Market Overview

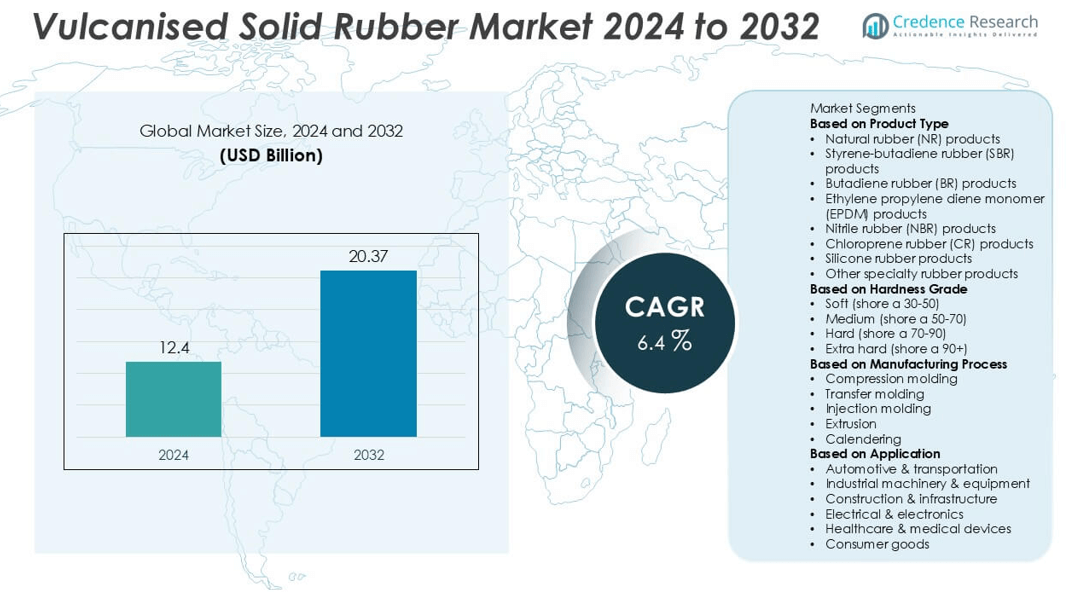

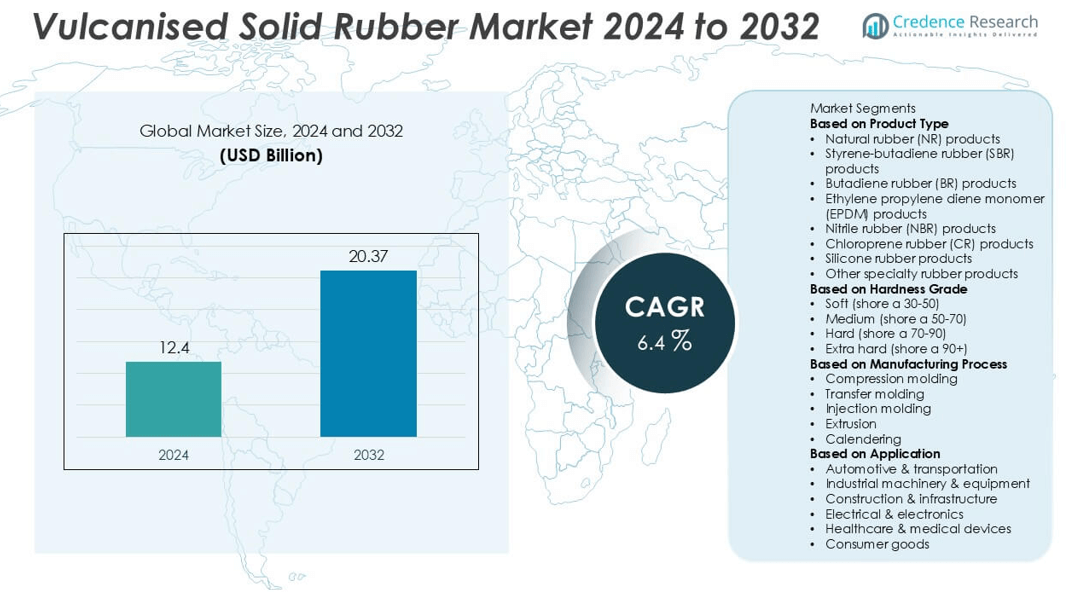

The Vulcanised Solid Rubber Market was valued at USD 12.4 billion in 2024 and is projected to reach USD 20.37 billion by 2032, growing at a CAGR of 6.4% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Vulcanised Solid Rubber Market Size 2024 |

