CHAPTER NO. 1 : INTRODUCTION 19

1.1.1. Report Description 19

Purpose of the Report 19

USP & Key Offerings 19

1.1.2. Key Benefits for Stakeholders 19

1.1.3. Target Audience 20

1.1.4. Report Scope 20

CHAPTER NO. 2 : EXECUTIVE SUMMARY 21

2.1. Industrial Catalyst Market Snapshot 21

2.1.1. South Africa Industrial Catalyst Market, 2018 – 2032 (USD Million) 22

CHAPTER NO. 3 : GEOPOLITICAL CRISIS IMPACT ANALYSIS 23

3.1. Russia-Ukraine and Israel-Palestine War Impacts 23

CHAPTER NO. 4 : INDUSTRIAL CATALYST MARKET – INDUSTRY ANALYSIS 24

4.1. Introduction 24

4.2. Market Drivers 25

4.2.1. Increasing demand for cleaner and sustainable industrial processes 25

4.2.2. Growth in the chemical and petrochemical industries 26

4.3. Market Restraints 27

4.3.1. High costs associated with catalyst production and recycling 27

4.4. Market Opportunities 28

4.4.1. Rising focus on green chemistry and eco-friendly catalytic solutions 28

4.5. Porter’s Five Forces Analysis 29

4.6. Buying Criteria 30

CHAPTER NO. 5 : IMPORT EXPORT ANALYSIS 31

5.1. Import Analysis by South Africa 31

5.1.1. South Africa Industrial Catalyst Market Import Volume/Revenue, By South Africa, 2018 – 2023 31

5.2. Export Analysis by South Africa 32

5.2.1. South Africa Industrial Catalyst Market Export Volume/Revenue, By South Africa, 2018 – 2023 32

CHAPTER NO. 6 : DEMAND SUPPLY ANALYSIS 33

6.1. Demand Analysis by South Africa 33

6.1.1. South Africa Industrial Catalyst Market Demand Volume/Revenue, By South Africa, 2018 – 2023 33

6.2. Supply Analysis by South Africa 34

6.2.1. South Africa Industrial Catalyst Market Supply Volume/Revenue, By South Africa, 2018 – 2023 34

CHAPTER NO. 7 : PRODUCTION ANALYSIS 35

7.1. Production Analysis by South Africa 35

7.1.1. South Africa Industrial Catalyst Market Production Volume/Revenue, By South Africa, 2018 – 2023 35

CHAPTER NO. 8 : PRICE ANALYSIS 36

8.1. Price Analysis by Type 36

8.1.1. South Africa Industrial Catalyst Market Price, By Type, 2018 – 2023 36

8.1.2. South Africa Type Market Price, By Type, 2018 – 2023 36

CHAPTER NO. 9 : RAW MATERIALS ANALYSIS 37

9.1. Key Raw Materials and Suppliers 37

9.2. Key Raw Materials Price Trend 37

CHAPTER NO. 10 : MANUFACTURING COST ANALYSIS 38

10.1. Manufacturing Cost Analysis 38

10.2. Manufacturing Process 38

CHAPTER NO. 11 : ANALYSIS COMPETITIVE LANDSCAPE 39

11.1. Company Market Share Analysis – 2023 39

11.2. Value Chain Analysis 39

11.2.1. South Africa Industrial Catalyst Market: Company Market Share, by Volume, 2023 40

11.2.2. South Africa Industrial Catalyst Market: Company Market Share, by Revenue, 2023 41

11.2.3. South Africa Industrial Catalyst Market: Top 6 Company Market Share, by Revenue, 2023 41

11.2.4. South Africa Industrial Catalyst Market: Top 3 Company Market Share, by Revenue, 2023 42

