1. Preface

1.1. Report Description

1.1.1. Purpose of the Report

1.1.2. Target Audience

1.1.3. USP and Key Offerings

1.2. Research Scope

1.3. Market Introduction

2. Executive Summary

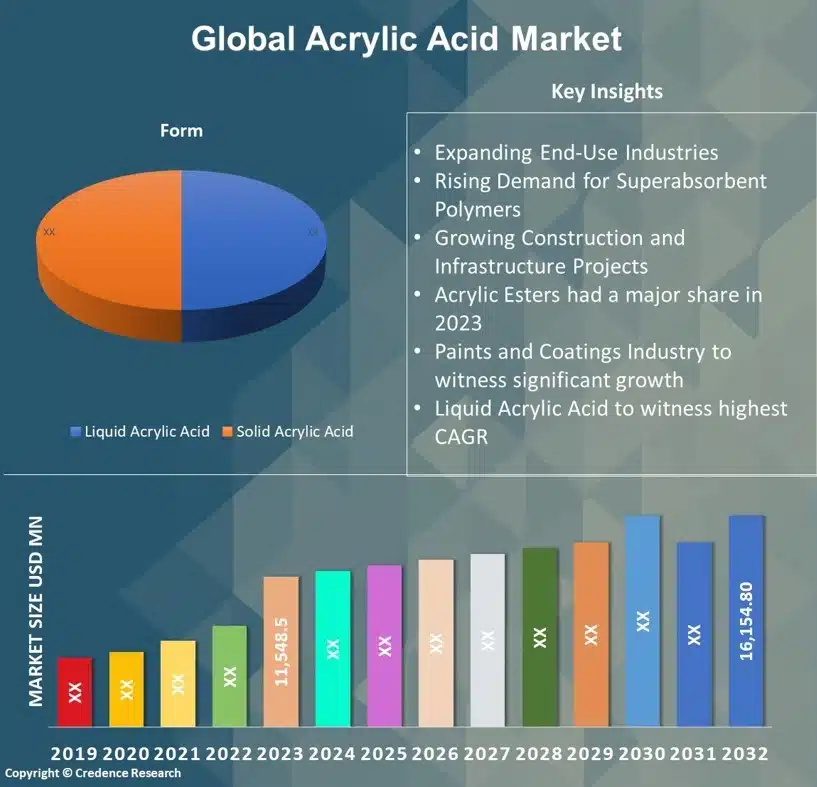

2.1. Market Snapshot: Global Acrylic Acid Market

2.1.1. Global Acrylic Acid Market, By Derivative Types

2.1.2. Global Acrylic Acid Market, By End-User Industries

2.1.3. Global Acrylic Acid Market, By Form

2.1.4. Global Acrylic Acid Market, By Application Methods

2.1.5. Global Acrylic Acid Market, By Production Process

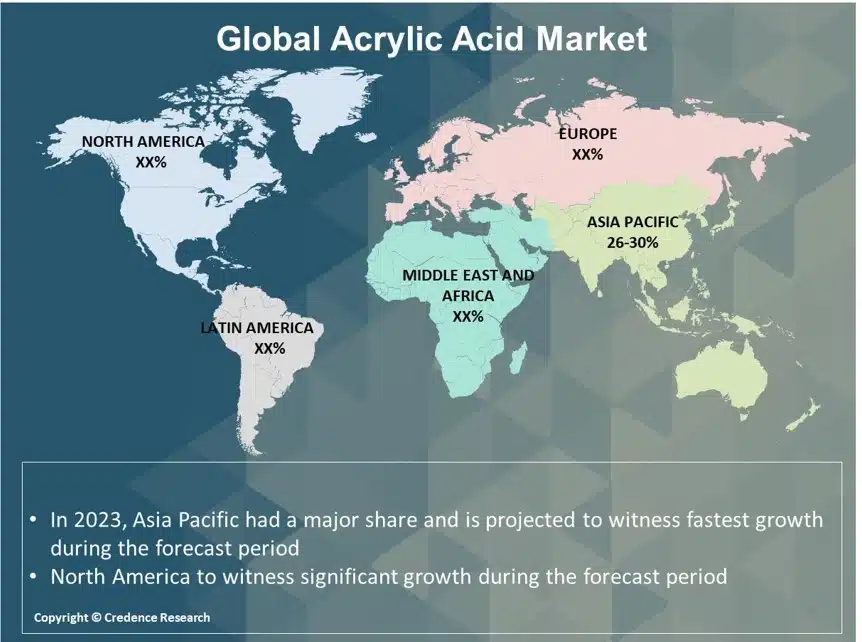

2.1.6. Global Acrylic Acid Market, By Region

2.2. Insights from Primary Respondents

3. Market Dynamics & Factors Analysis

3.1. Introduction

3.1.1. Global Acrylic Acid Market Value, 2019-2032, (US$ Mn)

3.1.2. Y-o-Y Growth Trend Analysis

3.2. Market Dynamics

3.2.1. Acrylic Acid Market Drivers

3.2.2. Acrylic Acid Market Restraints

3.2.3. Acrylic Acid Market Opportunities

3.2.4. Major Acrylic Acid Industry Challenges

3.3. Growth and Development Patterns

3.4. Investment Feasibility Analysis

3.5. Market Opportunity Analysis

3.5.1. Derivative Types

3.5.2. End-User Industries

3.5.3. Form

3.5.4. Application Methods

3.5.5. Production Process

3.5.6. Geography

4. Market Competitive Landscape Analysis

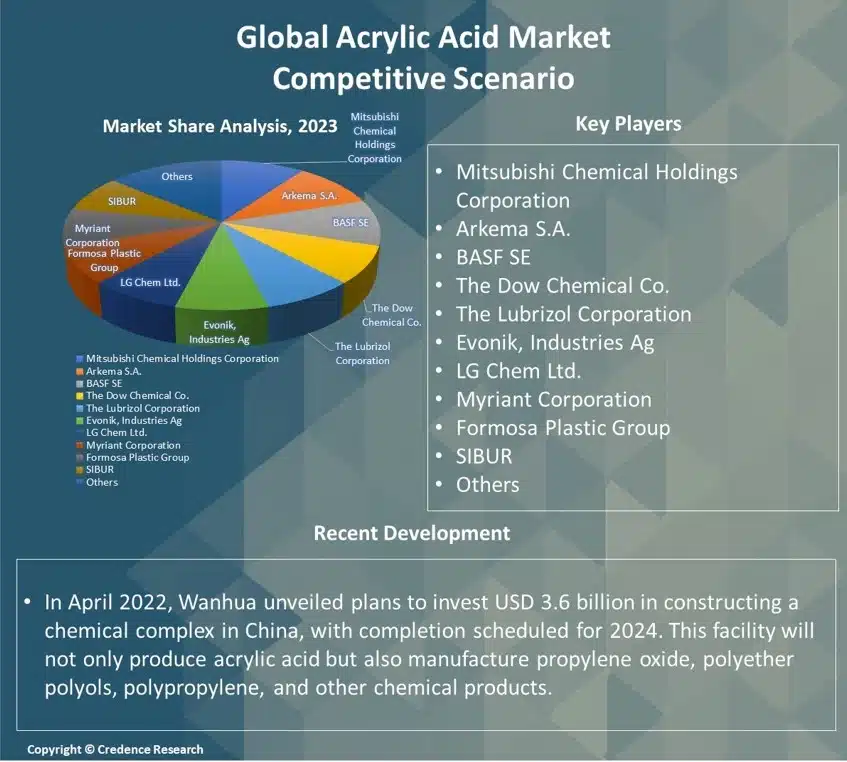

4.1. Company Market Share Analysis, 2023

4.1.1. Global Acrylic Acid Market: Company Market Share, Value 2023

4.1.2. Global Acrylic Acid Market: Top 6 Company Market Share, Value 2023

4.1.3. Global Acrylic Acid Market: Top 3 Company Market Share, Value 2023

4.2. Global Acrylic Acid Market: Company Revenue Share Analysis, 2023

4.3. Company Assessment Metrics, 2023

4.3.1. Stars

4.3.2. Emerging Leaders

4.3.3. Pervasive Players

4.3.4. Participants

4.4. Startups/ SMEs Assessment Metrics, 2023

4.4.1. Progressive Companies

4.4.2. Responsive Companies

4.4.3. Dynamic Companies

4.4.4. Starting Blocks

4.5. Strategic Development

4.5.1. Acquisition and Mergers

4.5.2. New Product Launch

4.5.3. Regional Expansion

4.5.4. Partnerships

4.6. Key Player Product Matrix

4.7. Potential for New Players in the Global Acrylic Acid Market

5. Premium Insights

5.1. STAR (Situation, Task, Action, Results) Analysis

5.2. Porter’s Five Forces Analysis

5.2.1. Threat of New Entrants

5.2.2. Bargaining Power of Buyers/Consumers

5.2.3. Bargaining Power of Suppliers

5.2.4. Threat of Substitute Types

5.2.5. Intensity of Competitive Rivalry

5.3. PESTEL Analysis

5.3.1. Political Factors

5.3.2. Economic Factors

5.3.3. Social Factors

5.3.4. Technological Factors

5.3.5. Environmental Factors

5.3.6. Legal Factors

5.4. Key Market Trends

5.4.1. Demand Side Trends

5.4.2. Supply Side Trends

5.5. Value Chain Analysis

5.6. Technology Analysis

5.6.1. Research and development in the global market

5.6.2. Patent Analysis

5.6.3. Emerging technologies and their potential disruption to the market

5.7. Consumer Behaviour Analysis

5.7.1. Consumer Preferences and Expectations

5.7.2. Factors Influencing Consumer Buying Decisions

5.7.2.1. North America

5.7.2.2. Europe

5.7.2.3. Asia Pacific

5.7.2.4. Latin America

5.7.2.5. Middle East and Africa

5.7.3. Consumer Pain Points

5.8. Analysis and Recommendations

5.9. Adjacent Market Analysis

6. Market Positioning of Key Players, 2023

6.1. Company market share of key players, 2023

6.2. Competitive Benchmarking

6.3. Market Positioning of Key Vendors

6.4. Geographical Presence Analysis

6.5. Major Strategies Adopted by Key Players

