CHAPTER NO. 1 : GENESIS OF THE MARKET

1.1 Market Prelude – Introduction & Scope

1.2 The Big Picture – Objectives & Vision

1.3 Strategic Edge – Unique Value Proposition

1.4 Stakeholder Compass – Key Beneficiaries

CHAPTER NO. 2 : EXECUTIVE LENS

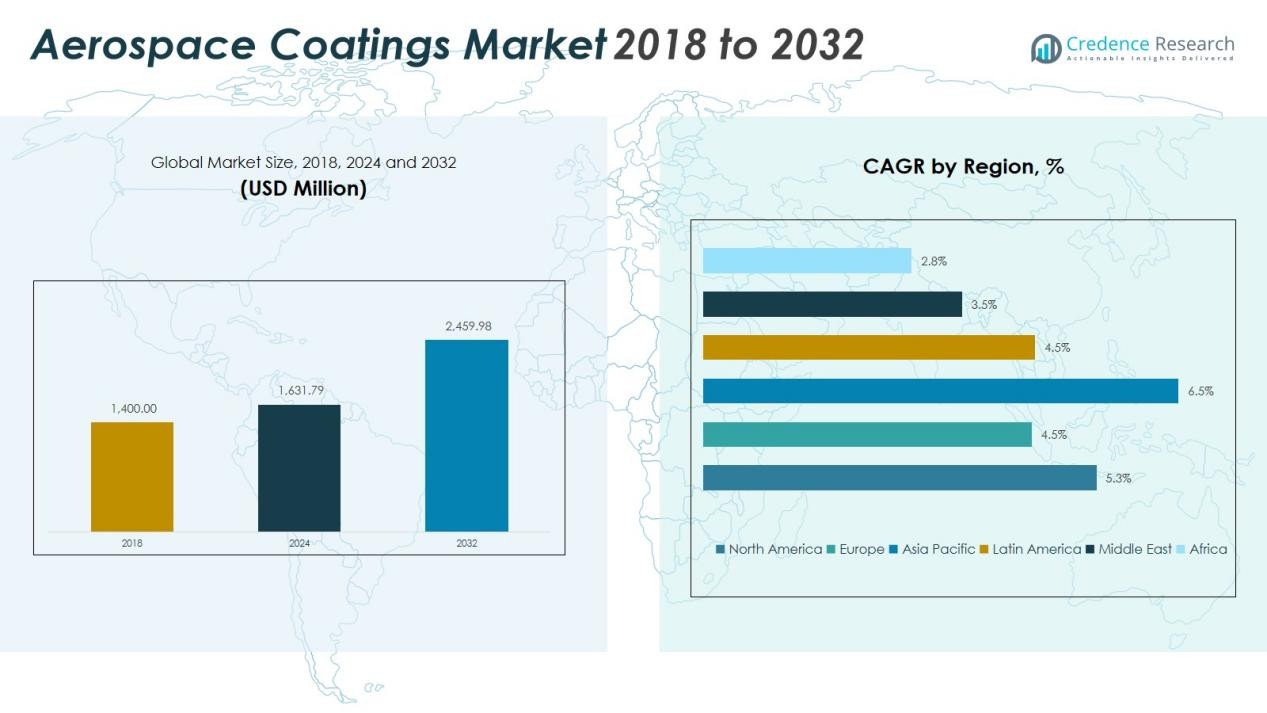

2.1 Pulse of the Industry – Market Snapshot

2.2 Growth Arc – Revenue Projections (USD Million)

2.3. Premium Insights – Based on Primary Interviews

CHAPTER NO. 3 : AEROSPACE COATINGS MARKET FORCES & INDUSTRY PULSE

3.1 Foundations of Change – Market Overview

3.2 Catalysts of Expansion – Key Market Drivers

3.2.1 Momentum Boosters – Growth Triggers

3.2.2 Innovation Fuel – Disruptive Technologies

3.3 Headwinds & Crosswinds – Market Restraints

3.3.1 Regulatory Tides – Compliance Challenges

3.3.2 Economic Frictions – Inflationary Pressures

3.4 Untapped Horizons – Growth Potential & Opportunities

3.5 Strategic Navigation – Industry Frameworks

3.5.1 Market Equilibrium – Porter’s Five Forces

3.5.2 Ecosystem Dynamics – Value Chain Analysis

3.5.3 Macro Forces – PESTEL Breakdown

3.6 Price Trend Analysis

3.6.1 Regional Price Trend

3.6.2 Price Trend by product

CHAPTER NO. 4 : KEY INVESTMENT EPICENTER

4.1 Regional Goldmines – High-Growth Geographies

4.2 Product Frontiers – Lucrative Product Categories

4.3 Application Sweet Spots – Emerging Demand Segments

CHAPTER NO. 5: REVENUE TRAJECTORY & WEALTH MAPPING

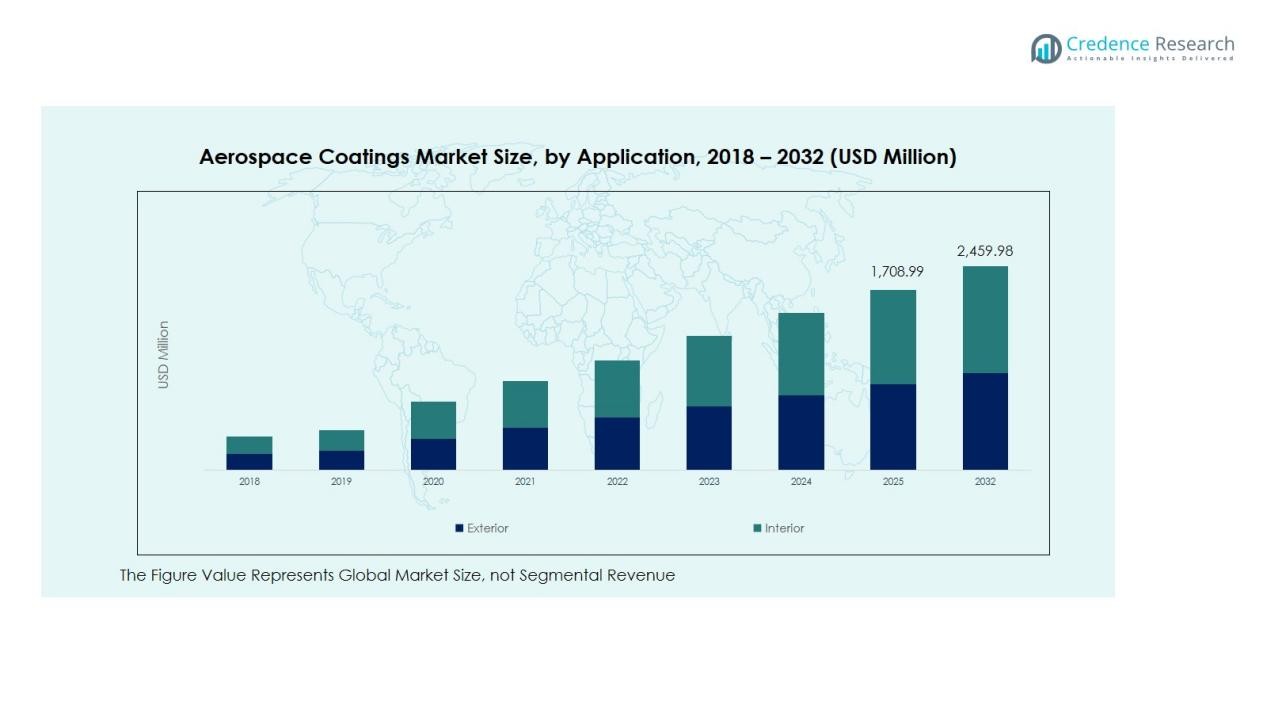

5.1 Momentum Metrics – Forecast & Growth Curves

5.2 Regional Revenue Footprint – Market Share Insights

5.3 Segmental Wealth Flow – Product Type & Application Revenue

CHAPTER NO. 6 : TRADE & COMMERCE ANALYSIS

6.1. Import Analysis by Region

6.1.1. Global Aerospace Coatings Market Import Revenue By Region

6.2. Export Analysis by Region

6.2.1. Global Aerospace Coatings Market Export Revenue By Region

CHAPTER NO. 7 : COMPETITION ANALYSIS

7.1. Company Market Share Analysis

