| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Corrosion Under Insulation Market Size 2024 |

USD 346.32 million |

| Corrosion Under Insulation Market, CAGR |

7.23% |

| Corrosion Under Insulation Markett Size 2032 |

USD 629.65 million |

Market Overview:

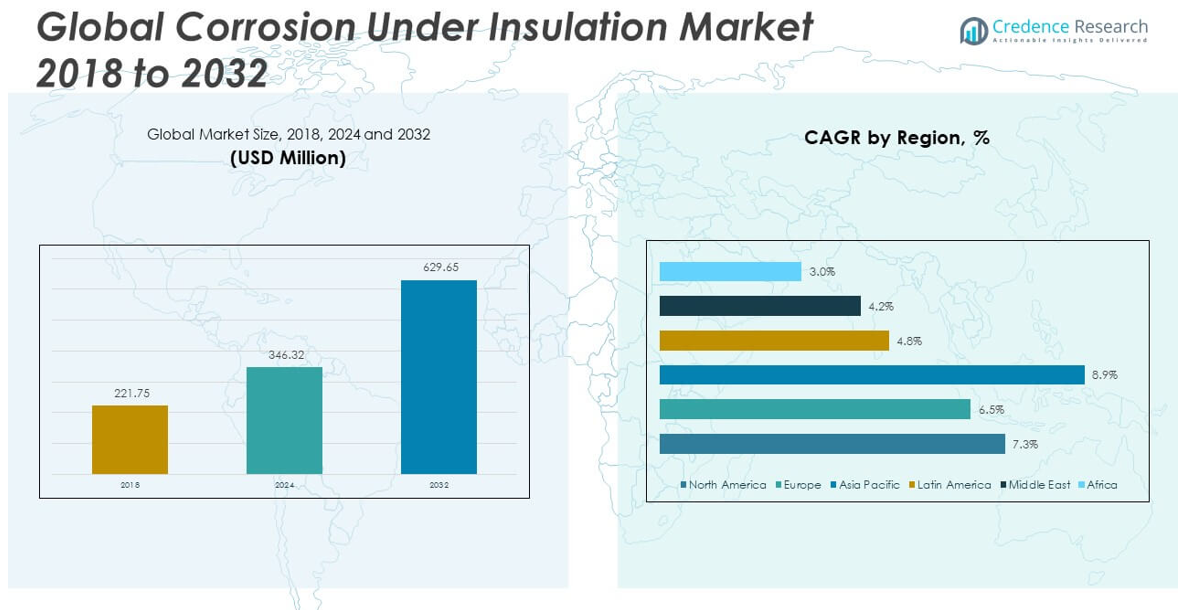

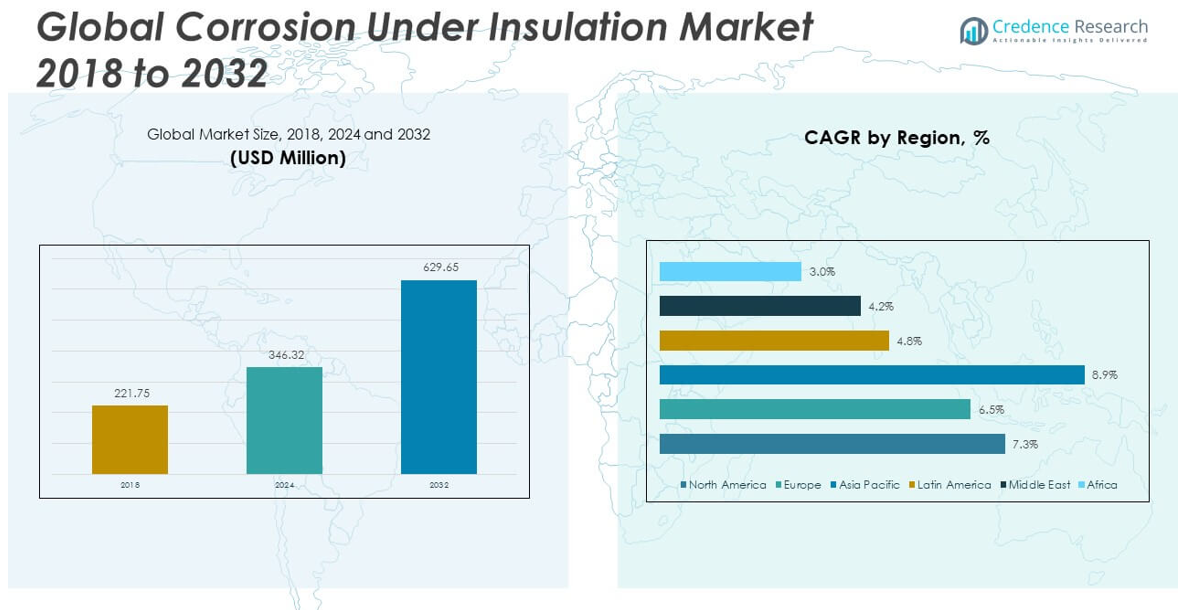

The Global Corrosion Under Insulation Market size was valued at USD 221.75 million in 2018 to USD 346.32 million in 2024 and is anticipated to reach USD 629.65 million by 2032, at a CAGR of 7.23% during the forecast period.

The growth of the global Corrosion Under Insulation (CUI) market is largely driven by the increasing demand for enhanced asset integrity management and predictive maintenance across industries such as oil & gas, petrochemicals, power generation, and marine sectors. Aging infrastructure in these industries, coupled with the hidden nature of CUI, has led to costly failures and unplanned downtime. As a result, industries are increasingly investing in advanced monitoring systems to detect corrosion early, enabling proactive maintenance and reducing the risk of catastrophic equipment failure. Regulatory compliance also plays a pivotal role in the adoption of CUI monitoring solutions, as strict safety standards set by organizations like OSHA and NACE compel industries to implement continuous monitoring systems for insulated equipment. Furthermore, technological advancements, including ultrasonic sensors, infrared thermography, and wireless monitoring systems, are significantly enhancing the accuracy and reliability of CUI detection, making these solutions more appealing to industries seeking improved asset management.

Regionally, the North American market leads due to the presence of a large number of aging pipelines, refineries, and chemical plants. The region’s strict regulatory environment and the focus on preventive maintenance drive the demand for CUI monitoring technologies. Europe follows closely, with a strong emphasis on sustainability and environmental regulations, pushing industries to adopt advanced monitoring systems. The Asia-Pacific (APAC) region is experiencing rapid growth, primarily due to industrialization, infrastructure development, and rising awareness of corrosion-related issues in countries like China, India, and Japan. Meanwhile, the Middle East and Africa (MEA) region presents significant opportunities, especially within the oil and gas sector, where maintaining the integrity of pipelines and equipment in harsh environments is critical.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Global Corrosion Under Insulation Market was valued at USD 221.75 million in 2018 and is expected to reach USD 629.65 million by 2032, with a CAGR of 7.23% from 2024 to 2032.