USD 12.4 billion |

| Vulcanised Solid Rubber Market, CAGR |

6.4% |

| Vulcanised Solid Rubber Market Size 2032 |

USD 20.37 billion |

The Vulcanised Solid Rubber Market grows steadily, driven by rising demand from automotive, industrial, and construction sectors that require durable and high-performance materials. It benefits from expanding infrastructure projects, increasing vehicle production, and greater use in healthcare and consumer goods.

The geographical analysis of the Vulcanised Solid Rubber Market highlights strong demand across Asia-Pacific, North America, Europe, Latin America, and the Middle East & Africa. Asia-Pacific leads growth due to rapid industrialization, large-scale automotive production, and expanding construction activities, supported by abundant raw material supply and cost-effective manufacturing bases. North America demonstrates steady adoption, driven by innovation, advanced industrial applications, and sustainability initiatives, while Europe emphasizes eco-friendly practices and strict compliance standards to strengthen product quality. Latin America and the Middle East & Africa continue to expand through infrastructure development and industrial diversification, creating new opportunities for manufacturers. Key players shaping the competitive environment include LANXESS (Germany), BASF SE (Germany), Arkema SA (France), and Eastman Chemical Company (US), who invest heavily in research, product innovation, and sustainable production. Their global presence, strategic collaborations, and focus on high-performance solutions enable them to maintain strong influence across multiple end-use industries.

Market Insights

- The Vulcanised Solid Rubber Market was valued at USD 12.4 billion in 2024 and is projected to reach USD 20.37 billion by 2032, growing at a CAGR of 6.4% during the forecast period.

- The market shows steady expansion supported by its wide use in automotive, industrial, construction, healthcare, and consumer goods sectors, with demand driven by durability, strength, and resilience in high-stress applications.

- Key drivers include rising vehicle production, increasing infrastructure investments, and the growing requirement for high-performance materials in critical industrial operations worldwide.

- Major trends reflect the shift toward sustainable and eco-friendly rubber products, innovation in recycling technologies, and the integration of digital monitoring systems that improve efficiency and performance tracking.

- Competitive analysis highlights leading players such as LANXESS, BASF SE, Arkema SA, Eastman Chemical Company, and Kumho Petrochemical, who focus on innovation, global expansion, and strategic partnerships to maintain strong market positions.

- Restraints include volatile raw material prices, strict environmental regulations, and supply chain disruptions, which create challenges for manufacturers in managing costs and ensuring consistent production capacity.

- Regional analysis shows Asia-Pacific leading in demand due to industrialization and automotive growth, North America and Europe advancing with sustainability and technological innovation, and Latin America and the Middle East & Africa expanding steadily through infrastructure projects and industrial diversification

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers

Growing Demand from Automotive and Transportation Sector

The Vulcanised Solid Rubber Market benefits from rising demand in the automotive and transportation sector. The material provides superior durability, resistance to wear, and enhanced strength, which makes it essential for manufacturing tires, seals, belts, and vibration-dampening components. Increasing vehicle production in both passenger and commercial categories supports its consistent adoption. Electric vehicle expansion further enhances the requirement for high-performance rubber materials that can handle advanced design standards. Manufacturers emphasize improved efficiency, reliability, and safety, which strengthens demand for vulcanised solid rubber. It continues to remain a preferred choice due to its long service life and performance consistency.

- For instance, Continental has stated they supplied tires to all ten of the world’s highest-volume EV manufacturers in 2023. In 2021, the company announced an EcoContact 6 summer tire with rolling resistance more than 15% better than the highest EU label rating, which improved EV range by 3-4%.

