables manufacturers to produce advanced designs while maintaining product safety. In medical applications, LSR’s biocompatibility supports its use in prosthetics and respiratory devices. The expanding wearable healthcare device segment boosts product demand. Manufacturers invest in automation and multi-cavity molds to optimize production. Increasing integration of smart technologies reinforces the material’s relevance.

Shift Toward Sustainable and Environmentally Friendly Silicone Elastomer Formulations

Sustainability has become a defining trend in the North America Silicone Elastomers Market, encouraging low-emission and recyclable formulations. Producers develop eco-friendly alternatives that reduce energy use and chemical waste. Regulatory bodies promote the use of silicone elastomers with minimal environmental impact. It supports adoption in green construction, energy-efficient appliances, and renewable systems. Companies introduce solvent-free and bio-based silicones to align with ESG initiatives. This transition reshapes product portfolios toward long-term circular economy models. Collaborative innovation with raw material suppliers strengthens eco-focused R&D. The focus on responsible production enhances brand credibility and market competitiveness.

Integration of Smart Manufacturing and Digital Production Processes

Digital transformation influences the North America Silicone Elastomers Market through smart manufacturing initiatives. Automation and predictive analytics improve production precision and reduce material waste. It enables faster prototyping and enhanced process monitoring for consistent quality. Companies integrate digital twin technology to simulate curing and molding conditions. This shift increases customization capabilities and shortens product development cycles. Manufacturers adopt AI-based systems to track performance metrics and process deviations. These developments create a data-driven production environment. The adoption of Industry 4.0 principles boosts scalability and operational resilience across regional plants.

- For instance, Dow announced a major upgrade and modernization of its Michigan Operations Industrial Park in Midland and Auburn in July 2024, with $120 million investment to support new process automation, digitalized production flows, and improved manufacturing of silicone gels, coatings, and encapsulants for electric vehicle batteries.

Expansion of Customized Silicone Grades for Specialized Industrial Applications

Rising demand for customized silicone grades shapes a significant trend in the North America Silicone Elastomers Market. End-users require application-specific properties such as enhanced dielectric strength or resistance to extreme temperatures. It allows tailored product designs for aerospace, marine, and defense systems. Material innovation supports rapid prototyping and precision assembly in critical sectors. Collaborations between producers and OEMs drive bespoke solutions for niche markets. These efforts result in silicone elastomers optimized for unique mechanical or environmental needs. The trend strengthens supply chain integration and product differentiation. Advanced material customization supports competitive positioning in high-value segments.

- For instance, in May 2024, Elkem introduced Silbione™ RT Gel 4660, a medical-grade silicone gel adhesive certified to ISO 10993, designed for wound care and wearable sensors, featuring direct substrate bonding without primer and gentle removal for sensitive healthcare applications.

Market Challenges Analysis

Fluctuating Raw Material Prices and Supply Chain Constraints

A major challenge facing the North America Silicone Elastomers Market is the volatility in raw material prices. Dependence on silicon metal and methyl chloride exposes producers to cost fluctuations. It affects production budgets and profit margins for manufacturers. Supply chain disruptions caused by trade barriers and logistics delays further strain operations. Regional shortages of feedstock materials delay manufacturing timelines. Import dependency for certain precursors increases vulnerability to external shocks. Companies are investing in vertical integration to stabilize supply channels. However, price instability continues to limit consistent profit realization. Developing resilient sourcing strategies remains crucial for maintaining competitiveness.

Regulatory Compliance and Environmental Restrictions Impacting Production

Environmental regulations represent another key challenge for the North America Silicone Elastomers Market, particularly in high-volume manufacturing regions. Compliance with safety and emission standards requires costly process upgrades. It restricts the use of certain curing agents and additives. Manufacturers must balance innovation with compliance to ensure sustainable growth. Strict waste disposal norms add operational burdens for small and mid-size producers. Meeting REACH and EPA guidelines requires extensive documentation and testing. These regulations slow product approval timelines and elevate compliance costs. Sustaining profitability while maintaining regulatory adherence demands strategic investment in cleaner technologies.

