Market Overview

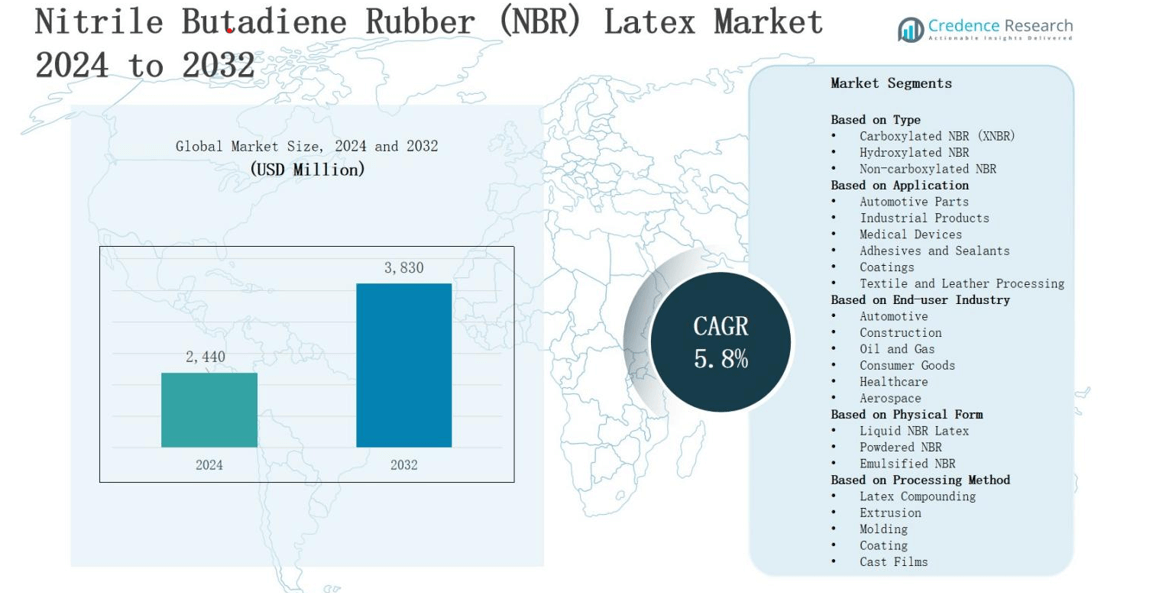

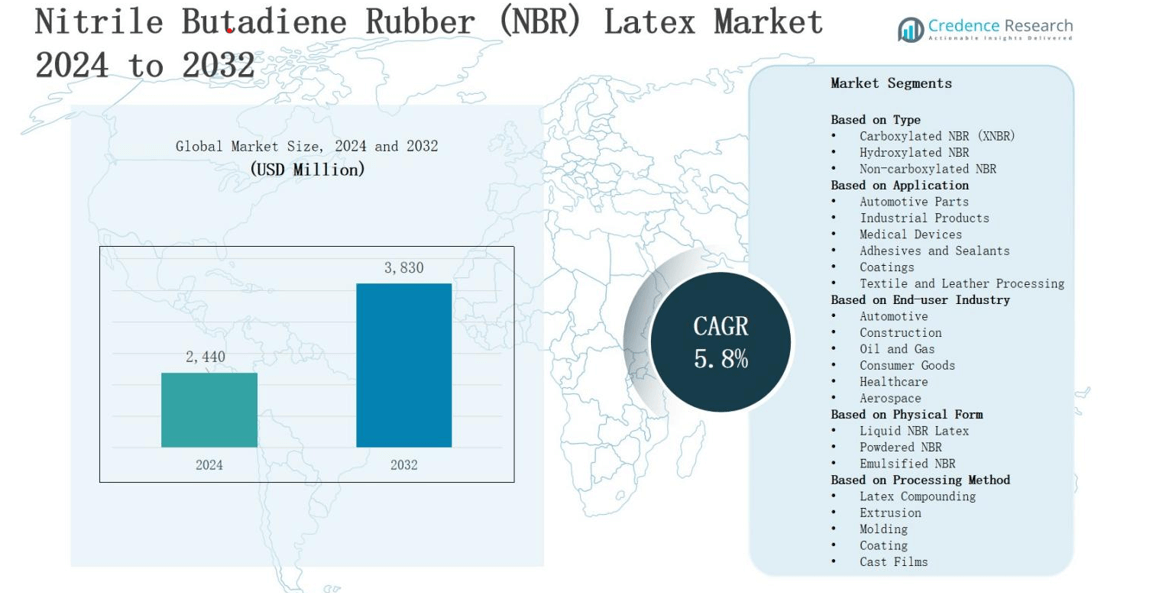

The nitrile butadiene rubber (NBR) latex market is projected to grow from USD 2,440 million in 2024 to USD 3,830 million by 2032, registering a CAGR of 5.8% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Nitrile Butadiene Rubber (NBR) Latex Market Size 2024 |

USD 2,440 million |

| Nitrile Butadiene Rubber (NBR) Latex Market, CAGR |

5.8% |

| Nitrile Butadiene Rubber (NBR) Latex Market Size 2032 |

USD 3,830 million |

The nitrile butadiene rubber (NBR) latex market grows with rising demand for disposable gloves across healthcare, food processing, and cleanroom industries. Increasing focus on hygiene and safety standards strengthens adoption. Strong chemical resistance and durability drive preference in industrial applications such as adhesives, sealants, and coatings. Rising investments in healthcare infrastructure and manufacturing expansion in Asia-Pacific further support growth. Trends highlight the shift toward sustainable and eco-friendly latex formulations, along with technological advancements in production processes. Growing e-commerce penetration and distribution efficiency enhance accessibility, while strategic partnerships and capacity expansions by key players accelerate market competitiveness and innovation.

The nitrile butadiene rubber (NBR) latex market shows diverse geographical dynamics across North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific leads with strong demand from healthcare and industrial sectors, while North America and Europe follow with strict regulatory standards and high healthcare spending. Latin America and the Middle East & Africa show growing opportunities in healthcare and construction. Key players include Arkema SA, BASF SE, Asahi Kasei Corporation, Dynasol Elastomers, Versalis S.p.A., Trinseo, Dow Chemical Company, Nizhnekamskneftekhim, LG Chem, Euro Latex, and Zeon Corporation.