11.3. South Africa Industrial Catalyst Market Company Volume Market Share, 2023 43

11.4. South Africa Industrial Catalyst Market Company Revenue Market Share, 2023 44

11.5. Company Assessment Metrics, 2023 44

11.5.1. Stars 44

11.5.2. Emerging Leaders 44

11.5.3. Pervasive Players 44

11.5.4. Participants 44

11.6. Start-ups /SMEs Assessment Metrics, 2023 44

11.6.1. Progressive Companies 44

11.6.2. Responsive Companies 44

11.6.3. Dynamic Companies 44

11.6.4. Starting Blocks 45

11.7. Strategic Developments 46

11.7.1. Acquisitions & Mergers 46

New Product Launch 46

South Africa Expansion 46

11.8. Key Players Product Matrix 47

CHAPTER NO. 12 : PESTEL & ADJACENT MARKET ANALYSIS 48

12.1. PESTEL 48

12.1.1. Political Factors 48

12.1.2. Economic Factors 48

12.1.3. Social Factors 48

12.1.4. Technological Factors 48

12.1.5. Environmental Factors 48

12.1.6. Legal Factors 48

12.2. Adjacent Market Analysis 48

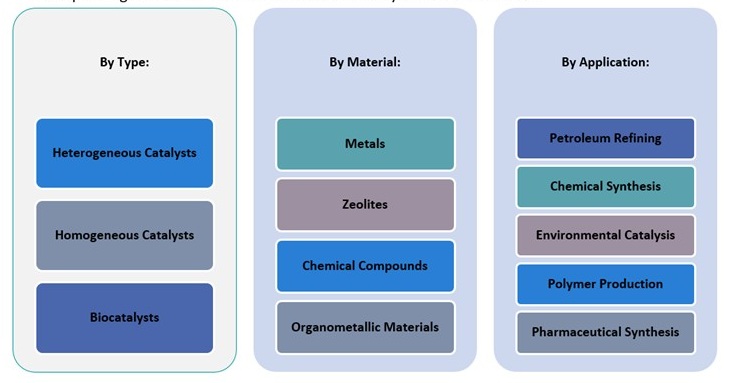

CHAPTER NO. 13 : INDUSTRIAL CATALYST MARKET – BY TYPE SEGMENT ANALYSIS 49

13.1. Industrial Catalyst Market Overview, by Type Segment 49

13.1.1. Industrial Catalyst Market Revenue Share, By Type, 2023 & 2032 50

13.1.2. Industrial Catalyst Market Attractiveness Analysis, By Type 51

13.1.3. Incremental Revenue Growth Opportunity, by Type, 2024 – 2032 51

13.1.4. Industrial Catalyst Market Revenue, By Type, 2018, 2023, 2027 & 2032 52

13.2. Heterogeneous Catalysts 53

13.3. Homogeneous Catalysts 54

13.4. Biocatalysts 55

CHAPTER NO. 14 : INDUSTRIAL CATALYST MARKET – BY APPLICATION SEGMENT ANALYSIS 56

14.1. Industrial Catalyst Market Overview, by Application Segment 56

14.1.1. Industrial Catalyst Market Revenue Share, By Application, 2023 & 2032 57

14.1.2. Industrial Catalyst Market Attractiveness Analysis, By Application 58

14.1.3. Incremental Revenue Growth Opportunity, by Application, 2024 – 2032 58

14.1.4. Industrial Catalyst Market Revenue, By Application, 2018, 2023, 2027 & 2032 59

14.2. Petroleum Refining 60

14.3. Chemical Synthesis 61

14.4. Environmental Catalysis 62

14.5. Polymer Production 63

14.6. Pharmaceutical Synthesis 64

CHAPTER NO. 15 : INDUSTRIAL CATALYST MARKET – BY MATERIAL SEGMENT ANALYSIS 65

15.1. Industrial Catalyst Market Overview, by Material Segment 65

15.1.1. Industrial Catalyst Market Revenue Share, By Material, 2023 & 2032 66

15.1.2. Industrial Catalyst Market Attractiveness Analysis, By Material 67

15.1.3. Incremental Revenue Growth Opportunity, by Material, 2024 – 2032 67

15.1.4. Industrial Catalyst Market Revenue, By Material, 2018, 2023, 2027 & 2032 68

15.2. Metals 69

15.3. Zeolites 70

15.4. Chemical Compounds 71

15.5. Organometallic Materials 72

CHAPTER NO. 16 : INDUSTRIAL CATALYST MARKET – SOUTH AFRICA ANALYSIS 73

16.1. Type 73

16.1.1. South Africa Industrial Catalyst Market Revenue, By Type, 2018 – 2023 (USD Million) 73

