| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Agricultural And Food Grade Rubber Conveyor Belt System Market Size 2024 |

USD 3,729.90 Million |

| Agricultural And Food Grade Rubber Conveyor Belt System Market, CAGR |

5.19% |

| Agricultural And Food Grade Rubber Conveyor Belt System Market Size 2032 |

USD 5,755.00 Million |

Market Overview

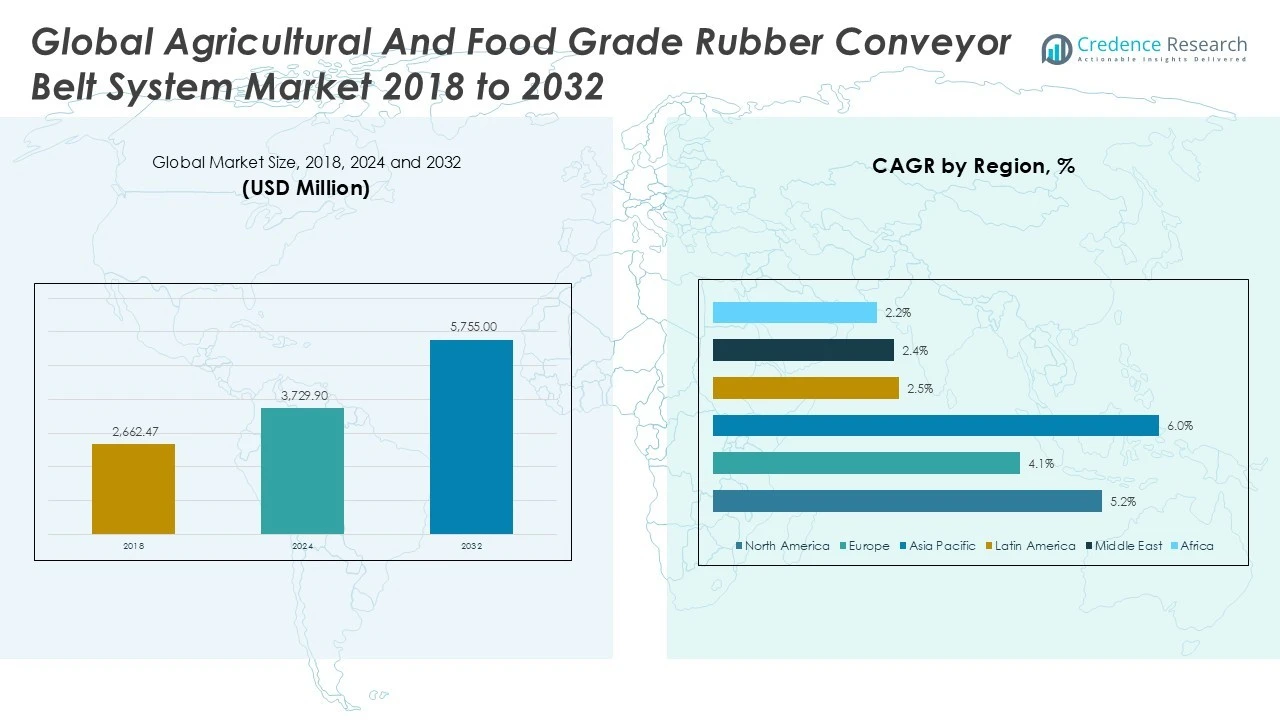

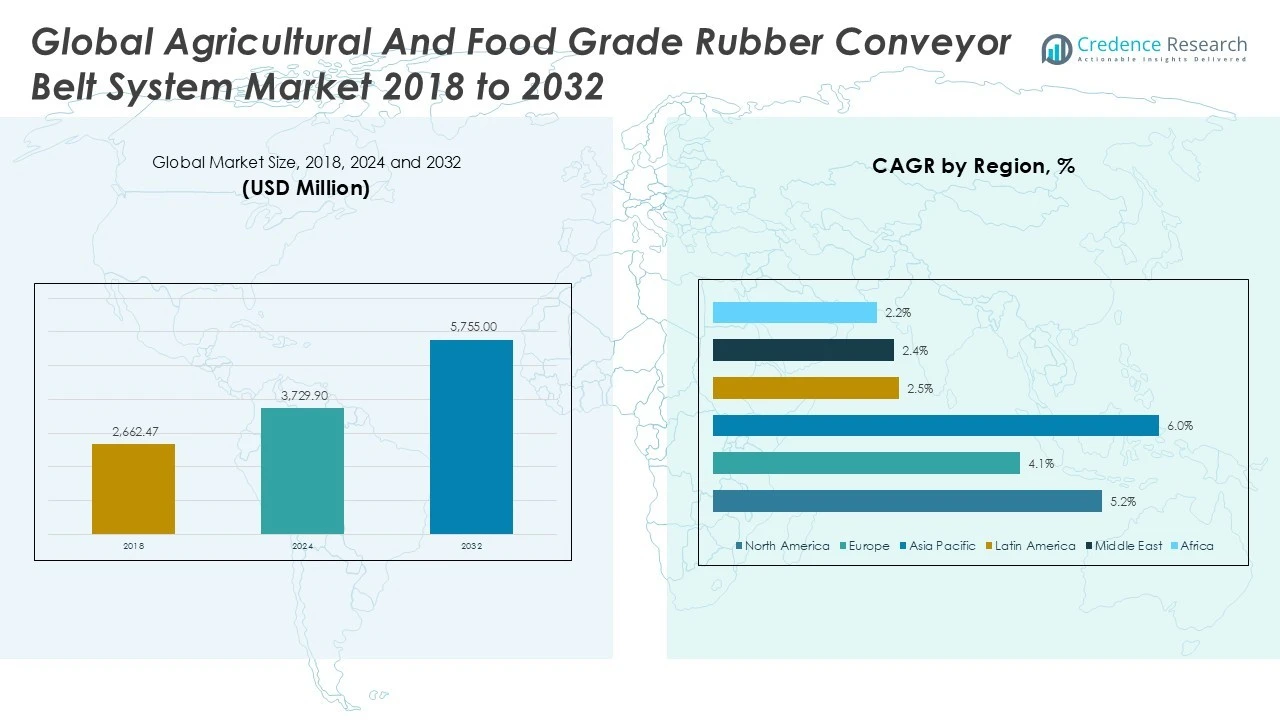

The Agricultural And Food Grade Rubber Conveyor Belt System Market size was valued at USD 2,662.47 million in 2018 to USD 3,729.90 million in 2024 and is anticipated to reach USD 5,755.00 million by 2032, at a CAGR of 5.19% during the forecast period.

The Agricultural and Food Grade Rubber Conveyor Belt System Market is experiencing robust growth, driven by the increasing adoption of automation and mechanized handling systems in the agriculture and food processing sectors. Rising demand for efficient, hygienic, and high-capacity material handling solutions, especially in large-scale farming and food manufacturing facilities, is fueling market expansion. Stricter food safety regulations and heightened awareness regarding contamination risks have led to greater emphasis on high-quality, food-grade conveyor materials. Technological advancements, such as the development of abrasion-resistant, oil-resistant, and easy-to-clean rubber belts, are enhancing product reliability and operational efficiency. Furthermore, the shift toward sustainable farming practices and the integration of IoT-enabled monitoring systems are shaping market trends, as stakeholders seek to optimize productivity while ensuring compliance with industry standards. These factors collectively contribute to sustained demand and ongoing innovation within the agricultural and food grade rubber conveyor belt system market.

The Agricultural and Food Grade Rubber Conveyor Belt System Market demonstrates strong regional diversity, with North America, Europe, and Asia Pacific leading in both demand and technological advancement. North America and Europe focus on automation and food safety compliance, driven by stringent regulations and high levels of industrialization in countries like the United States, Canada, Germany, and France. Asia Pacific, with major markets such as China, India, and Japan, exhibits rapid expansion due to large-scale agriculture, increasing food processing investments, and growing adoption of modern conveyor technologies. Latin America, the Middle East, and Africa show steady growth as agricultural modernization and food safety initiatives gradually take hold. Key players shaping the competitive landscape include Continental AG, Fenner PLC, and Dorner Mfg. Corp, all recognized for their innovative product offerings, global reach, and commitment to quality. These companies continue to influence market dynamics through advanced technology and strategic partnerships.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Agricultural and Food Grade Rubber Conveyor Belt System Market reached USD 3,729.90 million in 2024 and is expected to hit USD 5,755.00 million by 2032, with a CAGR of 5.19%.