6.5.1. Key Strategies Analysis

6.5.2. Mergers and Acquisitions

6.5.3. Partnerships

6.5.4. Product Launch

6.5.5. Geographical Expansion

6.5.6. Others

7. Impact Analysis of COVID 19 and Russia – Ukraine War on Acrylic Acid Market

7.1. Ukraine-Russia War Impact

7.1.1. Uncertainty and Economic Instability

7.1.2. Supply chain disruptions

7.1.3. Regional market shifts

7.1.4. Shift in government priorities

7.2. COVID-19 Impact Analysis

7.2.1. Supply Chain Disruptions

7.2.2. Demand Fluctuations

7.2.3. Shift in Product Mix

7.2.4. Reduced Industrial Activity

7.2.5. Regional Impact Analysis

7.2.5.1. North America

7.2.5.2. Europe

7.2.5.3. Asia Pacific

7.2.5.4. Latin America

7.2.5.5. Middle East and Africa

8. Global Acrylic Acid Market, By Derivative Types

8.1. Global Acrylic Acid Market Overview, by Derivative Types

8.1.1. Global Acrylic Acid Market Revenue Share, By Derivative Types, 2023 Vs 2032 (in %)

8.2. Acrylic Esters (Butyl Acrylate, Ethyl Acrylate, Methyl Acrylate, etc.)

8.2.1. Global Acrylic Acid Market, By Acrylic Esters, By Region, 2019-2032 (US$ Mn)

8.2.2. Market Dynamics for Acrylic Esters

8.2.2.1. Drivers

8.2.2.2. Restraints

8.2.2.3. Opportunities

8.2.2.4. Trends

8.3. Superabsorbent Polymers (SAP)

8.3.1. Global Acrylic Acid Market, By Superabsorbent Polymers (SAP), By Region, 2019-2032 (US$ Mn)

8.3.2. Market Dynamics for Superabsorbent Polymers (SAP)

8.3.2.1. Drivers

8.3.2.2. Restraints

8.3.2.3. Opportunities

8.3.2.4. Trends

8.4. Acrylic Polymers (Polyacrylic Acid)

8.4.1. Global Acrylic Acid Market, By Acrylic Polymers (Polyacrylic Acid), By Region, 2019-2032 (US$ Mn)

8.4.2. Market Dynamics for Acrylic Polymers (Polyacrylic Acid)

8.4.2.1. Drivers

8.4.2.2. Restraints

8.4.2.3. Opportunities

8.4.2.4. Trends

8.5. Others

8.5.1. Global Acrylic Acid Market, By Others, By Region, 2019-2032 (US$ Mn)

8.5.2. Market Dynamics for Others

8.5.2.1. Drivers

8.5.2.2. Restraints

8.5.2.3. Opportunities

8.5.2.4. Trends

9. Global Acrylic Acid Market, By End-User Industries

9.1. Global Acrylic Acid Market Overview, by End-User Industries

9.1.1. Global Acrylic Acid Market Revenue Share, By End-User Industries, 2023 Vs 2032 (in %)

9.2. Paints and Coatings Industry

9.2.1. Global Acrylic Acid Market, By Paints and Coatings Industry, By Region, 2019-2032 (US$ Mn)

9.2.2. Market Dynamics for Paints and Coatings Industry

9.2.2.1. Drivers

9.2.2.2. Restraints

9.2.2.3. Opportunities

9.2.2.4. Trends

9.3. Textiles Industry

9.3.1. Global Acrylic Acid Market, By Textiles Industry, By Region, 2019-2032 (US$ Mn)

9.3.2. Market Dynamics for Textiles Industry

9.3.2.1. Drivers

9.3.2.2. Restraints

9.3.2.3. Opportunities

9.3.2.4. Trends

9.4. Personal Care and Hygiene Industry

9.4.1. Global Acrylic Acid Market, By Personal Care and Hygiene Industry, By Region, 2019-2032 (US$ Mn)

9.4.2. Market Dynamics for IT and Telecom Sector

9.4.2.1. Drivers

9.4.2.2. Restraints

9.4.2.3. Opportunities

9.4.2.4. Trends

9.5. Water Treatment Industry

9.5.1. Global Acrylic Acid Market, By Water Treatment Industry, By Region, 2019-2032 (US$ Mn)

9.5.2. Market Dynamics for Water Treatment Industry

9.5.2.1. Drivers

9.5.2.2. Restraints

9.5.2.3. Opportunities

9.5.2.4. Trends

9.6. Others

9.6.1. Global Acrylic Acid Market, By Others, By Region, 2019-2032 (US$ Mn)

9.6.2. Market Dynamics for Others

9.6.2.1. Drivers

9.6.2.2. Restraints

9.6.2.3. Opportunities

9.6.2.4. Trends

10. Global Acrylic Acid Market, By Form

10.1. Global Acrylic Acid Market Overview, by Form