- The market growth is driven by the rising demand for predictive maintenance and asset integrity management, particularly in industries like oil & gas, petrochemicals, power generation, and marine sectors.

- Strict regulatory frameworks, such as those set by OSHA and NACE, are a key driver for the adoption of CUI monitoring systems, pushing industries to ensure compliance with safety and maintenance standards.

- Technological advancements in monitoring systems, including ultrasonic sensors, infrared thermography, and wireless inspection tools, are enhancing the detection and management of corrosion under insulation, improving maintenance processes.

- A growing focus on sustainability and reducing environmental impacts has led industries to adopt eco-friendly solutions, including corrosion-resistant coatings and materials, aligning with global environmental goals.

- High costs of implementation and maintenance of advanced monitoring systems remain a challenge, particularly for small and medium enterprises that face financial constraints.

- The complexity of detecting corrosion in hard-to-reach and challenging environments, such as confined spaces or extreme operating conditions, presents an ongoing challenge, demanding continuous innovation in inspection technologies.

Market Drivers:

Rising Demand for Predictive Maintenance and Asset Integrity Management

The growing focus on asset integrity and predictive maintenance drives the expansion of the Global Corrosion Under Insulation Market. Industries such as oil and gas, petrochemicals, power generation, and marine are placing increasing emphasis on preventing equipment failure and reducing downtime. The hidden nature of corrosion beneath insulation poses significant challenges, often leading to unexpected failures. By adopting advanced monitoring technologies, companies can detect CUI early, allowing for timely repairs and reducing the risk of catastrophic consequences. This proactive approach enhances the lifespan of critical infrastructure and optimizes operational efficiency, making predictive maintenance a key factor in market growth.

- For example, the Wi-Corr® CUI system utilizes patent-pending radio wave technology to detect corrosive environments up to 40 meters along insulated piping, providing actionable, real-time data and supporting both short- and long-term monitoring strategies.

