Market Overview

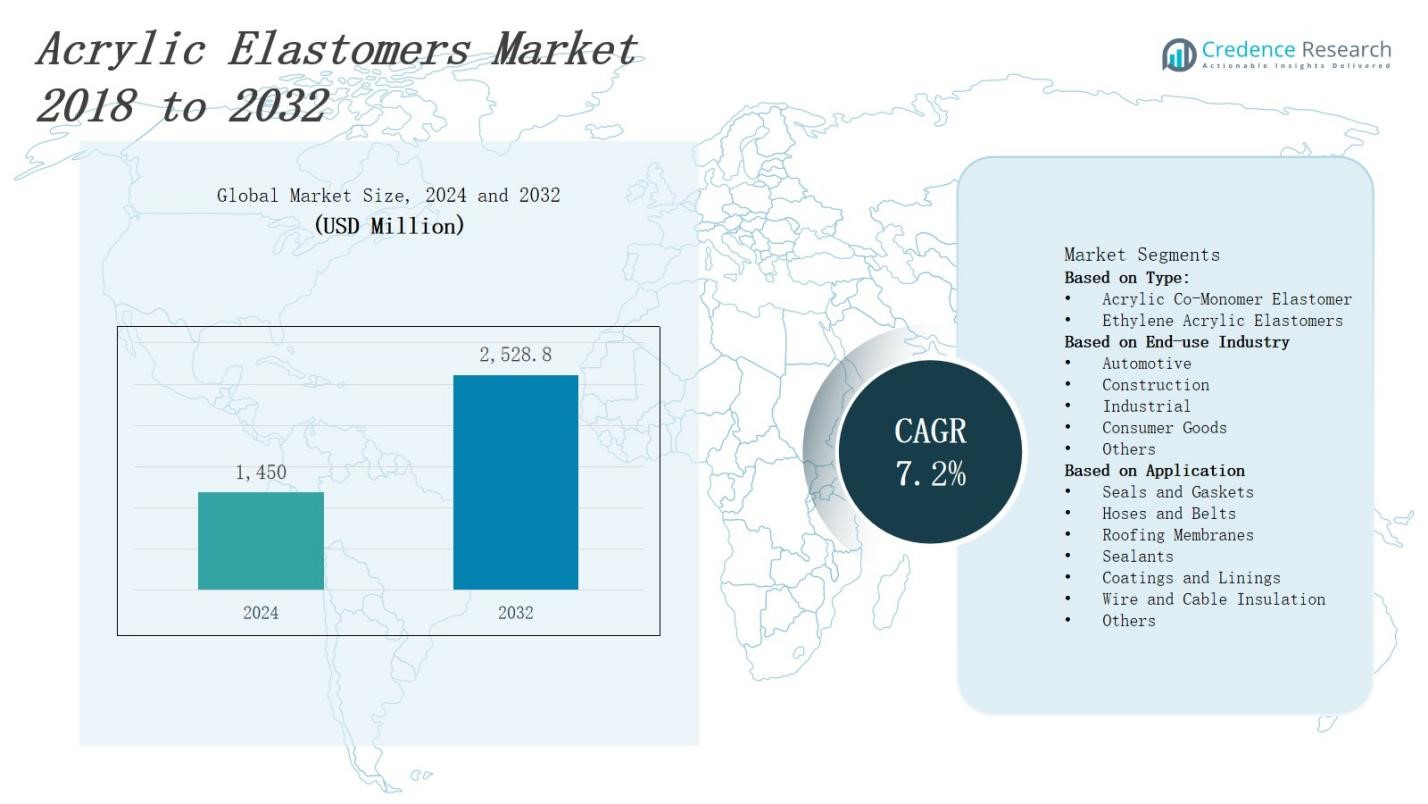

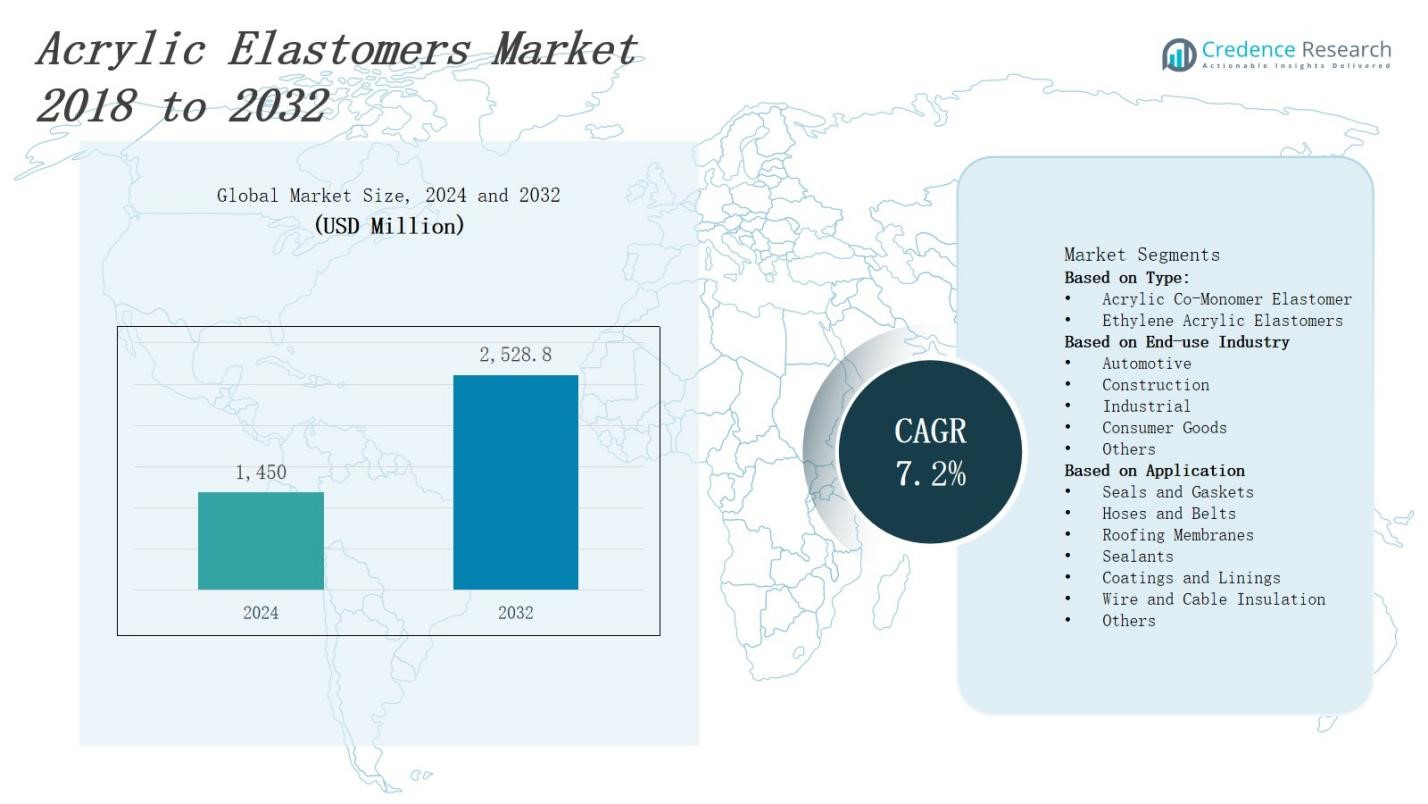

The acrylic elastomers market is projected to grow from USD 1,450 million in 2024 to USD 2,528.8 million by 2032, expanding at a CAGR of 7.2%.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Acrylic Elastomers Market Size 2024 |

USD 1,450 Million |

| Acrylic Elastomers Market, CAGR |

7.2% |

| Acrylic Elastomers Market Size 2032 |

USD 2,528.8 Million |

The acrylic elastomers market grows driven by increasing demand for high-performance, durable materials in automotive, construction, and adhesives applications. Manufacturers develop acrylic elastomers for their excellent weather resistance, flexibility, and chemical stability, meeting stringent regulatory standards. Rising industrialization and urbanization boost the need for advanced elastomeric solutions, while growing emphasis on lightweight and energy-efficient materials supports adoption. Technological advancements improve product formulations, enhancing performance and versatility. Additionally, expanding applications in coatings, sealants, and medical devices further propel market growth. These factors collectively drive innovation and increase global consumption of acrylic elastomers throughout the forecast period.

