Market Overview

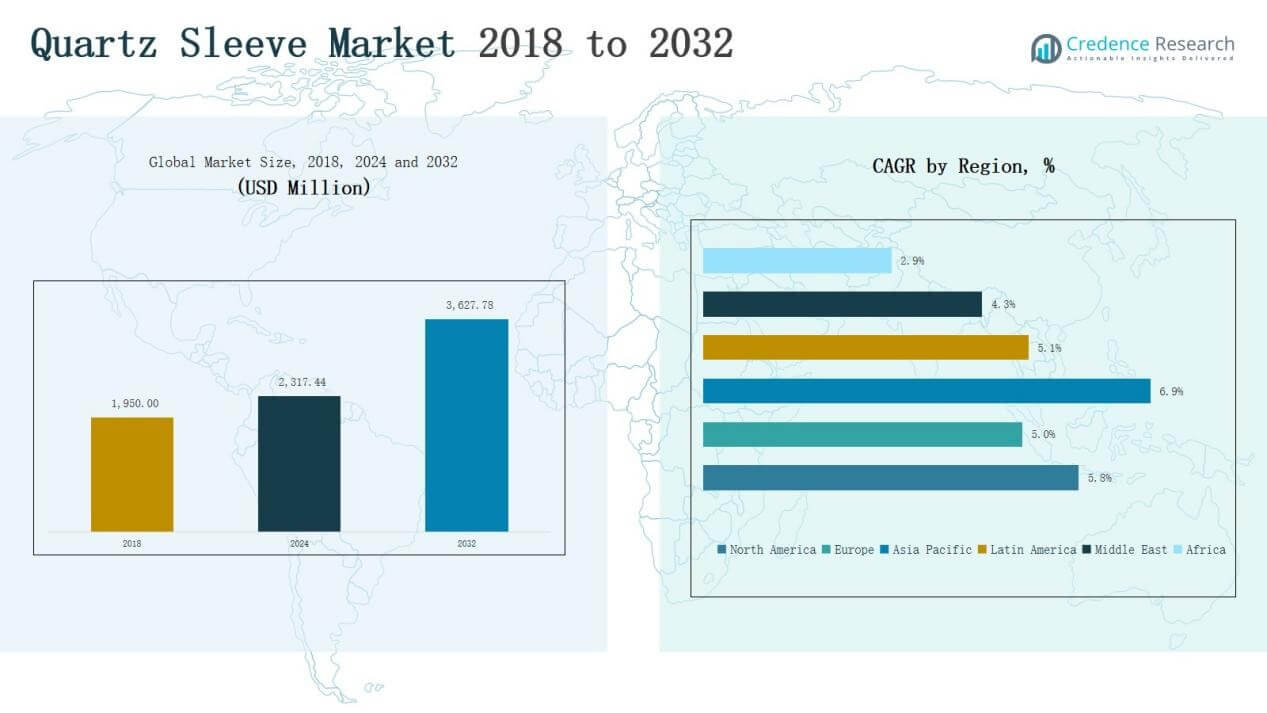

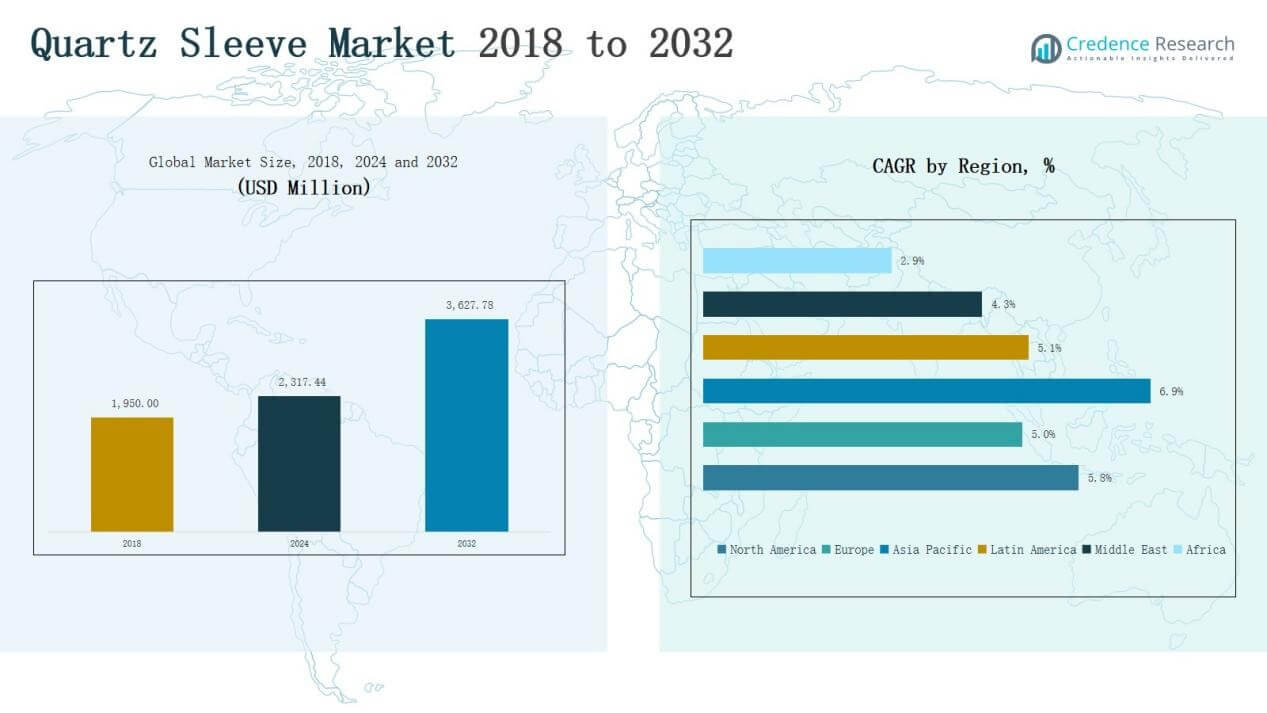

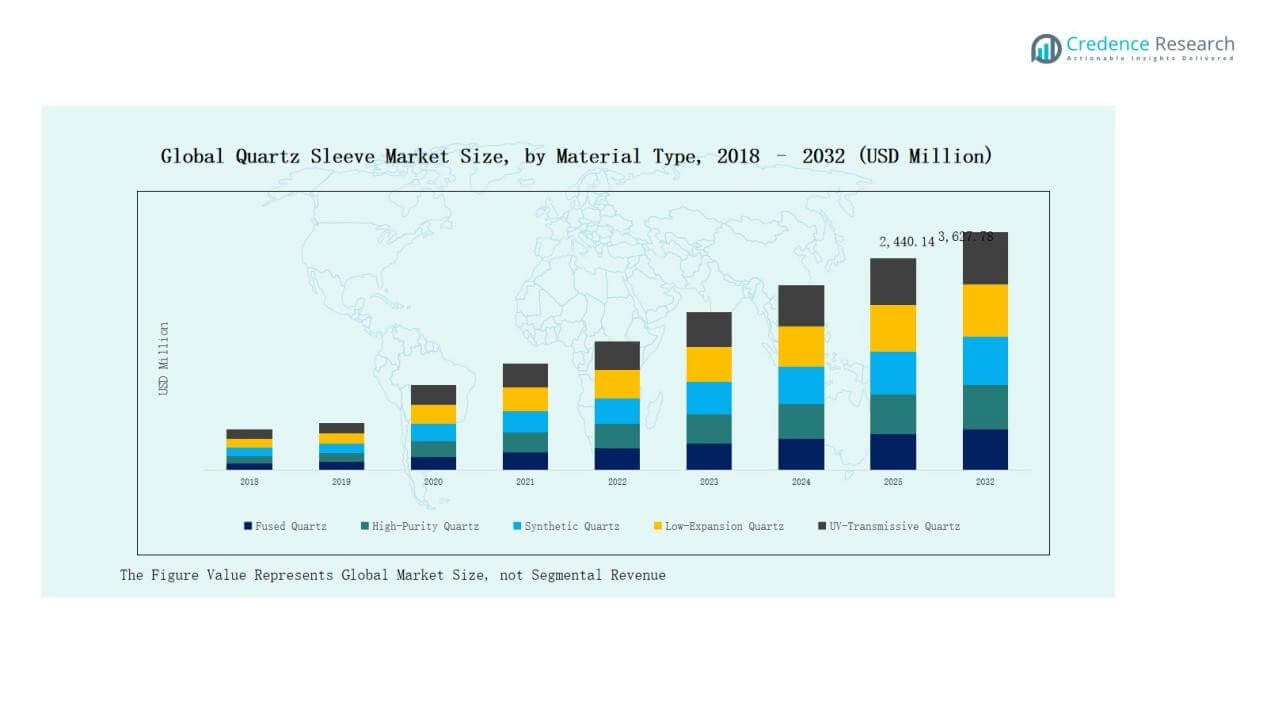

The Quartz Sleeve Market size was valued at USD 1,950.00 million in 2018, reached USD 2,317.44 million in 2024, and is anticipated to reach USD 3,627.78 million by 2032, at a CAGR of 5.83% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Quartz Sleeve Market Size 2024 |

USD 2,317.44 Million |

| Quartz Sleeve Market, CAGR |

5.83% |

| Quartz Sleeve Market Size 2032 |

USD 3,627.78 Million |

The Quartz Sleeve Market is shaped by established players such as Heraeus, Saint-Gobain, Momentive Performance Materials, Quartz Scientific, Tosoh Corporation, Wacker Chemie AG, SGL Carbon, and Savvy Glass, which compete through advanced product quality, material innovation, and strong global supply networks. These companies focus on enhancing UV transmission, durability, and high-purity quartz solutions to serve critical applications in water treatment, semiconductors, and pharmaceuticals. Regionally, North America led the market in 2024 with a 35.4% share, supported by strict sanitation regulations, widespread UV disinfection adoption, and significant investments in municipal water and healthcare infrastructure.

Market Insights

Market Insights

- The Quartz Sleeve Market grew from USD 1,950.00 million in 2018 to USD 2,317.44 million in 2024, and is projected to reach USD 3,627.78 million by 2032 at a 83% CAGR.

- Key players include Heraeus, Saint-Gobain, Momentive Performance Materials, Quartz Scientific, Tosoh Corporation, Wacker Chemie AG, SGL Carbon, and Savvy Glass, focusing on durability, UV transmission, and high-purity solutions.