Regulatory Compliance and Safety Standards

Strict regulatory frameworks are a key driver for the growth of the Global Corrosion Under Insulation Market. Regulatory bodies such as OSHA and NACE enforce stringent safety and maintenance standards to ensure the safety of workers and the integrity of industrial operations. Industries are increasingly investing in continuous monitoring solutions to comply with these regulations. CUI monitoring systems offer real-time data on equipment conditions, ensuring that companies meet the required safety standards. The growing demand to avoid costly fines and legal implications of non-compliance further accelerates the adoption of corrosion monitoring solutions.

- For instance, TE Connectivity’s wireless, battery-powered CUI sensors utilize LoRaWAN and NB-IoT protocols, enabling continuous monitoring of humidity and temperature between pipe and cladding, and simplifying compliance with regulatory inspection intervals.

Technological Advancements in CUI Monitoring Systems

Advancements in technology are playing a significant role in driving the Global Corrosion Under Insulation Market. Modern monitoring systems, such as ultrasonic sensors, infrared thermography, and wireless inspection devices, have enhanced the precision and reliability of detecting corrosion under insulation. These technologies offer real-time data, which helps companies make informed decisions about maintenance and repairs. The ability to detect CUI early and continuously, even in hard-to-reach areas, minimizes the risk of undetected corrosion. The integration of IoT and wireless capabilities in these systems also reduces maintenance costs and improves operational efficiency, contributing to market growth.

Focus on Sustainability and Environmental Impact

The increasing focus on sustainability and reducing environmental impact is also driving the Global Corrosion Under Insulation Market. Companies are under pressure to adopt environmentally friendly solutions that align with global sustainability goals. CUI prevention methods, such as protective coatings and monitoring systems, not only help maintain asset integrity but also reduce the environmental risks associated with corrosion-induced failures. Industries are shifting toward eco-friendly solutions, including corrosion-resistant materials, to minimize their carbon footprint and enhance operational sustainability. The growing demand for green and safe industrial practices further fuels the market’s expansion.

Market Trends:

Increasing Adoption of IoT and Wireless Technologies

The integration of IoT and wireless technologies is a prominent trend in the Global Corrosion Under Insulation Market. Industrial companies are increasingly implementing IoT-based sensors to monitor equipment conditions and detect CUI in real-time. These systems provide constant data feeds, allowing for early detection of corrosion and reducing the likelihood of unexpected failures. Wireless monitoring solutions eliminate the need for manual inspections and offer significant cost savings. With IoT-enabled devices, maintenance teams can access critical data remotely, ensuring more efficient monitoring and timely interventions. This trend is expected to continue growing as companies prioritize operational efficiency and cost-effective asset management solutions.

Shift Towards Preventive Maintenance Over Reactive Repairs

The shift from reactive maintenance to preventive measures is driving the growth of the Global Corrosion Under Insulation Market. Companies are increasingly recognizing the importance of identifying issues before they lead to equipment failure. Preventive maintenance strategies, supported by CUI monitoring technologies, help identify early signs of corrosion, allowing for timely repairs and reducing unplanned downtime. This proactive approach not only improves asset reliability but also lowers maintenance costs and enhances operational safety. Industries with large-scale infrastructure, such as petrochemicals and oil & gas, are at the forefront of this trend, emphasizing the need to extend asset life and improve overall system efficiency.

Development of Advanced Corrosion-Resistant Coatings and Materials

The development of advanced corrosion-resistant coatings and materials is another key trend in the Global Corrosion Under Insulation Market. Companies are investing in innovative protective coatings that prevent corrosion beneath insulation and extend the lifespan of critical equipment. These advanced coatings are designed to withstand harsh operating environments and are highly effective in industries such as oil & gas and power generation. Along with coatings, the adoption of corrosion-resistant materials, such as composites and high-strength alloys, is gaining momentum. These materials offer superior durability and resistance to environmental stressors, helping industries improve the performance and reliability of their equipment while reducing maintenance costs.

- For example, Sherwin-Williams’ Heat-Flex® ACE (Advanced CUI Epoxy) is an ultra-high-solids, solvent-free epoxy novolac coating that delivers best-in-class performance, withstanding CUI simulation tests at temperatures exceeding 204°C (400°F) in accordance with ISO TM21442.

