| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Aluminum Honeycomb Core Market Size 2024 |

USD 1,960.93 million |

| Aluminum Honeycomb Core Market, CAGR |

6.80% |

| Aluminum Honeycomb Core Market Size 2032 |

USD 3,446.92 million |

Market Overview:

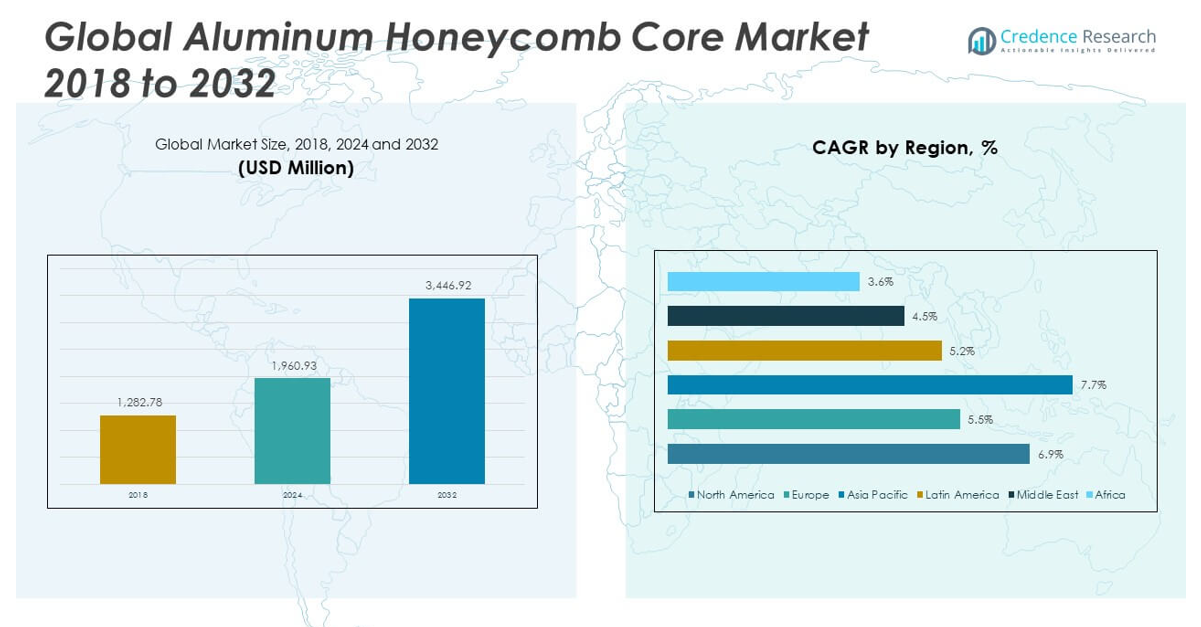

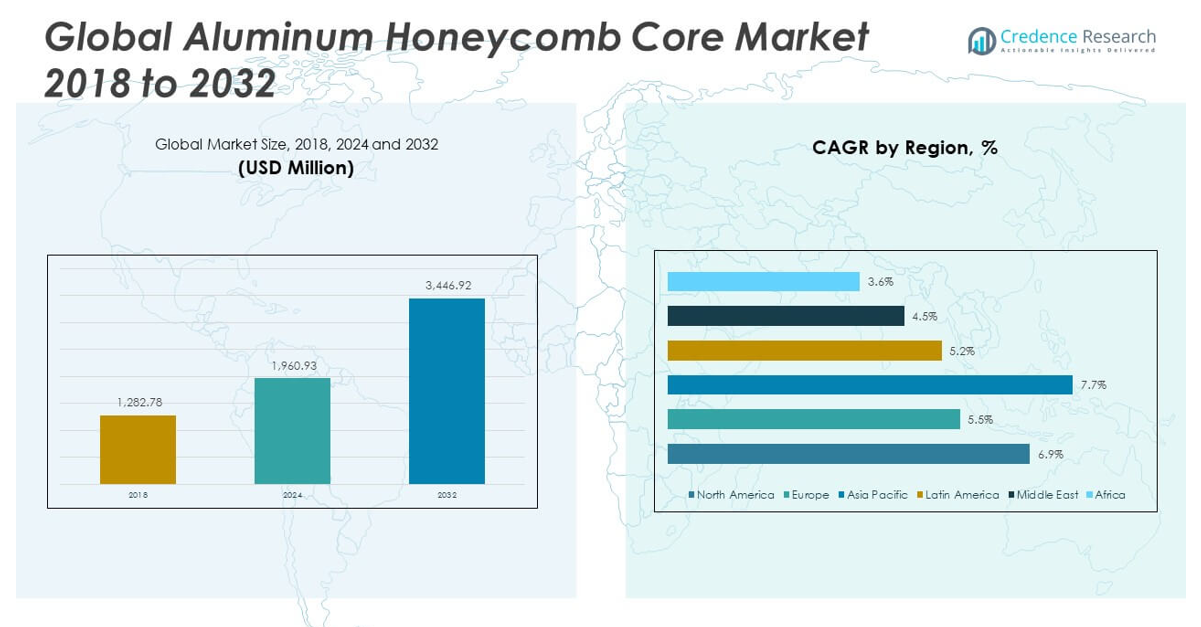

The Global Aluminum Honeycomb Core Market size was valued at USD 1,282.78 million in 2018 to USD 1,960.93 million in 2024 and is anticipated to reach USD 3,446.92 million by 2032, at a CAGR of 6.80% during the forecast period.

The global aluminum honeycomb core market is primarily driven by increasing demand for lightweight, high-strength materials across key sectors such as aerospace, automotive, construction, marine, and rail transportation. In aerospace and automotive industries, stringent environmental regulations and the push for fuel efficiency have heightened the need for materials that reduce overall weight without compromising structural integrity. Aluminum honeycomb cores offer an exceptional strength-to-weight ratio, excellent energy absorption, corrosion resistance, and fire retardance, making them ideal for use in aircraft flooring, automotive crash components, and EV battery enclosures. In the construction sector, their thermal insulation and acoustic properties support demand for sustainable building materials in modern infrastructure projects. Additionally, advancements in manufacturing processes such as perforated core designs and improved adhesive technologies are expanding their functional range and cost-efficiency.