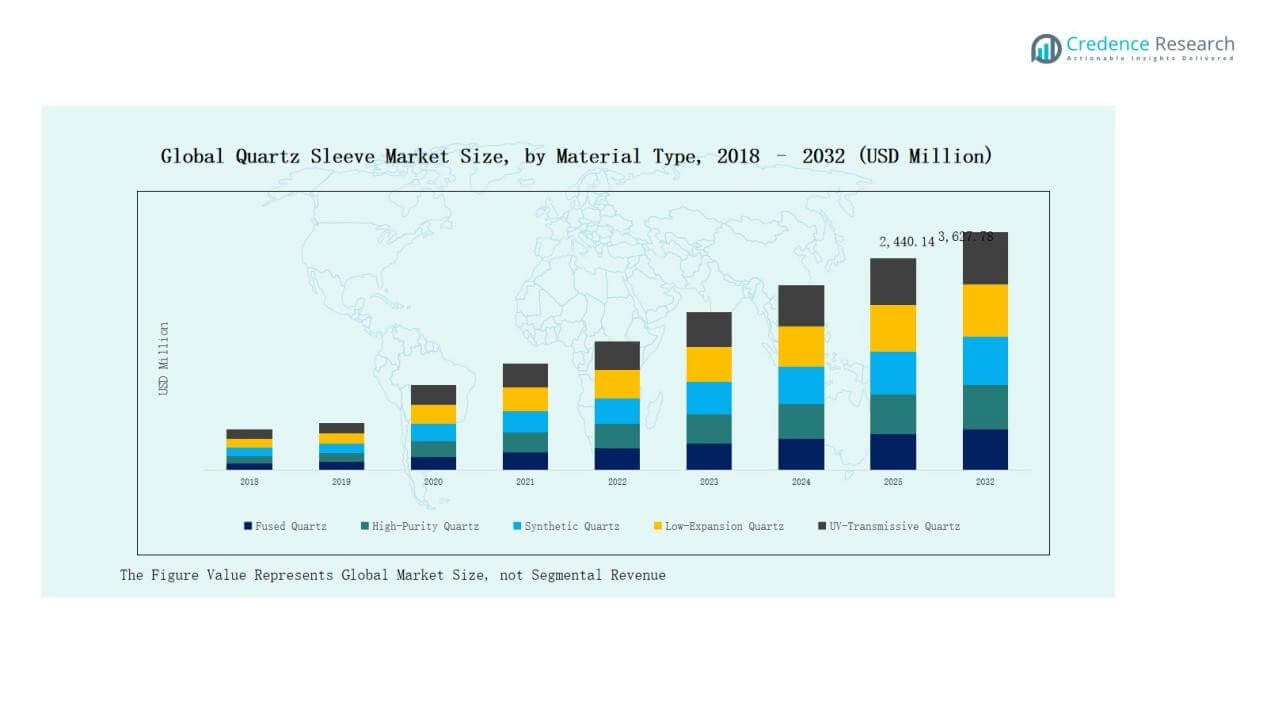

- By material type, fused quartz led with 36% share in 2024, followed by high-purity quartz driven by demand in semiconductors and pharmaceuticals, while synthetic and UV-transmissive quartz show rising adoption.

- By application, UV water disinfection dominated with 42% share in 2024, supported by municipal investments and regulatory standards, while air and surface disinfection gained traction in healthcare and food safety.

- North America led with 35.4% share in 2024, valued at USD 819.43 million, while Europe held 21.5% and Asia Pacific accounted for 25.7%, driven by urbanization and smart infrastructure projects.

Market Segment Insights

By Material Type

Fused quartz held the largest share of the Quartz Sleeve Market in 2024, accounting for 36% of total revenue. Its dominance is driven by exceptional thermal stability, high optical transmission, and chemical resistance, making it the preferred choice for UV disinfection systems. High-purity quartz followed, supported by rising demand in semiconductor and pharmaceutical applications where contamination control is critical. Synthetic and UV-transmissive quartz are steadily gaining traction with advanced lighting technologies, while low-expansion quartz serves niche chemical and industrial processes.

For instance, Heraeus introduced high-purity fused silica sleeves optimized for UV-C LED disinfection systems, targeting water and surface sterilization applications.

By Application

UV water disinfection dominated the Quartz Sleeve Market in 2024 with a 42% share. Strong adoption is fueled by rising concerns over safe drinking water, regulatory mandates, and investments in municipal treatment facilities. UV air disinfection followed, supported by demand in healthcare and commercial spaces for airborne pathogen control. Surface disinfection is expanding with food safety standards, while chemical processing relies on quartz’s durability under corrosive conditions. Other applications, including research and laboratory use, continue to contribute to overall growth.

For instance, Heraeus Noblelight introduced a specialized UV-C surface disinfection unit for packaging lines in the food industry.

By End-User

Water treatment emerged as the leading end-user segment, capturing 38% share of the Quartz Sleeve Market in 2024. Growth is driven by global initiatives for clean water access, urban population expansion, and stricter sanitation regulations. The food and beverage sector follows closely, adopting quartz sleeves for surface and air disinfection to ensure safety and compliance. Pharmaceuticals use quartz in sterile environments, while semiconductor and electronics industries leverage its purity and durability. Oil and gas applications remain niche but show steady adoption.

Key Growth Drivers

Key Growth Drivers

Rising Demand for UV Disinfection Technologies

The Quartz Sleeve Market is driven by increasing adoption of UV disinfection systems for water, air, and surface treatment. Governments and regulatory agencies are mandating stricter sanitation measures, especially in municipal water supply and healthcare facilities. Quartz sleeves enable high UV transmission and durability, making them essential for efficient disinfection. Growing public awareness about safe drinking water and pathogen-free environments has accelerated installations worldwide. This trend is particularly strong in developing economies with rapid urbanization and rising public health concerns.