Growing Demand for Remote and Automated Inspection Solutions

The increasing demand for remote and automated inspection solutions is reshaping the Global Corrosion Under Insulation Market. Traditional methods of inspecting CUI involve manual checks, which are time-consuming and often limited in scope. With advancements in drone technology, robotic systems, and automated inspection tools, companies can now conduct thorough inspections in hard-to-reach areas, improving accuracy and efficiency. Automated systems provide real-time feedback, allowing for quicker decision-making and reducing downtime. This trend aligns with the growing preference for digital transformation and automation across industries, which seek to optimize maintenance operations and enhance the safety of their workforce.

- For instance, Voliro AG, in partnership with Sixpec, launched the world’s first aerial Pulsed Eddy Current (PEC) inspection solution for CUI.The Voliro T drone is equipped with a lightweight, proprietary PEC sensor designed specifically for non-contact, non-destructive CUI inspection on insulated and coated assets.

Market Challenges Analysis:

High Costs of Implementation and Maintenance

One of the significant challenges facing the Global Corrosion Under Insulation Market is the high costs associated with the implementation and maintenance of CUI monitoring systems. Advanced monitoring technologies, such as ultrasonic sensors and infrared thermography, require substantial upfront investments. For many industries, especially small and medium enterprises, these costs can be prohibitive. Furthermore, regular maintenance and calibration of these systems add to the overall expenses. These financial constraints may hinder the widespread adoption of CUI monitoring solutions, particularly in cost-sensitive industries. Overcoming these barriers will require the development of more affordable and scalable solutions to make CUI prevention accessible to a broader range of industries.

Complexity in Detection and Inspections in Challenging Environments

Another challenge impacting the Global Corrosion Under Insulation Market is the complexity of detecting and inspecting corrosion in challenging environments. Corrosion under insulation often occurs in hard-to-reach areas, such as piping systems and vessels with complex geometries. Traditional inspection methods are time-consuming and may not detect early-stage corrosion. While advanced technologies like drones and robotic systems offer some solutions, they still face limitations in terms of accessibility, especially in confined spaces or extreme operating conditions. Ensuring the accuracy and reliability of detection systems in these environments remains a persistent challenge that requires ongoing technological advancements.

Market Opportunities:

Expansion in Emerging Markets

The Global Corrosion Under Insulation Market presents significant opportunities in emerging markets. Rapid industrialization in regions such as Asia-Pacific, Latin America, and the Middle East is driving the demand for CUI monitoring and protection solutions. As these regions continue to expand their industrial infrastructure, the need to safeguard critical assets from corrosion becomes more pressing. Companies in these markets are increasingly adopting advanced CUI technologies to ensure the longevity and safety of their operations. The growing awareness of corrosion-related risks and the need for proactive maintenance open new avenues for market expansion in these regions.

Advancement of Smart Coatings and Materials

The development of smart coatings and materials offers another promising opportunity in the Global Corrosion Under Insulation Market. Innovations in protective coatings that can detect and self-repair corrosion are gaining traction. These smart materials reduce the need for manual inspections and provide enhanced protection against corrosion under insulation. As industries seek more efficient and cost-effective solutions to manage corrosion, the demand for these advanced coatings is expected to rise. Companies investing in research and development of these technologies stand to benefit from the growing shift towards automated, long-lasting, and environmentally sustainable corrosion prevention methods.

Market Segmentation Analysis:

The Global Corrosion Under Insulation Market is segmented into product and application categories, each contributing significantly to its growth.

By Product Segment, the market is divided into Monitoring Systems and Coatings & Materials. Monitoring systems, such as ultrasonic sensors, infrared thermography, and wireless inspection solutions, offer real-time detection and early warning signs of corrosion, driving the demand for proactive maintenance. Coatings & materials, including corrosion-resistant coatings and advanced insulation materials, protect infrastructure from damage caused by environmental factors, further enhancing asset longevity and performance.

- For example, Subtera Pi360, is a handheld, cloud-connected terahertz sensor that enables non-intrusive, real-time detection of CUI, allowing for rapid inspection and immediate data analysis in the field.

By Application Segment, the market covers several industries with key demand coming from Oil & Gas, Chemical Industry, Power Generation, Marine, and Others. The oil and gas sector holds a significant share due to its reliance on pipelines and offshore platforms, which are prone to corrosion under insulation. The chemical industry follows closely, as industrial plants require durable protection for pipes, tanks, and other equipment. Power generation, including both renewable and traditional plants, also drives demand due to the critical need to maintain operational efficiency and safety. The marine sector benefits from corrosion management systems to withstand harsh marine environments, while the “Others” category includes sectors like manufacturing and mining, which also experience challenges related to corrosion.