Regionally, Asia-Pacific holds the largest share of the global aluminum honeycomb core market, led by China, India, Japan, and South Korea. Strong industrial growth, rapid urbanization, and massive infrastructure investments in these countries are driving demand across the transportation and construction sectors. China dominates the regional market, supported by robust aerospace manufacturing, electric vehicle production, and high-speed rail expansion. India’s smart city initiatives and growing use of energy-efficient building materials also contribute to regional growth. North America follows closely, with the United States leading due to its mature aerospace and defense sectors, high R&D spending, and strong focus on lightweight automotive materials. Europe ranks third, driven by sustainability regulations, innovations in automotive and aircraft design, and increased usage in architectural cladding. Countries like Germany, France, and the UK are key markets within the region. Meanwhile, Latin America and the Middle East & Africa are witnessing moderate growth, supported by infrastructure modernization and emerging industrial sectors.

Market Insights:

- The Global Aluminum Honeycomb Core Market reached USD 1,960.93 million in 2024 and is projected to hit USD 3,446.92 million by 2032, growing at a CAGR of 6.80%.

- Lightweight material demand in aerospace and automotive sectors continues to accelerate due to emission norms and efficiency targets.

- Construction companies prefer aluminum honeycomb cores for fire-resistant, thermally insulating panels in green and modular buildings.

- Technological upgrades in bonding, perforation, and cell precision are expanding product versatility and reducing waste.

- Regulatory focus on recyclable and fire-retardant materials boosts the adoption of aluminum cores in sustainable infrastructure.

- High production costs and fabrication complexity limit accessibility for smaller manufacturers and cost-sensitive markets.