Market Insights

- The nitrile butadiene rubber (NBR) latex market is projected to grow from USD 2,440 million in 2024 to USD 3,830 million by 2032, recording a CAGR of 5.8%.

- Carboxylated NBR (XNBR) leads with 52% share due to superior strength and resistance, followed by non-carboxylated NBR at 32% and hydroxylated NBR at 16%, supporting diverse industrial applications.

- By application, medical devices dominate with 38% share, followed by industrial products at 26% and automotive parts at 14%, while adhesives, coatings, and textile processing account for the remaining share.

- Healthcare holds 41% share among end-user industries, with automotive at 23%, construction at 13%, oil and gas at 9%, consumer goods at 8%, and aerospace at 6%, reflecting diverse adoption.

- Regionally, Asia-Pacific leads with 46% share, followed by North America at 21% and Europe at 19%, while Latin America and the Middle East & Africa each hold 7% share.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers

Rising Demand from Healthcare and Medical Applications

The nitrile butadiene rubber (NBR) latex market is strongly driven by the expanding use of disposable medical gloves and protective equipment. Healthcare facilities prioritize latex-free materials due to allergy concerns, creating significant demand for NBR-based alternatives. It offers superior puncture resistance and chemical protection compared to natural rubber. Growing global awareness about infection control standards further boosts demand. Expanding healthcare infrastructure and rising patient care requirements continue to stimulate consistent adoption across hospitals and clinics.

- For instance, Ansell Healthcare annually supplies over 1 billion nitrile gloves globally, emphasizing their hypoallergenic properties and durability that meet stringent medical safety standards.