- Increasing automation in agriculture and food processing drives demand for conveyor belt systems that boost efficiency and productivity.

- Rising focus on food safety and hygiene fuels the adoption of food-grade rubber belts, especially in regions with strict regulatory standards.

- Market trends include the integration of IoT and sensor-based monitoring, enabling real-time maintenance and higher operational reliability.

- Leading players such as Continental AG, Fenner PLC, and Dorner Mfg. Corp are investing in innovative product development and expanding their global presence to capture new opportunities.

- High initial investment and complex compliance requirements act as restraints, particularly for small and medium-sized enterprises in emerging markets.

- North America, Europe, and Asia Pacific remain the largest markets, with rapid growth in China, the U.S., Germany, and India due to ongoing industrial modernization and food sector expansion.

Market Drivers

Rising Demand for Automation and Mechanized Handling in Agriculture and Food Processing

The Agricultural and Food Grade Rubber Conveyor Belt System Market is seeing strong growth due to the rapid adoption of automation and mechanized handling systems across both agricultural and food processing operations. Large-scale farming enterprises and advanced food manufacturing facilities require efficient, reliable conveyor solutions to streamline material transport and minimize manual labor. This demand for automation improves productivity, reduces human error, and lowers operating costs. Conveyor belt systems enable continuous movement of bulk materials, which is vital for high-throughput environments. Companies are investing in modernizing their operations to stay competitive, driving the need for specialized conveyor belt systems designed for agricultural produce and food ingredients. The market benefits from manufacturers’ focus on innovative solutions tailored to the unique requirements of these sectors.

- For instance, automation in food processing has led to a 20% increase in efficiency and reduced labor dependency in European manufacturing plants.

Stringent Food Safety Regulations and Emphasis on Contamination Prevention

Food safety has become a key driver in the Agricultural and Food Grade Rubber Conveyor Belt System Market, as regulatory bodies set stricter standards to minimize contamination risks. Producers and processors need conveyor belts made from food-grade rubber materials that comply with global hygiene standards and are easy to clean and maintain. Compliance with regulations such as the Food Safety Modernization Act (FSMA) and Hazard Analysis Critical Control Point (HACCP) pushes market players to adopt high-quality materials and designs. This regulatory focus ensures safer handling and transport of food products, protecting both consumer health and brand reputation. The industry responds by introducing belts that resist bacterial growth, oil, and moisture while meeting durability requirements. Such features increase adoption across diverse food production environments.

- For instance, the European Union’s food safety regulations mandate the use of non-toxic, easy-to-clean conveyor belts in food processing facilities to prevent contamination.

Technological Advancements and Customization Drive Market Growth

Ongoing technological progress within the Agricultural and Food Grade Rubber Conveyor Belt System Market enables the development of advanced belt designs with improved resistance to abrasion, chemicals, and extreme temperatures. Manufacturers now offer custom-engineered solutions to address specific operational challenges faced by end users. IoT-enabled conveyor belts allow real-time monitoring of belt conditions, facilitating predictive maintenance and reducing downtime. Advanced rubber compounds and modular designs provide higher flexibility and longer service life, meeting the demands of modern agricultural and food processing applications. Companies focusing on research and development continue to launch innovative products, supporting market expansion. The integration of automation and intelligent features differentiates suppliers and attracts investment.

Sustainability Initiatives and Focus on Operational Efficiency

The Agricultural and Food Grade Rubber Conveyor Belt System Market is influenced by the growing focus on sustainable practices in agriculture and food production. Companies are sourcing eco-friendly rubber materials, reducing energy consumption, and optimizing conveyor system design for minimal waste. The shift toward sustainable manufacturing aligns with customer preferences for environmentally responsible solutions and compliance with environmental regulations. Market players also enhance operational efficiency by delivering low-maintenance, high-performance conveyor belts that increase uptime and productivity. These initiatives position the industry as a proactive participant in global sustainability efforts. The emphasis on resource efficiency supports long-term market growth and customer loyalty.

