Market Overview

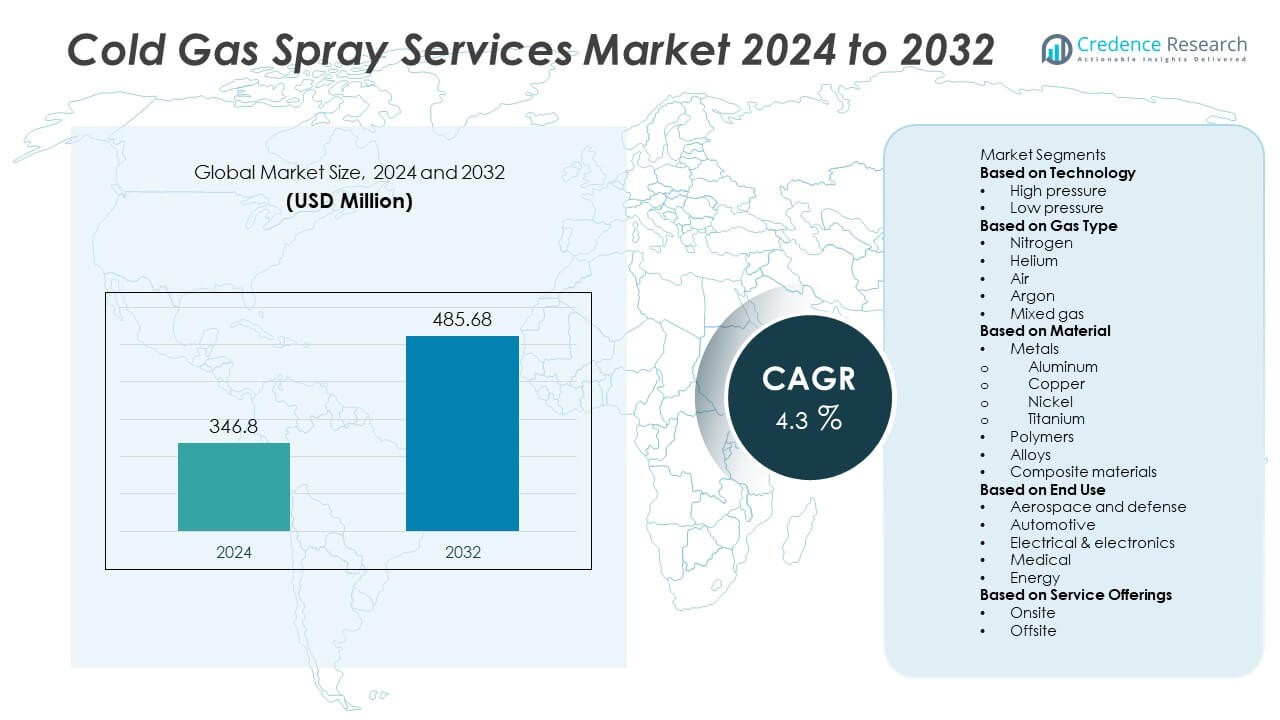

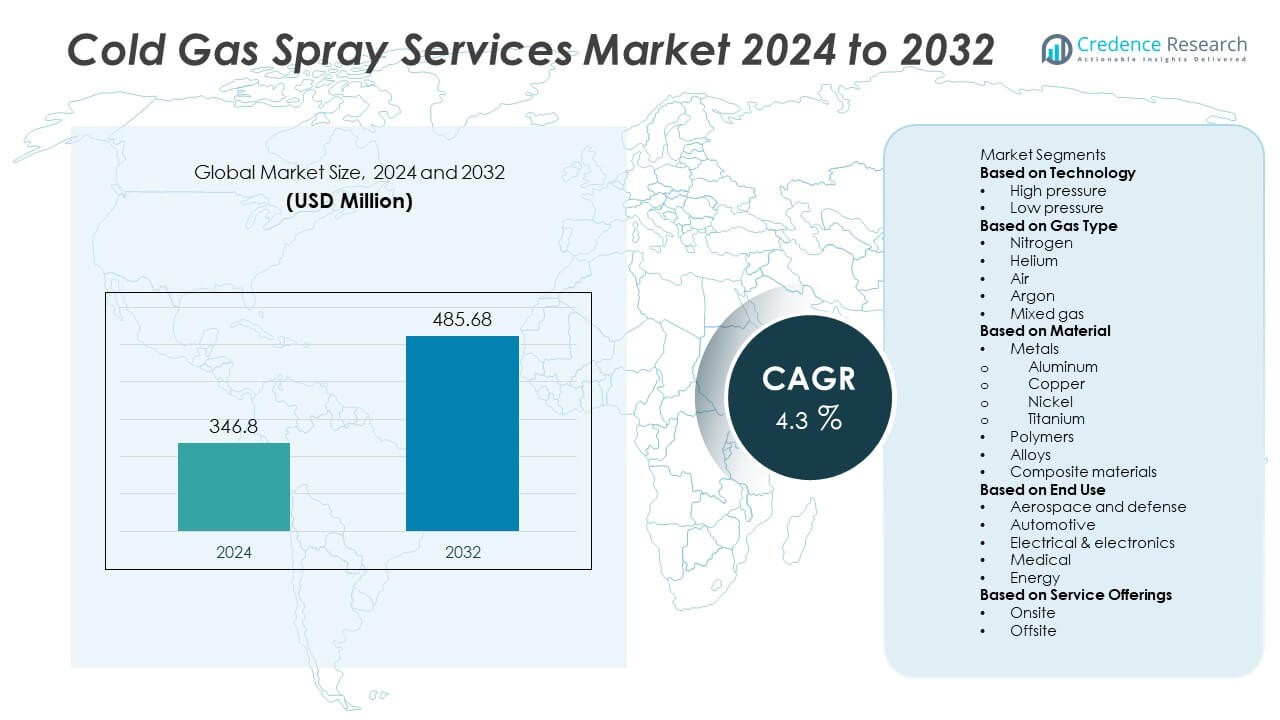

The Cold Gas Spray Services Market was valued at USD 346.8 million in 2024 and is projected to reach USD 485.68 million by 2032, reflecting a CAGR of 4.3% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Cold Gas Spray Services Market Size 2024 |

USD 346.8 Million |

| Cold Gas Spray Services Market, CAGR |

4.3% |

| Cold Gas Spray Services Market Size 2032 |

USD 485.68 Million |

The Cold Gas Spray Services Market benefits from rising demand for efficient, low-temperature coating solutions across aerospace, defense, and energy sectors. It enables high-performance surface restoration without damaging substrates, extending component lifespan and reducing downtime. Growing environmental regulations promote adoption of low-emission, sustainable coating methods.

The Cold Gas Spray Services Market spans multiple regions, with North America and Europe leading due to their advanced aerospace, defense, and energy sectors. These regions benefit from strong infrastructure, regulatory support, and early technology adoption, fostering steady demand for cold spray services. The Asia Pacific region is rapidly expanding, driven by growing industrialization, increasing defense budgets, and infrastructure development in countries like China, India, and Japan. Emerging markets in Latin America and the Middle East are gradually adopting cold spray technologies, focusing on energy and heavy industries. Key players shaping the market include Impact Innovations, known for its high-pressure cold spray systems widely used in aerospace repairs; Integrated Global Services, specializing in on-site cold spray repair solutions; Linde, offering advanced gas supply and technology integration; and Metallizing Equipment, providing customized cold spray coatings across various industrial sectors.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Cold Gas Spray Services Market was valued at USD 346.8 million in 2024 and is projected to reach USD 485.68 million by 2032, growing at a CAGR of 4.3% during the forecast period.

- Rising demand for efficient surface restoration in aerospace, defense, and energy sectors drives market growth by extending component life and reducing operational downtime.

- Adoption of automation and robotics enhances coating precision and throughput, supporting faster turnaround times and reducing labor dependency.

- Integration of cold spray with additive manufacturing expands applications in part production and repair, promoting innovation in customized manufacturing.

- High capital investment and limited skilled workforce availability pose significant challenges, restricting market penetration especially in emerging economies.

- North America and Europe lead market growth due to advanced infrastructure, regulatory support, and mature industrial sectors, while Asia Pacific shows rapid expansion driven by increasing defense budgets and industrialization.

- Leading players such as Impact Innovations, Integrated Global Services, Linde, and Metallizing Equipment focus on technological advancements and strategic partnerships to strengthen global presence and service offerings.