10.1.1. Global Acrylic Acid Market Revenue Share, By Form, 2023 Vs 2032 (in %)

10.2. Liquid Acrylic Acid

10.2.1. Global Acrylic Acid Market, By Liquid Acrylic Acid, By Region, 2019-2032 (US$ Mn)

10.2.2. Market Dynamics for Liquid Acrylic Acid

10.2.2.1. Drivers

10.2.2.2. Restraints

10.2.2.3. Opportunities

10.2.2.4. Trends

10.3. Solid Acrylic Acid

10.3.1. Global Acrylic Acid Market, By Solid Acrylic Acid, By Region, 2019-2032 (US$ Mn)

10.3.2. Market Dynamics for Solid Acrylic Acid

10.3.2.1. Drivers

10.3.2.2. Restraints

10.3.2.3. Opportunities

10.3.2.4. Trends

11. Global Acrylic Acid Market, By Application Methods

11.1. Global Acrylic Acid Market Overview, by Application Methods

11.1.1. Global Acrylic Acid Market Revenue Share, By Application Methods, 2023 Vs 2032 (in %)

11.2. Direct Synthesis

11.2.1. Global Acrylic Acid Market, By Direct Synthesis, By Region, 2019-2032 (US$ Mn)

11.2.2. Market Dynamics for Direct Synthesis

11.2.2.1. Drivers

11.2.2.2. Restraints

11.2.2.3. Opportunities

11.2.2.4. Trends

11.3. Esterification

11.3.1. Global Acrylic Acid Market, By Esterification, By Region, 2019-2032 (US$ Mn)

11.3.2. Market Dynamics for Esterification

11.3.2.1. Drivers

11.3.2.2. Restraints

11.3.2.3. Opportunities

11.3.2.4. Trends

11.4. Amidation

11.4.1. Global Acrylic Acid Market, By Amidation, By Region, 2019-2032 (US$ Mn)

11.4.2. Market Dynamics for Amidation

11.4.2.1. Drivers

11.4.2.2. Restraints

11.4.2.3. Opportunities

11.4.2.4. Trends

11.5. Others

11.5.1. Global Acrylic Acid Market, By Others, By Region, 2019-2032 (US$ Mn)

11.5.2. Market Dynamics for Others

11.5.2.1. Drivers

11.5.2.2. Restraints

11.5.2.3. Opportunities

11.5.2.4. Trends

12. Global Acrylic Acid Market, By Production Process

12.1. Global Acrylic Acid Market Overview, by Production Process

12.1.1. Global Acrylic Acid Market Revenue Share, By Production Process, 2023 Vs 2032 (in %)

12.2. Oxidation of Propylene

12.2.1. Global Acrylic Acid Market, By Oxidation of Propylene, By Region, 2019-2032 (US$ Mn)

12.2.2. Market Dynamics for Oxidation of Propylene

12.2.2.1. Drivers

12.2.2.2. Restraints

12.2.2.3. Opportunities

12.2.2.4. Trends

12.3. Oxidation of Acrolein

12.3.1. Global Acrylic Acid Market, By Oxidation of Acrolein, By Region, 2019-2032 (US$ Mn)

12.3.2. Market Dynamics for Oxidation of Acrolein

12.3.2.1. Drivers

12.3.2.2. Restraints

12.3.2.3. Opportunities

12.3.2.4. Trends

12.4. Others

12.4.1. Global Acrylic Acid Market, By Others, By Region, 2019-2032 (US$ Mn)

12.4.2. Market Dynamics for Others

12.4.2.1. Drivers

12.4.2.2. Restraints

12.4.2.3. Opportunities

12.4.2.4. Trends

13. Global Acrylic Acid Market, By Region

13.1. Global Acrylic Acid Market Overview, by Region

13.1.1. Global Acrylic Acid Market, By Region, 2023 vs 2032 (in%)

13.2. Derivative Types

13.2.1. Global Acrylic Acid Market, By Derivative Types, 2019-2032 (US$ Mn)

13.3. End-User Industries

13.3.1. Global Acrylic Acid Market, By End-User Industries, 2019-2032 (US$ Mn)

13.4. Form

13.4.1. Global Acrylic Acid Market, By Form, 2019-2032 (US$ Mn)

13.5. Application Methods

13.5.1. Global Acrylic Acid Market, By Application Methods, 2019-2032 (US$ Mn)

13.6. Production Process

13.6.1. Global Acrylic Acid Market, By Production Process, 2019-2032 (US$ Mn)

14. North America Acrylic Acid Market Analysis

14.1. Overview

14.1.1. Market Dynamics for North America

14.1.1.1. Drivers

14.1.1.2. Restraints

14.1.1.3. Opportunities

14.1.1.4. Trends

14.2. North America Acrylic Acid Market, by Derivative Types, 2019-2032(US$ Mn)

