Market Overview:

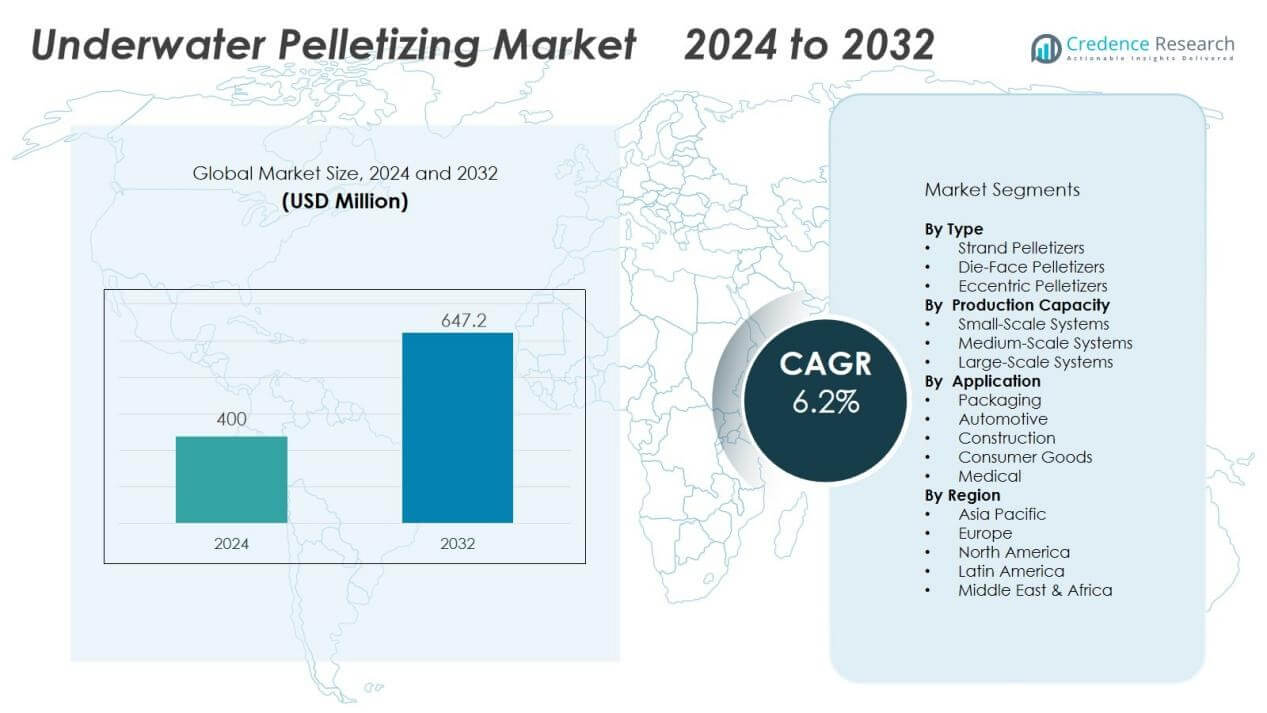

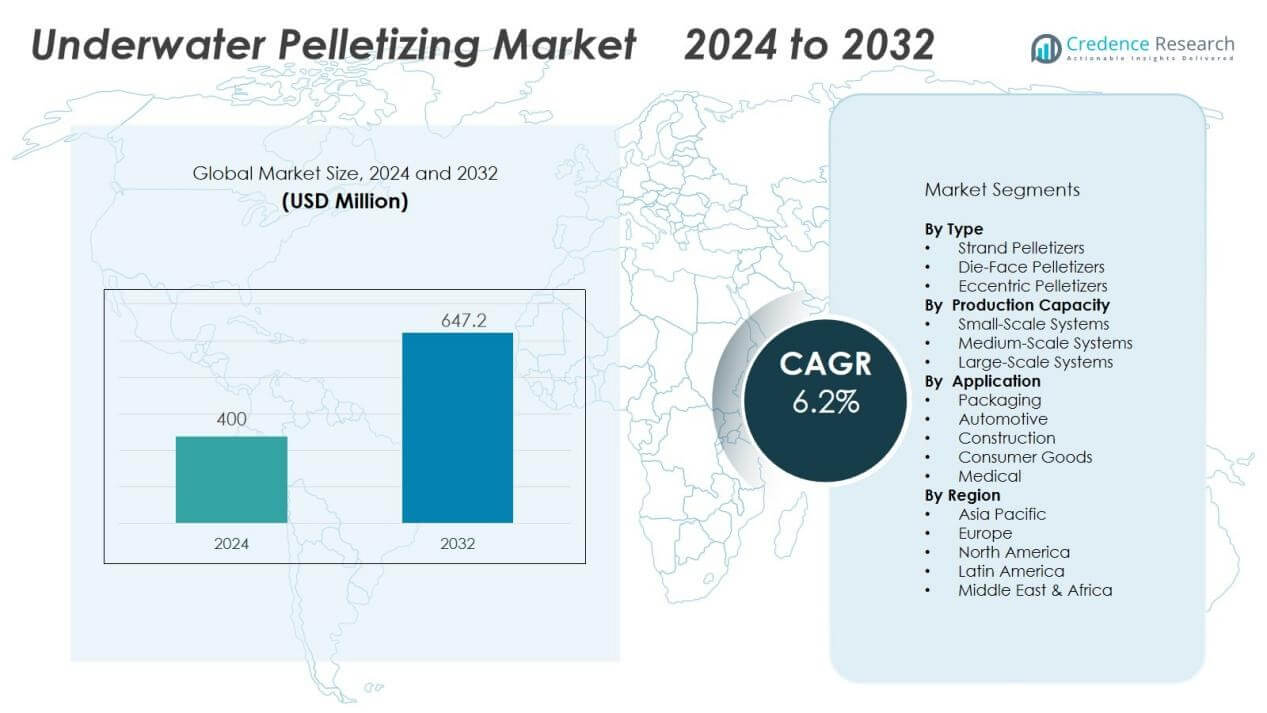

The Underwater pelletizing market size was valued at USD 400 million in 2024 and is anticipated to reach USD 647.2 million by 2032, at a CAGR of 6.2 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Underwater Pelletizing Market Size 2024 |

USD 400 Million |

| Underwater Pelletizing Market, CAGR |

6.2 % |

| Underwater Pelletizing Market Size 2032 |

USD 647.2 Million |

Key market drivers include the rising demand for efficient pelletizing solutions capable of handling a wide range of polymers and formulations. The shift toward sustainable materials and circular economy initiatives has prompted investments in advanced pelletizing technology, supporting the production of recycled and bio-based plastics. Technological advancements, such as automated control systems and improved cutting mechanisms, enhance productivity while reducing downtime and maintenance costs. Growth in packaging, automotive, construction, and electronics sectors further accelerates the adoption of underwater pelletizing systems globally.

Regionally, Asia-Pacific dominates the underwater pelletizing market due to its robust plastics manufacturing industry and strong investments in capacity expansion across China, India, and Southeast Asia. North America and Europe remain significant markets, driven by stringent environmental regulations, adoption of recycling practices, and a well-established polymer processing sector.

Market Insights:

- The underwater pelletizing market was valued at USD 400 million in 2024 and is expected to reach USD 647.2 million by 2032.

- Rising demand for high-quality thermoplastics and specialty polymers drives adoption in packaging, automotive, and consumer goods industries.

- Investments in sustainable materials and circular economy initiatives support growth in recycled and bio-based plastics production.

- Technological advancements in automation and precision cutting enhance system efficiency, flexibility, and reduce operational downtime.

- High initial investment and complex maintenance requirements pose challenges, especially for small and medium-sized manufacturers.

- Asia-Pacific leads the market with 45% share, driven by robust plastics manufacturing and strong capacity expansion in China, India, and Southeast Asia.

- North America and Europe remain significant markets, supported by advanced infrastructure, regulatory support for recycling, and strict environmental standards.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for High-Quality Thermoplastics and Polymers Across Industries:

The underwater pelletizing market benefits from the growing need for high-quality thermoplastics and specialty polymers across packaging, automotive, and consumer goods industries. Manufacturers seek advanced pelletizing solutions to produce uniform pellets that ensure superior product performance and consistency. The demand for lightweight and durable plastics in automotive and electronics sectors drives the adoption of reliable pelletizing systems. Companies invest in state-of-the-art equipment to maintain competitive advantage and deliver precise material specifications.