Market Drivers

Rising Demand for High-Performance Coatings in Aerospace and Defense

The Cold Gas Spray Services Market is expanding due to growing use in aerospace and defense sectors where component reliability is critical. It provides coatings with superior adhesion and mechanical strength, extending the service life of parts exposed to extreme conditions. The process maintains substrate integrity by avoiding high-temperature exposure, which prevents material degradation. Aerospace manufacturers rely on it for repairing turbine blades, landing gear, and structural elements with minimal downtime. Defense applications benefit from its ability to restore worn parts and improve resistance to wear, corrosion, and erosion. The need for efficient and durable repair solutions continues to drive adoption in these sectors.

- For instance, Impact Innovations GmbH reported over 150 turbine blade repairs completed using their EvoCSII cold spray system within a single year, significantly reducing component replacement frequency in aerospace fleets.

Stringent Environmental Regulations Favoring Low-Emission Coating Methods

Regulatory frameworks in multiple regions are encouraging adoption of cold gas spray technology due to its environmentally friendly characteristics. It operates without combustion, significantly reducing harmful particle emissions compared to conventional thermal spray methods. Industries under strict emission norms use it to meet compliance requirements while maintaining operational efficiency. The process also minimizes waste generation, which supports sustainability initiatives in manufacturing and maintenance operations. Companies in regions with rigorous environmental laws are shifting from older coating techniques to this cleaner alternative. The alignment with regulatory goals is expected to sustain long-term demand.

- For instance, Linde PLC integrated advanced gas supply and monitoring systems in their cold spray units, enabling a reduction of over 1,200 metric tons of CO₂ emissions annually across installations in Europe and North America.

Integration of Automation to Enhance Service Precision and Efficiency

Service providers in the Cold Gas Spray Services Market are integrating automation and robotics to improve coating precision, consistency, and throughput. Automated systems apply uniform coatings over complex geometries, reducing manual errors and improving overall quality. The technology allows rapid turnaround times for high-volume production while lowering labor dependency. Industries facing skilled labor shortages benefit from its programmable and repeatable operation. Robotic integration also enables consistent results for critical applications, ensuring adherence to tight tolerances. Growing focus on operational efficiency is reinforcing the shift toward automated cold spray services.

Expanding Role in Additive Manufacturing and Component Repair

The market is gaining traction from its use in additive manufacturing workflows for both part production and repair. It deposits metal layers without melting, avoiding problems like thermal distortion and residual stress. Industries such as energy, marine, and transportation use it to rebuild worn or damaged components to original specifications. This approach reduces replacement costs and extends the lifespan of expensive equipment. The compatibility with various metals and alloys increases its versatility across different industrial applications. Ongoing innovation in material deposition techniques is broadening its scope in advanced manufacturing environments.

Market Trends

Growing Use of Cold Spray in Hybrid Manufacturing Processes

The Cold Gas Spray Services Market is witnessing increased integration with hybrid manufacturing processes, combining additive and subtractive techniques for advanced component production. It allows precise metal deposition on substrates before machining, enabling manufacturers to create near-net-shape parts with minimal waste. This approach is gaining adoption in aerospace and medical device manufacturing for producing high-value, performance-critical components. The technology’s ability to bond dissimilar materials without thermal damage expands its use in complex assemblies. Service providers are investing in multi-functional systems that combine cold spray with CNC machining for seamless production workflows. The trend is strengthening its role in high-precision manufacturing.

- For instance, CenterLine (Windsor) Limited, a leading provider of cold spray and hybrid manufacturing solutions, has supplied over 60 hybrid cold spray systems globally, with clients reporting up to 35% reduction in machining times and material usage during aerospace part production.

Advancement in Portable Cold Spray Systems for On-Site Repairs

Portable cold spray units are becoming more advanced, driving demand in field repair services where downtime costs are high. It enables restoration of critical parts on-site without disassembly, reducing logistical challenges and operational delays. Energy, marine, and defense sectors are using these systems for emergency repairs in remote or operationally sensitive locations. Manufacturers are improving portability through lighter system designs and modular components that maintain industrial-grade performance. Service providers are also offering mobile repair teams equipped with high-performance portable units to expand market reach. The focus on rapid, location-independent repair capability is shaping future service offerings.

