Market Overview:

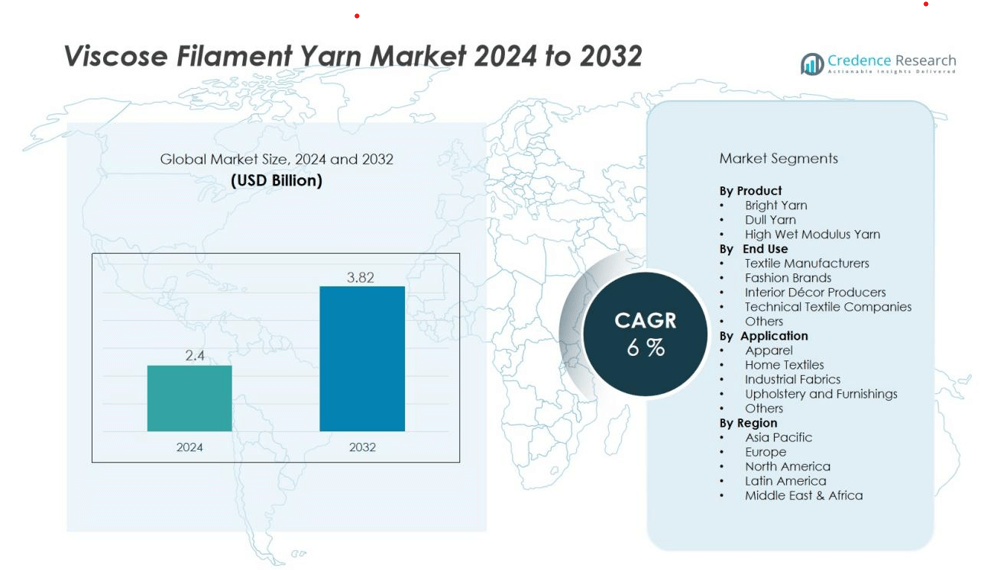

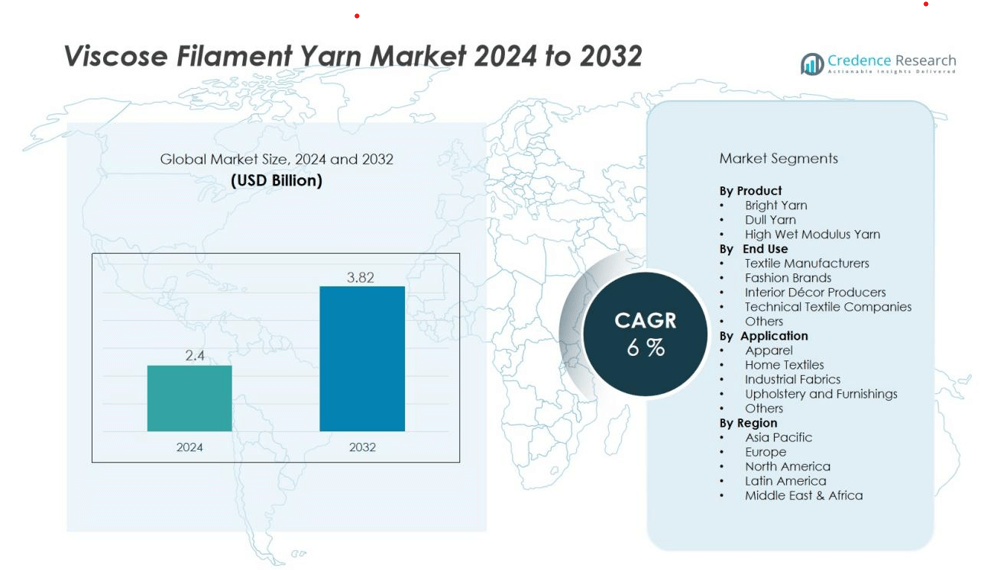

The Viscose Filament Yarn Market size was valued at USD 2.4 billion in 2024 and is anticipated to reach USD 3.82 billion by 2032, at a CAGR of 6 % during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Viscose Filament Yarn Market Size 2024 |

USD 2.4 billion |

| Viscose Filament Yarn Market, CAGR |

6% |

| Viscose Filament Yarn Market Size 2032 |

USD 3.82 billion |

The market is primarily driven by rising demand for sustainable, cellulosic-based yarns that offer silk-like drape and comfort in apparel and home textiles. Growth in global textile production—particularly in emerging economies—and a shift toward eco-friendly materials fuel demand for viscose filament yarn. Price volatility and raw material supply remain challenges, but the core driver remains the push for performance and sustainability in fabrics.