For instance, Alfaa UV introduced a UV disinfection system using UV-C light at 253.7 nanometers, effectively eliminating viruses and bacteria in municipal and industrial water treatment without chemicals.

Expanding Semiconductor and Electronics Applications

High-purity quartz sleeves play a critical role in semiconductor manufacturing, where contamination-free processing is essential. The rise of advanced electronics, including 5G infrastructure, electric vehicles, and miniaturized consumer devices, is fueling demand for precise, durable materials. Quartz sleeves ensure stability under extreme thermal and chemical conditions, enhancing process reliability. This factor has positioned the segment as a key driver of revenue growth. With ongoing technological advancements, semiconductor manufacturers are increasingly turning to quartz sleeves for process optimization and quality assurance.

For instance, SemiMat, a key supplier in Germany, produces ultra-pure quartz components like rings and process chambers that support epitaxy and plasma etching processes, crucial for semiconductor quality and reliability.

Growing Adoption in Pharmaceutical and Food Industries

Pharmaceutical and food sectors are major contributors to Quartz Sleeve Market expansion. These industries require controlled environments with high sterilization standards, where quartz sleeves ensure effective UV disinfection of surfaces, air, and process water. Rising global demand for safe pharmaceuticals, coupled with stricter FDA and EU standards, has reinforced adoption. In food and beverage, the push for enhanced food safety and reduced chemical use is accelerating uptake. As health-conscious consumers and regulators demand better hygiene, quartz sleeve adoption continues to grow.

Key Trends & Opportunities

Shift Toward High-Purity and UV-Transmissive Quartz

A notable trend in the Quartz Sleeve Market is the rising preference for high-purity and UV-transmissive quartz materials. These variants offer superior UV transmission, thermal stability, and resistance to harsh environments, making them highly suitable for advanced applications. Manufacturers are investing in refining production processes to meet quality demands from electronics, healthcare, and municipal utilities. This shift also creates opportunities for companies to differentiate products by offering higher efficiency quartz sleeves. Demand is expected to surge in industries where contamination-free performance is vital.

For instance, QSIL Netherlands produces quartz sleeves that allow up to 92% UV-C transmission, providing optimal protection and performance for UV lamps used in water purification systems.

Emergence of Smart Water and Air Systems

The integration of quartz sleeves into smart water and air disinfection systems presents new opportunities. IoT-enabled UV systems, used in both industrial and residential applications, rely on quartz sleeves to ensure effective and long-lasting operation. These systems provide real-time monitoring and automation, creating demand for high-performance components. Growth is supported by expanding smart city projects, rising investment in sustainable infrastructure, and consumer interest in connected devices. Quartz sleeve manufacturers are positioned to benefit by aligning product development with these technological advancements.

For instance, Lancaster Pump’s 7-Q10 UV quartz sleeve is designed to keep UV lamps dry and protected from impurities. Its function is to allow UV-C light to pass into the water while preventing minerals and other contaminants from coating the UV lamp, thereby ensuring optimal performance and component reliability in UV systems.

Key Challenges

High Production and Material Costs

One of the major challenges in the Quartz Sleeve Market is the high cost of production. Manufacturing requires advanced processing and high-purity raw quartz, which increases expenses. Energy-intensive refining and shaping processes further raise costs, making final products expensive compared to substitutes. For smaller customers, this cost factor limits adoption, especially in price-sensitive regions. Manufacturers face continuous pressure to optimize processes, reduce energy consumption, and source materials sustainably, without compromising quality. Balancing cost efficiency with performance remains a persistent challenge.

Competition from Substitute Materials

The market faces competition from alternative materials like borosilicate glass and other engineered composites that can serve in lower-end disinfection applications. While quartz offers superior UV transmission and durability, substitutes are often more cost-effective for basic needs. This creates challenges in maintaining market share, particularly in emerging economies where price sensitivity is high. Continuous innovation and highlighting quartz’s long-term reliability and efficiency are critical for retaining dominance. Without clear differentiation, quartz sleeves risk being displaced in certain low-end market segments.