Market Opportunities

Rising Opportunities in Electric Vehicles and Renewable Energy Systems

The growing electric vehicle market creates strong opportunities for the North America Silicone Elastomers Market. Silicone elastomers support energy efficiency by insulating battery packs and high-voltage cables. It enhances performance under fluctuating temperature conditions. Renewable energy projects also create demand for silicone components in solar modules and wind turbines. The region’s focus on sustainable power generation drives further innovation. Producers developing advanced grades for harsh environments gain competitive advantage. Integration with renewable energy infrastructure expands the scope for long-term applications. Strategic partnerships with EV manufacturers strengthen market positioning.

Increasing Penetration of Silicone Elastomers in Consumer Goods and Wearables

Consumer electronics and wearable devices provide new opportunities for the North America Silicone Elastomers Market. It offers superior flexibility, safety, and aesthetics suitable for modern designs. The demand for heat-resistant, lightweight materials is increasing across lifestyle and personal care products. Silicone’s hypoallergenic and durable nature enhances its use in consumer wearables. Producers invest in colorful and tactile silicone variants for brand differentiation. The combination of comfort and durability strengthens its role in next-generation smart devices. Growth in IoT-enabled consumer products continues to widen application areas.

Market Segmentation Analysis

By Type

Liquid Silicone Rubber (LSR) holds the dominant share in the North America Silicone Elastomers Market due to its versatility and excellent molding precision. It is widely used in electronics, medical, and automotive sectors. High Consistency Rubber (HCR) supports heavy-duty applications requiring strong mechanical resistance and high temperature tolerance. Fluorosilicone Elastomers are gaining traction in aerospace and fuel system applications for their superior chemical resistance. Others, including room temperature vulcanized silicones, find niche use in coatings and adhesives. Continuous product innovations enhance processing speed, reliability, and design flexibility across all types.

- For instance, in 2025, Momentive’s Silopren™ LSR 7000 series demonstrated sustained optical transmission after 6,480 hours at 150 °C, verified through internal product testing, confirming its long-term reliability for demanding automotive and electronics applications.

By Application

The automotive and transportation segment leads the North America Silicone Elastomers Market, supported by growing demand for sealing, insulation, and vibration-damping materials. Electrical and electronics sectors show strong growth due to expanding EV and smart device production. Construction follows with steady adoption in sealants and weatherproofing materials. Industrial machinery benefits from silicone elastomers’ resistance to extreme conditions and corrosion. Consumer goods and healthcare also contribute significantly due to hygiene and comfort requirements. Others, including renewable energy and defense, continue to expand applications. It reflects the material’s adaptability across diverse end-use industries.

- For instance, in October 2025, Silicone Engineering supplied defense-grade silicone gaskets and vibration-damping pads for armored vehicles and naval platforms, independently tested to meet A-A-59588 and MIL-STD standards for flame resistance, corrosion protection, and vibration control in military applications.

Segmentation

By Type

- Liquid Silicone Rubber (LSR)

- High Consistency Rubber (HCR)

- Fluorosilicone Elastomers

- Others

By Application

- Electrical & Electronics

- Automotive & Transportation

- Industrial Machinery

- Consumer Goods

- Construction

- Others

Regional Analysis

United States

The United States dominates the North America Silicone Elastomers Market with a 61% share. Strong demand from automotive, healthcare, and construction industries drives consistent growth. It benefits from an advanced manufacturing base, high R&D spending, and strong infrastructure development. Major producers, including Dow Inc. and Momentive, focus on innovations in liquid silicone rubber and medical-grade elastomers. The rise in electric vehicles and consumer electronics expands end-use applications. Stringent energy efficiency and sustainability standards encourage the use of high-performance silicone materials. The country’s well-established distribution networks further strengthen its regional leadership.