From a regional standpoint, the Asia-Pacific region dominates production and consumption, led by major manufacturing hubs in China and India. Europe and North America follow, with moderate expansion driven by eco-conscious consumer trends. Meanwhile, Latin America and the Middle East & Africa present smaller but growing segments as textile and apparel industries gain strength in those regions.

Market Insights:

- The Viscose Filament Yarn Market was valued at USD 1.72 billion in 2018, reached USD 2.4 billion in 2024, and is projected to hit USD 3.82 billion by 2032, registering a CAGR of 6% during 2024–2032.

- Asia-Pacific leads with 64% share, driven by large-scale textile manufacturing in China and India, strong export networks, and government support for sustainable fiber production.

- Europe holds 18% share, sustained by strict environmental policies and growing adoption of eco-certified viscose in luxury fashion and home décor applications.

- North America accounts for 10% share and remains the fastest-growing developed region due to rising demand for technical and performance-grade viscose fabrics in automotive and apparel sectors.

- By product, bright yarn dominates with 42% share due to its lustrous finish and versatility, while the apparel segment holds 53% share, supported by expanding fashion and home textile industries worldwide.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for Sustainable and Biodegradable Textiles

The global shift toward eco-friendly materials drives strong demand for viscose filament yarn. It offers biodegradability, softness, and breathability that align with sustainability goals in apparel and home furnishing industries. Fashion brands increasingly replace synthetic fibers with viscose to meet environmental regulations and consumer expectations. The growing preference for renewable cellulose-based fibers enhances the material’s adoption across high-end and everyday textile applications. The Viscose Filament Yarn Market benefits from the rising awareness of sustainable fiber alternatives.

- For instance, the Lenzing Group reached a cumulative milestone of producing over 300,000 tons of LENZING™ ECOVERO™ branded viscose fibers since the brand’s launch in 2017.

Expansion of the Apparel and Home Textile Industries

Rapid urbanization and higher disposable incomes stimulate demand for premium apparel and interior décor products. The fashion and home furnishing sectors rely on viscose yarn for its lustrous appearance and silk-like texture. It supports a wide range of uses including dresses, upholstery fabrics, curtains, and carpets. Continuous product innovation in lightweight, durable, and cost-effective viscose blends also widens its market reach. Strong consumer focus on comfort and style reinforces industry growth worldwide.

- For Instance, Lenzing AG, its LENZING™ ECOVERO™ viscose fibers were adopted by over 500 textile brands globally by late 2022.

Technological Advancements in Fiber Production Processes

Manufacturers continue investing in advanced spinning and chemical treatment technologies to improve yarn strength and dye uptake. Automation and digital control in production enhance uniformity and minimize waste. It enables large-scale, cost-efficient manufacturing while maintaining fiber quality. Cleaner production technologies also reduce water and chemical consumption, addressing sustainability concerns. These innovations strengthen the competitive edge of producers within the Viscose Filament Yarn Market.

Growing Investment in Textile Infrastructure and Supply Chain Integration

Governments and private firms invest heavily in textile parks and production facilities to boost domestic manufacturing. Vertical integration of spinning, weaving, and dyeing operations helps control costs and improve quality. It supports consistent supply for fast-growing fashion and retail industries. Partnerships among fiber producers and textile brands enhance market visibility and product innovation. Strong infrastructure development ensures stable long-term growth across emerging economies.

Market Trends:

Shift Toward Eco-Friendly and Regenerated Fiber Blends

The textile industry is steadily shifting toward biodegradable and renewable fibers, creating a strong trend in favor of viscose filament yarn. It serves as a sustainable substitute for polyester and nylon in fashion, upholstery, and interior fabrics. Manufacturers are introducing blends of viscose with cotton, linen, and recycled polyester to improve strength and texture. These combinations enhance breathability, color retention, and durability while aligning with circular economy principles. The rising consumer focus on ethically sourced fibers reinforces this trend. The Viscose Filament Yarn Market continues to benefit from sustainability certifications and global commitments to reduce textile waste.

- For instance, Grasim Industries’ Raysil viscose brand operates with a production capacity of 48,000 TPA from state-of-the-art manufacturing facilities, and holds Forest Stewardship Council (FSC) Chain of Custody certification as India’s first VFY manufacturer to achieve this distinction, ensuring 100% natural, biodegradable yarns sourced from responsibly managed forests.