14.2.1. Overview

14.2.2. SRC Analysis

14.3. North America Acrylic Acid Market, by End-User Industries, 2019-2032(US$ Mn)

14.3.1. Overview

14.3.2. SRC Analysis

14.4. North America Acrylic Acid Market, by Form, 2019-2032(US$ Mn)

14.4.1. Overview

14.4.2. SRC Analysis

14.5. North America Acrylic Acid Market, by Application Methods, 2019-2032(US$ Mn)

14.5.1. Overview

14.5.2. SRC Analysis

14.6. North America Acrylic Acid Market, by Production Process, 2019-2032(US$ Mn)

14.6.1. Overview

14.6.2. SRC Analysis

14.7. North America Acrylic Acid Market, by Country, 2019-2032 (US$ Mn)

14.7.1. North America Acrylic Acid Market, by Country, 2023 Vs 2032 (in%)

14.7.2. U.S.

14.7.3. Canada

14.7.4. Mexico

15. Europe Acrylic Acid Market Analysis

15.1. Overview

15.1.1. Market Dynamics for North America

15.1.1.1. Drivers

15.1.1.2. Restraints

15.1.1.3. Opportunities

15.1.1.4. Trends

15.2. Europe Acrylic Acid Market, by Derivative Types, 2019-2032(US$ Mn)

15.2.1. Overview

15.2.2. SRC Analysis

15.3. Europe Acrylic Acid Market, by End-User Industries, 2019-2032(US$ Mn)

15.3.1. Overview

15.3.2. SRC Analysis

15.4. Europe Acrylic Acid Market, by Form, 2019-2032(US$ Mn)

15.4.1. Overview

15.4.2. SRC Analysis

15.5. Europe Acrylic Acid Market, by Application Methods, 2019-2032(US$ Mn)

15.5.1. Overview

15.5.2. SRC Analysis

15.6. Europe Acrylic Acid Market, by Production Process, 2019-2032(US$ Mn)

15.6.1. Overview

15.6.2. SRC Analysis

15.7. Europe Acrylic Acid Market, by Country, 2019-2032 (US$ Mn)

15.7.1. Europe Acrylic Acid Market, by Country, 2023 Vs 2032 (in%)

15.7.2. UK

15.7.3. France

15.7.4. Germany

15.7.5. Italy

15.7.6. Spain

15.7.7. Benelux

15.7.8. Russia

15.7.9. Rest of Europe

16. Asia Pacific Acrylic Acid Market Analysis

16.1. Overview

16.1.1. Market Dynamics for North America

16.1.1.1. Drivers

16.1.1.2. Restraints

16.1.1.3. Opportunities

16.1.1.4. Trends

16.2. Asia Pacific Acrylic Acid Market, by Derivative Types, 2019-2032(US$ Mn)

16.2.1. Overview

16.2.2. SRC Analysis

16.3. Asia Pacific Acrylic Acid Market, by End-User Industries, 2019-2032(US$ Mn)

16.3.1. Overview

16.3.2. SRC Analysis

16.4. Asia Pacific Acrylic Acid Market, by Form, 2019-2032(US$ Mn)

16.4.1. Overview

16.4.2. SRC Analysis

16.5. Asia Pacific Acrylic Acid Market, by Application Methods, 2019-2032(US$ Mn)

16.5.1. Overview

16.5.2. SRC Analysis

16.6. Asia Pacific Acrylic Acid Market, by Production Process, 2019-2032(US$ Mn)

16.6.1. Overview

16.6.2. SRC Analysis

16.7. Asia Pacific Acrylic Acid Market, by Country, 2019-2032 (US$ Mn)

16.7.1. Asia Pacific Acrylic Acid Market, by Country, 2023 Vs 2032 (in%)

16.7.2. China

16.7.3. Japan

16.7.4. India

16.7.5. South Korea

16.7.6. South East Asia

16.7.7. Rest of Asia Pacific

17. Latin America Acrylic Acid Market Analysis

17.1. Overview

17.1.1. Market Dynamics for North America

17.1.1.1. Drivers

17.1.1.2. Restraints

17.1.1.3. Opportunities

17.1.1.4. Trends

17.2. Latin America Acrylic Acid Market, by Derivative Types, 2019-2032(US$ Mn)

17.2.1. Overview

17.2.2. SRC Analysis

17.3. Latin America Acrylic Acid Market, by End-User Industries, 2019-2032(US$ Mn)

17.3.1. Overview

17.3.2. SRC Analysis

17.4. Latin America Acrylic Acid Market, by Form, 2019-2032(US$ Mn)

17.4.1. Overview

17.4.2. SRC Analysis

17.5. Latin America Acrylic Acid Market, by Application Methods, 2019-2032(US$ Mn)

17.5.1. Overview

17.5.2. SRC Analysis

17.6. Latin America Acrylic Acid Market, by Production Process, 2019-2032(US$ Mn)

17.6.1. Overview