Expansion of Industrial and Construction Applications

The Vulcanised Solid Rubber Market gains strong momentum from industrial and construction uses. It offers excellent resilience under pressure, making it suitable for flooring, rollers, conveyor belts, and protective linings in heavy machinery. Rising infrastructure investments worldwide boost the need for robust materials that can withstand demanding environments. It delivers reliable performance in harsh conditions, where mechanical stress and abrasion resistance are critical. The construction sector increasingly relies on such solutions for long-term operational stability. The material’s versatility ensures steady growth across multiple end-use segments.

- For instance, Yokohama Rubber has developed energy-saving conveyor belts using high-elasticity compounds, which have shown a power consumption reduction of 73.3kW or 28.6% during a test with a cement company

Growing Importance in Healthcare and Consumer Goods

The Vulcanised Solid Rubber Market sees increasing adoption in healthcare and consumer goods. It plays a role in producing gloves, gaskets, footwear, and medical devices that require durability and safety compliance. Rising health awareness and stringent regulatory standards encourage manufacturers to select high-quality rubber solutions. It provides reliable elasticity, comfort, and resistance, which support product performance in critical applications. Consumer demand for long-lasting, sustainable products reinforces its position in the global market. Continuous innovation in design and material blends strengthens its relevance in these industries.

Sustainability Focus and Advancements in Recycling Technologies

The Vulcanised Solid Rubber Market benefits from stronger focus on sustainability and recycling. Industries recognize the need to reduce environmental impact by adopting eco-friendly solutions. It aligns with global regulations and sustainability targets through innovations that extend product lifecycle and enhance recyclability. Recycling technologies now allow recovery of rubber for reuse in multiple sectors, reducing reliance on virgin materials. Companies invest in green practices to meet consumer and regulatory expectations while maintaining profitability. This trend positions vulcanised solid rubber as a sustainable choice for future applications.

Market Trends

Integration of Advanced Manufacturing Processes

The Vulcanised Solid Rubber Market shows strong progress through the integration of advanced manufacturing processes. Automation and precision techniques improve product consistency, reduce defects, and enhance efficiency in large-scale production. It supports manufacturers in meeting strict industry standards while lowering operational costs. Adoption of modern molding and curing systems allows higher customization for specific end-use requirements. Companies focus on improving turnaround times to address rising demand from automotive and industrial sectors. These developments reinforce the competitiveness of vulcanised solid rubber across global markets.

- For instance, Continental AG, through its ContiConnect sensor generation and AI-based algorithms, now offers automated tire tread depth measurements for commercial vehicles with data updated daily. This technology allows for the precise planning of tire services, significantly reducing the number of manual inspections.

Rising Popularity of High-Performance Rubber Compounds

The Vulcanised Solid Rubber Market witnesses an increasing shift toward high-performance rubber compounds. Industries demand superior resistance to heat, chemicals, and mechanical stress for critical applications. It delivers reliable outcomes in areas such as aerospace, heavy machinery, and energy infrastructure, where performance standards are non-negotiable. Manufacturers emphasize research to develop new formulations that extend product lifespan. The move toward high-performance solutions reflects a growing preference for quality-driven investments. This trend highlights the importance of continuous innovation in material science.

- For instance, Parker Hannifin Corporation’s high-performance fluoroelastomer seals are designed for extreme temperatures up to 260°C and offer chemical resistance for critical aerospace and energy infrastructure sealing applications.

Expansion of Sustainable and Eco-Friendly Product Lines

The Vulcanised Solid Rubber Market advances with greater focus on sustainability and eco-friendly product lines. Companies invest in renewable raw materials and energy-efficient production methods to align with global climate targets. It encourages the adoption of circular economy principles where recycling and reusability play a central role. Sustainable product lines attract regulatory approval and consumer trust, giving firms a competitive advantage. Increasing awareness of environmental impact drives consistent interest in green alternatives. The emphasis on sustainability ensures steady transformation in industry practices.