Market Trends

Adoption of Advanced Materials and Smart Conveyor Technologies Accelerates Market Evolution

The Agricultural and Food Grade Rubber Conveyor Belt System Market is witnessing a trend toward the use of advanced materials and smart technologies. Manufacturers are introducing belts with superior resistance to abrasion, oils, and chemicals, ensuring longer service life and enhanced performance in harsh environments. IoT integration and sensor-enabled monitoring systems provide real-time insights into belt conditions, allowing operators to anticipate maintenance needs and minimize downtime. This movement toward intelligent, data-driven operations helps companies improve operational efficiency and optimize production flows. Advanced coatings and surface treatments make belts easier to clean, aligning with stringent hygiene standards in food handling. These developments set new benchmarks for safety and reliability in agricultural and food-grade applications.

- For instance, IoT-enabled conveyor belt systems have improved predictive maintenance and reduced downtime by 30% in food processing plants.

Customization and Modular Solutions Gain Traction Among End Users

Demand for tailored conveyor belt solutions is rising in the Agricultural and Food Grade Rubber Conveyor Belt System Market, with manufacturers offering modular designs to accommodate specific operational requirements. End users now expect conveyor systems that integrate seamlessly with existing machinery, support a variety of product types, and fit unique spatial constraints. Modular belts offer flexibility for expansion or reconfiguration, helping users respond quickly to evolving production demands. It also supports rapid replacement and reduced maintenance costs, which are critical in minimizing production interruptions. Custom color options, anti-microbial properties, and unique surface patterns reflect this shift toward personalization. Such tailored solutions help customers achieve both operational efficiency and compliance with regulatory standards.

- For instance, modular conveyor belt systems have seen increased adoption in food processing due to their flexibility and ease of maintenance.

Growing Emphasis on Sustainability and Eco-Friendly Production

Sustainability has emerged as a prominent trend within the Agricultural and Food Grade Rubber Conveyor Belt System Market, prompting manufacturers to adopt environmentally responsible practices. Use of recyclable rubber materials, reduced use of harmful chemicals, and optimization of manufacturing processes demonstrate industry commitment to sustainability. It is common to see companies promoting energy-efficient production and transportation systems, aligning with the broader push for green supply chains. Clients increasingly favor suppliers that demonstrate transparency in sourcing and production practices. This trend supports the development of circular economy models and enhances brand credibility. Sustainability initiatives now play a decisive role in supplier selection and market positioning.

Rising Investment in Automation and Digital Transformation Across Agriculture and Food Processing

The Agricultural and Food Grade Rubber Conveyor Belt System Market is experiencing a surge in automation and digital transformation investments. Companies are deploying automated conveyor systems with integrated robotics, vision systems, and software solutions for streamlined material handling and packaging processes. Digital platforms enable better production planning, remote monitoring, and quick troubleshooting, leading to increased productivity. Automation not only addresses labor shortages but also elevates quality control and traceability standards. The integration of advanced technologies reflects a long-term commitment to operational excellence and future readiness. Market participants prioritizing digital solutions are well-positioned to capture emerging opportunities and drive sustained growth.

Market Challenges Analysis

Complex Regulatory Landscape and Maintenance Challenges Hinder Adoption

Strict compliance with food safety standards creates ongoing challenges for the Agricultural and Food Grade Rubber Conveyor Belt System Market. Frequent changes to hygiene and contamination prevention regulations require continuous product innovation and documentation. Manufacturers must ensure that conveyor belts consistently meet regional and international standards, which can complicate product design and increase operational costs. Maintenance and cleaning of belts in demanding environments often disrupt operations and require specialized expertise. It is essential for market participants to develop solutions that simplify compliance and reduce downtime. Navigating the complex regulatory landscape while ensuring product durability and ease of maintenance remains a central challenge for the industry.

For instance, compliance with FDA and EU food safety regulations has led to increased adoption of non-toxic, wear-resistant rubber conveyor belts in food processing.

High Initial Investment and Cost Sensitivity Impact Market Expansion

The Agricultural and Food Grade Rubber Conveyor Belt System Market faces significant challenges due to the high upfront costs associated with advanced conveyor systems and quality food-grade materials. Many small and medium-sized enterprises (SMEs) in agriculture and food processing hesitate to invest in modern conveyor solutions because of budget constraints and uncertain returns. It remains difficult for cost-sensitive players to justify expenditures on automation when traditional manual labor may appear more affordable in the short term. Fluctuating raw material prices, especially for specialized rubber compounds, further impact project feasibility and profitability. Market participants must navigate these cost pressures while convincing customers of the long-term value and efficiency gains offered by modern conveyor belt systems. Balancing affordability with innovation stands as a critical concern in expanding market adoption.

