Market Overview

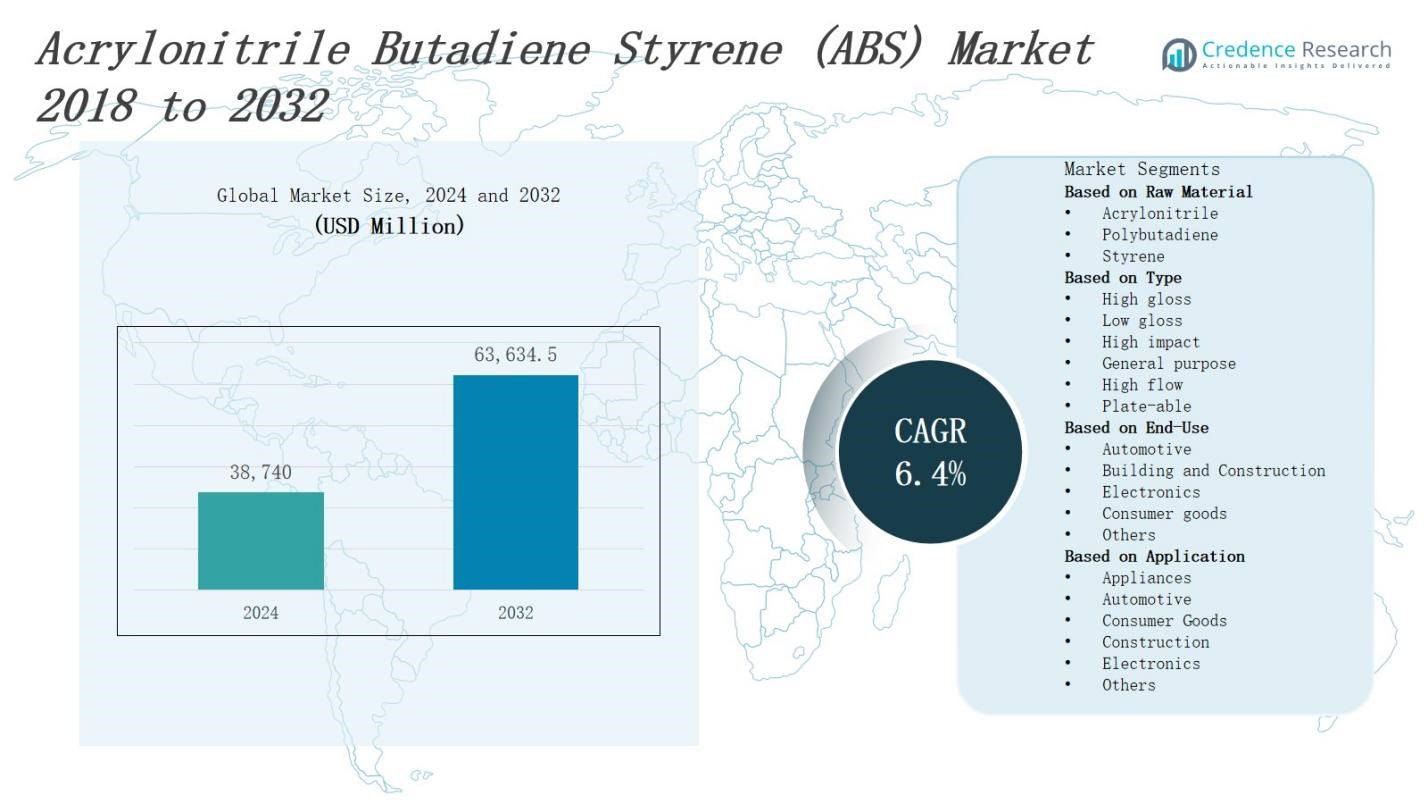

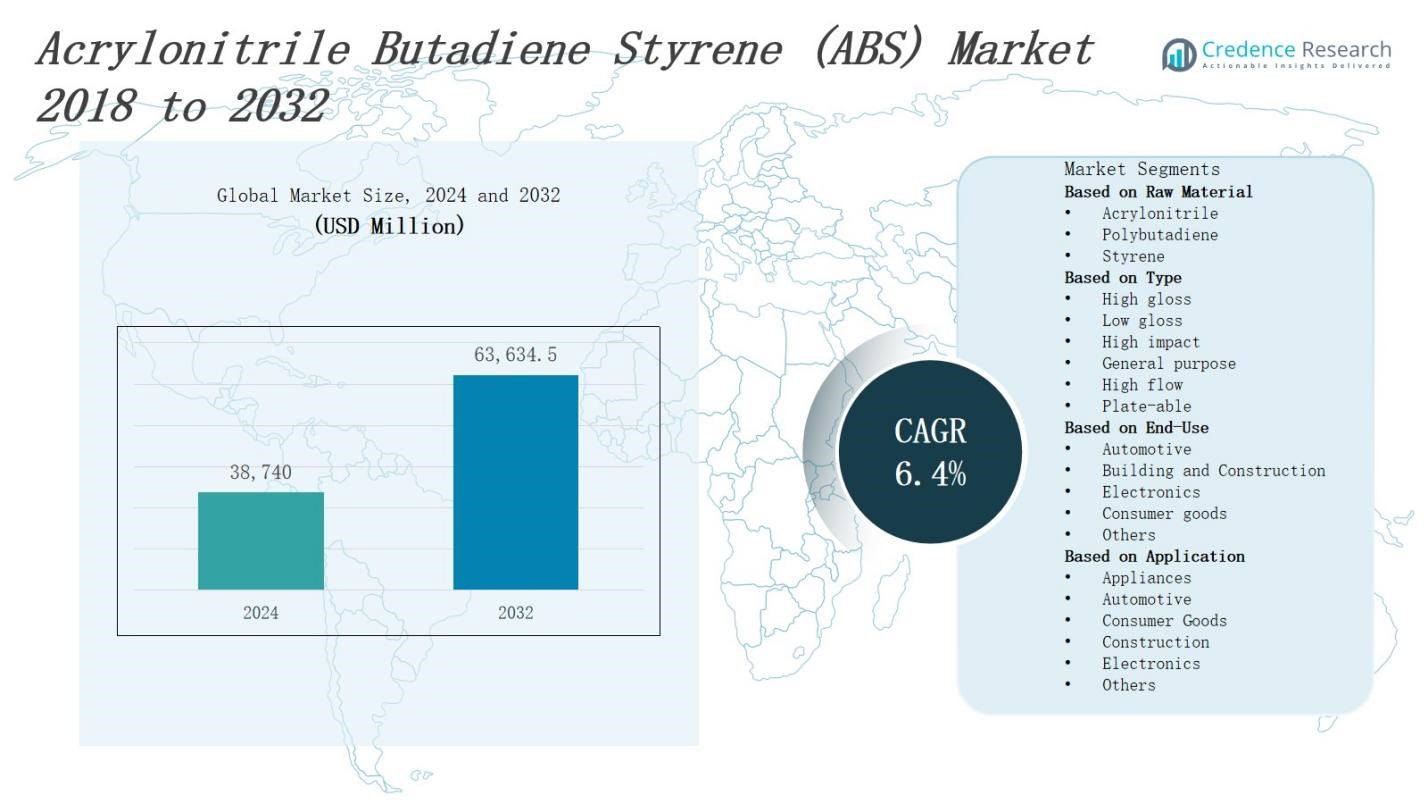

The acrylonitrile butadiene styrene (ABS) market is projected to grow from USD 38,740 million in 2024 to USD 63,634.5 million by 2032, expanding at a CAGR of 6.4%.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Acrylonitrile Butadiene Styrene (ABS) Market Size 2024 |

USD 38,740 Million |

| Acrylonitrile Butadiene Styrene (ABS) Market, CAGR |

6.4% |

| Acrylonitrile Butadiene Styrene (ABS) Market Size 2032 |

USD 63,634.5 Million |

The acrylonitrile butadiene styrene (ABS) market grows driven by increasing demand for lightweight, durable, and impact-resistant plastics across automotive, electronics, and construction sectors. Rising urbanization and industrialization boost the need for versatile materials that offer excellent mechanical properties and ease of processing. Manufacturers focus on developing eco-friendly and recycled ABS variants to address sustainability concerns and comply with stringent environmental regulations. Advancements in extrusion and injection molding technologies enhance product quality and manufacturing efficiency. Growing adoption of ABS in 3D printing and consumer goods further supports market expansion, positioning ABS as a critical material in diverse industrial applications worldwide.