- For example, Marine vessels use advanced coatings like ZRC Worldwide’s PFAS-free paints to protect against the harsh, corrosive marine environment.

Segmentation:

By Product Segment:

- Monitoring Systems

- Coatings & Materials

By Application Segment:

- Oil & Gas

- Chemical Industry

- Power Generation

- Marine

- Others

By Region Segment:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

North America Regional Analysis

The North America Global Corrosion Under Insulation Market size was valued at USD 92.32 million in 2018, projected to reach USD 142.62 million in 2024, and is anticipated to grow to USD 260.05 million by 2032, at a CAGR of 7.3% during the forecast period. North America holds a significant share of the market, driven by a well-established industrial base, particularly in the oil and gas, petrochemical, and power generation sectors. The region’s aging infrastructure, along with stringent regulatory standards such as OSHA and NACE, drives the adoption of CUI monitoring technologies. The U.S. is the leading country in this market, accounting for a substantial portion of the regional market share. The demand for predictive maintenance and the focus on improving asset integrity across critical infrastructure further fuel market growth. Continuous advancements in CUI detection technologies and increased awareness of corrosion-related risks also contribute to the region’s market dominance.

Europe Regional Analysis

The Europe Global Corrosion Under Insulation Market size was valued at USD 73.06 million in 2018, projected to reach USD 110.55 million in 2024, and is expected to grow to USD 190.93 million by 2032, at a CAGR of 6.5% during the forecast period. Europe is witnessing steady growth, primarily due to strict environmental regulations and the growing demand for sustainability in industrial operations. The oil and gas, chemical, and manufacturing sectors are major contributors to the market in the region. The rising awareness of the economic impact of corrosion-related failures and the regulatory push for maintaining asset integrity drive the demand for advanced CUI monitoring solutions. Leading economies like Germany, the UK, and France are adopting corrosion prevention technologies to safeguard critical assets and reduce unplanned downtime, boosting market growth in the region.

Asia Pacific Regional Analysis

The Asia Pacific Global Corrosion Under Insulation Market size was valued at USD 41.57 million in 2018, projected to reach USD 70.51 million in 2024, and is expected to reach USD 145.59 million by 2032, at a CAGR of 8.9% during the forecast period. Asia Pacific is the fastest-growing region for the CUI market, driven by rapid industrialization, increasing infrastructure projects, and rising awareness of corrosion risks. Countries like China, India, and Japan are witnessing significant growth due to their expanding industrial sectors, especially in oil, gas, and power generation. The rising demand for predictive maintenance and advanced monitoring solutions in these rapidly developing economies further boosts the market. The Asia Pacific market is also characterized by an increasing focus on sustainability, creating more opportunities for advanced corrosion-resistant coatings and monitoring systems.

Latin America Regional Analysis

The Latin America Global Corrosion Under Insulation Market size was valued at USD 7.37 million in 2018, projected to reach USD 11.30 million in 2024, and is expected to grow to USD 17.18 million by 2032, at a CAGR of 4.8% during the forecast period. Latin America, while still a smaller market compared to other regions, is experiencing steady growth driven by the expansion of industrial activities in sectors such as oil, gas, and chemicals. The region’s need for corrosion management is increasing due to the rising number of aging infrastructures and the growing focus on enhancing industrial safety standards. Countries like Brazil, Mexico, and Argentina are adopting CUI monitoring technologies to improve the reliability of their critical infrastructure and reduce downtime, contributing to market growth.

Middle East Regional Analysis

The Middle East Global Corrosion Under Insulation Market size was valued at USD 4.95 million in 2018, projected to reach USD 6.90 million in 2024, and is expected to grow to USD 10.03 million by 2032, at a CAGR of 4.2% during the forecast period. The Middle East region holds a significant position in the global CUI market, largely due to its vast oil and gas industry, which demands robust corrosion management solutions. The harsh environmental conditions in the region, such as extreme temperatures and high humidity, accelerate the need for efficient corrosion protection technologies. Countries like Saudi Arabia, the UAE, and Qatar are actively investing in advanced CUI monitoring solutions to extend the lifespan of critical infrastructure and reduce the risk of unplanned shutdowns, driving market growth.