Innovation in High-Performance and Functional Yarn Applications

Manufacturers are developing high-tenacity and moisture-resistant viscose filament yarns for technical and performance textiles. It supports applications in activewear, medical fabrics, and automotive interiors that require softness and strength. Advancements in spinning and finishing technologies enable better uniformity, dyeability, and tactile comfort. Brands increasingly demand multifunctional fibers that combine style and performance, expanding the product’s use beyond traditional apparel. Investments in R&D focus on flame-retardant, antibacterial, and temperature-regulating yarn variants. This innovation-driven environment strengthens product differentiation and enhances the global competitiveness of the Viscose Filament Yarn Market.

- For Instance, Aditya Birla Group produces high-tenacity viscose filament yarn (HTVF) with a typical conditioned tenacity ranging from approximately 22 to 25 cN/tex

Market Challenges Analysis:

Fluctuating Raw Material Prices and Environmental Regulations

Volatile pulp prices and strict environmental regulations pose significant challenges for viscose filament yarn manufacturers. It depends heavily on wood-based cellulose, making producers vulnerable to changes in raw material availability and forestry regulations. Rising costs of chemicals used in fiber processing further strain profit margins. Environmental compliance related to wastewater discharge and emissions increases operational expenses for producers. The Viscose Filament Yarn Market faces ongoing pressure to balance production efficiency with sustainability goals.

Competition from Synthetic and Alternative Cellulosic Fibers

The presence of low-cost synthetic fibers such as polyester and nylon continues to restrict market expansion. It competes with new-generation cellulosic fibers like lyocell and modal that offer superior strength and eco-performance. Price-sensitive customers often prefer synthetics due to their durability and ease of maintenance. Manufacturers struggle to maintain competitive pricing while ensuring fiber quality. Limited consumer awareness of viscose’s environmental benefits also slows substitution rates. The Viscose Filament Yarn Market must innovate and promote performance advantages to strengthen its position against these alternatives.

Market Opportunities:

Expansion in Sustainable Fashion and Eco-Certified Product Lines

Growing demand for sustainable clothing opens strong opportunities for viscose filament yarn producers. Fashion brands seek biodegradable fibers to meet environmental standards and consumer expectations. It aligns well with eco-label programs such as OEKO-TEX and FSC certifications, enhancing its appeal in premium apparel lines. Investments in greener production technologies can help manufacturers capture larger shares in the sustainable textile segment. Rising global awareness about microplastic pollution supports greater use of natural-based fibers. The Viscose Filament Yarn Market gains traction as brands emphasize transparency and sustainability in supply chains.

Emerging Demand from Technical and Industrial Applications

Industrial sectors present new avenues for viscose filament yarn in filtration fabrics, tire cords, and medical textiles. It offers strength, absorbency, and chemical resistance suitable for technical uses. Growth in healthcare, automotive, and construction industries creates long-term potential for functional viscose variants. Manufacturers can develop specialized products such as flame-retardant or high-tenacity yarns to target these sectors. Expanding end-use diversity helps reduce dependency on the apparel market. The Viscose Filament Yarn Market benefits from this shift toward performance-driven and application-specific innovation.

Market Segmentation Analysis:

By Product

The market is segmented into bright, dull, and high wet modulus yarns. Bright yarn holds the largest share due to its luster and silk-like finish, making it ideal for decorative fabrics and apparel. Dull yarn is preferred in formalwear and home furnishings for its soft texture and matte appearance. High wet modulus yarn continues to gain popularity in applications demanding high strength and moisture resistance. The Viscose Filament Yarn Market benefits from diversified product offerings that cater to both performance and aesthetic requirements.

- For Instance, Jilin Chemical Fiber Group supplies various fibers, including acrylic and viscose yarns, to clients in over 30 countries across multiple continents.

By Application

Key applications include apparel, home textiles, and industrial fabrics. Apparel remains the dominant segment supported by growing demand for soft, breathable, and comfortable fabrics. It serves a wide range of clothing such as dresses, linings, and scarves. Home textiles including upholstery and curtains also contribute steadily due to rising residential and hospitality developments. Industrial fabrics show gradual adoption driven by advancements in technical-grade viscose.

- For instance, Birla Cellulose (Grasim Industries), the world’s largest viscose producer, operates five plants across India, Thailand, and Indonesia with a combined production capacity of 456,000 tonnes annually, with its LIVA brand featuring in over 70 million garments across 100 major global brands.

By End Use

Major end users include textile manufacturers, fashion brands, and interior décor producers. Textile manufacturers utilize it extensively for weaving and knitting high-quality fabrics. Fashion brands incorporate viscose yarn into eco-conscious product lines to meet sustainability standards. Interior décor companies rely on its sheen and drape to enhance design appeal. The Viscose Filament Yarn Market continues to evolve with increasing integration across value chains and growing end-user diversification.