The acrylic elastomers market spans key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. North America and Europe lead with established automotive and construction industries, holding 30% and 28% market shares respectively. Asia Pacific commands the largest share at 32% due to rapid industrialization. Latin America and the Middle East & Africa contribute 6% and 4%, driven by emerging infrastructure projects. Leading key players in this market include Arkema S.A., BASF SE, DowDuPont Inc., Mitsubishi Chemical Holdings Corporation, and Nippon Shokubai Co. Ltd., focusing on innovation and regional expansion.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The acrylic elastomers market is expected to grow from USD 1,450 million in 2024 to USD 2,528.8 million by 2032, at a CAGR of 7.2%.

- Increasing demand in automotive, construction, and adhesives sectors drives market growth due to superior weather resistance, flexibility, and chemical stability of acrylic elastomers.

- Technological advancements improve product formulations, enhancing elasticity, adhesion, and durability, while supporting compliance with stringent environmental regulations.

- Expanding applications across industries such as textiles, packaging, electronics, coatings, sealants, and medical devices broaden market reach and diversification.

- North America and Europe hold 30% and 28% market shares respectively, supported by established industries and strict sustainability standards.

- Asia Pacific leads with 32% market share, fueled by rapid industrialization, infrastructure development, and growing demand for affordable, high-performance elastomer solutions.

- Market challenges include raw material price volatility, supply chain disruptions, and stringent regulatory compliance, which require innovation and strategic sourcing to maintain competitiveness.

Market Drivers

Rising Demand in Automotive and Construction Sectors

The acrylic elastomers market benefits from increasing demand in the automotive and construction industries due to their superior weather resistance and flexibility. These sectors require materials that withstand harsh environmental conditions while maintaining durability. Acrylic elastomers offer excellent UV stability and chemical resistance, making them ideal for exterior coatings, sealants, and adhesives. The growth of infrastructure projects and vehicle manufacturing globally drives steady consumption. It also supports manufacturers in developing specialized formulations to meet industry-specific requirements. Growing focus on sustainability and longer service life further boosts market adoption.

- For instance, The Swiss company Huber + Suhner AG uses DuPont’s Vamac ethylene acrylic elastomer for insulating battery cables in electric and hybrid vehicles such as the Tesla Roadster, valuing its high temperature tolerance (-40°C to 150°C) and chemical resistance.

Advancements in Product Formulations and Performance

Innovations in acrylic elastomer formulations enhance performance characteristics such as elasticity, adhesion, and chemical resistance. The acrylic elastomers market leverages these technological improvements to provide versatile solutions for diverse applications. Manufacturers invest in research to create low-VOC and eco-friendly products complying with stringent environmental regulations. Enhanced durability and processing efficiency reduce maintenance costs and improve end-product quality. These advancements increase the material’s appeal in demanding sectors including coatings, adhesives, and medical devices. It encourages broader application and strengthens market growth potential.

- For instance, BASF has developed acrylic elastomers with improved heat and chemical resistance, which are increasingly used in automotive seals to withstand demanding thermal and mechanical conditions.

Expanding Applications Across Industries

The acrylic elastomers market expands due to its adaptability in various industries such as textiles, packaging, and electronics. The material’s excellent flexibility and resistance to aging support its use in protective films, flexible packaging, and electronic components. Growing consumer preference for lightweight and durable products boosts demand. Acrylic elastomers also find increasing use in specialty adhesives and sealants that require high performance under extreme conditions. It enables manufacturers to penetrate new markets and diversify applications, supporting sustained market expansion globally.

Increasing Regulatory Pressure and Sustainability Focus

Regulatory authorities impose strict standards on chemical safety and environmental impact, driving demand for compliant acrylic elastomers. The acrylic elastomers market aligns with these regulations by offering low-toxicity, low-VOC, and recyclable materials. Companies focus on sustainable manufacturing processes and eco-friendly product lines to meet consumer and regulatory expectations. This shift supports long-term adoption in green building projects, automotive components, and packaging. It also promotes innovation in biodegradable and bio-based elastomer solutions. Compliance with evolving regulations strengthens market competitiveness and growth prospects.