- For instance, Kermetico, Inc. has introduced portable cold spray units such as the Compact CS System, which have been deployed in over 30 industrial sites worldwide by 2023. These portable systems have facilitated numerous emergency repairs, with documented cases showing a reduction of repair times by several days, allowing critical assets to return to service promptly.

Increased Application in High-Value Component Restoration

Industries are expanding the use of cold gas spray for restoring high-value components to original specifications. It offers dimensional restoration with minimal thermal impact, making it suitable for aerospace landing gear, turbine components, and industrial pump housings. This trend supports cost efficiency by extending equipment life instead of full replacement. Service providers are optimizing process parameters to achieve coating densities and bonding strengths comparable to new parts. The ability to handle advanced alloys and hard-to-machine materials is enhancing its role in repair operations. Growing repair-focused demand is reinforcing its importance in asset maintenance strategies.

Material Innovations Expanding Application Potential

Continuous innovation in feedstock powders is driving new opportunities for cold spray applications across multiple sectors. It now supports deposition of metals such as titanium, Inconel, and copper alloys, opening doors for high-performance engineering solutions. Research and development efforts are focusing on optimizing particle size distribution and morphology for improved deposition efficiency. Service providers are working closely with material suppliers to tailor powders for specific performance outcomes. Enhanced material capabilities are enabling cold spray to penetrate industries such as nuclear, biomedical, and renewable energy. This material-driven expansion is increasing the market’s application diversity and competitiveness.

Market Challenges Analysis

High Capital Costs and Limited Access to Skilled Operators

The Cold Gas Spray Services Market faces significant challenges due to the high initial investment required for advanced equipment and operational infrastructure. It demands specialized systems capable of delivering precise particle velocities and controlled deposition, which increases acquisition costs for service providers. Maintenance and calibration requirements further raise operational expenses, limiting adoption among smaller firms. The shortage of skilled operators with expertise in process optimization and material handling compounds the issue. Training programs are not yet widely available, creating reliance on experienced technicians who are in short supply. This combination of financial and workforce barriers slows expansion, especially in emerging markets.

Process Limitations in Material Compatibility and Deposition Control

Certain limitations in material compatibility and deposition consistency continue to challenge the Cold Gas Spray Services Market. It struggles with achieving uniform adhesion on substrates with complex surface chemistries or geometries, reducing efficiency in specific applications. Feedstock powders must meet strict specifications for particle size and morphology, restricting material sourcing options. Process control becomes more difficult when working with high-hardness alloys or composite materials. In some cases, post-spray machining or finishing is necessary to meet dimensional and surface quality requirements, adding time and cost. These technical constraints hinder the technology’s ability to fully replace other established coating and repair methods

Market Opportunities

Rising Demand for Advanced Surface Restoration in High-Performance Industries

The Cold Gas Spray Services Market holds strong opportunities in sectors requiring high-performance surface restoration and component life extension. It offers the ability to restore worn or corroded parts without altering the substrate’s structural integrity, making it ideal for aerospace, defense, and energy industries. Growing emphasis on reducing downtime and extending asset service life drives demand for precision repair solutions. Cold spray’s capability to deposit oxidation-resistant and wear-resistant coatings opens new avenues for critical applications. The increasing need for maintenance of high-value components, such as turbine blades and aerospace structural parts, supports service adoption. This demand is further supported by industries seeking sustainable repair methods to minimize material waste.

Expansion Potential in Emerging Industrial and Research Applications

Opportunities are expanding in emerging markets where Cold Gas Spray Services can address niche manufacturing and prototyping needs. It enables rapid production of custom coatings and structural reinforcements for medical devices, electronics, and renewable energy components. Research institutions and R&D facilities are adopting cold spray services to explore novel material combinations and advanced coating architectures. Its ability to work with metals, alloys, and composites without thermal distortion makes it valuable for high-precision, low-temperature applications. The integration of automation and robotics into service offerings further enhances its competitiveness. These capabilities position the technology for growth in both established industries and innovative new sectors.