- Asia-Pacific leads the market with 41% share, driven by industrial growth in China, India, Japan, and South Korea, while North America and Europe follow with steady demand from aerospace and automotive industries.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Surging Demand for Lightweight Materials in Aerospace and Automotive Sectors

The Global Aluminum Honeycomb Core Market is expanding rapidly due to the strong demand for lightweight materials that meet performance and regulatory requirements. In the aerospace industry, manufacturers prioritize components that reduce aircraft weight to improve fuel efficiency and meet emission standards. Aluminum honeycomb cores offer high stiffness-to-weight ratios, making them ideal for aircraft floors, doors, partitions, and control surfaces. The automotive industry also benefits from weight reduction through these materials, particularly in electric vehicles, where battery efficiency is critical. Leading automakers are integrating honeycomb cores in crash structures, hoods, and trunk floors to meet fuel economy targets without compromising safety. These factors drive consistent adoption across both commercial and defense sectors.

- For example, The Gill Corporation-France produces ALPHEX™ commercial-grade aluminum honeycomb using 3003 or 3104 alloy foils, with densities ranging from 17 kg/m³ (for 25 mm cell size, 70 μm foil) to 93 kg/m³ (for 5.2 mm cell size, 70 μm foil). The stabilized compressive strength reaches up to 4.81 MPa, and shear strength in the L-direction can be as high as 2.71 MPa for the densest configurations.

Rising Adoption in Sustainable and High-Performance Construction Applications

Construction firms are increasingly turning to aluminum honeycomb cores for sustainable and high-strength building materials. These cores provide excellent thermal insulation, fire resistance, and acoustic performance, which are essential in modern green building designs. The Global Aluminum Honeycomb Core Market benefits from growing investments in commercial and institutional infrastructure that prioritize energy efficiency and environmental compliance. Applications include curtain wall panels, ceilings, raised floors, and architectural claddings. Builders value the dimensional stability and low maintenance needs of these panels in both interior and exterior installations. It supports regulatory goals in urban construction, especially in regions adopting LEED or equivalent sustainability certifications. Expanding urban development and modular construction trends further support market growth.

- For example, ReynoArch panels are 100% recyclable, contributing to circular economy goals and reducing environmental impact. Their panels are engineered for easy installation, high rigidity, and improved safety, with applications extending from curtain wall panels to raised floors and architectural claddings.

Advancements in Manufacturing Technology Improve Product Versatility

Innovations in bonding techniques, perforation patterns, and composite integration have enhanced the versatility of aluminum honeycomb cores. Improved production processes allow precise control over cell size, wall thickness, and adhesive quality, which boosts strength and reliability. The Global Aluminum Honeycomb Core Market continues to benefit from manufacturers offering customized solutions for aerospace, rail, and marine requirements. These technological improvements enable applications in noise reduction, ventilation, and moisture control while maintaining structural performance. Automation and digital tools in core fabrication reduce material waste and lower production costs. It also shortens lead times, making the product more accessible to mid-sized and emerging manufacturers. As production efficiency increases, so does product availability across wider end-use sectors.

Increasing Regulatory Pressures Favor Use of Recyclable and Fire-Resistant Materials

Tightening international regulations on emissions, fire safety, and material recyclability support the market’s upward trajectory. Aluminum honeycomb cores are 100% recyclable, making them compatible with circular economy models and environmental reporting standards. The Global Aluminum Honeycomb Core Market benefits from growing legislative support for sustainable materials across aerospace, construction, and transport industries. Their non-combustible properties meet fire code compliance in public and high-rise structures, leading to increased use in cladding and partition systems. Governments and industry bodies now require proof of product performance in fire resistance and environmental impact, which positions honeycomb cores as a preferred option. It also aligns with corporate ESG strategies that prioritize low-carbon, high-durability components.

Market Trends:

Integration of Aluminum Honeycomb Cores in Urban Mobility and Micro-Mobility Solutions

The Global Aluminum Honeycomb Core Market is witnessing growing incorporation in next-generation urban mobility systems. Lightweight electric bikes, scooters, and last-mile delivery vehicles use these cores to enhance structural integrity while maintaining low weight. Designers prefer honeycomb panels for chassis, battery housings, and protective shells due to their energy absorption and vibration dampening properties. The expansion of smart cities has accelerated the demand for compact and efficient mobility solutions that rely on lightweight materials. It supports fleet durability and safety in high-density urban environments. Start-ups and OEMs in the micro-mobility space now partner with composite manufacturers to develop custom panel formats using aluminum cores. This shift highlights a new end-use segment beyond traditional transport sectors.