Market Trends

Growth of Eco-Friendly and Sustainable Elastomer Solutions

The acrylic elastomers market shows a clear trend toward eco-friendly and sustainable product development. Manufacturers focus on creating low-VOC and bio-based elastomers to meet growing environmental regulations and consumer demand for greener materials. It helps companies reduce carbon footprint and align with global sustainability goals. Investments in renewable raw materials and recyclable elastomer products gain traction. This trend drives innovation in product formulations that maintain performance while minimizing environmental impact, broadening market acceptance and competitiveness.

- For instance, Dow’s NORDEL™ REN EPDM is a bio-based, ISCC PLUS certified elastomer that delivers traditional performance with a lower carbon footprint, aligning with sustainability goals without compromising quality.

Integration of Advanced Polymerization Techniques

Advanced polymerization technologies shape the acrylic elastomers market by improving material properties and production efficiency. Techniques such as controlled radical polymerization enable precise molecular structure control, resulting in elastomers with enhanced elasticity, durability, and chemical resistance. It also reduces waste and energy consumption during manufacturing. The improved process flexibility allows customization for specific industrial applications like automotive coatings and adhesives. Adoption of these technologies helps manufacturers meet stringent quality standards and customer requirements, reinforcing market growth.

- For instance, Arkema uses Controlled Radical Polymerization (CRP) to produce Nanostrength® acrylic block copolymers with well-defined molecular structures, offering enhanced mechanical strength and tackiness without cross-linking, suitable for hot-melt and solvent-based adhesives.

Rising Adoption in Coatings and Sealants Applications

The acrylic elastomers market experiences increased adoption in coatings and sealants due to their superior adhesion and weather resistance. The demand for durable, flexible coatings that protect surfaces from corrosion and UV damage drives this trend. It supports application in building exteriors, automotive finishes, and industrial equipment. Manufacturers innovate to develop formulations with faster curing times and enhanced compatibility with various substrates. This trend reflects a shift toward high-performance materials that extend product life and reduce maintenance costs, strengthening market prospects.

Expansion into Emerging Industries and Regions

Emerging industries such as electronics, healthcare, and flexible packaging contribute to the acrylic elastomers market’s expansion. Growing demand for lightweight, flexible, and durable materials in these sectors drives adoption. It enables manufacturers to diversify applications beyond traditional markets. Rapid industrialization and urbanization in regions like Asia Pacific boost consumption. Companies target these markets with tailored products and strategic partnerships. This trend supports sustained revenue growth and global market penetration.

Market Challenges Analysis

Volatility in Raw Material Prices and Supply Chain Disruptions

The acrylic elastomers market faces significant challenges due to fluctuating raw material costs and supply chain uncertainties. Dependence on petroleum-based feedstocks subjects manufacturers to price volatility driven by global oil market dynamics. It increases production costs and affects profit margins. Supply chain disruptions, including transportation delays and geopolitical tensions, further impact timely material availability. These issues force companies to optimize inventory management and explore alternative sourcing strategies. Persistent volatility may slow down new product development and limit market expansion opportunities.

Stringent Regulatory Compliance and Environmental Concerns

The acrylic elastomers market contends with strict regulations related to chemical safety, emissions, and environmental impact. Compliance requires substantial investments in product reformulation and manufacturing process improvements. It pressures manufacturers to reduce volatile organic compounds (VOCs) and hazardous substances while maintaining performance standards. Regulatory variations across regions complicate global operations and increase compliance costs. Environmental concerns also drive demand for sustainable alternatives, challenging traditional acrylic elastomer products. Balancing regulatory adherence with innovation remains a critical hurdle for market participants.

Market Opportunities

Expansion into Emerging Markets and Growing Industrialization

The acrylic elastomers market presents substantial opportunities in emerging economies experiencing rapid industrialization and urbanization. Rising infrastructure development and automotive production in regions such as Asia Pacific and Latin America drive demand for high-performance elastomeric materials. It enables manufacturers to tap into new customer bases and diversify revenue streams. Expanding middle-class populations and increasing disposable incomes further stimulate consumption across construction, coatings, and adhesives sectors. Strategic partnerships and localized production facilities can accelerate market penetration in these regions.