7.1.1. Global Aerospace Coatings Market: Company Market Share

7.2. Global Aerospace Coatings Market Company Revenue Market Share

7.3. Strategic Developments

7.3.1. Acquisitions & Mergers

7.3.2. New Product Launch

7.3.3. Regional Expansion

7.4. Competitive Dashboard

7.5. Company Assessment Metrics, 2024

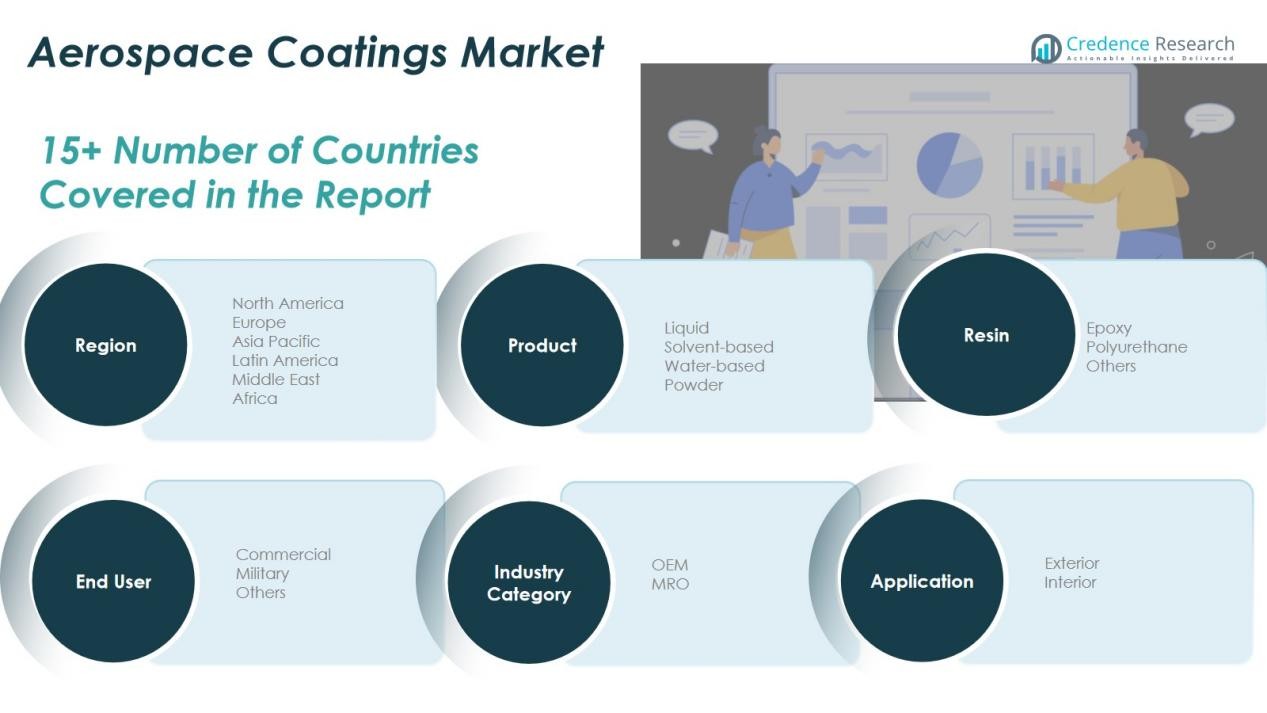

CHAPTER NO. 8 : AEROSPACE COATINGS MARKET – BY PRODUCT SEGMENT ANALYSIS

8.1. Aerospace Coatings Market Overview by Product Segment

8.1.1. Aerospace Coatings Market Revenue Share By Product

8.2. Liquid

8.3 Solvent-based

8.4. Water-based

8.5. Powder

CHAPTER NO. 9 : AEROSPACE COATINGS MARKET – BY APPLICATION SEGMENT ANALYSIS

9.1. Aerospace Coatings Market Overview by Application Segment

9.1.1. Aerospace Coatings Market Revenue Share By Application

9.2. Exterior

9.3. Interior

CHAPTER NO. 10 : AEROSPACE COATINGS MARKET – BY INDUSTRY CATEGORY SEGMENT ANALYSIS

10.1. Aerospace Coatings Market Overview by Industry Category Segment

10.1.1. Aerospace Coatings Market Revenue Share By Industry Category

10.2. OEM

10.3. MRO

CHAPTER NO. 11 : AEROSPACE COATINGS MARKET – BY RESIN SEGMENT ANALYSIS

11.1. Aerospace Coatings Market Overview by Resin

11.1.1. Aerospace Coatings Market Revenue Share By Resin

11.2. Epoxy

11.3 Polyurethane

11.4. Others

CHAPTER NO. 12 : AEROSPACE COATINGS MARKET – BY END USER SEGMENT ANALYSIS

12.1. Aerospace Coatings Market Overview by End User Segment

12.1.1. Aerospace Coatings Market Revenue Share By End User

12.2. Commercial

12.3. Military

12.4. Others

CHAPTER NO. 13 : AEROSPACE COATINGS MARKET – REGIONAL ANALYSIS

13.1. Aerospace Coatings Market Overview by Region Segment

13.1.1. Global Aerospace Coatings Market Revenue Share By Region

13.1.2. Regions

13.1.3. Global Aerospace Coatings Market Revenue By Region

13.1.4. Product Type

13.1.5. Global Aerospace Coatings Market Revenue By Product Type

13.1.6. Application