Emergence of Aluminum Honeycomb in Renewable Energy and Wind Turbine Applications

Growing interest in renewable energy structures is creating opportunities for aluminum honeycomb cores in solar panel frames and wind turbine nacelles. These cores offer excellent rigidity and corrosion resistance, which are crucial in harsh outdoor and marine environments. The Global Aluminum Honeycomb Core Market is gaining traction among renewable energy developers seeking lightweight, weatherproof materials for energy infrastructure. Wind turbine housings and platform panels now incorporate honeycomb structures to reduce weight and maintenance costs. It allows easier installation and improves component lifespan under high mechanical stress. Energy system designers use these cores to meet weight and safety standards without sacrificing strength. Their compatibility with other composites makes them suitable for hybrid renewable installations.

- For example, Corex Honeycomb, in collaboration with TWI LTD, has manufactured wind turbine blades incorporating aluminum honeycomb cores for a 9.7-meter rotor blade project. The honeycomb structure provides a high rigidity-to-weight ratio and maintains density regardless of environmental changes, which is critical for outdoor and marine installations.

Expansion of Decorative and Interior Design Use Across Hospitality and Retail Sectors

Aluminum honeycomb cores are gaining popularity in aesthetic and functional interior design applications across hotels, airports, and luxury retail environments. These materials support seamless, flush-finished surfaces that require both strength and lightweight construction. The Global Aluminum Honeycomb Core Market is expanding into decorative applications such as feature walls, counters, ceilings, and art installations. Their ability to support large, flat panels without warping under thermal or mechanical load enhances visual appeal in high-traffic areas. Architects use aluminum cores with wood, stone, or high-pressure laminate facings to achieve premium finishes while reducing dead load. It enables fast installation and structural stability, especially in prefabricated modular designs. The trend aligns with the demand for durable yet design-flexible materials.

Growing Role of Aluminum Honeycomb in Defense and Tactical Equipment Design

Military and defense organizations are increasingly exploring aluminum honeycomb cores for protective gear, vehicle armor, and mobile command infrastructure. Their impact resistance and shock absorption characteristics make them ideal for tactical shelters, blast-resistant panels, and lightweight ballistic structures. The Global Aluminum Honeycomb Core Market is expanding into specialized defense applications where high-performance materials are essential for mission success. It supports load-bearing functionality without compromising mobility or rapid deployment requirements. Defense contractors use these cores in UAV frames, portable bridges, and armored vehicles to reduce transport weight. Their corrosion resistance under extreme weather and combat conditions enhances operational durability. Demand is growing for field-tested materials that combine structural integrity with tactical adaptability.

- For instance, Plascore’s AltuCore™ offers custom cylindrical honeycomb cores with static crush strengths ranging from 1,000 to 8,000 psi, and dynamic crush strengths 10–40% higher depending on impact velocity. These cores are engineered for single-use energy absorption in both aerospace and defense applications.

Market Challenges Analysis:

High Manufacturing Costs and Complex Fabrication Processes Limit Widespread Adoption

The Global Aluminum Honeycomb Core Market faces a significant challenge in terms of high production costs and technically demanding fabrication processes. Manufacturing honeycomb cores requires precision equipment, advanced bonding techniques, and rigorous quality control to ensure consistent cell structure and performance. These requirements lead to elevated capital investments, making it difficult for small and mid-sized manufacturers to enter the market. It increases the final cost of aluminum honeycomb panels, making them less accessible for cost-sensitive applications in construction or mass-market automotive segments. Customization needs across different industries further complicate production and inventory management. Companies must balance engineering performance with commercial viability to expand market penetration beyond niche sectors.