Market Opportunities

Expansion of Precision Agriculture and Smart Food Processing Presents Growth Potential

The Agricultural and Food Grade Rubber Conveyor Belt System Market stands to benefit from the growing adoption of precision agriculture and smart food processing technologies. Farms and food manufacturers are investing in digital solutions and automation to boost efficiency, traceability, and product quality. These advancements require conveyor belt systems that integrate seamlessly with IoT devices, sensors, and automated sorting equipment. Companies that offer compatible, smart-ready conveyor solutions will find new revenue streams in this rapidly evolving landscape. The demand for customized belts that can handle specialized crops or delicate food items further expands the market. Forward-thinking manufacturers who align their product development with the needs of smart agriculture and food processing will capture emerging opportunities.

Sustainable Materials and Green Certifications Unlock Competitive Advantage

Increasing consumer and regulatory emphasis on sustainability creates a promising avenue for the Agricultural and Food Grade Rubber Conveyor Belt System Market. Customers are seeking conveyor belts made from recyclable, bio-based, or low-emission materials to meet environmental goals. Companies that prioritize green certifications and transparent sourcing can differentiate themselves in a crowded market. It is possible to secure partnerships with environmentally conscious brands and organizations by demonstrating a strong commitment to sustainable practices. The shift toward eco-friendly operations opens doors for innovation in product design and supply chain management. Manufacturers ready to invest in sustainable solutions will position themselves for long-term growth and stronger customer loyalty.

Market Segmentation Analysis:

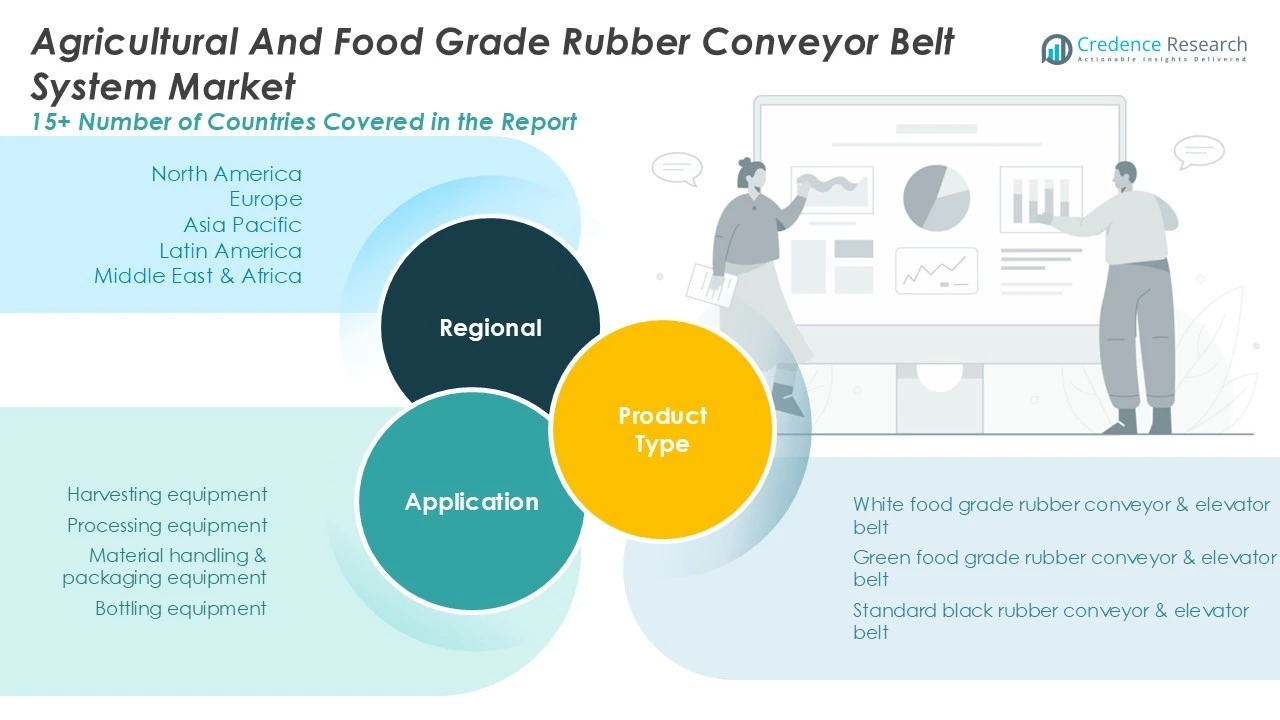

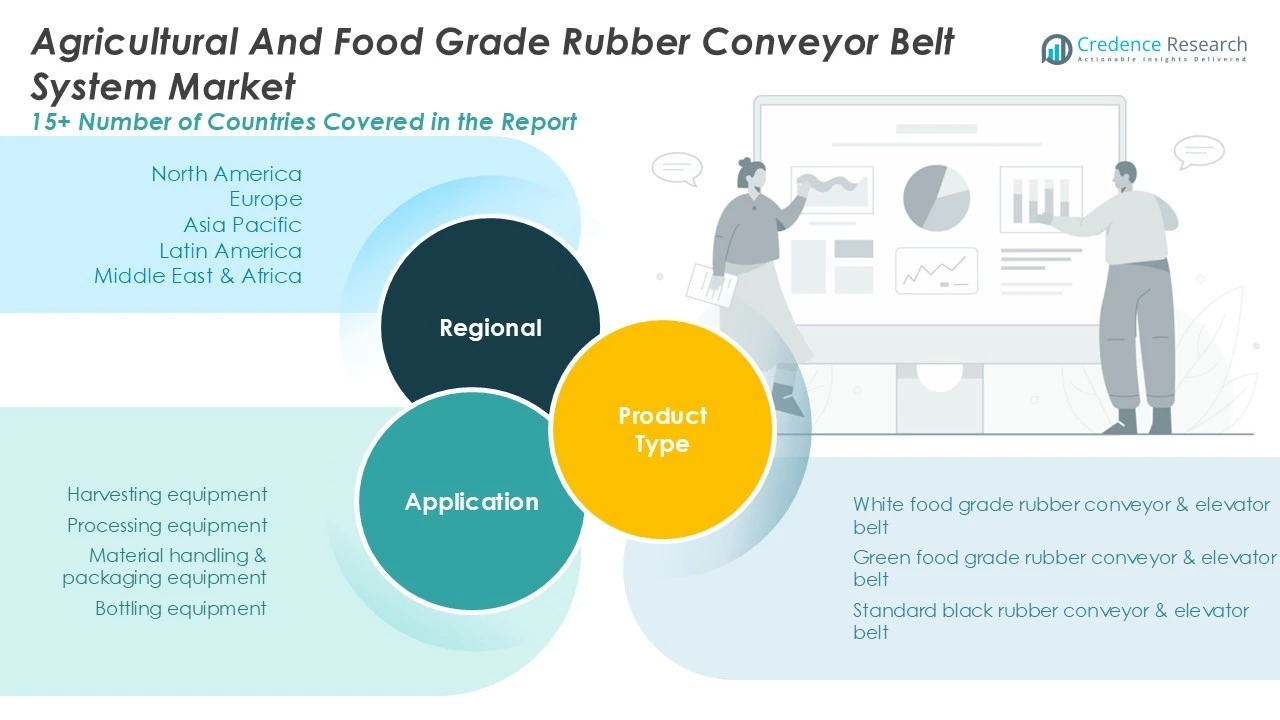

By Product Type:

The Agricultural and Food Grade Rubber Conveyor Belt System Market is segmented by product type into white food grade rubber conveyor & elevator belts, green food grade rubber conveyor & elevator belts, and standard black rubber conveyor & elevator belts. White food grade belts hold significant importance in the food processing sector due to their compliance with stringent hygiene standards and their resistance to staining, odor absorption, and chemical exposure. Food processors rely on these belts to ensure contamination-free handling of products, making them the preferred choice in environments where cleanliness and food safety are paramount. Green food grade rubber belts offer similar food safety features while providing greater visibility in operational settings, supporting color-coding protocols and easy identification of wear or contaminants. Standard black rubber belts, typically used in agricultural operations, deliver robust performance for heavy-duty material handling and provide cost-effective solutions where direct contact with food is not a primary concern.