13.1.7. Global Aerospace Coatings Market Revenue By Application

13.1.8. Industry Category

13.1.9. Global Aerospace Coatings Market Revenue By Industry Category

13.1.10. Resin

13.1.12. Global Aerospace Coatings Market Revenue By Resin

13.1.13. End User

13.1.14. Global Aerospace Coatings Market Revenue By End User

CHAPTER NO. 14 : NORTH AMERICA AEROSPACE COATINGS MARKET – COUNTRY ANALYSIS

14.1. North America Aerospace Coatings Market Overview by Country Segment

14.1.1. North America Aerospace Coatings Market Revenue Share By Region

14.2. North America

14.2.1. North America Aerospace Coatings Market Revenue By Country

14.2.2. Product Type

14.2.3. North America Aerospace Coatings Market Revenue By Product Type

14.2.4. Application

14.2.5. North America Aerospace Coatings Market Revenue By Application

14.2.6. Industry Category

14.2.7. North America Aerospace Coatings Market Revenue By Industry Category

14.2.8. Resin

14.2.9. North America Aerospace Coatings Market Revenue By Resin

14.2.10. End User

14.2.11. North America Aerospace Coatings Market Revenue By End User

14.3. U.S.

14.4. Canada

14.5. Mexico

CHAPTER NO. 15 : EUROPE AEROSPACE COATINGS MARKET – COUNTRY ANALYSIS

15.1. Europe Aerospace Coatings Market Overview by Country Segment

15.1.1. Europe Aerospace Coatings Market Revenue Share By Region

15.2. Europe

15.2.1. Europe Aerospace Coatings Market Revenue By Country

15.2.2. Product Type

15.2.3. Europe Aerospace Coatings Market Revenue By Product Type

15.2.4. Application

15.2.5. Europe Aerospace Coatings Market Revenue By Application

15.2.6. Industry Category

15.2.7. Europe Aerospace Coatings Market Revenue By Industry Category

15.2.8. Resin

15.2.9. Europe Aerospace Coatings Market Revenue By Resin

15.2.10. End User

15.2.11. Europe Aerospace Coatings Market Revenue By End User

15.3. UK

15.4. France

15.5. Germany

15.6. Italy

15.7. Spain

15.8. Russia

15.9. Rest of Europe