Supply Chain Vulnerabilities

Quartz sleeve production is highly dependent on consistent access to high-quality raw materials. Disruptions in mining, refining, or transportation of quartz can significantly affect supply availability and pricing. Recent global events have highlighted vulnerabilities in raw material supply chains, impacting delivery schedules and cost structures. This challenge is compounded by regional concentration of quartz sources, leaving manufacturers exposed to geopolitical risks and export restrictions. Diversifying supply networks and building local processing capabilities are key strategies to mitigate these vulnerabilities.

Regional Analysis

North America

The North America Quartz Sleeve Market was valued at USD 698.10 million in 2018, reached USD 819.43 million in 2024, and is anticipated to reach USD 1,280.97 million by 2032, registering a CAGR of 5.70%. The region accounted for 35.4% of the global market in 2024, driven by strong adoption of UV disinfection systems across municipal water treatment, healthcare, and food industries. The U.S. dominated within the region, contributing USD 687.51 million in 2024, supported by regulatory mandates and high infrastructure investments in water and air purification technologies.

Europe

Europe held a significant share of the Quartz Sleeve Market, valued at USD 440.31 million in 2018, increasing to USD 499.58 million in 2024, and projected to reach USD 731.19 million by 2032, at a CAGR of 4.85%. The region represented 21.5% of global revenue in 2024, supported by stringent EU water quality directives and rapid uptake in pharmaceutical and food safety sectors. Germany led with USD 119.20 million in 2024, holding the largest country share, followed by the UK and France, highlighting advanced adoption of UV-based disinfection technologies.

Asia Pacific

Japan and Australia reflect the rising role of Asia Pacific in the Quartz Sleeve Market. Japan reached USD 109.50 million in 2018, USD 118.41 million in 2024, and is set to achieve USD 186.88 million by 2032, at a CAGR of 5.72%. Australia followed with USD 32.88 million in 2018, USD 37.81 million in 2024, and an expected USD 62.48 million by 2032, growing at 6.39% CAGR. Together, Asia Pacific accounted for nearly 25.7% share in 2024, driven by rapid urbanization, smart water infrastructure projects, and the expansion of semiconductor manufacturing in Japan and neighboring economies.