Limited Material Substitutability and Performance Sensitivity Under Certain Conditions

Performance sensitivity in extreme operational environments presents another challenge for the Global Aluminum Honeycomb Core Market. Though known for strength and lightweight benefits, aluminum honeycomb cores can exhibit vulnerability to shear forces, prolonged moisture exposure, and certain chemical agents. It requires protective facings or coatings in harsh conditions, adding to overall system costs and engineering complexity. Compatibility issues with adhesives or composite skins may arise during panel assembly, requiring specialized knowledge and tools. Market adoption also depends on material education and performance validation, particularly in newer sectors like micro-mobility or renewable energy. Designers must carefully assess whether aluminum honeycomb meets structural demands or if alternative materials offer better lifecycle value. Addressing these concerns remains critical to expanding application diversity and long-term reliability.

Market Opportunities:

Expanding Use in Electric Vehicles and Battery Enclosure Designs Offers Growth Potential

The Global Aluminum Honeycomb Core Market holds strong opportunities in the electric vehicle (EV) segment, where weight reduction and structural integrity remain top priorities. EV manufacturers seek advanced materials for battery enclosures, underbody protection, and crash structures that meet safety and thermal management standards. It offers excellent energy absorption and fire resistance, making it ideal for shielding battery packs and improving vehicle safety. As global EV production scales up, the demand for lightweight and recyclable materials will grow across both passenger and commercial vehicle categories. Automakers are collaborating with material suppliers to develop application-specific core designs, supporting faster integration into vehicle platforms. This trend presents a clear path for market expansion through innovation and supply chain partnerships.

Rising Demand for Modular and Prefabricated Construction Supports Market Growth

Modern construction practices increasingly favor prefabricated and modular methods that require lightweight, high-strength materials for ease of transport and assembly. The Global Aluminum Honeycomb Core Market benefits from this shift, especially in commercial, healthcare, and temporary infrastructure projects. It enables faster installation, reduced structural load, and compliance with fire and energy codes. Builders use honeycomb panels in partitions, ceilings, and exterior cladding to improve building efficiency and aesthetics. The rising focus on sustainable materials and green certifications creates further demand for aluminum-based core panels. This construction shift opens long-term opportunities for customized, panel-ready core systems tailored for urban development.

Market Segmentation Analysis:

The Global Aluminum Honeycomb Core Market is segmented by grade type and application, reflecting diverse usage across high-performance and commercial industries.

By grade type, 3003 aluminum honeycomb core holds a notable share due to its balanced cost, corrosion resistance, and formability, making it suitable for general-purpose applications. The 5052 grade offers enhanced strength and fatigue resistance, widely used in automotive and marine environments. The 5056 grade delivers higher mechanical performance, preferred in aerospace and defense where durability under stress is critical. Commercial-grade aluminum honeycomb cores cater to cost-sensitive construction and decorative applications where structural demands are moderate.

- For example, Plascore Inc. offers 5056 aluminum honeycomb cores for aerospace and defense, where superior mechanical performance and durability under high stress are required. Their Aerospace Grade Honeycomb is used in helicopter rotor blades, aircraft flooring, and missile components.

By application, aerospace remains the leading segment due to stringent requirements for lightweight, high-strength materials in aircraft structures and interiors. The automotive segment is expanding steadily, driven by the shift to electric vehicles and the need for lightweight crash-absorbing components. Construction applications rely on honeycomb panels for facades, partitions, and ceilings, supporting energy efficiency and fire safety. The “others” segment includes marine, rail, and industrial uses, where demand is growing for corrosion-resistant, low-weight materials. The market continues to diversify across applications and grades, aligning with technological, regulatory, and efficiency-driven demands.

- For example, Hexcel’s HexWeb® honeycomb is used in the Airbus A350 XWB for primary and secondary aircraft structures, including floors, control surfaces, and doors. The company’s case study highlights the use of honeycomb cores to reduce weight and meet stringent safety and performance standards.