Segmentations:

By Product

- Bright Yarn

- Dull Yarn

- High Wet Modulus Yarn

By Application

- Apparel

- Home Textiles

- Industrial Fabrics

- Upholstery and Furnishings

- Others

By End Use

- Textile Manufacturers

- Fashion Brands

- Interior Décor Producers

- Technical Textile Companies

- Others

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia-Pacific Leads Global Production and Consumption

Asia-Pacific holds 64% share of the global viscose filament yarn market in 2024, making it the dominant regional hub. China and India account for the majority of global output due to large-scale manufacturing capacities and cost advantages. It benefits from abundant raw material availability, supportive government policies, and a growing textile export base. Expanding apparel and home furnishing industries continue to strengthen regional demand. Leading producers invest in automation and environmentally friendly processes to meet sustainability standards. The Viscose Filament Yarn Market experiences its fastest growth in this region driven by industrial expansion and rising consumer income levels.

Europe Shows Steady Growth Driven by Sustainability Policies

Europe holds 18% share of the global market, supported by strict environmental regulations and demand for eco-certified fibers. It emphasizes sustainable sourcing and closed-loop manufacturing, particularly in Italy, Germany, and Austria. European textile manufacturers adopt viscose filament yarn for luxury fabrics, fashion apparel, and home décor. Growth is supported by innovation in circular production and biodegradable fiber solutions. The region also benefits from increased collaboration between fiber producers and apparel brands. The Viscose Filament Yarn Market in Europe continues to evolve through green product innovation and supply chain transparency.

North America Expands Through Niche and Technical Applications

North America accounts for 10% share of the global market, driven by adoption in fashion and technical textile sectors. The United States remains a key importer of high-quality viscose yarn for apparel and interior products. It emphasizes performance and sustainability, with rising use in automotive and medical fabrics. Domestic manufacturers explore new blends combining viscose with organic cotton and recycled materials. Technological advancements support small-scale production with enhanced fiber performance. The Viscose Filament Yarn Market in North America benefits from niche innovation and steady consumer preference for premium eco-conscious fabrics.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Xinxiang Bailu Chemical Fibre Group

- Grasim Industries

- Yibin Grace Group

- Shandong Helon Textile Sci. & Tech.

- Lenzing AG

- Sanyou Chemical Fiber Co., Ltd.

- Sateri Holdings Limited

- Aditya Birla Group

- Glanzstoff Industries

- Kelheim Fibres GmbH

- Eastman Chemical Company

Competitive Analysis:

The Viscose Filament Yarn Market remains moderately consolidated, with competition driven by technology, product quality, and sustainability initiatives. Key players include Xinxiang Bailu Chemical Fibre Group, Grasim Industries, Yibin Grace Group, and Shandong Helon Textile Sci. & Tech. These companies invest heavily in process optimization, eco-friendly production methods, and product innovation to strengthen their market positions. It focuses on enhancing fiber strength, colorfastness, and environmental performance to meet global standards. Strategic collaborations with textile manufacturers help expand distribution and brand visibility. Companies also prioritize certifications and circular manufacturing models to attract sustainability-focused clients. Competitive intensity continues to rise as regional producers upgrade technology and target export-driven growth.

Recent Developments:

- In April 2025, Yibin Grace Group launched China’s first recycled textile dissolving pulp facility.

- In July 2025, Sanyou Chemical Fiber Co., Ltd. entered a strategic partnership with Circ, locking in a five-year purchase agreement for recycled pulp from Circ’s commercial-scale facility to produce lyocell staple fibers with 30% recycled content.

Report Coverage:

The research report offers an in-depth analysis based on Product, Application, End Use and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- Rising demand for eco-friendly and biodegradable fibers will continue to drive adoption of viscose filament yarn.

- Fashion and home textile industries will expand usage due to growing preference for sustainable and soft fabrics.

- Technological advancements in fiber spinning and dyeing processes will improve product quality and reduce waste.

- Manufacturers will focus on circular production systems to meet global sustainability and emission standards.

- Integration of viscose with other fibers such as cotton, polyester, and lyocell will enhance performance and texture.

- Expansion of textile manufacturing hubs in Asia-Pacific will strengthen supply chains and reduce production costs.

- Innovation in high-tenacity and functional yarns will open new opportunities in technical and industrial applications.

- Strategic mergers and collaborations among key producers will improve capacity and global market presence.

- Increasing consumer awareness of eco-labeled and certified textiles will create brand differentiation for producers.

- The Viscose Filament Yarn Market will evolve toward sustainable innovation, diversified applications, and long-term competitive stability.