CHAPTER NO. 16 : ASIA PACIFIC AEROSPACE COATINGS MARKET – COUNTRY ANALYSIS

16.1. Asia Pacific Aerospace Coatings Market Overview by Country Segment

16.1.1. Asia Pacific Aerospace Coatings Market Revenue Share By Region

16.2. Asia Pacific

16.2.1. Asia Pacific Aerospace Coatings Market Revenue By Country

16.2.2. Product Type

16.2.3. Asia Pacific Aerospace Coatings Market Revenue By Product Type

16.2.4. Application

16.2.5. Asia Pacific Aerospace Coatings Market Revenue By Application

16.2.6. Industry Category

16.2.7. Asia Pacific Aerospace Coatings Market Revenue By Industry Category

16.2.8. Resin

16.2.9. Asia Pacific Aerospace Coatings Market Revenue By Resin

16.2.10. End User

16.2.11. Asia Pacific Aerospace Coatings Market Revenue By End User

16.3. China

16.4. Japan

16.5. South Korea

16.6. India

16.7. Australia

16.8. Southeast Asia

16.9. Rest of Asia Pacific

CHAPTER NO. 17 : LATIN AMERICA AEROSPACE COATINGS MARKET – COUNTRY ANALYSIS

17.1. Latin America Aerospace Coatings Market Overview by Country Segment

17.1.1. Latin America Aerospace Coatings Market Revenue Share By Region

17.2. Latin America

17.2.1. Latin America Aerospace Coatings Market Revenue By Country

17.2.2. Product Type

17.2.3. Latin America Aerospace Coatings Market Revenue By Product Type

17.2.4. Application

17.2.5. Latin America Aerospace Coatings Market Revenue By Application

17.2.6. Industry Category

17.2.7. Latin America Aerospace Coatings Market Revenue By Industry Category

17.2.8. Resin

17.2.9. Latin America Aerospace Coatings Market Revenue By Resin

17.2.10. End User

17.2.11. Latin America Aerospace Coatings Market Revenue By End User

17.3. Brazil

17.4. Argentina

17.5. Rest of Latin America

CHAPTER NO. 18 : MIDDLE EAST AEROSPACE COATINGS MARKET – COUNTRY ANALYSIS

18.1. Middle East Aerospace Coatings Market Overview by Country Segment

18.1.1. Middle East Aerospace Coatings Market Revenue Share By Region