Digitalization and Smart Monitoring in Rubber Applications

The Vulcanised Solid Rubber Market benefits from digitalization and smart monitoring technologies. Integration of sensors and connected systems in rubber components provides real-time performance data. It helps industries track wear, stress levels, and overall reliability with greater accuracy. Predictive maintenance enabled by digital tools minimizes downtime and reduces long-term operational costs. Adoption of digital solutions strengthens partnerships between manufacturers and end-users seeking advanced monitoring capabilities. This shift aligns with broader industrial trends toward smart manufacturing and connected infrastructure.

Market Challenges Analysis

Volatility in Raw Material Prices and Supply Chain Constraints

The Vulcanised Solid Rubber Market faces challenges from fluctuating raw material costs and supply chain disruptions. Natural rubber and synthetic rubber, which serve as key inputs, remain sensitive to global price movements and geopolitical factors. It creates uncertainty for manufacturers, making cost management and pricing strategies difficult to stabilize. Supply chain interruptions caused by transportation delays, labor shortages, or regional restrictions further strain market growth. Companies must invest in alternative sourcing strategies to reduce dependency on limited suppliers. These issues often impact production schedules and limit the ability to meet rising demand efficiently.

Regulatory Pressures and Environmental Concerns

The Vulcanised Solid Rubber Market also encounters difficulties due to strict regulations and environmental pressures. Governments enforce stringent policies on emissions, recycling standards, and safe disposal of rubber products. It challenges manufacturers to adapt production processes while maintaining cost-effectiveness. Compliance with international regulations requires significant investment in new technologies and infrastructure. Environmental concerns related to non-biodegradable waste intensify scrutiny on the industry. Firms unable to meet sustainability benchmarks risk reputational damage and market exclusion. These challenges underline the need for consistent innovation and proactive adaptation.

Market Opportunities

Rising Demand from Emerging Economies and Infrastructure Growth

The Vulcanised Solid Rubber Market holds strong opportunities in emerging economies where infrastructure development and industrial expansion accelerate material demand. Rapid urbanization in Asia-Pacific, Latin America, and parts of Africa boosts the need for durable flooring, seals, belts, and protective linings. It positions the market to benefit from government-backed projects in transportation, construction, and energy. Growing middle-class populations also create higher demand for automobiles, consumer goods, and healthcare products that rely on vulcanised rubber. Local manufacturing initiatives supported by favorable policies further encourage adoption. These factors open long-term growth pathways for market players targeting new regions.

Innovation in Sustainable Materials and Recycling Solutions

The Vulcanised Solid Rubber Market also presents opportunities through innovation in sustainable materials and advanced recycling technologies. Companies investing in eco-friendly formulations can address tightening environmental regulations while appealing to environmentally conscious customers. It supports the industry’s transition toward circular economy models where recycled rubber becomes a valuable resource for multiple sectors. Breakthroughs in recycling efficiency reduce costs and expand end-use possibilities for recovered rubber products. Collaborations between research institutions and industry leaders strengthen innovation pipelines. Growing emphasis on sustainable practices creates profitable opportunities for firms that align with global green initiatives.

Market Segmentation Analysis:

By Product Type

The Vulcanised Solid Rubber Market is segmented by type into natural and synthetic rubber, each offering distinct performance benefits. Natural rubber maintains strong demand due to its elasticity, tensile strength, and abrasion resistance, making it critical for tires, belts, and seals. It continues to be favored in industries that prioritize flexibility and resilience. Synthetic rubber, on the other hand, demonstrates growth through its superior resistance to heat, oil, and chemicals. It serves as a reliable choice for automotive, aerospace, and industrial applications where durability and performance consistency are essential. Manufacturers balance both types to serve varied end-use requirements and strengthen market reach.

- For instance, Continental AG produces tires that use up to 12 different vulcanized rubber compounds, with specific compounds incorporating natural rubber for optimal elasticity and wear resistance.