Expansion in Food Processing and Cleanroom Industries

The food processing and cleanroom industries fuel market growth by requiring reliable barrier protection. The nitrile butadiene rubber (NBR) latex market benefits from its non-allergenic properties and excellent resistance to oils and fats. Stringent safety standards in food handling drive usage of gloves and coatings manufactured with NBR latex. Cleanroom environments also adopt it to ensure contamination-free processes. Growing packaged food consumption worldwide increases demand. Industrial hygiene regulations strengthen reliance on these protective materials across production facilities.

- For instance, Top Glove’s nitrile gloves are widely used in semiconductor cleanrooms where ISO Class 5 or higher standards are enforced to prevent particulate contamination.

Superior Performance in Industrial and Chemical Applications

Industrial applications such as adhesives, sealants, and coatings significantly contribute to growth. The nitrile butadiene rubber (NBR) latex market benefits from its strong resistance to oils, fuels, and chemicals. Manufacturers in automotive, construction, and chemical sectors adopt NBR latex products for durability and performance. It ensures longer service life and reduces maintenance costs in harsh operating environments. Increasing industrialization in emerging economies continues to raise demand. Strategic use in diverse manufacturing processes drives further expansion of applications.

Innovation and Regional Manufacturing Expansion

The nitrile butadiene rubber (NBR) latex market witnesses strong momentum from innovation in eco-friendly formulations and advanced production techniques. Manufacturers invest in sustainable latex solutions to address environmental concerns. It enhances product value and widens market acceptance among responsible buyers. Regional expansion, especially in Asia-Pacific, supports availability through increased production capacity. Rising global e-commerce platforms further boost product accessibility. Strategic alliances and capacity investments by leading players ensure competitive strength and sustained growth momentum worldwide.

Market Trends

Growing Adoption of Disposable Gloves Across Sectors

The nitrile butadiene rubber (NBR) latex market experiences a strong trend in the rising adoption of disposable gloves across healthcare, food processing, and cleanroom applications. Demand is supported by stricter hygiene standards, rising awareness of safety protocols, and growing regulatory oversight. It continues to replace natural rubber due to allergy concerns and superior chemical resistance. Expanding healthcare services and industrial hygiene requirements globally ensure sustained glove demand, making protective applications a leading growth driver.

- For instance, during the COVID-19 response, the U.S. Food and Drug Administration (FDA) confirmed emergency use authorizations for millions of NBR-based gloves imported by companies like Ansell to address the surge in hospital PPE demand.

Shift Toward Sustainable and Eco-Friendly Formulations

Sustainability is shaping future demand patterns in the nitrile butadiene rubber (NBR) latex market. Manufacturers focus on developing eco-friendly formulations to reduce environmental impact. It helps companies comply with stricter regulations and align with global sustainability goals. Innovation in green chemistry and water-based processing enhances performance while addressing ecological concerns. Buyers increasingly value sustainable sourcing and production transparency, encouraging producers to invest in cleaner processes. This trend strengthens competitiveness and improves long-term adoption across industries.

- For instance, Synthomer has pioneered bio-based nitrile latexes made with at least 20% bio-based feedstock, certified under the International Sustainability and Carbon Certification (ISCC) system, enabling glove makers to lower their carbon emissions without sacrificing quality

Technological Advancements in Manufacturing Processes

Technological innovation drives efficiency in the nitrile butadiene rubber (NBR) latex market, supporting consistent product quality and scalability. Automation, digital monitoring, and advanced polymerization techniques improve performance and reduce production costs. It allows manufacturers to meet growing global demand while maintaining compliance with safety and quality standards. Enhanced material properties such as improved tensile strength and chemical resistance expand industrial applications. These advancements create opportunities for broader usage across automotive, construction, and chemical manufacturing industries.