18.2. Middle East

18.2.1. Middle East Aerospace Coatings Market Revenue By Country

18.2.2. Product Type

18.2.3. Middle East Aerospace Coatings Market Revenue By Product Type

18.2.4. Application

18.2.5. Middle East Aerospace Coatings Market Revenue By Application

18.2.6. Industry Category

18.2.7. Middle East Aerospace Coatings Market Revenue By Industry Category

18.2.8. Resin

18.2.9. Middle East Aerospace Coatings Market Revenue By Resin

18.2.10. End User

18.2.11. Middle East Aerospace Coatings Market Revenue By End User

18.3. GCC Countries

18.4. Israel

18.5. Turkey

18.6. Rest of Middle East

CHAPTER NO. 19 : AFRICA AEROSPACE COATINGS MARKET – COUNTRY ANALYSIS

19.1. Africa Aerospace Coatings Market Overview by Country Segment

19.1.1. Africa Aerospace Coatings Market Revenue Share By Region

19.2. Africa

19.2.1. Africa Aerospace Coatings Market Revenue By Country

19.2.2. Product Type

19.2.3. Africa Aerospace Coatings Market Revenue By Product Type

19.2.4. Application

19.2.5. Africa Aerospace Coatings Market Revenue By Application

19.2.6. Industry Category

19.2.7. Africa Aerospace Coatings Market Revenue By Industry Category

19.2.8. Resin

19.2.9. Africa Aerospace Coatings Market Revenue By Resin

19.2.10. End User

19.2.11. Africa Aerospace Coatings Market Revenue By End User

19.3. South Africa

19.4. Egypt

19.5. Rest of Africa

CHAPTER NO. 20 : COMPANY PROFILES

20.1. AkzoNobel N.V

20.1.1. Company Overview

20.1.2. Product Portfolio

20.1.3. Financial Overview

20.1.4. Recent Developments

20.1.5. Growth Strategy

20.1.6. SWOT Analysis

20.2. PPG Industries, Inc.

20.3. Sherwin-Williams

20.4. Hentzen Coatings, Inc.

20.5. Mankiewicz Gebr. & Co

20.6. Axalta Coating Systems Ltd

20.7. Saint-Gobain S.A

20.8. Henkel Corporation

20.9. IHI Ionbond AG

20.10. Zircotec Ltd

20.11. LORD Corporation

20.12. AHC Oberflächentechnik

20.13. BryCoat Inc.

20.14. NV Specialty Coatings.