Market Segmentation Analysis:

By Technology

The Cold Gas Spray Services Market segments primarily into high-pressure and low-pressure cold spray services. High-pressure systems dominate due to their ability to generate particle velocities exceeding 1,000 meters per second, which ensures superior coating density and adhesion. This technology is widely used in aerospace and heavy industrial sectors for critical component repair and surface enhancement. Low-pressure cold spray services offer advantages in portability and cost-effectiveness, serving research, prototyping, and light-duty industrial repairs. It caters to applications requiring less intensive coating properties but benefits from operational flexibility and lower infrastructure demands.

- For instance, Impact Innovations GmbH’s EvoCSII high-pressure system achieves particle velocities of up to 1,200 meters per second and has been deployed in over 100 installations globally, supporting aerospace component refurbishment with consistently high coating quality and adhesion strength.

By Gas Type

The Cold Gas Spray Services Market primarily utilizes nitrogen and helium gases. Nitrogen remains the preferred choice due to its availability and lower cost, providing sufficient particle acceleration for many coating applications. Helium, though more expensive, delivers higher particle velocities because of its lower atomic mass, enabling coatings on materials that require more delicate or precise deposition processes. Service providers select the gas type based on the substrate and coating material, balancing performance requirements with operational expenses. For example, helium-based cold spray services are prevalent in aerospace and defense sectors where coating uniformity and material integrity are paramount.

- For instance, Höganäs AB, a major metal powder and cold spray technology provider, utilizes helium-assisted cold spray technology through partnerships to improve aerospace coatings.

By Material

Material segmentation in the Cold Gas Spray Services Market focuses on metals, alloys, and composite powders. Metals such as copper, aluminum, and titanium dominate due to their extensive industrial applications, including electrical conductivity and lightweight structural components. Alloy powders like nickel-based superalloys and stainless steel are used for high-strength, corrosion-resistant coatings in energy, aerospace, and marine applications. Composite powders, which combine metals with ceramics or polymers, serve specialized functions by imparting wear resistance, thermal barriers, or enhanced mechanical properties. The versatility of cold spray technology in accommodating diverse materials expands its service scope across multiple industries. It enables tailored coating solutions that meet specific performance criteria, supporting the demand for customized surface engineering.

Segments:

Based on Technology

- High pressure

- Low pressure

Based on Gas Type

- Nitrogen

- Helium

- Air

- Argon

- Mixed gas

Based on Material

- Metals

- Aluminum

- Copper

- Nickel

- Titanium

- Polymers

- Alloys

- Composite materials

Based on End Use

- Aerospace and defense

- Automotive

- Electrical & electronics

- Medical

- Energy

Based on Service Offerings

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America

The Cold Gas Spray Services Market in North America holds the largest market share, driven by its well-established aerospace, defense, and energy sectors, which heavily rely on cold spray services for component repair and surface enhancement. The presence of key service providers and advanced manufacturing infrastructure further consolidates its market dominance. Demand for cost-effective maintenance solutions and the emphasis on reducing downtime are critical factors supporting steady growth in this region.

Europe

Europe accounts for the second-largest share in the Cold Gas Spray Services Market, primarily due to stringent environmental regulations and significant investment in sustainable manufacturing technologies. The aerospace and automotive industries in countries such as Germany, France, and the UK actively adopt cold spray services to extend the lifespan of critical components while complying with regulatory standards. The region’s focus on reducing carbon footprints and promoting eco-friendly repair methods accelerates market penetration. Growing collaboration between service providers and industrial players fosters innovation and expands application scope.

Asia Pacific

The Asia Pacific region is experiencing rapid growth and captures a notable market share fueled by expanding industrial manufacturing bases in China, India, Japan, and South Korea. Rising aerospace manufacturing activities, infrastructure development, and increasing defense budgets boost demand for cold spray services. The region benefits from a growing skilled workforce and government initiatives promoting advanced surface engineering technologies. Emerging economies in this region present significant opportunities for service providers due to increasing investments in heavy industries, transportation, and energy sectors.

Latin America

Latin America holds a smaller but gradually increasing share of the Cold Gas Spray Services Market. Industrial sectors such as oil and gas, mining, and manufacturing drive demand in countries like Brazil and Mexico. The growing focus on asset life extension and cost-effective maintenance solutions supports market growth. However, slower technological adoption and limited infrastructure pose challenges to rapid expansion.