Regional Expansion and Strategic Partnerships

Global producers are expanding operations, particularly in Asia-Pacific, to meet rising demand. The nitrile butadiene rubber (NBR) latex market benefits from increased regional manufacturing capacity and competitive cost structures. It helps companies ensure better supply chain resilience and faster response to market shifts. Strategic partnerships with healthcare providers, distributors, and industrial players strengthen market penetration. Rising e-commerce distribution channels enhance accessibility across regions. This expansion trend positions manufacturers to capture emerging growth opportunities in both developed and developing markets.

Market Challenges Analysis

Volatility in Raw Material Prices and Supply Chain Disruptions

The nitrile butadiene rubber (NBR) latex market faces significant challenges due to fluctuations in raw material prices, particularly butadiene and acrylonitrile. These petrochemical-based inputs are subject to supply-demand imbalances, geopolitical tensions, and crude oil price volatility. It creates cost pressures for manufacturers and reduces profit margins, especially for small and mid-sized players. Supply chain disruptions during global crises further worsen the issue, causing delays and inconsistent material availability. Uncertainty in pricing hampers long-term planning and investment decisions for producers and end users.

Stringent Environmental Regulations and Competition from Alternatives

Tightening environmental regulations on petrochemical-based materials present another critical challenge for the nitrile butadiene rubber (NBR) latex market. Regulatory authorities push industries toward sustainable practices, requiring manufacturers to upgrade processes and invest in cleaner technologies. It raises production costs and slows adoption in cost-sensitive markets. Competition from alternative materials such as natural rubber latex and emerging synthetic substitutes adds further pressure. Buyers seeking eco-friendly options may shift away from traditional NBR latex products, creating risks for established market players.

Market Opportunities

Expansion in Healthcare and Hygiene Applications

The nitrile butadiene rubber (NBR) latex market presents strong opportunities in healthcare and hygiene sectors, where disposable gloves and protective equipment remain essential. Rising global focus on infection control, combined with increasing investments in hospital infrastructure, strengthens demand. It provides advantages over natural rubber by reducing allergy risks and offering superior chemical resistance. Growth in pharmaceutical manufacturing and diagnostic services further supports adoption. Emerging markets with underdeveloped healthcare systems also create untapped potential, driving future expansion opportunities in medical-grade latex products.

Innovation in Sustainable Solutions and Industrial Applications

The nitrile butadiene rubber (NBR) latex market benefits from opportunities in sustainable innovations and industrial usage. Manufacturers investing in eco-friendly formulations can meet regulatory requirements and appeal to environmentally conscious buyers. It creates prospects for green product lines in food processing, cleanroom operations, and industrial coatings. Rising industrialization in Asia-Pacific and Latin America expands demand across automotive, construction, and chemical industries. Strategic partnerships and technology-driven production efficiency can further enhance market penetration, opening pathways for long-term growth and competitiveness.

Market Segmentation Analysis:

By Type

The nitrile butadiene rubber (NBR) latex market by type is dominated by carboxylated NBR (XNBR), holding 52% share in 2024. XNBR offers superior tensile strength, abrasion resistance, and chemical stability, making it highly preferred for gloves, seals, and gaskets. Non-carboxylated NBR follows with about 32% share, mainly used in adhesives, foams, and coatings. Hydroxylated NBR accounts for nearly 16% share, driven by its applications in specialty formulations where higher elasticity and oil resistance are required.

- For instance, Ansell uses carboxylated NBR in its Microflex examination gloves, which are designed for high resistance against punctures and harsh chemicals.

By Application

Medical devices lead the application segment with 38% share in the nitrile butadiene rubber (NBR) latex market. Strong demand for disposable gloves, surgical products, and infection-control solutions drives growth in this category. Industrial products follow with about 26% share, supported by use in gaskets, seals, and hoses. Automotive parts contribute 14% share, driven by the need for fuel- and oil-resistant components. Adhesives and sealants hold 10%, coatings 7%, while textile and leather processing make up 5% of total applications.