The acrylonitrile butadiene styrene (ABS) market spans key regions including North America, Europe, Asia Pacific, and the Rest of the World. Asia Pacific leads with the largest share due to rapid industrialization and expanding automotive and electronics sectors. North America and Europe hold substantial market shares driven by advanced manufacturing and strict environmental regulations. The Rest of the World shows moderate growth from emerging economies. Key players such as INEOS Styrolution Group GmbH, Trinseo, SABIC, BASF SE, LG Chem, and Toray Industries actively compete by focusing on innovation, sustainability, and expanding global presence.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The acrylonitrile butadiene styrene (ABS) market will grow from USD 38,740 million in 2024 to USD 63,634.5 million by 2032 at a CAGR of 6.4%.

- Increasing demand for lightweight, durable, and impact-resistant plastics in automotive, electronics, and construction sectors drives market growth.

- Manufacturers focus on eco-friendly and recycled ABS variants to meet sustainability goals and comply with environmental regulations.

- Advances in extrusion and injection molding improve product quality, efficiency, and allow customized formulations for diverse applications.

- Asia Pacific leads the market with 38% share due to rapid industrialization and expanding automotive and electronics manufacturing.

- North America holds 28% share with strong automotive and electronics demand supported by advanced manufacturing infrastructure.

- Europe accounts for 24% share, emphasizing sustainability, regulatory compliance, and demand from automotive and construction sectors.

Market Drivers

Growing Demand in Automotive and Electronics Industries

The acrylonitrile butadiene styrene (ABS) market benefits from strong demand in automotive and electronics sectors. Manufacturers favor ABS for its lightweight and impact-resistant properties, which enhance vehicle fuel efficiency and durability. Electronics producers use ABS in housings and components due to its excellent electrical insulation and aesthetic finish. Increasing consumer preference for high-performance, durable products drives adoption. Urbanization and rising disposable incomes further support growth in these industries, thereby expanding the market for ABS materials globally.

- For instance, Bosch integrates ABS components in electric vehicles to improve energy efficiency and braking performance, enabling better regenerative braking compatibility. This compact ABS design supports the lightweight requirements of modern EVs.

Advancements in Manufacturing Technologies

Improvements in extrusion and injection molding techniques boost the acrylonitrile butadiene styrene (ABS) market by increasing production efficiency and product quality. Advanced machinery enables precise control over ABS material properties, resulting in better surface finish and dimensional accuracy. These technological advancements reduce waste and lower production costs, making ABS more competitive against alternative plastics. The capability to produce customized ABS formulations also helps manufacturers meet specific industry requirements, supporting broader market acceptance.

- For instance, LG Chemical invested in a cutting-edge ABS production facility in South Korea in 2022, incorporating advanced extrusion and injection molding machinery to enhance precision, reduce waste, and increase output efficiency in high-quality ABS formulations.

Sustainability and Environmental Regulations

The acrylonitrile butadiene styrene (ABS) market experiences pressure to adopt sustainable solutions due to stricter environmental regulations worldwide. It drives manufacturers to develop recycled and bio-based ABS variants that reduce carbon footprint and meet regulatory standards. Growing consumer awareness about environmental impact encourages companies to focus on eco-friendly production methods. This shift enhances the market’s long-term viability by aligning product development with sustainability goals, fostering adoption across environmentally conscious industries.

Expanding Applications in Consumer Goods and 3D Printing

The acrylonitrile butadiene styrene (ABS) market grows with rising usage in consumer goods and 3D printing applications. ABS offers versatility, toughness, and ease of processing, making it ideal for products such as toys, household items, and appliances. The 3D printing industry increasingly relies on ABS filament for prototyping and manufacturing durable parts. These expanding applications diversify demand sources, enabling the market to maintain steady growth amid changing industrial landscapes and evolving customer needs worldwide.

Market Trends

Shift Towards Sustainable and Recycled ABS Materials

The acrylonitrile butadiene styrene (ABS) market demonstrates a clear trend toward sustainable and recycled materials. Manufacturers increase investments in developing bio-based ABS and post-consumer recycled content to reduce environmental impact. Regulatory pressures and consumer demand for greener products drive innovation in sustainable formulations. It enhances the market’s appeal among environmentally conscious buyers and supports compliance with global eco-friendly standards. This shift also encourages partnerships across the value chain to promote circular economy principles in plastics production.