Innovation in Sustainable and High-Performance Elastomer Solutions

The growing emphasis on sustainability offers the acrylic elastomers market opportunities to innovate eco-friendly and bio-based products. It encourages investment in research focused on developing low-VOC, recyclable, and biodegradable elastomers without compromising durability and flexibility. Rising consumer awareness and stricter environmental regulations create demand for green materials in automotive, construction, and packaging industries. Collaborations between chemical producers and end-users can accelerate adoption of sustainable solutions. These innovations position the market to meet evolving industry needs and enhance competitive advantage.

Market Segmentation Analysis:

By Type

The acrylic elastomers market segments into acrylic co-monomer elastomers and ethylene acrylic elastomers, each serving distinct performance requirements. Acrylic co-monomer elastomers offer superior heat and weather resistance, making them suitable for demanding outdoor applications. Ethylene acrylic elastomers provide enhanced flexibility and chemical resistance, supporting diverse industrial uses. It allows manufacturers to tailor products based on specific functional needs, driving adoption across various sectors. The growing demand for durable, high-performance elastomers encourages continuous product innovation within these types.

- For instance, DowDuPont (US) develops ethylene-based acrylic elastomers, including ethylene acrylic elastomers (AEM), widely used for their chemical and temperature resistance in automotive and industrial applications.

By End-Use Industry

The acrylic elastomers market serves multiple industries, including automotive, construction, industrial, consumer goods, and others. The automotive sector leads demand due to stringent requirements for weather-resistant and durable components. Construction applications benefit from acrylic elastomers’ flexibility and UV resistance in sealants and roofing membranes. Industrial and consumer goods sectors use these elastomers in hoses, belts, and protective coatings. It enables broad market penetration by catering to diverse application needs, supporting sustained growth and expanded industry relevance.

- For instance, in the automotive sector, acrylic elastomers are used by companies such as Dow in seals, gaskets, and hoses that require resistance to heat, chemicals, and weathering, especially in electric vehicles that demand durable, lightweight components.

By Application

Applications within the acrylic elastomers market span seals and gaskets, hoses and belts, roofing membranes, sealants, coatings and linings, wire and cable insulation, and others. Seals and gaskets demand high elasticity and chemical stability, while roofing membranes require excellent weather resistance. The market also experiences growth in coatings and linings due to durability and adhesion benefits. Wire and cable insulation applications leverage the material’s electrical properties and flexibility. It drives market expansion by addressing specialized performance requirements across sectors.

Segments:

Based on Type:

- Acrylic Co-Monomer Elastomer

- Ethylene Acrylic Elastomers

Based on End-use Industry

- Automotive

- Construction

- Industrial

- Consumer Goods

- Others

Based on Application

- Seals and Gaskets

- Hoses and Belts

- Roofing Membranes

- Sealants

- Coatings and Linings

- Wire and Cable Insulation

- Others

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America holds 30% of the acrylic elastomers market share, driven by strong automotive and construction sectors. The region benefits from advanced manufacturing infrastructure and high adoption of innovative elastomer technologies. It features strict regulatory standards that encourage the development of low-VOC and sustainable products. The United States leads demand due to investments in infrastructure upgrades and increasing vehicle production. The region’s focus on sustainability and product performance supports steady market growth. It also provides opportunities for research collaborations and technological advancements.

Europe

Europe accounts for 28% of the acrylic elastomers market, supported by mature industrial and construction markets. Countries such as Germany, France, and the UK invest heavily in eco-friendly materials, propelling demand for acrylic elastomers. It serves applications in automotive manufacturing, roofing, and sealants that require durability and weather resistance. Stringent environmental regulations compel manufacturers to innovate low-emission and recyclable elastomers. The region’s emphasis on energy efficiency and sustainability fuels market expansion. It also benefits from well-established supply chains and skilled labor.

Asia Pacific

Asia Pacific commands 32% market share in the acrylic elastomers market, led by rapid industrialization and urbanization in China, India, and Southeast Asia. Rising infrastructure development and automotive production drive significant elastomer consumption. It offers vast growth potential through expanding end-use industries like construction, consumer goods, and electronics. The region attracts investments from global manufacturers establishing local production facilities. It experiences increasing demand for affordable yet high-performance elastomer solutions. Growing environmental awareness further promotes adoption of sustainable products.