Shift Toward Sustainability and Circular Economy Initiatives Stimulates Innovation:

Increasing focus on sustainability prompts manufacturers to invest in underwater pelletizing systems capable of processing recycled and bio-based materials. The market supports global initiatives for reducing plastic waste and promoting the circular economy. It enables efficient conversion of post-consumer and post-industrial plastics into reusable pellets for various applications. Manufacturers benefit from technology upgrades that facilitate recycling and align with environmental regulations.

- For instance, Gamma Meccanica’s underwater pelletizer TI 5.6 allows the granulation of recycled PET at capacities reaching 2,800kg/h, helping transform high-MFI plastics into uniform, reusable pellets for downstream manufacturing.

Technological Advancements Enhance Efficiency and Operational Flexibility:

Advancements in automation, precision cutting, and process control improve the efficiency and flexibility of underwater pelletizing systems. It allows producers to quickly switch between different polymer grades and product specifications without compromising output quality. Automated monitoring and feedback systems optimize production and reduce operational downtime. Companies rely on these innovations to improve productivity and lower maintenance costs.

- For instance, Nordson’s BKG® Type AH D pelletizer features a blade wear indicator with automatic in-operation blade sharpening, which extends blade lifetime by up to 30%, reducing machine downtime for maintenance and ensuring optimal operational performance even at throughputs of up to 11,500kg/hr.

Expansion of Polymer Processing Capacity in Emerging Economies Drives Market Growth:

The underwater pelletizing market expands rapidly in Asia-Pacific, driven by strong investments in polymer processing infrastructure across China, India, and Southeast Asia. Growing demand for plastic components in construction, packaging, and automotive industries supports capacity expansion. It benefits from government policies promoting industrialization and foreign direct investment. Global players collaborate with local manufacturers to address rising demand and ensure supply chain resilience.

Market Trends:

Adoption of Automation, Digitalization, and Smart Process Controls Accelerates Modernization:

The underwater pelletizing market witnesses rapid integration of automation and digital technologies to enhance productivity, quality, and operational reliability. Advanced systems equipped with smart sensors, real-time data analytics, and remote monitoring enable manufacturers to optimize pelletizing processes and reduce manual intervention. Automation supports precise control over temperature, pressure, and pellet size, leading to consistent output and minimal waste. Digitalization allows predictive maintenance and quick identification of process deviations, helping companies minimize downtime and maintenance expenses. The market benefits from growing interest in Industry 4.0 practices, which enable seamless connectivity between equipment and centralized management platforms. Companies leverage these technological advancements to meet evolving customer requirements for custom formulations and high-volume production runs.

- For instance, Nordson’s BKG® Type AH D pelletizer features a blade wear indicator with automatic in-operation blade sharpening, which extends blade lifetime by up to 30%, reducing machine downtime for maintenance and ensuring optimal operational performance even at throughputs of up to 11,500kg/hr.

Rising Focus on Recycled and Biodegradable Polymers Creates New Opportunities for Innovation:

Sustainability trends continue to influence the underwater pelletizing market, driving investments in solutions tailored for recycled and biodegradable plastics. The demand for eco-friendly packaging, automotive components, and consumer products prompts manufacturers to seek advanced pelletizing systems compatible with challenging materials such as bioplastics and post-consumer recyclates. Companies develop cutting mechanisms, filtration systems, and water management solutions specifically designed to maintain pellet quality when processing recycled content. This focus supports regulatory compliance and strengthens brand reputation among environmentally conscious customers. The market evolves to address new material challenges and enable flexible, high-efficiency production lines, reflecting broader shifts toward circular economy goals and green manufacturing standards.

- For instance, EREMA customers produce more than 14 million tonnes of plastic pellets every year, and annually, they process 2.5 million tonnes of PET into food-grade rPET, which is then used to make beverage bottles and similar products.

Market Challenges Analysis:

High Initial Investment and Complex Maintenance Requirements Limit Adoption:

The underwater pelletizing market faces challenges related to the high upfront costs and technical complexity of advanced pelletizing systems. Small and medium-sized manufacturers may hesitate to adopt modern equipment due to significant capital investment and ongoing maintenance demands. Complex machinery requires skilled operators and regular technical support, increasing operational expenses. Frequent wear on cutting components and pumps can lead to production interruptions if not addressed promptly. Companies must balance the need for productivity with cost control, making the decision to upgrade or expand capacity more difficult.