16.2. South Africa Industrial Catalyst Market Revenue, By Type, 2024 – 2032 (USD Million) 73

16.3. Application 74

16.3.1. South Africa Industrial Catalyst Market Revenue, By Application, 2018 – 2023 (USD Million) 74

16.3.2. South Africa Industrial Catalyst Market Revenue, By Application, 2024 – 2032 (USD Million) 74

16.4. Material 75

16.4.1. South Africa Industrial Catalyst Market Revenue, By Material, 2018 – 2023 (USD Million) 75

16.4.2. South Africa Industrial Catalyst Market Revenue, By Material, 2024 – 2032 (USD Million) 75

CHAPTER NO. 17 : COMPANY PROFILES 76

17.1.1. Company Overview 76

17.1.2. Product Portfolio 76

17.1.3. Swot Analysis 76

17.1.4. Business Strategy 77

17.1.5. Financial Overview 77

17.2. Arkema Group (Regional operations) 78

17.3. Johnson Matthey (Regional operations) 78

17.4. BASF SE (Regional operations) 78

17.5. Haldor Topsoe A/S (Regional operations) 78

17.6. Qatar Petroleum 78

17.7. Evonik Industries AG (Regional operations) 78

17.8. PetroSA 78

17.9. Dow Inc. (Regional operations) 78

17.10. Chevron Phillips Chemical Company (Regional operations) 78

List of Figures

FIG NO. 1. South Africa Industrial Catalyst Market Revenue, 2018 – 2032 (USD Million) 22

FIG NO. 2. Porter’s Five Forces Analysis for South Africa Industrial Catalyst Market 29

FIG NO. 3. South Africa Industrial Catalyst Market Import Volume/Revenue, By South Africa, 2018 – 2023 31

FIG NO. 4. South Africa Industrial Catalyst Market Export Volume/Revenue, By South Africa, 2018 – 2023 32

FIG NO. 5. South Africa Industrial Catalyst Market Demand Volume/Revenue, By South Africa, 2018 – 2023 33

FIG NO. 6. South Africa Industrial Catalyst Market Supply Volume/Revenue, By South Africa, 2018 – 2023 34

FIG NO. 7. South Africa Industrial Catalyst Market Production Volume/Revenue, By South Africa, 2018 – 2023 35

FIG NO. 8. South Africa Industrial Catalyst Market Price, By Type, 2018 – 2023 36

FIG NO. 9. Raw Materials Price Trend Analysis, 2018 – 2023 37

FIG NO. 10. Manufacturing Cost Analysis 38

FIG NO. 11. Manufacturing Process 38

FIG NO. 12. Value Chain Analysis for South Africa Industrial Catalyst Market 39

FIG NO. 13. Company Share Analysis, 2023 40

FIG NO. 14. Company Share Analysis, 2023 41

FIG NO. 15. Company Share Analysis, 2023 41

FIG NO. 16. Company Share Analysis, 2023 42

FIG NO. 17. Industrial Catalyst Market – Company Volume Market Share, 2023 43

FIG NO. 18. Industrial Catalyst Market – Company Revenue Market Share, 2023 44

FIG NO. 19. Industrial Catalyst Market Revenue Share, By Type, 2023 & 2032 50

FIG NO. 20. Market Attractiveness Analysis, By Type 51

FIG NO. 21. Incremental Revenue Growth Opportunity by Type, 2024 – 2032 51

FIG NO. 22. Industrial Catalyst Market Revenue, By Type, 2018, 2023, 2027 & 2032 52