By Hardness Grade

The Vulcanised Solid Rubber Market is also segmented by grade, with industrial grade occupying a dominant share due to widespread use in automotive, construction, and heavy machinery. It supports conveyor belts, gaskets, and vibration-dampening products that ensure operational reliability. Medical grade follows closely, with demand driven by healthcare products such as gloves, tubing, and medical equipment components that require safety and compliance. It also expands through specialty grades designed for aerospace, defense, and advanced engineering applications that demand unique formulations and enhanced durability. The diversity of grades reflects the market’s adaptability across highly regulated and performance-driven industries.

- For instance, Wacker Chemie AG manufactures medical-grade silicone rubber compounds under its SILPURAN brand, which meet strict healthcare standards for biocompatibility and safety in medical device manufacturing.

By Manufacturing Process

The Vulcanised Solid Rubber Market is further segmented by process, with compression molding remaining widely adopted due to its ability to produce durable components like seals and gaskets with consistent quality. It offers cost-effective production for medium to large-scale volumes. Injection molding gains traction for its precision and efficiency, supporting complex product designs in automotive and consumer goods. Extrusion continues to hold importance for profiles, sheets, and continuous products used across construction and industrial sectors. Other specialized processes provide flexibility for customized applications and niche demands. The variety of manufacturing processes ensures producers can adapt to evolving product specifications while maintaining efficiency and competitiveness.Segments:

Based on Product Type

- Natural rubber (NR) products

- Styrene-butadiene rubber (SBR) products

- Butadiene rubber (BR) products

- Ethylene propylene diene monomer (EPDM) products

- Nitrile rubber (NBR) products

- Chloroprene rubber (CR) products

- Silicone rubber products

- Other specialty rubber products

Based on Hardness Grade

- Soft (shore a 30-50)

- Medium (shore a 50-70)

- Hard (shore a 70-90)

- Extra hard (shore a 90+)

Based on Manufacturing Process

- Compression molding

- Transfer molding

- Injection molding

- Extrusion

- Calendering

Based on Application

- Automotive & transportation

- Industrial machinery & equipment

- Construction & infrastructure

- Electrical & electronics

- Healthcare & medical devices

- Consumer goods

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

Asia-Pacific

Asia-Pacific holds the largest share of the Vulcanised Solid Rubber Market, accounting for approximately 42% of global revenue in 2024. The region’s dominance is driven by strong automotive production, rapid industrialization, and large-scale infrastructure development. China, India, Japan, and South Korea serve as key contributors, supported by abundant raw material availability and cost-effective manufacturing facilities. It continues to benefit from rising demand for tires, conveyor belts, and construction materials, which are vital to expanding economies. Government-led investments in smart cities, renewable energy projects, and advanced transportation networks further fuel growth. Asia-Pacific is expected to maintain its leading position due to favorable demographics, urbanization, and increasing adoption of sustainable production methods.

North America

North America represents around 21% of the Vulcanised Solid Rubber Market, with steady growth driven by innovation and sustainability initiatives. The United States dominates regional demand, supported by advanced automotive, aerospace, and industrial sectors. It benefits from strong investment in research and development to improve material performance, durability, and recycling technologies. Manufacturers in North America prioritize eco-friendly solutions to comply with stringent environmental regulations, boosting adoption of recycled and high-performance rubber compounds. The healthcare industry also contributes significantly, with medical devices and safety equipment requiring durable rubber components. Rising adoption of smart monitoring systems in industrial applications strengthens the market outlook in this region.

Europe

Europe accounts for nearly 19% of the Vulcanised Solid Rubber Market, reflecting stable demand across automotive, construction, and industrial applications. Germany, France, Italy, and the United Kingdom lead the regional market due to advanced automotive manufacturing capabilities and strong industrial bases. It faces regulatory pressure to enhance sustainability, encouraging companies to focus on energy-efficient production methods and recycling initiatives. Demand for vulcanised solid rubber also grows in healthcare, consumer goods, and renewable energy infrastructure. European firms invest heavily in research to produce innovative formulations that extend product lifespan while reducing environmental impact. The region’s strong focus on compliance and quality standards sustains long-term growth prospects.