Variability in Raw Material Quality and Process Integration Issues Impede Efficiency:

Variations in raw material quality present operational hurdles for the underwater pelletizing market, affecting pellet consistency and product performance. It must address the integration of pelletizing systems with existing polymer processing lines, which may involve compatibility and process synchronization issues. Inconsistent feedstock or improper process calibration can lead to increased waste and downtime. Adhering to stringent quality and environmental standards adds further complexity. Manufacturers face pressure to maintain efficiency and quality while minimizing resource consumption and regulatory risk.

Market Opportunities:

Expansion of Bioplastics and Sustainable Materials Creates Growth Prospects for Equipment Providers:

The underwater pelletizing market stands to benefit from rapid growth in the bioplastics sector and the shift toward sustainable material production. Governments and major brands pursue aggressive targets for reducing plastic waste and carbon emissions, fueling investments in bio-based and compostable polymers. Equipment providers have the opportunity to develop systems optimized for processing new material formulations that require precise temperature and moisture control. Manufacturers are open to adopting innovative pelletizing technologies that support circular economy goals and help achieve regulatory compliance. This trend expands the addressable market for system suppliers and technology developers.

Rising Investments in Emerging Markets Support Infrastructure Development and System Upgrades:

Emerging economies in Asia-Pacific, Latin America, and the Middle East are witnessing significant investments in polymer processing and manufacturing infrastructure. The underwater pelletizing market can capitalize on these investments by offering advanced systems designed for high-capacity, energy-efficient operation. It meets the needs of local producers seeking to upgrade legacy equipment and align with global quality standards. Strategic partnerships with regional players open new channels for market entry and customer engagement. Companies that tailor solutions for local requirements and support after-sales services can build long-term growth opportunities.

Market Segmentation Analysis:

By Type:

The underwater pelletizing market includes strand pelletizers, die-face pelletizers, and eccentric pelletizers. Strand pelletizers are preferred for their versatility in processing a wide range of thermoplastics and engineering polymers. Die-face pelletizers offer superior performance for specialty materials and high-throughput applications, making them ideal for continuous production lines. Eccentric pelletizers address niche requirements, particularly for sensitive or specialty polymers that demand precise cutting and minimal thermal exposure.

- For example, Intype’s Die-Face Cutter Type Pelletizing Machine is equipped with an advanced low-temperature mixing screw and vacuum-assisted degassing, resulting in steady pellet output and strong pellet density, with some models capable of producing up to 1,200kg/hr of uniform pellets for engineering plastics.

By Production Capacity:

It segments into small, medium, and large-scale systems. Small-capacity pelletizing lines cater to R&D facilities and niche manufacturers requiring flexible, low-volume production. Medium-capacity systems suit regional converters and custom compounders balancing efficiency and product diversity. Large-scale underwater pelletizing systems dominate high-volume industrial operations, supporting global polymer producers seeking consistent output and process reliability.

- For instance, GEMCO Energy portable pellet production line offers a specific output of 400–600 kg/h, supporting testing, innovation, and compact environments for laboratory and small business use.

By Application:

The underwater pelletizing market serves packaging, automotive, construction, consumer goods, and medical sectors. Packaging applications drive major demand due to high-volume polymer consumption and strict quality requirements. Automotive and construction sectors leverage pelletizing systems for specialty materials with advanced performance attributes. Consumer goods and medical applications require uniform pellets to ensure product safety and regulatory compliance. It continues to expand its reach into new applications, reflecting broader material innovation and industry shifts.

Segmentations:

By Type:

- Strand Pelletizers

- Die-Face Pelletizers

- Eccentric Pelletizers

By Production Capacity:

- Small-Scale Systems

- Medium-Scale Systems

- Large-Scale Systems

By Application:

- Packaging

- Automotive

- Construction

- Consumer Goods

- Medical

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia-Pacific :

Asia-Pacific holds a 45% market share in the underwater pelletizing market, driven by rapid growth in plastics manufacturing and significant investments in production capacity across China, India, and Southeast Asia. Strong demand from packaging, automotive, and consumer goods industries supports the adoption of advanced pelletizing systems. Governments in the region encourage industrialization and support technological upgrades in polymer processing. It benefits from a robust supplier ecosystem and rising exports of plastic resins and finished products. Leading manufacturers establish regional headquarters and technical centers to enhance customer support and service responsiveness. The growing focus on sustainable production and recycling drives further investments in next-generation pelletizing solutions.