By End-user Industry

Healthcare dominates the end-user industry segment, accounting for nearly 41% share in the nitrile butadiene rubber (NBR) latex market. Rising global healthcare expenditure and demand for gloves and protective gear drive growth. Automotive follows with about 23% share, supported by NBR’s use in seals, hoses, and vibration-resistant parts. Construction holds 13%, driven by adhesives and coatings. Oil and gas represent 9%, consumer goods 8%, and aerospace 6%, where durability and chemical resistance enhance product applications.

- For instance, Continental AG integrates NBR-based elastomers in under‑the‑hood components like fuel hoses, due to their superior oil and abrasion resistance.

Segments:

Based on Type

- Carboxylated NBR (XNBR)

- Hydroxylated NBR

- Non-carboxylated NBR

Based on Application

- Automotive Parts

- Industrial Products

- Medical Devices

- Adhesives and Sealants

- Coatings

- Textile and Leather Processing

Based on End-user Industry

- Automotive

- Construction

- Oil and Gas

- Consumer Goods

- Healthcare

- Aerospace

Based on Physical Form

- Liquid NBR Latex

- Powdered NBR

- Emulsified NBR

Based on Processing Method

- Latex Compounding

- Extrusion

- Molding

- Coating

- Cast Films

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America holds 21% share of the nitrile butadiene rubber (NBR) latex market, supported by strong healthcare and industrial demand. The region benefits from advanced medical infrastructure, rising glove consumption, and stringent safety regulations. It is also driven by demand in automotive and oil and gas industries requiring chemical-resistant materials. U.S. manufacturers invest in capacity expansion and sustainable formulations to meet regulatory expectations. Growing emphasis on hygiene standards across healthcare and food processing continues to push adoption. The region remains a key importer due to limited domestic raw material availability.

Europe

Europe accounts for 19% share of the nitrile butadiene rubber (NBR) latex market, led by healthcare, automotive, and construction applications. Demand is reinforced by strict regulatory standards for worker protection and hygiene. It benefits from established industrial sectors that adopt high-performance adhesives, coatings, and sealants. Rising investments in eco-friendly formulations align with the region’s sustainability goals. Germany, France, and the U.K. represent key consumers with robust healthcare spending. Expansion of industrial coatings and protective equipment markets adds steady momentum across the continent.

Asia-Pacific

Asia-Pacific dominates with 46% share of the nitrile butadiene rubber (NBR) latex market, driven by rapid industrialization and healthcare expansion. China, India, and Southeast Asia are leading contributors due to rising glove manufacturing and automotive demand. It benefits from cost-effective production and availability of petrochemical feedstocks. Governments support manufacturing growth with infrastructure development and foreign investment. Rising healthcare awareness fuels disposable glove consumption. The region attracts global players establishing production facilities, creating strong competition and expanding regional capacity.

Latin America

Latin America holds 7% share of the nitrile butadiene rubber (NBR) latex market, supported by increasing demand in healthcare and automotive sectors. Brazil and Mexico lead consumption, driven by expanding hospital infrastructure and industrial growth. It faces challenges from limited raw material supply and dependence on imports. Local manufacturers are investing in medical-grade glove production to meet regional needs. Rising urbanization supports construction-driven demand for adhesives and coatings. Growth opportunities remain untapped in emerging economies across the region.

Middle East & Africa

The Middle East & Africa represents 7% share of the nitrile butadiene rubber (NBR) latex market, fueled by growth in healthcare, oil and gas, and construction. Demand is concentrated in GCC nations, South Africa, and Nigeria. It benefits from increasing government spending on healthcare systems and safety regulations. Oil and gas operations require durable, chemical-resistant materials, creating industrial demand. Rising glove consumption during health crises accelerated adoption. Regional opportunities are expanding through partnerships and investments in healthcare and industrial sectors.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Trinseo

- Zeon Corporation

- LG Chem

- Euro Latex

- Arkema SA

- Nizhnekamskneftekhim

- Asahi Kasei Corporation

- Versalis S.p.A.