- For instance, Sulapac Ltd has developed biobased plastic materials, such as Sulapac Luxe and Luxe Flex, that serve as sustainable replacements for ABS in cosmetic packaging.

Integration of Advanced Additives for Enhanced Performance

The acrylonitrile butadiene styrene (ABS) market incorporates advanced additives to improve material properties such as flame retardancy, UV resistance, and thermal stability. These enhancements extend ABS’s application scope in industries requiring stringent safety and durability standards. It allows manufacturers to tailor products for specific end uses, including automotive interiors, electrical enclosures, and outdoor equipment. The trend toward multifunctional ABS formulations strengthens the material’s competitiveness against alternative polymers, fostering broader adoption across technical sectors.

Rising Adoption in 3D Printing and Rapid Prototyping

The acrylonitrile butadiene styrene (ABS) market benefits from increasing demand in 3D printing and rapid prototyping. ABS filament serves as a preferred material due to its toughness, heat resistance, and ease of machining. It supports product development cycles by enabling quick iterations and functional part production. Growing interest in additive manufacturing from automotive, healthcare, and consumer electronics sectors fuels this trend. Expanding 3D printing capabilities widen the scope of ABS applications, contributing to steady market growth.

Focus on Lightweight and High-Strength Applications

The acrylonitrile butadiene styrene (ABS) market trends toward lightweight and high-strength applications, particularly in automotive and electronics manufacturing. It meets industry requirements for materials that reduce overall product weight without compromising durability or safety. This trend aligns with global efforts to improve fuel efficiency and energy consumption. ABS’s balance of mechanical strength and processability positions it as a preferred choice for structural components and consumer products demanding reliability and performance under stress.

- For instance, ABS plastic interior trim panels and protective casings like airbag covers benefit from its toughness and easy moldability, ensuring both passenger safety and aesthetic appeal.

Market Challenges Analysis

Volatility in Raw Material Prices Impacting Production Costs

The acrylonitrile butadiene styrene (ABS) market faces significant challenges due to fluctuations in raw material prices. Variability in the cost of acrylonitrile, butadiene, and styrene monomers directly affects manufacturing expenses and profit margins. It complicates pricing strategies and supply chain management for producers. Unstable feedstock availability, influenced by geopolitical tensions and crude oil market shifts, further exacerbates cost unpredictability. Manufacturers must navigate these uncertainties while maintaining competitive pricing and product quality, which restrains market growth and investment opportunities.

Environmental Concerns and Regulatory Compliance Pressures

The acrylonitrile butadiene styrene (ABS) market contends with stringent environmental regulations and growing public scrutiny over plastic waste. It faces increasing pressure to reduce carbon footprint and enhance recyclability. Regulatory frameworks across key regions mandate compliance with emission limits and sustainable waste management practices. These requirements drive manufacturers to invest heavily in research and development for eco-friendly ABS variants, raising production complexity and costs. Resistance from consumers and policymakers toward non-biodegradable plastics creates additional barriers, limiting unrestricted market expansion.

Market Opportunities

Expansion into Emerging Markets with Growing Industrialization

The acrylonitrile butadiene styrene (ABS) market has significant opportunities in emerging economies driven by rapid industrialization and urbanization. Increasing automotive production, electronics manufacturing, and construction activities in regions like Asia Pacific and Latin America create strong demand for ABS materials. It enables manufacturers to tap into new customer bases seeking durable and versatile plastics. Investments in local production facilities and strategic partnerships can enhance market penetration and reduce supply chain costs. Expanding infrastructure and rising disposable incomes further support sustained growth potential in these markets.

Development of Innovative, Eco-Friendly ABS Solutions

The acrylonitrile butadiene styrene (ABS) market can capitalize on rising demand for sustainable and bio-based polymers. It presents opportunities to develop recycled ABS and biodegradable alternatives that align with global environmental initiatives. Innovation in product formulations to enhance recyclability and reduce carbon emissions can attract environmentally conscious consumers and businesses. Collaborations with research institutions and adoption of advanced manufacturing technologies may accelerate the commercialization of green ABS variants. These developments open new revenue streams and strengthen the market’s competitive positioning.