FIG NO. 23. South Africa Industrial Catalyst Market for Heterogeneous Catalysts, Revenue (USD Million) 2018 – 2032 53

FIG NO. 24. South Africa Industrial Catalyst Market for Homogeneous Catalysts, Revenue (USD Million) 2018 – 2032 54

FIG NO. 25. South Africa Industrial Catalyst Market for Biocatalysts, Revenue (USD Million) 2018 – 2032 55

FIG NO. 26. Industrial Catalyst Market Revenue Share, By Application, 2023 & 2032 57

FIG NO. 27. Market Attractiveness Analysis, By Application 58

FIG NO. 28. Incremental Revenue Growth Opportunity by Application, 2024 – 2032 58

FIG NO. 29. Industrial Catalyst Market Revenue, By Application, 2018, 2023, 2027 & 2032 59

FIG NO. 30. South Africa Industrial Catalyst Market for Petroleum Refining, Revenue (USD Million) 2018 – 2032 60

FIG NO. 31. South Africa Industrial Catalyst Market for Chemical Synthesis, Revenue (USD Million) 2018 – 2032 61

FIG NO. 32. South Africa Industrial Catalyst Market for Environmental Catalysis, Revenue (USD Million) 2018 – 2032 62

FIG NO. 33. South Africa Industrial Catalyst Market for Polymer Production, Revenue (USD Million) 2018 – 2032 63

FIG NO. 34. South Africa Industrial Catalyst Market for Pharmaceutical Synthesis, Revenue (USD Million) 2018 – 2032 64

FIG NO. 35. Industrial Catalyst Market Revenue Share, By Material, 2023 & 2032 66

FIG NO. 36. Market Attractiveness Analysis, By Material 67

FIG NO. 37. Incremental Revenue Growth Opportunity by Material, 2024 – 2032 67

FIG NO. 38. Industrial Catalyst Market Revenue, By Material, 2018, 2023, 2027 & 2032 68

FIG NO. 39. South Africa Industrial Catalyst Market for Metals, Revenue (USD Million) 2018 – 2032 69

FIG NO. 40. South Africa Industrial Catalyst Market for Zeolites, Revenue (USD Million) 2018 – 2032 70

FIG NO. 41. South Africa Industrial Catalyst Market for Chemical Compounds, Revenue (USD Million) 2018 – 2032 71

FIG NO. 42. South Africa Industrial Catalyst Market for Organometallic Materials, Revenue (USD Million) 2018 – 2032 72

List of Tables

TABLE NO. 1. : South Africa Industrial Catalyst Market: Snapshot 21

TABLE NO. 2. : Drivers for the Industrial Catalyst Market: Impact Analysis 25

TABLE NO. 3. : Restraints for the Industrial Catalyst Market: Impact Analysis 27

TABLE NO. 4. : South Africa Industrial Catalyst Market Revenue, By Type, 2018 – 2023 36

TABLE NO. 5. : Key Raw Materials & Suppliers 37

TABLE NO. 6. : South Africa Industrial Catalyst Market Revenue, By Type, 2018 – 2023 (USD Million) 73

TABLE NO. 7. : South Africa Industrial Catalyst Market Revenue, By Type, 2024 – 2032 (USD Million) 73

TABLE NO. 8. : South Africa Industrial Catalyst Market Revenue, By Application, 2018 – 2023 (USD Million) 74

TABLE NO. 9. : South Africa Industrial Catalyst Market Revenue, By Application, 2024 – 2032 (USD Million) 74

TABLE NO. 10. : South Africa Industrial Catalyst Market Revenue, By Material, 2018 – 2023 (USD Million) 75

TABLE NO. 11. : South Africa Industrial Catalyst Market Revenue, By Material, 2024 – 2032 (USD Million) 75