Africa Regional Analysis

The Africa Global Corrosion Under Insulation Market size was valued at USD 2.48 million in 2018, projected to reach USD 4.44 million in 2024, and is expected to grow to USD 5.88 million by 2032, at a CAGR of 3.0% during the forecast period. The market in Africa is relatively smaller but is expected to witness gradual growth, particularly in the oil, gas, and mining sectors. The increasing industrialization and infrastructure development across countries like Nigeria, South Africa, and Egypt create opportunities for CUI monitoring and protection solutions. The region faces challenges due to budget constraints and the need for cost-effective solutions; however, the growing focus on asset integrity and minimizing the economic impact of corrosion-induced failures presents opportunities for market expansion.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Emerson Electric Co.

- 3M Company

- General Electric

- Honeywell International Inc.

- Parker Hannifin Corporation

- MISTRAS Group, Inc.

- SGS SA

- Intertek Group plc

- TÜV Rheinland

- Zetec, Inc.

Competitive Analysis:

The competitive landscape of the Global Corrosion Under Insulation Market is marked by the presence of several key players offering advanced solutions to monitor and mitigate corrosion. Leading companies such as Emerson Electric Co., Intertek Group, and Sulzer Ltd. dominate the market by providing a range of innovative technologies including ultrasonic sensors, infrared thermography, and advanced coating solutions. These companies focus on enhancing the reliability of their monitoring systems and expanding their product portfolios to address various industrial applications. Market leaders invest heavily in research and development to offer more cost-effective and efficient solutions. New entrants are also emerging with innovative technologies aimed at lowering costs and improving the accessibility of corrosion monitoring systems. Competition in the market is expected to intensify as industries across oil and gas, power generation, and petrochemicals seek advanced, scalable, and sustainable corrosion management solutions.

Recent Developments:

- In July 2024, Parker Hannifin Corporation announced it had signed a definitive agreement to sell its North America Composites & Fuel Containment (CFC) Division to SK Capital Partners. The CFC Division, a key provider of engineered carbon fiber composite components for the aerospace and defense markets, will continue to operate independently, supporting Parker Hannifin’s strategy to focus on core businesses while enabling growth for the CFC unit under new ownership. The transaction is expected to close in the fourth quarter of 2024.

- In August 2024, Honeywell introduced its Emissions Management Suite, now Hazardous Location (HazLoc) and marine certified, making it one of the industry’s first end-to-end solutions for offshore oil and gas assets to measure, monitor, report, and reduce emissions.

Market Concentration & Characteristics:

The Global Corrosion Under Insulation Market exhibits moderate concentration, with a few key players dominating the space. Leading companies such as Emerson Electric Co., Intertek Group, and Sulzer Ltd. hold a significant share, leveraging advanced technologies and extensive industry expertise. These market leaders focus on innovation, offering comprehensive solutions that address a wide range of industries, including oil and gas, petrochemical, and power generation. The market also sees the presence of smaller, specialized players targeting niche applications and offering cost-effective solutions. The competitive dynamics are driven by factors such as technological advancements, cost-efficiency, and the growing demand for predictive maintenance systems. Despite the dominance of established companies, the market is witnessing increased entry of new players offering innovative monitoring systems, which is expected to diversify the market further and intensify competition.

Report Coverage:

The research report offers an in-depth analysis based on product and application. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Global Corrosion Under Insulation Market is expected to grow significantly due to increasing demand for asset integrity management solutions across industries.

- The adoption of IoT-enabled monitoring systems will enhance real-time detection and maintenance, driving market growth.

- Technological innovations in sensors and coatings will offer more cost-effective and efficient solutions, broadening market adoption.

- Predictive maintenance will become more prevalent as industries seek to reduce downtime and extend the life of critical infrastructure.

- Regulatory pressure will push companies to adopt more advanced corrosion monitoring technologies to comply with safety and environmental standards.

- The oil and gas industry will continue to be a major driver, given its heavy reliance on corrosion protection for pipelines and offshore platforms.

- Emerging markets, particularly in Asia-Pacific and the Middle East, will see substantial market growth due to rapid industrialization.

- The increasing focus on sustainability will accelerate the demand for eco-friendly and long-lasting corrosion prevention solutions.

- The market will benefit from enhanced product offerings by key players investing in research and development to create smart, self-healing coatings.

- Smaller, specialized players will enter the market, increasing competition and driving innovation in corrosion protection technologies.