By Application:

The Agricultural and Food Grade Rubber Conveyor Belt System Market addresses diverse equipment needs, including harvesting equipment, processing equipment, material handling & packaging equipment, and bottling equipment. In harvesting operations, conveyor belts enable efficient crop collection and reduce manual labor, enhancing productivity on large farms. Processing equipment applications demand belts that withstand frequent cleaning and exposure to oils, moisture, and chemicals, making food-grade rubber essential for safe and durable performance. Material handling & packaging equipment require conveyor belts with superior load-bearing capacity and flexibility to manage bulk transport, sorting, and packaging of both raw and processed food products. Bottling equipment utilizes conveyor systems to move containers swiftly and smoothly through filling, capping, and labeling stages, with food-grade belts supporting hygiene requirements and operational efficiency.

Segments:

Based on Product Type:

- White food grade rubber conveyor & elevator belt

- Green food grade rubber conveyor & elevator belt

- Standard black rubber conveyor & elevator belt

Based on Application:

- Harvesting equipment

- Processing equipment

- Material handling & packaging equipment

- Bottling equipment

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America Agricultural and Food Grade Rubber Conveyor Belt System Market

North America Agricultural and Food Grade Rubber Conveyor Belt System Market grew from USD 797.29 million in 2018 to USD 1,100.03 million in 2024 and is projected to reach USD 1,704.18 million by 2032, reflecting a compound annual growth rate (CAGR) of 5.2%. North America is holding a 30% market share. The United States and Canada drive growth in this region, with widespread adoption of advanced automation in agriculture and stringent food safety standards supporting market demand. Large-scale farming and the presence of established food processing industries further accelerate product uptake. North American manufacturers focus on product innovation and compliance with local regulations, positioning the region as a leader in high-performance conveyor belt systems.

Europe Agricultural and Food Grade Rubber Conveyor Belt System Market

Europe Agricultural and Food Grade Rubber Conveyor Belt System Market grew from USD 576.29 million in 2018 to USD 769.19 million in 2024 and is anticipated to reach USD 1,094.73 million by 2032, registering a CAGR of 4.1%. Europe holds a 20% market share. Key countries such as Germany, France, and the United Kingdom emphasize sustainable agriculture and high food safety standards, driving the adoption of food-grade conveyor solutions. The market in Europe benefits from robust investments in automation and efficient food supply chains. Manufacturers focus on compliance with the European Union’s regulatory framework and green initiatives, making the region a hub for innovative and environmentally conscious solutions.

Asia Pacific Agricultural and Food Grade Rubber Conveyor Belt System Market

Asia Pacific Agricultural and Food Grade Rubber Conveyor Belt System Market grew from USD 1,106.12 million in 2018 to USD 1,609.77 million in 2024 and is forecast to reach USD 2,642.84 million by 2032, at a CAGR of 6.0%. Asia Pacific accounts for the largest market share at 46%. China, India, and Japan are at the forefront, propelled by rapid industrialization, modernization of agriculture, and the growth of food processing sectors. Demand for cost-effective, high-capacity conveyor systems continues to rise with expanding export-oriented industries. Local and international manufacturers compete to deliver solutions tailored for diverse operational environments and regulatory requirements.

Latin America Agricultural and Food Grade Rubber Conveyor Belt System Market

Latin America Agricultural and Food Grade Rubber Conveyor Belt System Market grew from USD 78.70 million in 2018 to USD 108.07 million in 2024 and is expected to reach USD 135.89 million by 2032, achieving a CAGR of 2.5%. Latin America holds a 2% market share. Brazil, Mexico, and Argentina are leading countries, driven by the need to improve efficiency in large-scale agriculture and food export operations. Limited automation in smaller operations constrains growth, though regional investment in food safety and processing infrastructure is steadily rising.

Middle East Agricultural and Food Grade Rubber Conveyor Belt System Market

Middle East Agricultural and Food Grade Rubber Conveyor Belt System Market grew from USD 62.73 million in 2018 to USD 78.90 million in 2024 and will likely reach USD 98.72 million by 2032, reflecting a CAGR of 2.4%. The Middle East commands a 2% market share. Saudi Arabia and the United Arab Emirates invest in food processing capacity and modern agricultural practices. Water scarcity and the drive for food security support the adoption of efficient conveyor solutions. Manufacturers serving this region emphasize durability and compliance with hygiene requirements in challenging climatic conditions.