- Dynasol Elastomers

- Dow Chemical Company

- BASF SE

Competitive Analysis

The nitrile butadiene rubber (NBR) latex market is characterized by strong competition among global and regional manufacturers focusing on product innovation, capacity expansion, and sustainability initiatives. It is shaped by leading players such as Arkema SA, BASF SE, Asahi Kasei Corporation, Dynasol Elastomers, Versalis S.p.A., Trinseo, Dow Chemical Company, Nizhnekamskneftekhim, LG Chem, Euro Latex, and Zeon Corporation. Companies prioritize enhancing production efficiency, securing raw material supply, and meeting strict regulatory standards to strengthen their market position. Strategic partnerships with healthcare providers and industrial manufacturers enhance distribution networks and ensure consistent demand. Major players invest in research to develop eco-friendly formulations that meet rising sustainability requirements and customer expectations. Asia-Pacific remains a focal point for production growth, with investments directed toward meeting the expanding demand for gloves, industrial products, and coatings. Competitive intensity continues to rise with firms seeking differentiation through product quality, application-specific performance, and global supply chain resilience to capture a larger market share.

Recent Developments

- In January 2024, Synthomer introduced its new sustainable NBR latex line under the SyNovus™ Plus platform. The formulation delivers sustainability benefits with lower curing temperatures, consuming 10–20% less energy and reducing carbon emissions in production lines.

- In May 2025, ARLANXEO and TSRC inaugurated a relocated and expanded joint-venture NBR plant in Nantong, China, boosting annual capacity to 40,000 tons per year.

- In 2025, Sybron introduced a new range of biodegradable NBR gloves that degrade by 81% within 491 days, targeting sustainability-focused markets.

- On August 24, 2024, PETRONAS Chemicals Group (PCG) and LG Chem entered into a strategic partnership to build a Nitrile Butadiene Latex (NBL) manufacturing plant within the Pengerang Integrated Complex in Johor, Malaysia. The plant is set to deliver 200,000 tons per annum capacity.

Market Concentration & Characteristics

The nitrile butadiene rubber (NBR) latex market is moderately concentrated, with a mix of global leaders and regional players competing across healthcare, industrial, and automotive applications. It is defined by high entry barriers due to raw material dependency, regulatory compliance, and capital-intensive production requirements. Major players such as BASF SE, Arkema SA, Zeon Corporation, and LG Chem dominate with advanced production capabilities and strong distribution networks. Competition is shaped by product innovation, sustainability initiatives, and expansion into high-growth regions like Asia-Pacific. Market characteristics highlight strong reliance on healthcare demand, particularly disposable gloves, alongside rising use in adhesives, coatings, and sealants. It shows resilience through diversified applications, though raw material volatility and regulatory pressures remain key challenges. Strategic partnerships, technological improvements, and capacity expansions continue to reinforce competitiveness, while regional producers focus on niche opportunities to capture market share and strengthen long-term positioning.

Report Coverage

The research report offers an in-depth analysis based on Type, Application, End-User Industry, Physical Form, Processing Method and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Rising healthcare investments will increase demand for medical-grade gloves and protective applications worldwide.

- Manufacturers will focus on sustainable latex formulations to meet tightening global environmental and regulatory standards.

- Expanding automotive and industrial sectors will strengthen adoption of NBR latex in seals and coatings.

- Asia-Pacific will continue dominating production and consumption, supported by cost advantages and strong regional demand.

- North America and Europe will drive adoption through strict hygiene regulations and healthcare infrastructure development.

- Latin America will show growth with expanding hospital networks and rising food processing industry requirements.

- Middle East & Africa will expand usage in oil and gas, construction, and healthcare applications.

- Strategic partnerships and mergers will strengthen global supply chains and improve product accessibility across regions.

- Technological innovation in production will enhance performance, durability, and sustainability of NBR latex-based products.

- E-commerce growth will improve distribution efficiency, driving stronger market penetration for industrial and healthcare products.