Latin America

Latin America contributes around 10% of the Vulcanised Solid Rubber Market, supported by rising industrialization and infrastructure investments. Brazil and Mexico dominate regional demand, with automotive production and construction projects driving material adoption. It benefits from government-led initiatives aimed at expanding transportation networks, energy systems, and housing development. The industrial sector also shows steady use of conveyor belts, rollers, and protective linings in mining and manufacturing. Growing consumer demand for footwear, household products, and healthcare solutions enhances market opportunities. Although economic volatility poses some challenges, increasing foreign investment and regional trade partnerships are likely to support sustained growth.

Middle East & Africa

The Middle East & Africa holds approximately 8% of the Vulcanised Solid Rubber Market, with demand rising steadily due to expanding infrastructure and industrial projects. Gulf countries, including Saudi Arabia and the UAE, invest heavily in construction, oil and gas, and transportation, which accelerates material usage. It also benefits from mining activities in Africa, where durable rubber products are critical for equipment and machinery. Healthcare and consumer goods segments expand gradually as population growth drives higher demand for durable everyday products. Manufacturers explore partnerships and joint ventures to strengthen distribution networks across this region. While the market share remains comparatively smaller, long-term prospects remain positive due to ongoing urbanization and industrial diversification efforts.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

Competitive Analysis

The competitive landscape of the Vulcanised Solid Rubber Market is shaped by leading players such as LANXESS (Germany), BASF SE (Germany), Arkema SA (France), Eastman Chemical Company (US), Kumho Petrochemical (South Korea), Sumitomo Chemical Co., Ltd. (Japan), Duslo, a.s. (Slovakia), Shandong Stair Chemical & Technology Co., Ltd (China), Willing New Materials Technology Co., Ltd (China), and King Industries, Inc (US). These companies focus on expanding their product portfolios, enhancing manufacturing efficiency, and investing in research and development to deliver high-performance and sustainable rubber solutions. It enables them to cater to diverse industries including automotive, construction, industrial, and healthcare. Strategic partnerships, mergers, and acquisitions remain central to strengthening global presence and accessing new customer bases. Many of these players adopt eco-friendly production methods and recycling innovations to align with tightening environmental regulations. Competitive intensity is further influenced by regional players offering cost-effective solutions, creating a balance between quality-driven global firms and price-sensitive local suppliers. The market is expected to witness continued innovation in product formulations, processing techniques, and digital integration, allowing companies to differentiate offerings and secure long-term growth opportunities in both developed and emerging economies.

Recent Developments

- In June 2025, Continental AG , the company increased the share of renewable and recycled materials used in tire production by 2–3 percentage points over 2024 levels and plans to exceed 40 percent by 2030.

- In April 2025, Trelleborg AB the company finalized the acquisition of National Gummi AB, specializing in extruded rubber profiles and gaskets.

- In March 2025, LANXESS at Tire Technology Expo, LANXESS unveiled sustainable rubber additives, including the Vulkanox HS Scopeblue (over 55 percent renewable), the Aflux SD processing agent slated for Q2 2025, plus Rhenodiv release agents and other solutions.

- In March 2024, HEXPOL AB HEXPOL announced an investment in a devulcanization line at its Czech site to recycle cured rubber into new material.

Report Coverage

The research report offers an in-depth analysis based on Product Type, Hardness Grade, Manufacturing Process, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The market will experience steady growth supported by rising demand from automotive and industrial applications.

- Infrastructure development in emerging economies will continue to create new opportunities for adoption.

- Manufacturers will focus on developing eco-friendly and recyclable rubber solutions to meet sustainability targets.

- Advancements in processing techniques will improve efficiency and enable greater customization.

- Digital technologies and smart monitoring systems will enhance product performance and reliability.

- Healthcare and consumer goods sectors will expand their share due to demand for durable and safe materials.

- Global players will strengthen market presence through mergers, acquisitions, and strategic partnerships.

- Fluctuating raw material availability will encourage investment in alternative sourcing and synthetic rubber innovation.

- Regulatory frameworks will drive innovation in energy-efficient and low-emission production processes.

- The market will maintain long-term relevance through versatility across multiple industries and applications.