Middle East & Africa

The Middle East & Africa region holds a modest share but shows promising potential due to its vast energy sector and increasing interest in advanced repair technologies. Countries with significant oil and gas operations are investing in surface restoration services to enhance equipment reliability and reduce operational downtime. Infrastructure development projects and defense modernization initiatives are expected to further stimulate demand. Service providers are exploring partnerships and local presence to capitalize on emerging opportunities in this region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

Competitive Analysis

The Cold Gas Spray Services Market is highly competitive, driven by key players such as Impact Innovations, Integrated Global Services, Linde, Metallizing Equipment, OC Oerlikon Management, Flame Spray, Hoganas, Hannecard Roller Coatings, Kermetico, and Praxair Technology. These companies focus on technological innovation, expanding service capabilities, and strategic collaborations to maintain market leadership. Impact Innovations leads with its high-pressure cold spray systems, widely adopted in aerospace and defense for critical component repair. Integrated Global Services emphasizes on-site repair solutions, offering flexible and rapid deployment to reduce customer downtime. Linde strengthens its position by providing advanced gas supply infrastructure and integrating cold spray technology with complementary industrial services. Metallizing Equipment customizes coatings for various sectors, emphasizing precision and quality. OC Oerlikon Management combines cold spray services with surface engineering expertise to deliver tailored solutions. Market leaders invest heavily in R&D to enhance process efficiency, coating adhesion, and material compatibility. Strategic partnerships and global service networks enable these players to penetrate emerging markets and meet diverse customer needs. Continuous innovation in automation and robotics further differentiates their service offerings, positioning them to capitalize on growing demand across aerospace, energy, and industrial manufacturing sectors.

Recent Developments

- In June 2025, Integrated Global Services (IGS) enhanced its Thermal Sprayed Aluminum (TSA) and online thermal spray solutions. These advancements focused on providing long-lasting corrosion protection for refinery and petrochemical assets.

- In February 2025, Praxair Surface Technologies (now Linde Advanced Material Technologies)introduced a new cold gas spray coating system specifically designed to improve the wear resistance of aerospace components. This system aims to reduce maintenance expenses and boost the operational efficiency of aircraft.

- In October 2024, Metallizing Equipment and other providers saw increased adoption of high-pressure cold spray services, with recent improvements enhancing deposition rates and efficiency. This adoption is primarily driven by the aerospace and industrial sectors, with a focus on repair and refurbishment applications.

Market Concentration & Characteristics

The Cold Gas Spray Services Market exhibits a moderately concentrated competitive landscape characterized by several established players and emerging specialized service providers. It is marked by a combination of technologically advanced firms with global reach and smaller regional companies focusing on niche applications. The market demands high capital investment and specialized expertise, which limits the entry of new competitors and reinforces the position of incumbent players. Service providers differentiate themselves through innovation in coating technologies, integration of automation, and the ability to offer customized, on-site repair solutions. Collaboration between equipment manufacturers and service companies enhances the delivery of comprehensive cold spray solutions. The market’s characteristics include strong emphasis on quality control, regulatory compliance, and adaptability to diverse industrial requirements. This creates a competitive environment where customer relationships and technological capabilities drive success. It also encourages continuous R&D efforts to improve coating performance and expand material compatibility. Geographic expansion and strategic partnerships remain key strategies for market players seeking to increase their footprint and address growing demand in aerospace, defense, energy, and manufacturing sectors. Overall, the Cold Gas Spray Services Market balances technological innovation with operational efficiency, creating a dynamic yet focused industry landscape.

Report Coverage

The research report offers an in-depth analysis based on Technology, Gas Type, Material, End-User, Services offerings and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Cold Gas Spray Services Market will continue expanding due to increasing demand for advanced surface repair and coating solutions.

- Growth in aerospace and defense sectors will drive the need for high-precision cold spray repairs and restorations.

- Automation and robotics integration will enhance service efficiency and coating consistency.

- Adoption of cold spray services in additive manufacturing will increase for producing customized parts.

- Emerging markets will offer new growth opportunities as industrial infrastructure develops.

- Environmental regulations will push industries to prefer low-emission, sustainable coating methods.

- Service providers will focus on developing portable systems for on-site repairs in remote locations.

- Advances in powder materials will expand the range of applications across different industries.

- Strategic partnerships and collaborations will enable global service network expansion.

- Continuous innovation will improve coating quality, reduce processing time, and lower operational costs.