Canada

Canada holds a 23% share in the North America Silicone Elastomers Market, supported by growing applications in healthcare, industrial machinery, and renewable energy systems. Increasing investments in medical device manufacturing and green infrastructure support silicone elastomer adoption. It benefits from regulatory emphasis on sustainable construction materials and healthcare product innovation. Domestic companies focus on precision molding and low-emission formulations to align with environmental goals. Demand for advanced insulation and sealing materials in cold climates continues to expand. The growing role of renewable projects strengthens Canada’s position as a high-growth regional market. Its stable economy and advanced research sector promote continuous product development.

Mexico

Mexico accounts for a 16% share in the North America Silicone Elastomers Market, driven by strong growth in the automotive and consumer goods sectors. Expanding industrial zones and low manufacturing costs attract major silicone producers to establish production facilities. It serves as a key export base for automotive components and electronic parts. The government’s initiatives supporting foreign investments accelerate technology transfer and industrial modernization. Increasing demand for durable materials in electronics, packaging, and infrastructure adds to market expansion. Collaborations between global and local manufacturers improve supply chain efficiency. Mexico’s proximity to the U.S. enhances its strategic importance within the regional market.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Dow Inc. (USA)

- Wacker Chemie AG (Germany)

- Momentive Performance Materials Inc. (USA)

- Shin-Etsu Chemical Co., Ltd. (Japan)

- China National Bluestar (Group) Co., Ltd. (China)

- Reiss Manufacturing Inc. (USA)

- Mesgo S.p.A. (Italy)

- Zhejiang Xinan Chemical Industrial Group Co., Ltd. (China)

- Stockwell Elastomerics (USA)

- Specialty Silicone Products, Inc. (USA)

Competitive Analysis

The North America Silicone Elastomers Market features a highly competitive landscape with major players such as Dow Inc., Wacker Chemie AG, Momentive Performance Materials Inc., and Shin-Etsu Chemical Co., Ltd. Companies focus on expanding production capacity, developing medical-grade and high-purity elastomers, and strengthening distribution networks. It witnesses continuous innovation in low-volatile and heat-resistant formulations to meet industrial and environmental standards. Mergers and partnerships enhance market presence and accelerate R&D initiatives. Firms emphasize automation and digitalized production to reduce costs and improve product quality. Competitive strategies also include regional expansions and tailored product offerings for automotive, healthcare, and electronics sectors. Market consolidation trends indicate stronger collaboration between raw material suppliers and end-use manufacturers.

Recent Developments

- In September 2025, Freudenberg Sealing Technologies announced the acquisition of DMH Group, marking a notable step in expanding their elastomer and sealing solutions portfolio throughout North America. This acquisition enables Freudenberg to diversify into advanced silicone elastomer capabilities and reinforces its market presence across critical industrial sectors.

- In June 2025, Dow unveiled its new low carbon silicone elastomer blends under the Decarbia platform at the Suppliers’ Day in New York City. As part of this launch, the company introduced targeted products for beauty and personal care applications such as conditioners, styling agents, and film formers for color cosmetics and sun care, accompanied by an innovative formulation kit designed to elevate consumer routines.

Report Coverage

The research report offers an in-depth analysis based on Type and Application. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The North America Silicone Elastomers Market will experience strong growth driven by rising demand across healthcare, automotive, and electronics sectors.

- Increasing focus on energy-efficient and sustainable materials will enhance the use of silicone elastomers in construction and renewable energy projects.

- Technological advancements in liquid silicone rubber processing will enable precision manufacturing for complex industrial and medical applications.

- Expanding electric vehicle production will boost demand for high-temperature-resistant silicone components in battery and cable insulation.

- The market will see growing investments in automation and digital production systems to optimize operational efficiency.

- Collaboration between regional manufacturers and global chemical firms will support innovation and material development.

- Regulatory support for low-emission and eco-friendly elastomers will accelerate the shift toward green formulations.

- Expansion of e-commerce and consumer electronics sectors will create steady demand for flexible, durable silicone products.

- North America’s healthcare modernization and aging population will drive continuous use of medical-grade silicone elastomers.

- Strategic mergers and capacity expansions among key players will consolidate market presence and improve supply chain resilience.