17.6.2. SRC Analysis

17.7. Latin America Acrylic Acid Market, by Country, 2019-2032 (US$ Mn)

17.7.1. Latin America Acrylic Acid Market, by Country, 2023 Vs 2032 (in%)

17.7.2. Brazil

17.7.3. Argentina

17.7.4. Rest of Latin America

18. Middle East Acrylic Acid Market Analysis

18.1. Overview

18.1.1. Market Dynamics for North America

18.1.1.1. Drivers

18.1.1.2. Restraints

18.1.1.3. Opportunities

18.1.1.4. Trends

18.2. Middle East Acrylic Acid Market, by Derivative Types, 2019-2032(US$ Mn)

18.2.1. Overview

18.2.2. SRC Analysis

18.3. Middle East Acrylic Acid Market, by End-User Industries, 2019-2032(US$ Mn)

18.3.1. Overview

18.3.2. SRC Analysis

18.4. Middle East Acrylic Acid Market, by Form, 2019-2032(US$ Mn)

18.4.1. Overview

18.4.2. SRC Analysis

18.5. Middle East Acrylic Acid Market, by Application Methods, 2019-2032(US$ Mn)

18.5.1. Overview

18.5.2. SRC Analysis

18.6. Middle East Acrylic Acid Market, by Production Process, 2019-2032(US$ Mn)

18.6.1. Overview

18.6.2. SRC Analysis

18.7. Middle East Acrylic Acid Market, by Country, 2019-2032 (US$ Mn)

18.7.1. Middle East Acrylic Acid Market, by Country, 2023 Vs 2032 (in%)

18.7.2. UAE

18.7.3. Saudi Arabia

18.7.4. Rest of Middle East

19. Africa Acrylic Acid Market Analysis

19.1. Overview

19.1.1. Market Dynamics for North America

19.1.1.1. Drivers

19.1.1.2. Restraints

19.1.1.3. Opportunities

19.1.1.4. Trends

19.2. Africa Acrylic Acid Market, by Derivative Types, 2019-2032(US$ Mn)

19.2.1. Overview

19.2.2. SRC Analysis

19.3. Africa Acrylic Acid Market, by End-User Industries, 2019-2032(US$ Mn)

19.3.1. Overview

19.3.2. SRC Analysis

19.4. Africa Acrylic Acid Market, by Form, 2019-2032(US$ Mn)

19.4.1. Overview

19.4.2. SRC Analysis

19.5. Africa Acrylic Acid Market, by Application Methods, 2019-2032(US$ Mn)

19.5.1. Overview

19.5.2. SRC Analysis

19.6. Africa Acrylic Acid Market, by Production Process, 2019-2032(US$ Mn)

19.6.1. Overview

19.6.2. SRC Analysis

19.7. Africa Acrylic Acid Market, by Country, 2019-2032 (US$ Mn)

19.7.1. Middle East Acrylic Acid Market, by Country, 2023 Vs 2032 (in%)

19.7.2. South Africa

19.7.3. Egypt

19.7.4. Rest of Africa

20. Company Profiles

20.1. Mitsubishi Chemical Holdings Corporation

20.1.1. Company Overview

20.1.2. Products/Services Portfolio

20.1.3. Geographical Presence

20.1.4. SWOT Analysis

20.1.5. Financial Summary

20.1.5.1. Market Revenue and Net Profit (2019-2023)

20.1.5.2. Business Segment Revenue Analysis

20.1.5.3. Geographical Revenue Analysis

20.2. Arkema S.A.

20.3. BASF SE

20.4. The Dow Chemical Co.

20.5. The Lubrizol Corporation

20.6. Evonik, Industries Ag

20.7. LG Chem Ltd.

20.8. Myriant Corporation

20.9. Formosa Plastic Group

20.10. SIBUR

20.11. Others

21. Research Methodology

21.1. Research Methodology

21.2. Phase I – Secondary Research

21.3. Phase II – Data Modelling

21.3.1. Company Share Analysis Model

21.3.2. Revenue Based Modelling

21.4. Phase III – Primary Research

21.5. Research Limitations

21.5.1. Assumptions

List of Figures

FIG. 1 Global Acrylic Acid Market: Research Methodology

FIG. 2 Market Size Estimation – Top Down & Bottom up Approach

FIG. 3 Global Acrylic Acid Market Segmentation

FIG. 4 Global Acrylic Acid Market, by Derivative Types, 2023 (US$ Mn)

FIG. 5 Global Acrylic Acid Market, by End-User Industries, 2023 (US$ Mn)

FIG. 6 Global Acrylic Acid Market, by Form, 2023 (US$ Mn)

FIG. 7 Global Acrylic Acid Market, by Application Method, 2023 (US$ Mn)

FIG. 8 Global Acrylic Acid Market, by Production Process, 2023 (US$ Mn)