Market Segmentation Analysis:

By Raw Material

The acrylonitrile butadiene styrene (ABS) market segments based on key raw materials: acrylonitrile, polybutadiene, and styrene. Each component influences the polymer’s properties, including strength, flexibility, and chemical resistance. Acrylonitrile enhances thermal and chemical stability, while polybutadiene provides impact resistance. Styrene contributes to processability and surface finish. Manufacturers adjust raw material ratios to meet specific application requirements. This segmentation enables tailored ABS grades for diverse industrial needs, supporting product versatility and market growth.

- For instance, styrene’s contribution to surface finish and processability is evident in ABS used for consumer electronics, providing a shiny, hard surface that is easy to mold and machine during production.

By Type

The acrylonitrile butadiene styrene (ABS) market divides into several types, including high gloss, low gloss, high impact, general purpose, high flow, and plate-able grades. High gloss ABS suits aesthetic applications requiring smooth finishes, while low gloss offers matte textures. High impact variants provide enhanced toughness for demanding environments. General purpose ABS serves broad usage across industries. High flow types facilitate intricate molding, and plate-able grades allow metal coating for decorative purposes. This segmentation supports customization and addresses varied manufacturing demands.

- For instance, SABIC’s high gloss ABS is widely used in consumer electronics like smartphone housings, where smooth, shiny finishes are critical.

By End-Use

The acrylonitrile butadiene styrene (ABS) market categorizes end-use into automotive, building and construction, electronics, consumer goods, and others. It drives demand through automotive parts requiring durability and lightweight properties. The construction sector uses ABS for piping and fittings due to corrosion resistance. Electronics benefit from ABS’s electrical insulation and design flexibility. Consumer goods utilize ABS for household items and toys, emphasizing safety and aesthetics. This segmentation aligns ABS supply with sector-specific performance criteria, promoting widespread adoption.

Segments:

Based on Raw Material

- Acrylonitrile

- Polybutadiene

- Styrene

Based on Type

- High gloss

- Low gloss

- High impact

- General purpose

- High flow

- Plate-able

Based on End-Use

- Automotive

- Building and Construction

- Electronics

- Consumer goods

- Others

Based on Application

- Appliances

- Automotive

- Consumer Goods

- Construction

- Electronics

- Others

Based on Technology

- Extrusion

- Injection Molding

- Blow Molding

- Others

Based on Grade

- Flame Retardant Grade

- Impact

- Gloss

- Platable

- Composite Grade

- Others

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America holds a significant share of 28% in the acrylonitrile butadiene styrene (ABS) market, driven by strong demand from automotive and electronics industries. It benefits from advanced manufacturing infrastructure and high adoption of innovative plastics. The presence of key manufacturers and strict regulatory standards promote development of high-quality ABS products. Growing investments in sustainable materials and technological advancements in processing contribute to steady growth. Consumer preference for durable and lightweight materials in automotive and consumer goods further supports market expansion. The region’s established supply chains and skilled workforce maintain its competitive edge.

Europe

Europe accounts for 24% of the acrylonitrile butadiene styrene (ABS) market, supported by robust automotive production and construction sectors. It emphasizes sustainability and compliance with stringent environmental regulations, encouraging development of recycled and eco-friendly ABS variants. The region hosts several major manufacturers investing in research and development to improve material performance. Demand for ABS in electrical and consumer applications remains strong due to technological innovation and consumer trends. Growing infrastructure projects and urbanization enhance the need for durable plastics. Europe’s focus on circular economy principles drives adoption of sustainable polymers.

Asia Pacific

Asia Pacific leads the acrylonitrile butadiene styrene (ABS) market with a 38% share, fueled by rapid industrialization, urbanization, and expanding automotive and electronics manufacturing hubs. It experiences high demand from emerging economies like China, India, and Southeast Asian countries. Increasing disposable incomes and infrastructural development drive consumption across building, consumer goods, and automotive sectors. The region attracts foreign direct investment and benefits from favorable government policies promoting manufacturing growth. It remains a hotspot for new production facilities due to cost advantages and growing market potential. Rising adoption of advanced technologies supports market diversification and innovation.