Africa Agricultural and Food Grade Rubber Conveyor Belt System Market

Africa Agricultural and Food Grade Rubber Conveyor Belt System Market grew from USD 41.33 million in 2018 to USD 63.95 million in 2024 and is projected to reach USD 78.64 million by 2032, with a CAGR of 2.2%. Africa holds a 1% market share. South Africa, Egypt, and Nigeria are key markets, focusing on developing agricultural supply chains and food processing sectors. Limited access to advanced technology and infrastructure presents growth challenges, but increasing government support and international investment encourage market penetration. Manufacturers targeting Africa develop affordable, robust conveyor belt systems suitable for local conditions.

Key Player Analysis

- Continental AG

- Dorner Mfg. Corp

- MAFDEL

- REVEYRON SAS

- Siban Peosa SA

- Trelleborg Slovenija D.O.O

- VIS GmbH

- Fenner PLC

- Volta Belting Technology Ltd.

- SIG S.p.A

- Artego SA

- Derco BV

Competitive Analysis

The Agricultural and Food Grade Rubber Conveyor Belt System Market features a competitive landscape shaped by several prominent players, including Continental AG, Fenner PLC, Dorner Mfg. Corp, MAFDEL, REVEYRON SAS, Siban Peosa SA, Trelleborg Slovenija D.O.O, VIS GmbH, Volta Belting Technology Ltd., SIG S.p.A, Artego SA, and Derco BV. These companies leverage extensive R&D capabilities and global manufacturing footprints to deliver specialized conveyor solutions tailored to the needs of agricultural and food processing clients. Leading companies invest in research and development to create conveyor belts that meet stringent hygiene and safety requirements while also offering durability and ease of maintenance. Many players prioritize expanding their global footprint through strategic partnerships, acquisitions, and targeted market entry into high-growth regions. The market sees active development of solutions tailored for automation, smart technologies, and sustainability, reflecting shifting customer preferences and regulatory expectations. Competitive strategies emphasize reliability, cost-effectiveness, and after-sales support to attract and retain customers in both developed and emerging markets. Strong competition encourages ongoing advancements in food-grade materials, IoT integration, and eco-friendly manufacturing. This dynamic environment ensures that end users benefit from a wide selection of technologically advanced and compliant conveyor belt systems.

Recent Developments

In 2024, Forbo Movement Systems launched the RE 4/2 U0/U0 belt, manufactured from 100% recycled PET and compliant with FDA, EU, and MHLW regulations.

Market Concentration & Characteristics

The Agricultural and Food Grade Rubber Conveyor Belt System Market displays a moderate to high level of concentration, with a select group of established global manufacturers holding significant market share. It features a blend of large multinational firms and specialized regional players, each leveraging expertise in material science, engineering, and compliance to address sector-specific requirements. The market is characterized by high barriers to entry due to strict regulatory standards, technological demands, and the need for specialized production capabilities. It demonstrates strong customer orientation, with an emphasis on durability, food safety, customization, and integration with modern automation systems. Companies in this space invest in continuous product innovation to maintain competitiveness and respond to evolving industry needs. The market’s structure supports steady growth, driven by rising automation, regulatory pressure, and increasing demand for high-performance, food-safe conveyor solutions across both mature and emerging economies.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage

The research report offers an in-depth analysis based on Product Type, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Agricultural and Food Grade Rubber Conveyor Belt System Market is projected to grow steadily, driven by increasing demand for efficient material handling in agriculture and food processing industries.

- Rising focus on food safety and hygiene standards is propelling the adoption of food-grade rubber conveyor belts that meet stringent regulatory requirements.

- Technological advancements, including the integration of IoT and automation, are enhancing the functionality and efficiency of conveyor belt systems in the agricultural sector.

- The market is experiencing a shift towards sustainable and eco-friendly materials, with manufacturers developing recyclable and biodegradable rubber conveyor belts.

- Expansion of the food processing industry, particularly in emerging economies, is creating new opportunities for conveyor belt system providers.

- Challenges such as high initial investment costs and maintenance requirements may hinder market growth, especially among small and medium-sized enterprises.

- North America and Europe are expected to maintain significant market shares due to established food processing industries and stringent food safety regulations.

- Asia Pacific is anticipated to witness the highest growth rate, fueled by rapid industrialization, urbanization, and increasing investments in the agriculture sector.

- The market is moderately consolidated, with key players focusing on strategic partnerships, mergers, and acquisitions to expand their global presence.

- Continuous research and development efforts are essential for innovation in product design, material composition, and compliance with evolving industry standards.