FIG. 9 Global Acrylic Acid Market, by Geography, 2023 (US$ Mn)

FIG. 10 Attractive Investment Proposition, by Derivative Types, 2023

FIG. 11 Attractive Investment Proposition, by End-User Industries, 2023

FIG. 12 Attractive Investment Proposition, by Form, 2023

FIG. 13 Attractive Investment Proposition, by Application Methods, 2023

FIG. 14 Attractive Investment Proposition, by Production Process, 2023

FIG. 15 Attractive Investment Proposition, by Geography, 2023

FIG. 16 Global Market Share Analysis of Key Acrylic Acid Market Manufacturers, 2023

FIG. 17 Global Market Positioning of Key Acrylic Acid Market Manufacturers, 2023

FIG. 18 Global Acrylic Acid Market Value Contribution, By Derivative Types, 2023 & 2032 (Value %)

FIG. 19 Global Acrylic Acid Market, by Acrylic Esters, Value, 2019-2032 (US$ Mn)

FIG. 20 Global Acrylic Acid Market, by Superabsorbent Polymers (SAP), Value, 2019-2032 (US$ Mn)

FIG. 21 Global Acrylic Acid Market, by Acrylic Polymers (Polyacrylic Acid), Value, 2019-2032 (US$ Mn)

FIG. 22 Global Acrylic Acid Market, by Others, Value, 2019-2032 (US$ Mn)

FIG. 23 Global Acrylic Acid Market Value Contribution, By End-User Industries, 2023 & 2032 (Value %)

FIG. 24 Global Acrylic Acid Market, by Paints and Coatings Industry, Value, 2019-2032 (US$ Mn)

FIG. 25 Global Acrylic Acid Market, by Textiles Industry, Value, 2019-2032 (US$ Mn)

FIG. 26 Global Acrylic Acid Market, by Personal Care and Hygiene Industry, Value, 2019-2032 (US$ Mn)

FIG. 27 Global Acrylic Acid Market, by Water Treatment Industry, Value, 2019-2032 (US$ Mn)

FIG. 28 Global Acrylic Acid Market, by Others, Value, 2019-2032 (US$ Mn)

FIG. 29 Global Acrylic Acid Market Value Contribution, By Form, 2023 & 2032 (Value %)

FIG. 30 Global Acrylic Acid Market, by Liquid Acrylic Acid, Value, 2019-2032 (US$ Mn)

FIG. 31 Global Acrylic Acid Market, by Solid Acrylic Acid, Value, 2019-2032 (US$ Mn)

FIG. 32 Global Acrylic Acid Market Value Contribution, By Application Methods, 2023 & 2032 (Value %)

FIG. 33 Global Acrylic Acid Market, by Direct Synthesis, Value, 2019-2032 (US$ Mn)

FIG. 34 Global Acrylic Acid Market, by Esterification, Value, 2019-2032 (US$ Mn)

FIG. 35 Global Acrylic Acid Market, by Amidation, Value, 2019-2032 (US$ Mn)

FIG. 36 Global Acrylic Acid Market, by Others, Value, 2019-2032 (US$ Mn)

FIG. 37 Global Acrylic Acid Market Value Contribution, By Production Process, 2023 & 2032 (Value %)

FIG. 38 Global Acrylic Acid Market, by Oxidation of Propylene, Value, 2019-2032 (US$ Mn)

FIG. 39 Global Acrylic Acid Market, by Oxidation of Acrolein, Value, 2019-2032 (US$ Mn)

FIG. 40 Global Acrylic Acid Market, by Others, Value, 2019-2032 (US$ Mn)

FIG. 41 North America Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 42 U.S. Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 43 Canada Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 44 Mexico Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 45 Europe Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 46 Germany Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 47 France Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 48 U.K. Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 49 Italy Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 50 Spain Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 51 Benelux Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 52 Russia Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 53 Rest of Europe Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 54 Asia Pacific Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 55 China Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 56 Japan Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 57 India Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 58 South Korea Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 59 South-East Asia Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 60 Rest of Asia Pacific Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 61 Latin America Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 62 Brazil Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 63 Argentina Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 64 Rest of Latin America Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 65 Middle East Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 66 UAE Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 67 Saudi Arabia Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 68 Rest of Middle East Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 69 Africa Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 70 South Africa Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 71 Egypt Acrylic Acid Market, 2019-2032 (US$ Mn)

FIG. 72 Rest of Africa Acrylic Acid Market, 2019-2032 (US$ Mn)

List of Tables

TABLE 1 Market Snapshot: Global Acrylic Acid Market

TABLE 2 Global Acrylic Acid Market: Market Drivers Impact Analysis

TABLE 3 Global Acrylic Acid Market: Market Restraints Impact Analysis

TABLE 4 Global Acrylic Acid Market, by Competitive Benchmarking, 2023

TABLE 5 Global Acrylic Acid Market, by Geographical Presence Analysis, 2023

TABLE 6 Global Acrylic Acid Market, by Key Strategies Analysis, 2023

TABLE 7 Global Acrylic Acid Market, by Acrylic Esters, By Region, 2019-2023 (US$ Mn)

TABLE 8 Global Acrylic Acid Market, by Acrylic Esters, By Region, 2024-2032 (US$ Mn)

TABLE 9 Global Acrylic Acid Market, by Superabsorbent Polymers (SAP), By Region, 2019-2023 (US$ Mn)

TABLE 10 Global Acrylic Acid Market, by Superabsorbent Polymers (SAP), By Region, 2024-2032 (US$ Mn)

TABLE 11 Global Acrylic Acid Market, by Acrylic Polymers (Polyacrylic Acid), By Region, 2019-2023 (US$ Mn)

TABLE 12 Global Acrylic Acid Market, by Acrylic Polymers (Polyacrylic Acid), By Region, 2024-2032 (US$ Mn)

TABLE 13 Global Acrylic Acid Market, by Others, By Region, 2019-2023 (US$ Mn)

TABLE 14 Global Acrylic Acid Market, by Others, By Region, 2024-2032 (US$ Mn)