Latin America

Latin America holds 6% of the acrylic elastomers market share, fueled by emerging automotive and construction industries in Brazil and Mexico. It benefits from ongoing infrastructure projects and rising disposable incomes that boost demand for quality elastomeric materials. The region faces challenges due to supply chain complexities but shows promise through government initiatives supporting industrial growth. Manufacturers explore partnerships to strengthen market presence. The market remains focused on balancing cost-effectiveness with performance requirements.

Middle East and Africa

The Middle East and Africa represent 4% of the acrylic elastomers market, with growth driven by expanding construction and industrial sectors. Investments in urban development and energy infrastructure increase elastomer demand. It experiences gradual adoption of advanced elastomer technologies due to evolving regulatory standards. The region’s potential lies in rising awareness of sustainable materials and increasing foreign direct investment. Companies target niche applications such as roofing membranes and sealants to establish footholds. It offers long-term opportunities amid economic diversification efforts.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- DowDuPont Inc.

- Nippon Shokubai Co. Ltd.

- Arkema S.A.

- Denka Corp.

- Zeon Corporation

- BASF SE

- Der-Gom SRL

- Hitachi Chemical Co. Ltd

- Mitsubishi Chemical Holdings Corporation

- Momentive Specialty Chemicals Inc.

- NOK Corporation

Competitive Analysis

The acrylic elastomers market features intense competition among global chemical manufacturers focusing on innovation, quality, and sustainability. Leading players such as Arkema S.A., BASF SE, DowDuPont Inc., and Mitsubishi Chemical Holdings Corporation invest heavily in research and development to enhance product performance and meet evolving regulatory standards. It drives formulation improvements, including low-VOC and bio-based elastomers, to address environmental concerns. Companies pursue strategic partnerships and regional expansions to strengthen market presence and access emerging economies. Differentiation through customized solutions and advanced polymerization technologies remains critical. Competitive pricing and efficient supply chain management also influence market dynamics. It compels manufacturers to optimize operations and respond swiftly to changing customer demands, sustaining their market position and fostering growth opportunities.

Recent Developments

- In 2023, Arkema introduced “Kynar VT-2,” a new acrylic elastomer that performs exceptionally at high temperatures and adverse chemical conditions. Kynar VT-2 is designed for demanding industrial applications such as aerospace, oil and gas, and chemical processing.

- In 2023, Zeon Corporation announced plans to increase production capacity for hydrogenated nitrile butadiene rubber (HNBR) and acrylic rubber (ACM) to address rising demand from the automotive industry.

- In June 2025, Dow announced the sale of its 50% ownership in DowAksa Advanced Composites Holdings BV to its joint venture partner, Aksa Akrilik Kimya Sanayi A.S. This move is part of Dow’s strategy to focus on its core businesses and streamline operations.

Market Concentration & Characteristics

The acrylic elastomers market demonstrates a moderately concentrated competitive landscape dominated by key multinational chemical manufacturers such as Arkema S.A., BASF SE, DowDuPont Inc., and Mitsubishi Chemical Holdings Corporation. It features high entry barriers due to the need for advanced research and development capabilities, regulatory compliance, and established distribution networks. These leading companies focus on product innovation, sustainability, and regional expansion to maintain market share and meet evolving customer demands. The market emphasizes specialized formulations that provide superior weather resistance, flexibility, and chemical stability across diverse applications. It also requires continuous investment in sustainable manufacturing practices to align with environmental regulations. Mid-sized and regional players contribute through niche product offerings and localized solutions, enhancing market diversity. Overall, the acrylic elastomers market balances innovation, regulatory adherence, and strategic partnerships to sustain growth and competitiveness in a dynamic global environment.

Report Coverage

The research report offers an in-depth analysis based on Type, End-User Industry, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The acrylic elastomers market will expand due to rising demand in automotive and construction industries.

- Innovations in eco-friendly and bio-based elastomer formulations will gain momentum.

- Manufacturers will focus on improving product durability and chemical resistance.

- Emerging economies will offer significant growth opportunities through infrastructure development.

- Regulatory pressure will drive adoption of low-VOC and sustainable materials.

- Advanced polymerization techniques will enhance elastomer performance and customization.

- Expansion into new applications such as medical devices and electronics will increase.

- Companies will strengthen regional presence through partnerships and local manufacturing.

- Supply chain optimization will remain critical to managing raw material volatility.

- Growing consumer preference for lightweight, flexible materials will support product innovation and demand.