North America :

North America accounts for a 26% share of the underwater pelletizing market, backed by established polymer processing infrastructure and widespread adoption of recycling practices. The region demonstrates consistent demand for high-performance pelletizing equipment in packaging, automotive, and construction applications. Stringent regulations related to waste management and plastic recycling drive investments in efficient and eco-friendly systems. Major companies prioritize technology upgrades that improve material efficiency and operational reliability. It maintains a reputation for technological innovation and collaborates with research institutions to develop advanced solutions. Stable economic conditions and strong end-user industries sustain regional market growth.

Europe :

Europe represents a 21% market share in the underwater pelletizing market, supported by advanced manufacturing capabilities and strict environmental standards. The region emphasizes the adoption of sustainable materials, aligning with ambitious circular economy targets and regulatory requirements. Leading players develop premium-grade polymers and specialty compounds for automotive, electronics, and medical applications. It invests in high-efficiency, automated pelletizing systems that deliver superior pellet quality and resource efficiency. Collaborative efforts between industry, government, and academia drive product innovation and support workforce development. The commitment to sustainability positions Europe as a key market for technology adoption and new product development.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Coperion

- Cowell Extrusion

- CGC Technology

- Nordson

- Chuangbo Machine

- Cowin Extrusion

- Farrel Pomini

- MAAG

- Crown Machine

- ECON

- Neoplast

Competitive Analysis:

The underwater pelletizing market features strong competition among global players such as Coperion, Cowell Extrusion, CGC Technology, Nordson, Chuangbo Machine, Cowin Extrusion, Farrel Pomini, and MAAG. These companies focus on developing advanced pelletizing systems that offer high throughput, reliability, and adaptability to a wide range of polymers. It drives innovation in automation, process control, and energy efficiency to meet evolving customer needs. Leading players invest in expanding service networks, technical support, and after-sales solutions to strengthen customer relationships. The market values product differentiation through customization, robust design, and compatibility with sustainable materials. Strategic collaborations with polymer producers and continuous research and development activities reinforce competitive positioning. It remains dynamic, shaped by rapid technological advancements and growing demand for specialty and recycled polymers across diverse industries.

Recent Developments:

- In August 2024, Coperion completed the integration of the Schenck Process Food and Performance Materials (FPM) group, bringing several brands such as Baker Perkins and Unifiller under its portfolio.

- June 2025: CGC Digital (Malaysia) established a partnership with B2B Finpal to expand digital lending solutions for MSMEs.

- In July 2025, Nordson launched the VersaBlue® II Melter, a new adhesive dispensing solution aimed at the hygiene sector.

Market Concentration & Characteristics:

The underwater pelletizing market exhibits moderate concentration, with a mix of established global players and specialized regional manufacturers. Leading companies maintain a strong presence by offering advanced, customizable systems and comprehensive after-sales support. It features high entry barriers due to significant capital investment, technical expertise, and stringent quality requirements. Product differentiation centers on automation, energy efficiency, and compatibility with diverse polymers, including recycled and biodegradable materials. Continuous innovation and technology upgrades drive competition, while long-term relationships with major polymer producers strengthen market positions. The market remains dynamic, shaped by regulatory developments, customer demands, and rapid adoption of digital process controls.

Report Coverage:

The research report offers an in-depth analysis based on Type, Production Capacity, Application and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- Equipment providers will focus on modular designs to support flexible production and faster changeover between polymer grades.

- It will adopt advanced digital process control features to enable real‑time process optimization and predictive maintenance.

- Manufacturers will pursue water‑recycling and filtration innovations to reduce resource consumption and minimize waste discharge.

- The market will develop systems tailored for handling post‑consumer plastics and bio‑based materials with sensitive properties.

- Leaders will form strategic alliances with polymer producers and recyclers to co‑develop solutions for new formulations.

- Service offerings will expand to include remote diagnostics, performance analytics, and usage‑based maintenance contracts.

- Equipment makers will gradually integrate AI‑based control algorithms to enhance throughput, pellet uniformity, and energy efficiency.

- Focused markets in Latin America, Middle East, and Africa will create demand for robust and lower‑cost pelletizing lines suited to local conditions.

- Manufacturers will seek regulatory approval and industry certification in regions enforcing strict environmental and safety standards.

- It will support circular economy goals by enabling closed‑loop pellet production from recycled streams, boosting sustainability credentials.