TABLE 15 Global Acrylic Acid Market, by Paints and Coatings Industry, By Region, 2019-2023 (US$ Mn)

TABLE 16 Global Acrylic Acid Market, by Paints and Coatings Industry, By Region, 2024-2032 (US$ Mn)

TABLE 17 Global Acrylic Acid Market, by Textiles Industry, By Region, 2019-2023 (US$ Mn)

TABLE 18 Global Acrylic Acid Market, by Textiles Industry, By Region, 2024-2032 (US$ Mn)

TABLE 19 Global Acrylic Acid Market, by Personal Care and Hygiene Industry, By Region, 2019-2023 (US$ Mn)

TABLE 20 Global Acrylic Acid Market, by Personal Care and Hygiene Industry, By Region, 2024-2032 (US$ Mn)

TABLE 21 Global Acrylic Acid Market, by Water Treatment Industry, By Region, 2019-2023 (US$ Mn)

TABLE 22 Global Acrylic Acid Market, by Water Treatment Industry, By Region, 2024-2032 (US$ Mn)

TABLE 23 Global Acrylic Acid Market, by Others, By Region, 2019-2023 (US$ Mn)

TABLE 24 Global Acrylic Acid Market, by Others, By Region, 2024-2032 (US$ Mn)

TABLE 25 Global Acrylic Acid Market, by Liquid Acrylic Acid, By Region, 2019-2023 (US$ Mn)

TABLE 26 Global Acrylic Acid Market, by Liquid Acrylic Acid, By Region, 2024-2032 (US$ Mn)

TABLE 27 Global Acrylic Acid Market, by Solid Acrylic Acid, By Region, 2019-2023 (US$ Mn)

TABLE 28 Global Acrylic Acid Market, by Solid Acrylic Acid, By Region, 2024-2032 (US$ Mn)

TABLE 29 Global Acrylic Acid Market, by Direct Synthesis, By Region, 2019-2023 (US$ Mn)

TABLE 30 Global Acrylic Acid Market, by Direct Synthesis, By Region, 2024-2032 (US$ Mn)

TABLE 31 Global Acrylic Acid Market, by Esterification, By Region, 2019-2023 (US$ Mn)

TABLE 32 Global Acrylic Acid Market, by Esterification, By Region, 2024-2032 (US$ Mn)

TABLE 33 Global Acrylic Acid Market, by Amidation, By Region, 2019-2023 (US$ Mn)

TABLE 34 Global Acrylic Acid Market, by Amidation, By Region, 2024-2032 (US$ Mn)

TABLE 35 Global Acrylic Acid Market, by Others, By Region, 2019-2023 (US$ Mn)

TABLE 36 Global Acrylic Acid Market, by Others, By Region, 2024-2032 (US$ Mn)

TABLE 37 Global Acrylic Acid Market, by Oxidation of Propylene, By Region, 2019-2023 (US$ Mn)

TABLE 38 Global Acrylic Acid Market, by Oxidation of Propylene, By Region, 2024-2032 (US$ Mn)

TABLE 39 Global Acrylic Acid Market, by Oxidation of Acrolein, By Region, 2019-2023 (US$ Mn)

TABLE 40 Global Acrylic Acid Market, by Oxidation of Acrolein, By Region, 2024-2032 (US$ Mn)

TABLE 41 Global Acrylic Acid Market, by Others, By Region, 2019-2023 (US$ Mn)

TABLE 42 Global Acrylic Acid Market, by Others, By Region, 2024-2032 (US$ Mn)

TABLE 43 Global Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 44 Global Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 45 Global Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 46 Global Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 47 Global Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 48 Global Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 49 Global Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 50 Global Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 51 Global Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 52 Global Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 53 Global Acrylic Acid Market, by Region, 2019-2023 (US$ Mn)

TABLE 54 Global Acrylic Acid Market, by Region, 2024-2032 (US$ Mn)

TABLE 55 North America Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 56 North America Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 57 North America Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 58 North America Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 59 North America Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 60 North America Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 61 North America Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 62 North America Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 63 North America Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 64 North America Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 65 North America Acrylic Acid Market, by Country, 2019-2023 (US$ Mn)

TABLE 66 North America Acrylic Acid Market, by Country, 2024-2032 (US$ Mn)

TABLE 67 United States Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 68 United States Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 69 United States Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 70 United States Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 71 United States Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 72 United States Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 73 United States Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 74 United States Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 75 United States Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 76 United States Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 77 Canada Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 78 Canada Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 79 Canada Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 80 Canada Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 81 Canada Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 82 Canada Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 83 Canada Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 84 Canada Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 85 Canada Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 86 Canada Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 87 Mexico Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 88 Mexico Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 89 Mexico Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 90 Mexico Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 91 Mexico Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 92 Mexico Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 93 Mexico Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 94 Mexico Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 95 Mexico Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 96 Mexico Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 97 Europe Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 98 Europe Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 99 Europe Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 100 Europe Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 101 Europe Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 102 Europe Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 103 Europe Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 104 Europe Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 105 Europe Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 106 Europe Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 107 Europe Acrylic Acid Market, by Country, 2019-2023 (US$ Mn)

TABLE 108 Europe Acrylic Acid Market, by Country, 2024-2032 (US$ Mn)