Rest of the World

The Rest of the World region holds 10% of the acrylonitrile butadiene styrene (ABS) market, with demand coming from Latin America, Middle East, and Africa. It experiences moderate growth driven by expanding automotive and construction activities in key countries. Market development focuses on improving supply chains and increasing local production capabilities. Emerging infrastructure projects and rising consumer goods industries create new opportunities. Environmental regulations and economic diversification efforts encourage adoption of innovative and sustainable ABS materials. It remains a growing segment with potential for increased market penetration over the forecast period.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Kumho Petrochemical

- BASF SE

- Emco Industrial Plastics

- Toray Industries Inc

- Trinseo

- Ravago Americas

- Formosa Chemicals & Fibre Corp.

- Mitsui Chemicals, Inc

- INEOS Styrolution Group GmbH

- Elix Polymers

- SABIC

- LG Chem

Competitive Analysis

The acrylonitrile butadiene styrene (ABS) market features intense competition among global and regional players focused on innovation, quality, and sustainability. Leading companies such as INEOS Styrolution Group GmbH, Trinseo, SABIC, BASF SE, and LG Chem invest heavily in research and development to enhance product performance and develop eco-friendly ABS variants. It pressures manufacturers to optimize production processes and expand their product portfolios to meet diverse industry requirements. Strategic partnerships, mergers, and acquisitions help companies strengthen market presence and geographic reach. The emphasis on regulatory compliance and customer-centric solutions drives continuous improvement. Competitive pricing strategies and supply chain efficiencies remain critical for maintaining market share in this rapidly evolving landscape.

Recent Developments

- In January 2025, Plastivar partnered with INEOS Styrolution to use its ABS products for new edgebanding collections, marking a product partnership launch.

- In June 2024, Trinseo launched new ABS and SAN resins containing up to 60% recycled content under the MAGNUM™ CR and MAGNUM™ ECO+ brands. These resins use post-consumer recycled styrene from household waste and reduce the carbon footprint by up to 18% compared to traditional grades.

- In December 2024, SABIC launched the LNP™ ELCRES™ SLX1271SR resin, enhancing scratch and mar resistance for automotive molded-in color exterior components within its weatherable copolymer portfolio.

- In April 2025, Trinseo launched MAGNUM ECO+, MAGNUM CR, and TYRIL CR recycled-content ABS and SAN resins aimed at mobility and consumer goods, offering up to 18% lower carbon footprints while maintaining incumbent performance.

Market Concentration & Characteristics

The acrylonitrile butadiene styrene (ABS) market exhibits a moderately concentrated structure dominated by a few global key players such as INEOS Styrolution Group GmbH, Trinseo, SABIC, BASF SE, and LG Chem. These companies leverage extensive research and development capabilities to innovate and improve product performance, focusing on sustainability and regulatory compliance. It drives competitive differentiation through customized ABS formulations and enhanced processing technologies. The market’s characteristics include high capital intensity, advanced manufacturing processes, and strong emphasis on quality control. Regional players also contribute by addressing local demand with tailored solutions. Strategic partnerships, mergers, and acquisitions shape the competitive landscape, enabling broader geographic reach and capacity expansion. It maintains a balance between innovation and cost efficiency, with players investing heavily in eco-friendly products to meet evolving environmental standards and consumer preferences. This dynamic fosters sustained growth and continuous evolution within the market.

Report Coverage

The research report offers an in-depth analysis based on Raw Material, Type, End-Use, Application, Technology, Grade and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The acrylonitrile butadiene styrene (ABS) market will expand due to rising demand in automotive and electronics sectors.

- Manufacturers will focus on developing more sustainable and recycled ABS materials.

- Advances in processing technologies will improve product quality and reduce manufacturing costs.

- Adoption of ABS in 3D printing and rapid prototyping will increase significantly.

- Emerging economies will offer new growth opportunities for ABS producers.

- Regulatory pressures will push companies to innovate eco-friendly ABS variants.

- Integration of advanced additives will enhance ABS performance for specialized applications.

- Strategic collaborations and mergers will shape competitive dynamics in the market.

- Consumer goods industries will drive diversified applications of ABS materials.

- Investments in research and development will continue to support product innovation and market expansion.