Segmentation:

By Grade Type:

- 3003 Aluminum Honeycomb Core

- 5052 Aluminum Honeycomb Core

- 5056 Aluminum Honeycomb Core

- Commercial-Grade Aluminum Honeycomb Core

By Application:

- Aerospace

- Automotive

- Construction

- Others

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

The North America Aluminum Honeycomb Core Market size was valued at USD 417.34 million in 2018 to USD 629.08 million in 2024 and is anticipated to reach USD 1,109.93 million by 2032, at a CAGR of 6.9% during the forecast period. North America holds a 25% share of the Global Aluminum Honeycomb Core Market, driven by the strong presence of aerospace, defense, and high-end automotive manufacturing. The United States leads regional demand due to established aircraft production facilities and strict lightweighting mandates in transportation. It supports a wide range of applications in aircraft flooring, rail interiors, and architectural facades. Investments in green buildings and energy-efficient infrastructure also push construction-grade honeycomb adoption. Major industry players operate regionally with advanced R&D capabilities, supporting innovation and supply stability. Government support for defense modernization and electric vehicle manufacturing further reinforces market growth.

The Europe Aluminum Honeycomb Core Market size was valued at USD 239.17 million in 2018 to USD 345.56 million in 2024 and is anticipated to reach USD 552.27 million by 2032, at a CAGR of 5.5% during the forecast period. Europe accounts for 14% of the Global Aluminum Honeycomb Core Market, supported by stringent environmental regulations and widespread demand for recyclable materials. Countries like Germany, France, and the UK utilize aluminum honeycomb panels in high-performance automotive components, aircraft structures, and building retrofits. It addresses regional goals for reducing emissions and improving energy performance across sectors. The region also favors architectural integration of aluminum cores due to fire safety compliance and aesthetic flexibility. Advanced construction techniques and prefabricated solutions benefit from the material’s lightweight yet durable nature. The presence of key composite manufacturers supports competitive pricing and regional customization.

The Asia Pacific Aluminum Honeycomb Core Market size was valued at USD 511.12 million in 2018 to USD 812.97 million in 2024 and is anticipated to reach USD 1,524.31 million by 2032, at a CAGR of 7.7% during the forecast period. Asia Pacific dominates the Global Aluminum Honeycomb Core Market with a 39% market share, led by rapid infrastructure expansion and high-volume production in China, India, Japan, and South Korea. China leads regional consumption, supported by its massive aerospace industry, EV production, and high-speed rail projects. It also benefits from government investments in modular construction and public transport. India’s construction sector increasingly adopts aluminum honeycomb panels in smart cities and commercial developments. South Korea and Japan emphasize lightweight components in marine, electronics, and defense manufacturing. Growing domestic demand, coupled with rising export activity, secures the region’s leadership position.

The Latin America Aluminum Honeycomb Core Market size was valued at USD 60.87 million in 2018 to USD 91.89 million in 2024 and is anticipated to reach USD 143.06 million by 2032, at a CAGR of 5.2% during the forecast period. Latin America contributes 4% to the Global Aluminum Honeycomb Core Market, with demand centered in Brazil, Mexico, and Argentina. Infrastructure upgrades, airport expansions, and metro rail projects support market growth in this region. It finds use in partition panels, lightweight doors, and composite construction systems. The automotive industry in Mexico is gradually integrating aluminum honeycomb cores in crash structures and energy-absorbing panels. Imports from North America and Europe remain high due to limited local manufacturing. Gradual adoption of sustainable building practices presents further opportunities across urban hubs.

The Middle East Aluminum Honeycomb Core Market size was valued at USD 35.21 million in 2018 to USD 49.11 million in 2024 and is anticipated to reach USD 72.54 million by 2032, at a CAGR of 4.5% during the forecast period. The Middle East holds 3% of the Global Aluminum Honeycomb Core Market, driven by demand from luxury construction, hospitality, and infrastructure projects. Countries like the UAE and Saudi Arabia invest in large-scale developments where honeycomb panels serve as durable and fire-resistant cladding materials. It supports architectural facades in airports, stadiums, and high-rise towers. The regional focus on energy-efficient materials is growing but still limited by cost sensitivities. Adoption remains dependent on government-backed construction initiatives and tourism-driven investments. Market players focus on customized panels for niche architectural requirements.

The Africa Aluminum Honeycomb Core Market size was valued at USD 19.06 million in 2018 to USD 32.32 million in 2024 and is anticipated to reach USD 44.81 million by 2032, at a CAGR of 3.6% during the forecast period. Africa contributes 2% to the Global Aluminum Honeycomb Core Market, with slow but steady growth seen in urban construction and transport infrastructure. South Africa leads regional demand, using aluminum honeycomb cores in public buildings, airports, and select transport applications. It supports low-weight construction panels where concrete alternatives are not viable. The region faces limitations in local manufacturing, relying heavily on imports for advanced materials. Market expansion is tied to economic development and government infrastructure budgets. Greater awareness of fire safety and energy-efficient materials may help accelerate adoption over the forecast period.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Hexcel Corporation

- Alcoa Corporation

- Arconic Corporation

- Kaiser Aluminum Corporation

- Dongguan Jinyu Aluminum Co., Ltd.

- Shanghai Metal Corporation

- Nippon Light Metal Co., Ltd.

Competitive Analysis:

The Global Aluminum Honeycomb Core Market features a moderately fragmented competitive landscape, with key players focusing on product innovation, strategic collaborations, and capacity expansion to maintain market position. Leading companies include Hexcel Corporation, Argosy International, Corex Honeycomb, Euro-Composites, and Plascore Inc. It reflects strong competition in aerospace-grade and construction-grade segments, where quality standards and customization capabilities drive differentiation. Companies actively invest in R&D to improve strength-to-weight ratios, fire resistance, and environmental performance of their honeycomb cores. Strategic partnerships with OEMs in the aerospace, automotive, and construction sectors help strengthen distribution and application reach. Regional players in Asia Pacific and Europe are gaining traction by offering cost-effective alternatives and expanding local production capabilities. Pricing pressure, material availability, and compliance with international standards remain key competitive factors. The market rewards firms that deliver tailored solutions while ensuring consistent quality, timely delivery, and strong technical support across end-use industries.

Recent Developments:

- In June 2025, Hexcel Corporation signed a long-term partnership agreement with Kongsberg Defence & Aerospace (KONGSBERG) at the Paris Air Show. This strategic partnership will secure Hexcel’s position as a leading supplier of advanced composite materials for KONGSBERG’s defense and aerospace programs over the coming years, reinforcing Hexcel’s role in supplying lightweighting solutions for aerospace and defense applications.

- In August 2023, Arconic Corporation was acquired by Apollo Global Management in a $5.2 billion all-cash transaction, completed. This acquisition takes Arconic private, with Apollo Funds and a minority investment from Irenic Capital Management. The move is expected to provide Arconic with additional resources and strategic support to pursue long-term growth in the aluminum products and architectural solutions market.

Market Concentration & Characteristics:

The Global Aluminum Honeycomb Core Market exhibits moderate market concentration, with a mix of multinational corporations and specialized regional manufacturers competing across application segments. It is characterized by high entry barriers due to complex manufacturing processes, capital-intensive equipment, and stringent quality standards. Aerospace and defense dominate high-margin demand, while construction and transportation sectors contribute to volume-based growth. Product differentiation depends on core geometry, material grade, fire resistance, and compatibility with composite systems. The market emphasizes long-term contracts, technical certifications, and supply reliability. Innovation in lightweight, recyclable, and thermally efficient cores defines the competitive edge. Regional supply chains and customization capabilities support agile response to diverse customer requirements.

Report Coverage:

The research report offers an in-depth analysis based on grade type and application. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Rising demand for lightweight materials in electric vehicles will accelerate core integration in structural and safety components.

- Aerospace sector will continue to adopt advanced honeycomb cores for next-generation aircraft design and interior applications.

- Modular construction growth will increase the use of honeycomb panels in prefabricated walls, ceilings, and cladding systems.

- Expanding renewable energy infrastructure will create new opportunities in wind turbine nacelles and solar panel framing.

- Innovations in core geometry and composite bonding will enhance product performance across diverse industries.

- Regional manufacturing expansion in Asia Pacific will improve cost competitiveness and supply chain resilience.

- Sustainability goals and recycling mandates will support adoption of aluminum cores in green-certified projects.

- Defense applications will expand due to the material’s impact resistance and suitability for mobile tactical structures.

- Architectural designers will adopt honeycomb panels for their aesthetic flexibility and fire-rated performance.

- Strategic partnerships between OEMs and material suppliers will drive tailored solutions and application-specific growth.