TABLE 109 Germany Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 110 Germany Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 111 Germany Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 112 Germany Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 113 Germany Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 114 Germany Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 115 Germany Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 116 Germany Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 117 Germany Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 118 Germany Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 119 France Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 120 France Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 121 France Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 122 France Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 123 France Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 124 France Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 125 France Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 126 France Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 127 France Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 128 France Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 129 United Kingdom Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 130 United Kingdom Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 131 United Kingdom Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 132 United Kingdom Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 133 United Kingdom Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 134 United Kingdom Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 135 United Kingdom Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 136 United Kingdom Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 137 United Kingdom Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 138 United Kingdom Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 139 Italy Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 140 Italy Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 141 Italy Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 142 Italy Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 143 Italy Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 144 Italy Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 145 Italy Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 146 Italy Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 147 Italy Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 148 Italy Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 149 Spain Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 150 Spain Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 151 Spain Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 152 Spain Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 153 Spain Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 154 Spain Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 155 Spain Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 156 Spain Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 157 Spain Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 158 Spain Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 159 Benelux Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 160 Benelux Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 161 Benelux Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 162 Benelux Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 163 Benelux Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 164 Benelux Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 165 Benelux Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 166 Benelux Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 167 Benelux Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 168 Benelux Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 169 Russia Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 170 Russia Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 171 Russia Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 172 Russia Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 173 Russia Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 174 Russia Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 175 Russia Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 176 Russia Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 177 Russia Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 178 Russia Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 179 Rest of Europe Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 180 Rest of Europe Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 181 Rest of Europe Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 182 Rest of Europe Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 183 Rest of Europe Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 184 Rest of Europe Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 185 Rest of Europe Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 186 Rest of Europe Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 187 Rest of Europe Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 188 Rest of Europe Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 189 Asia Pacific Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 190 Asia Pacific Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 191 Asia Pacific Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 192 Asia Pacific Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 193 Asia Pacific Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 194 Asia Pacific Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 195 Asia Pacific Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 196 Asia Pacific Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 197 Asia Pacific Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 198 Asia Pacific Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 199 China Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 200 China Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 201 China Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 202 China Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 203 China Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 204 China Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 205 China Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 206 China Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 207 China Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 208 China Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 209 Japan Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 210 Japan Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 211 Japan Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 212 Japan Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 213 Japan Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 214 Japan Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 215 Japan Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 216 Japan Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 217 Japan Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 218 Japan Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 219 India Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 220 India Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 221 India Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 222 India Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 223 India Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 224 India Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 225 India Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 226 India Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 227 India Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 228 India Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 229 South Korea Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 230 South Korea Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 231 South Korea Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 232 South Korea Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 233 South Korea Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 234 South Korea Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 235 South Korea Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 236 South Korea Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 237 South Korea Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 238 South Korea Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 239 South-East Asia Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 240 South-East Asia Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 241 South-East Asia Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 242 South-East Asia Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 243 South-East Asia Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 244 South-East Asia Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 245 South-East Asia Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 246 South-East Asia Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 247 South-East Asia Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 248 South-East Asia Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 249 Rest of Asia Pacific Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 250 Rest of Asia Pacific Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 251 Rest of Asia Pacific Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 252 Rest of Asia Pacific Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 253 Rest of Asia Pacific Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 254 Rest of Asia Pacific Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 255 Rest of Asia Pacific Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 256 Rest of Asia Pacific Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 257 Rest of Asia Pacific Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 258 Rest of Asia Pacific Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 259 Latin America Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 260 Latin America Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 261 Latin America Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 262 Latin America Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 263 Latin America Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 264 Latin America Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 265 Latin America Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 266 Latin America Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 267 Latin America Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 268 Latin America Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 269 Brazil Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 270 Brazil Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 271 Brazil Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 272 Brazil Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 273 Brazil Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 274 Brazil Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 275 Brazil Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 276 Brazil Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 277 Brazil Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 278 Brazil Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 279 Argentina Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 280 Argentina Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 281 Argentina Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 282 Argentina Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 283 Argentina Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 284 Argentina Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 285 Argentina Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 286 Argentina Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 287 Argentina Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 288 Argentina Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 289 Rest of Latin America Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 290 Rest of Latin America Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 291 Rest of Latin America Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 292 Rest of Latin America Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 293 Rest of Latin America Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 294 Rest of Latin America Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 295 Rest of Latin America Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 296 Rest of Latin America Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 297 Rest of Latin America Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 298 Rest of Latin America Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 299 Middle East Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 300 Middle East Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 301 Middle East Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 302 Middle East Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 303 Middle East Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 304 Middle East Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 305 Middle East Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 306 Middle East Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 307 Middle East Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 308 Middle East Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 309 UAE Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 310 UAE Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 311 UAE Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 312 UAE Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 313 UAE Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 314 UAE Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 315 UAE Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 316 UAE Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 317 UAE Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 318 UAE Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 319 Saudi Arabia Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 320 Saudi Arabia Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 321 Saudi Arabia Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 322 Saudi Arabia Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 323 Saudi Arabia Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 324 Saudi Arabia Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 325 Saudi Arabia Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 326 Saudi Arabia Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 327 Saudi Arabia Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 328 Saudi Arabia Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 329 Rest of Middle East Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 330 Rest of Middle East Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 331 Rest of Middle East Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 332 Rest of Middle East Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 333 Rest of Middle East Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 334 Rest of Middle East Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 335 Rest of Middle East Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 336 Rest of Middle East Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 337 Rest of Middle East Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 338 Rest of Middle East Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 339 Africa Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 340 Africa Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 341 Africa Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 342 Africa Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 343 Africa Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 344 Africa Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 345 Africa Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 346 Africa Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 347 Africa Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 348 Africa Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 349 South Africa Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 350 South Africa Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 351 South Africa Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 352 South Africa Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 353 South Africa Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 354 South Africa Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 355 South Africa Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 356 South Africa Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 357 South Africa Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 358 South Africa Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 359 Egypt Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 360 Egypt Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 361 Egypt Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 362 Egypt Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 363 Egypt Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 364 Egypt Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 365 Egypt Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 366 Egypt Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 367 Egypt Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 368 Egypt Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)

TABLE 369 Rest of Africa Acrylic Acid Market, by Derivative Types, 2019-2023 (US$ Mn)

TABLE 370 Rest of Africa Acrylic Acid Market, by Derivative Types, 2024-2032 (US$ Mn)

TABLE 371 Rest of Africa Acrylic Acid Market, by End-User Industries, 2019-2023 (US$ Mn)

TABLE 372 Rest of Africa Acrylic Acid Market, by End-User Industries, 2024-2032 (US$ Mn)

TABLE 373 Rest of Africa Acrylic Acid Market, by Form, 2019-2023 (US$ Mn)

TABLE 374 Rest of Africa Acrylic Acid Market, by Form, 2024-2032 (US$ Mn)

TABLE 375 Rest of Africa Acrylic Acid Market, by Application Methods, By Region, 2019-2023 (US$ Mn)

TABLE 376 Rest of Africa Acrylic Acid Market, by Application Methods, By Region, 2024-2032 (US$ Mn)

TABLE 377 Rest of Africa Acrylic Acid Market, by Production Process, 2019-2023 (US$ Mn)

TABLE 378 Rest of Africa Acrylic Acid Market, by Production Process, 2024-2032 (US$ Mn)