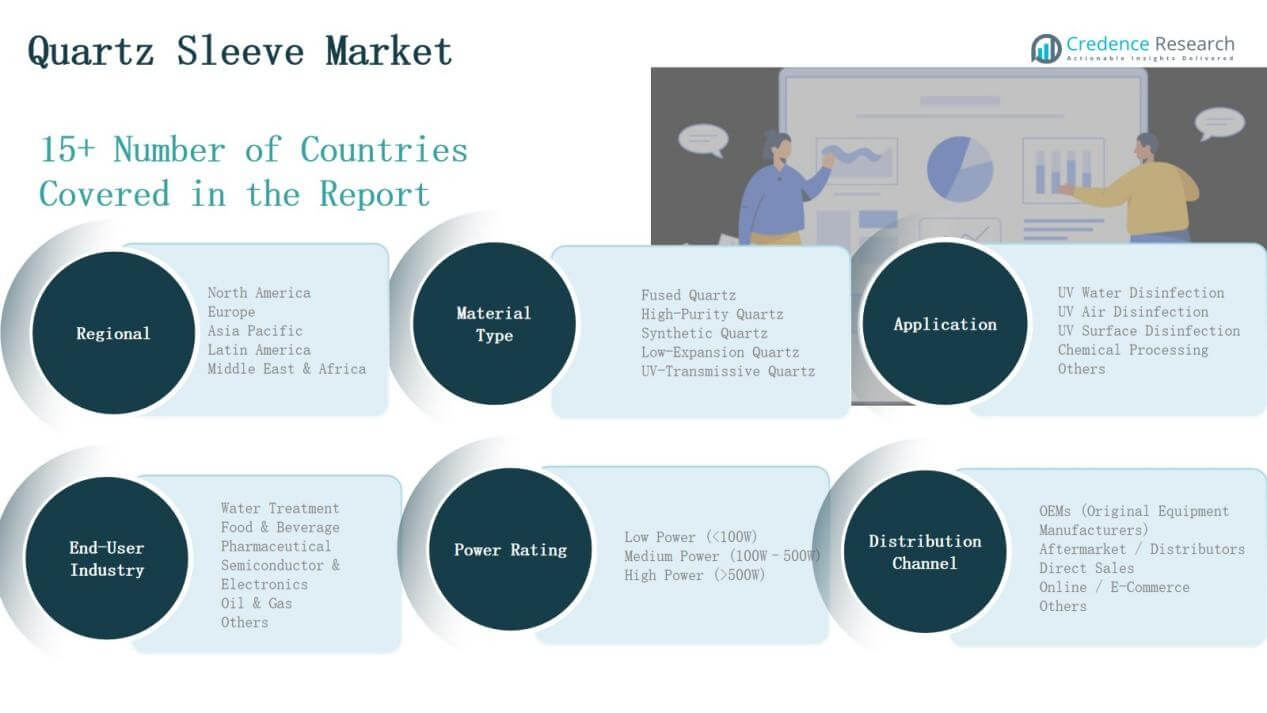

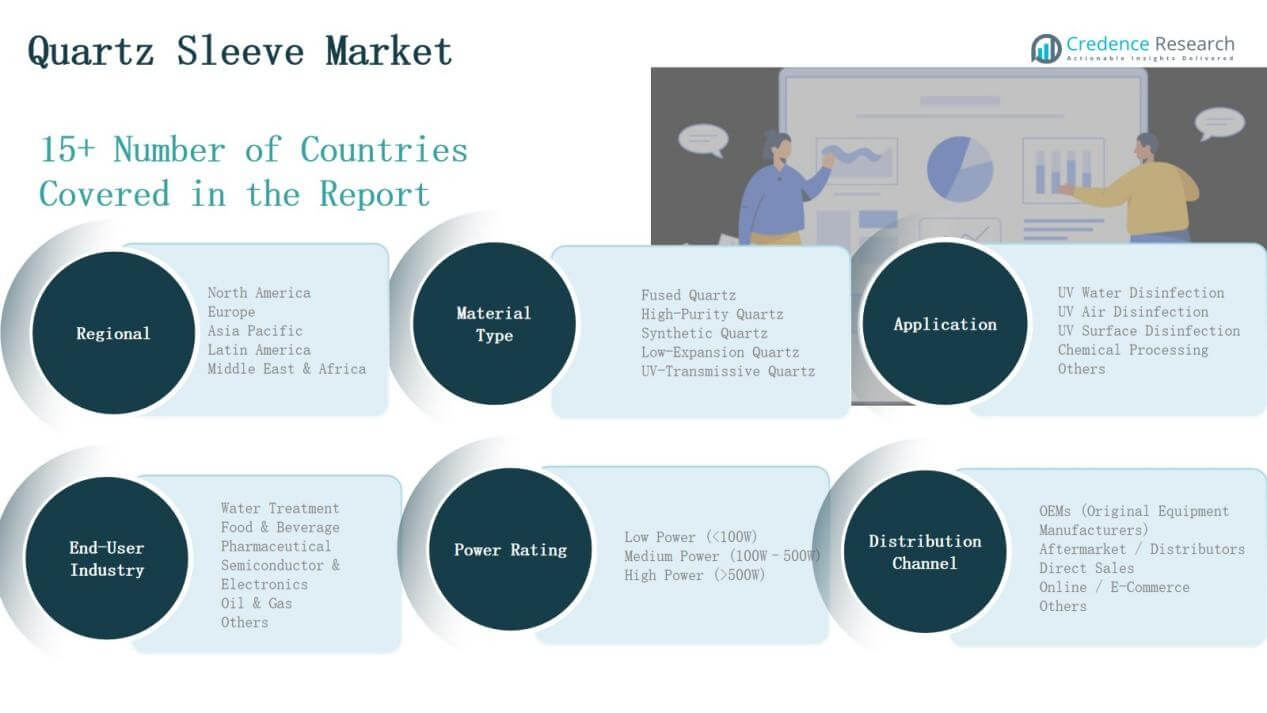

Market Segmentations:

Market Segmentations:

By Material Type

- Fused Quartz

- High-Purity Quartz

- Synthetic Quartz

- Low-Expansion Quartz

- UV-Transmissive Quartz

By Application

- UV Water Disinfection

- UV Air Disinfection

- UV Surface Disinfection

- Chemical Processing

- Others

By End-User

- Water Treatment

- Food & Beverage

- Pharmaceutical

- Semiconductor & Electronics

- Oil & Gas

- Others

By Power Rating

- Low Power (<100W)

- Medium Power (100W–500W)

- High Power (>500W)

By Distribution Channel

- OEMs (Original Equipment Manufacturers)

- Aftermarket / Distributors

- Direct Sales

- Online / E-Commerce

- Others

By Region

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Competitive Landscape

The Quartz Sleeve Market is moderately consolidated, with global and regional players competing on product quality, material purity, and application-specific performance. Leading companies such as Heraeus, Saint-Gobain, Momentive Performance Materials, Quartz Scientific, and Tosoh Corporation dominate through strong product portfolios, advanced manufacturing capabilities, and established supply networks. These firms invest heavily in R&D to enhance UV transmittance, durability, and chemical resistance, catering to critical sectors like water treatment, pharmaceuticals, and semiconductors. Regional players including Herbert Schneider GmbH, Savvy Glass, and Maxsil strengthen competition by offering cost-effective solutions and customized products for niche markets. Strategic partnerships with OEMs, distributors, and end-user industries are common, helping players expand market reach. Rising demand for UV-based disinfection in healthcare and municipal sectors has also spurred capacity expansions and product innovations. Competitive intensity is further shaped by price sensitivity in emerging economies, supply chain resilience for high-purity quartz, and differentiation through sustainability-focused production practices.

Key Players

- Heraeus

- Quartz Scientific, Inc.

- Saint-Gobain

- Momentive Performance Materials

- Herbert Schneider GmbH

- Savvy Glass

- Tosoh Corporation

- KBTW

- Vesuvius

- Maxsil

- Koufu

- Mondi Group

- SGL Carbon

- Wacker Chemie AG

- QSI Quartz

Recent Developments

- In December 2024, Mitsubishi Chemical Group announced plans to upgrade production capacity of its Mitsubishi Synthetic Silica at the Kyushu-Fukuoka Plant. This high-purity synthetic silica is used in semiconductor manufacturing, especially for quartz crucibles and components in semiconductor equipment.

- In October 2023, Classic Marble Company, an Indian-based company, launched the KalingaStone Quartz product line comprising seven white quartz variations designed for strength, hygiene, and resistance to stains and wear.

- In 2025, Haitian Group completed the acquisition of Heraeus’s photovoltaics business units in Shanghai and Singapore for approximately €66 million.

Report Coverage

The research report offers an in-depth analysis based on Material Type, Application, End-User and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand for UV disinfection systems will continue to expand across municipal and industrial sectors.

- High-purity and UV-transmissive quartz sleeves will gain wider adoption in advanced applications.

- Semiconductor and electronics industries will increase reliance on quartz sleeves for contamination-free processing.

- Food and pharmaceutical sectors will drive stronger uptake due to stricter hygiene regulations.

- Smart water and air purification systems will create new opportunities for quartz sleeve integration.

- Manufacturers will invest in sustainable production methods to address environmental concerns.

- Regional supply chain diversification will reduce risks from raw material shortages.

- Partnerships with OEMs and distributors will strengthen global market penetration.

- Price-sensitive regions will encourage innovation in cost-efficient quartz sleeve solutions.

- Growing R&D in material science will enhance performance and expand new application areas.

Market Insights

Market Insights Key Growth Drivers

Key Growth Drivers Market Segmentations:

Market Segmentations: