| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| China Plastic Welding Equipment Market Size 2024 |

USD 1,403.93 Million |

| China Plastic Welding Equipment Market, CAGR |

9.22% |

| China Plastic Welding Equipment Market Size 2032 |

USD 2,843.69 Million |

Market Overview

China Plastic Welding Equipment Market size was valued at USD 1,403.93 million in 2024 and is anticipated to reach USD 2,843.69 million by 2032, at a CAGR of 9.22% during the forecast period (2024-2032).

The China Plastic Welding Equipment market is driven by the increasing demand for plastic products across diverse industries such as automotive, electronics, and packaging. The rapid growth in manufacturing and industrialization has led to a higher need for efficient and precise welding technologies. Additionally, the rise of automation and technological advancements in welding methods, such as laser, ultrasonic, and hot plate welding, are enhancing production capabilities and reducing operational costs. The growing focus on sustainability and eco-friendly solutions is further accelerating the adoption of plastic welding technologies, as these methods allow for strong, durable joints that reduce waste and improve product life. Moreover, the expanding middle class and rising consumer demand for packaged goods are pushing the need for high-quality, cost-effective welding solutions. These factors collectively contribute to the market’s expansion, positioning China as a key player in the global plastic welding equipment sector.

The China Plastic Welding Equipment market is driven by key regions such as Beijing, Shanghai, Guangzhou, and Shenzhen, each playing a significant role in the country’s manufacturing landscape. These regions are home to industries that heavily rely on plastic welding technologies, including electronics, automotive, packaging, and medical devices. Major players in the market include Emerson Electric Co., Leister Technologies AG, Dukane Corporation, and Herrmann Ultraschalltechnik GmbH & Co. KG, among others. These companies are instrumental in providing advanced welding solutions tailored to the growing demand for precision, automation, and energy efficiency in plastic manufacturing. With a strong focus on innovation, these key players continue to drive technological advancements, ensuring the continued evolution of the plastic welding sector. The regional distribution and strategic presence of these companies contribute to the overall growth and competitiveness of the market in China.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The China Plastic Welding Equipment market was valued at USD 1,403.93 million in 2024 and is expected to reach USD 2,843.69 million by 2032, growing at a CAGR of 9.22% from 2024 to 2032.

- The global plastic welding equipment market was valued at USD 11,340.00 million in 2024 and is projected to reach USD 19,842.36 million by 2032, growing at a CAGR of 7.24% from 2024 to 2032.

- Growing industrialization and manufacturing demand in sectors like automotive and electronics are driving the market.

- Technological advancements, including automation and smart manufacturing, are enhancing the efficiency of plastic welding equipment.

- The market is seeing a shift toward energy-efficient and environmentally friendly welding technologies.

- Competitive landscape includes key players such as Emerson Electric Co., Leister Technologies AG, and Dukane Corporation, focusing on innovation and product development.

- High initial investment and maintenance costs are significant market restraints, limiting adoption among smaller manufacturers.

- Regional markets such as Beijing, Shanghai, Guangzhou, and Shenzhen are key drivers, with each region contributing uniquely to market growth.

Report Scope

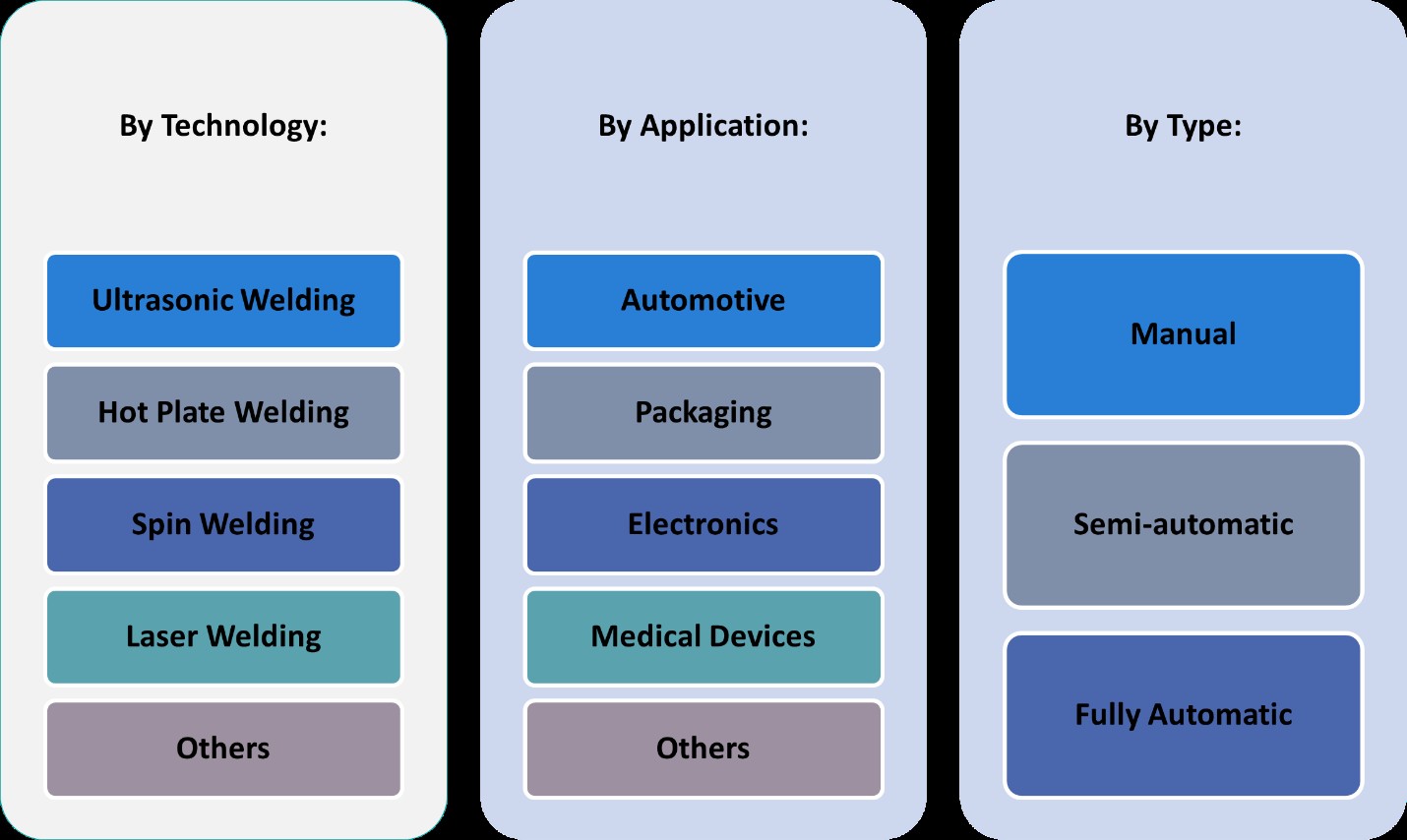

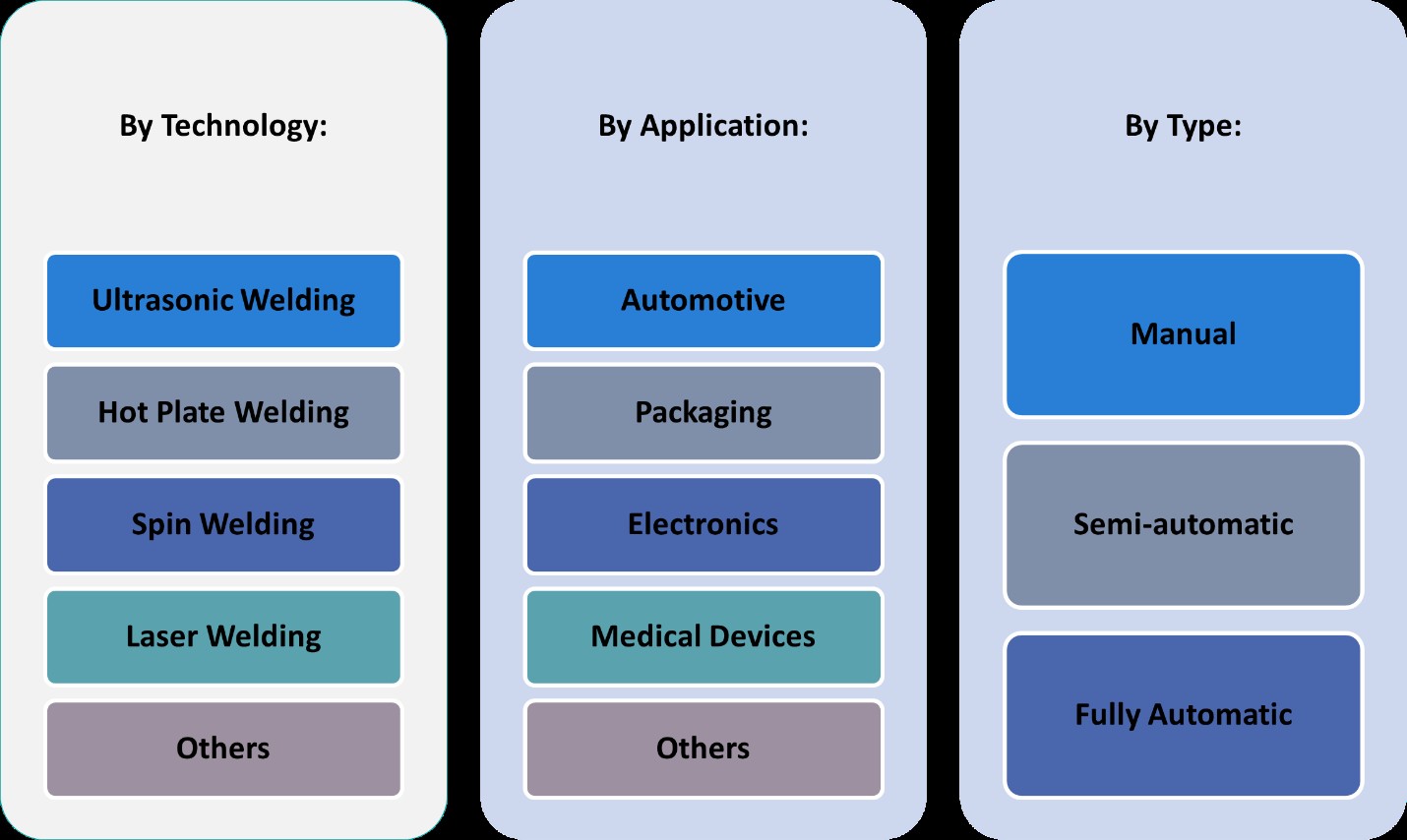

This report segments the China Plastic Welding Equipment Market as follows:

Market Drivers

Growing Industrialization and Manufacturing Demand

The rapid industrialization and expansion of manufacturing sectors in China are major drivers of the plastic welding equipment market. For instance, the China Government Work Report 2025 emphasizes the country’s focus on enhancing manufacturing capabilities through initiatives under the 14th Five-Year Plan. As one of the world’s largest manufacturing hubs, China’s increasing output of plastic products in industries like automotive, electronics, and packaging has led to a significant rise in demand for reliable and efficient plastic welding technologies. The need for high-performance, durable plastic components in these industries requires advanced welding methods capable of meeting strict production standards. Plastic welding equipment plays a vital role in ensuring precision, efficiency, and cost-effectiveness in manufacturing processes, further fueling its adoption.

Rising Focus on Sustainability and Environmental Concerns

China’s growing focus on sustainability and environmental responsibility is another key driver of the plastic welding equipment market. For instance, the Ministry of Ecology and Environment has introduced policies promoting eco-friendly manufacturing practices, as highlighted in the Plastic-Management Policy report. The demand for eco-friendly products and processes has encouraged manufacturers to adopt plastic welding methods that minimize waste and improve the recyclability of plastic components. Compared to traditional adhesive-based joining methods, plastic welding technologies produce stronger, more durable joints, reducing the need for additional materials and minimizing environmental impact. This aligns with China’s broader environmental goals, including reducing plastic waste and promoting circular economy practices. The adoption of plastic welding equipment that supports these goals is expected to grow steadily, driving the market forward.

Technological Advancements in Welding Methods

Innovations in welding technologies are significantly impacting the growth of the plastic welding equipment market in China. The development of cutting-edge welding methods such as laser welding, ultrasonic welding, and hot plate welding has revolutionized plastic joining processes. These advanced techniques offer higher precision, faster processing speeds, and better overall efficiency, making them ideal for industries with high-volume production needs. The integration of automation into these welding methods has further increased production efficiency, reducing operational costs and improving product consistency. As a result, Chinese manufacturers are increasingly adopting these modern solutions, driving demand for advanced plastic welding equipment.

Expanding Consumer Markets and Packaging Demand

The expanding consumer market in China, driven by a growing middle class and increasing disposable incomes, has created substantial demand for packaged goods. This, in turn, has elevated the need for plastic welding equipment in the packaging industry. Plastic packaging, known for its lightweight, cost-effective, and durable properties, is used extensively in consumer goods packaging. Plastic welding technologies help improve the quality and strength of these packaging solutions, ensuring the integrity of products during transportation and storage. As the demand for packaged goods continues to rise, particularly in food and beverage, cosmetics, and pharmaceuticals, the plastic welding equipment market in China is expected to expand further, catering to these growing needs.

Market Trends

Adoption of Automation and Smart Manufacturing

A prominent trend in the China Plastic Welding Equipment market is the growing adoption of automation and smart manufacturing systems. As industries seek to improve production efficiency and reduce labor costs, automation plays a critical role in optimizing the plastic welding process. For instance, the Ministry of Industry and Information Technology (MIIT) highlights the integration of Industry 4.0 technologies, such as IoT and AI, into manufacturing processes to enhance production efficiency. Smart welding equipment, integrated with advanced sensors and control systems, enables real-time monitoring and precise adjustments during the welding process. This trend enhances the consistency and quality of welded joints while minimizing human error.

Shift Towards Energy-Efficient Welding Technologies

Energy efficiency is another growing trend in the Chinese plastic welding equipment market. For instance, the Ministry of Ecology and Environment promotes the adoption of energy-efficient technologies like ultrasonic and laser welding, which consume less power while delivering precision results. As energy costs rise and environmental concerns increase, manufacturers are seeking welding technologies that consume less power while maintaining high performance. Techniques such as ultrasonic welding, laser welding, and vibration welding are gaining popularity due to their ability to deliver precision results with lower energy consumption compared to traditional methods. This shift toward energy-efficient welding not only reduces operational costs for manufacturers but also aligns with China’s broader efforts to reduce carbon emissions and promote sustainability in its industrial sectors.

Increased Focus on Customization and Versatility

With the growing demand for plastic products in diverse industries, the trend toward customization and versatility in welding equipment is becoming more evident. Manufacturers are increasingly seeking plastic welding equipment that can handle a wide range of materials, from thermoplastics to composites, and accommodate different welding methods. Multi-functional welding machines, capable of performing various welding techniques such as hot plate, ultrasonic, and friction welding, are gaining traction. This trend allows manufacturers to enhance their production capabilities and adapt quickly to changing market requirements, providing flexibility in meeting the specific needs of different applications. Customized welding solutions also help companies optimize their operations, offering better scalability and efficiency.

Emphasis on Precision and Quality Control

As plastic welding applications become more complex, especially in sectors like automotive, electronics, and medical devices, there is an increasing emphasis on precision and quality control. The demand for high-quality welded joints with minimal defects is pushing manufacturers to invest in advanced plastic welding equipment that ensures precise control over parameters such as temperature, pressure, and time. The use of advanced monitoring and feedback systems, coupled with automated processes, helps achieve superior weld quality with minimal variation. This trend is crucial for industries where the reliability and durability of plastic components are paramount, such as in automotive safety features and medical device manufacturing. Enhanced quality control capabilities are expected to continue driving market growth, especially in high-performance sectors.

Market Challenges Analysis

High Initial Investment and Maintenance Costs

One of the primary challenges facing the China Plastic Welding Equipment market is the high initial investment and maintenance costs associated with advanced welding technologies. The sophisticated equipment, particularly those incorporating automation, smart features, and energy-efficient solutions, often requires significant capital outlay. Smaller and mid-sized manufacturers may find it challenging to afford these high upfront costs, limiting their ability to invest in cutting-edge plastic welding technologies. Additionally, maintaining these advanced systems can be costly, requiring specialized training for operators and technicians, along with ongoing servicing and repairs. These financial barriers may slow the adoption of advanced plastic welding solutions, especially among cost-sensitive enterprises.

Technical Complexity and Skill Shortage

Another key challenge in the market is the technical complexity of modern plastic welding equipment, which demands highly skilled operators. For instance, the Skills Shortages in the Chinese Labor Market report highlights the acute shortage of workers trained in advanced welding technologies like laser and ultrasonic welding. The growing sophistication of welding technologies, including laser and ultrasonic welding, requires operators to have specialized training and expertise to ensure optimal performance. This skill gap can result in operational inefficiencies, higher error rates, and suboptimal weld quality, potentially undermining the benefits of advanced equipment. Addressing this challenge requires a concerted effort to invest in workforce development and training programs to keep pace with evolving technology.

Market Opportunities

The China Plastic Welding Equipment market presents significant opportunities driven by the rapid advancements in manufacturing technologies and the increasing demand for plastic products across various industries. As China continues to lead global manufacturing, the demand for high-quality, efficient, and automated welding solutions is expanding. Industries such as automotive, electronics, packaging, and medical devices are increasingly relying on advanced plastic welding technologies for precision and durability in their products. This trend opens up vast opportunities for suppliers of plastic welding equipment to cater to these sectors, particularly with the rise of applications in lightweight automotive parts, electronic housings, and specialized medical equipment. Furthermore, the shift toward sustainable manufacturing practices provides a unique opportunity for welding equipment manufacturers to develop energy-efficient and environmentally friendly solutions, further enhancing their market position.

The growing emphasis on smart manufacturing and Industry 4.0 technologies offers another promising opportunity for the China Plastic Welding Equipment market. As manufacturers move toward automation and integrated systems, there is a growing demand for welding equipment that supports data-driven decision-making, predictive maintenance, and process optimization. This creates a significant opportunity for the development of welding equipment with advanced sensors, real-time monitoring capabilities, and AI-driven features. By incorporating these cutting-edge technologies, manufacturers can offer more efficient, reliable, and cost-effective solutions to meet the evolving needs of their customers. As the market for plastic products continues to diversify and expand, there is a considerable opportunity for innovation and growth within the plastic welding equipment sector in China.

Market Segmentation Analysis:

By Type:

The China Plastic Welding Equipment market is segmented by type into manual, semi-automatic, and fully automatic systems. Manual plastic welding equipment is often preferred for small-scale operations or specialized applications where human intervention ensures precision and flexibility. However, it is more labor-intensive and less efficient compared to automated alternatives. Semi-automatic welding equipment offers a balance between manual control and automation, providing improved efficiency and consistency for mid-scale production. These systems are commonly used in industries where moderate production volumes are required, such as in small automotive parts or packaging. Fully automatic plastic welding equipment is gaining traction in large-scale production environments where high throughput and minimal human intervention are crucial. This segment is particularly popular in the automotive and electronics industries, where precision, speed, and consistency are paramount. Fully automated systems not only improve production efficiency but also enhance the quality and uniformity of welded joints, making them an essential tool for high-volume manufacturers in China.

By Application:

The application segment of the China Plastic Welding Equipment market is diverse, encompassing industries such as electronics, packaging, automotive, medical devices, and others. The electronics industry has witnessed significant adoption of plastic welding equipment due to the need for precise, durable, and lightweight components in consumer electronics and electronic housings. In packaging, plastic welding technologies are essential for creating strong, leak-proof seals in flexible packaging, particularly in food and beverage applications. The automotive industry is a major driver, with plastic welding used in manufacturing lightweight components, ensuring improved fuel efficiency and vehicle performance. Medical devices also present significant opportunities for plastic welding, as precise and clean welds are necessary for ensuring safety and sterility in medical products. Other sectors such as construction, aerospace, and consumer goods further expand the market, with applications ranging from pipe fittings to personal protective equipment. Each of these applications benefits from specialized plastic welding technologies, contributing to the overall market growth in China.

Segments:

Based on Type:

- Manual

- Semi-automatic

- Fully Automatic

Based on Application:

- Electronics

- Packaging

- Automotive

- Medical Devices

- Others

Based on Technology:

- Ultrasonic Welding

- Hot Plate Welding

- Spin Welding

- Laser Welding

- Others

Based on the Geography:

- Beijing

- Shanghai

- Guangzhou

- Shenzhen

Regional Analysis

Beijing

Beijing holds a prominent share of 25% in the China Plastic Welding Equipment market, driven by its status as a major industrial hub and capital city. The region is home to several high-tech manufacturing industries, including electronics, automotive, and medical devices, where plastic welding is crucial for producing precise and durable components. Beijing’s proximity to research and development centers and a highly skilled workforce further boosts the demand for advanced plastic welding technologies. The government’s strong emphasis on industrial innovation and sustainable manufacturing practices also fosters growth in the adoption of automated and energy-efficient welding systems.

Shanghai

Shanghai leads the market with a 30% share, making it the largest contributor to the plastic welding equipment market in China. As the financial and industrial powerhouse of the country, Shanghai has a diverse manufacturing base, including electronics, automotive, packaging, and consumer goods industries. The city’s focus on smart manufacturing, automation, and high-end technology adoption accelerates the demand for advanced plastic welding solutions. Moreover, Shanghai’s significant position in global trade facilitates the import and export of welding equipment, making it a key market for both domestic and international players.

Guangzhou

Guangzhou, with a market share of 20%, is a vital region for plastic welding equipment, particularly due to its strong presence in the manufacturing of consumer goods, packaging, and automotive components. The region’s well-established supply chain and proximity to key industrial zones make it a crucial player in China’s manufacturing landscape. Guangzhou’s emphasis on mass production and cost-efficient solutions increases the demand for semi-automatic and fully automatic welding systems that ensure high throughput and precision in manufacturing processes. The continued industrial expansion in the region contributes to the steady growth of plastic welding equipment adoption.

Shenzhen

Shenzhen accounts for 25% of the market share, driven by its status as a global technology hub and a leader in the electronics industry. As a center for electronics manufacturing, Shenzhen’s demand for plastic welding equipment is fueled by the need for precise, high-quality welded joints in consumer electronics, smartphones, and other electronic components. The city’s emphasis on innovation and advanced manufacturing technologies further accelerates the adoption of automated plastic welding solutions. Additionally, Shenzhen’s position as a key player in the tech industry facilitates the rapid integration of new technologies, including smart and energy-efficient welding systems, ensuring continuous market growth.

Key Player Analysis

- Emerson Electric Co.

- Leister Technologies AG

- Dukane Corporation

- Herrmann Ultraschalltechnik GmbH & Co. KG

- Branson Ultrasonics Corporation

- Frimo Group GmbH

- Bielomatik Leuze GmbH & Co. KG

- CHN-TOP Machinery Group

- Haitian International Holdings Ltd.

- Xinpoint Corporation

Competitive Analysis

The competitive landscape of the China Plastic Welding Equipment market is shaped by key players who are leading innovation and driving market growth. Major companies in the market include Emerson Electric Co., Leister Technologies AG, Dukane Corporation, Herrmann Ultraschalltechnik GmbH & Co. KG, Branson Ultrasonics Corporation, Frimo Group GmbH, Bielomatik Leuze GmbH & Co. KG, CHN-TOP Machinery Group, Haitian International Holdings Ltd., and Xinpoint Corporation. These companies are continuously focusing on technological advancements, offering a wide range of plastic welding solutions such as ultrasonic welding, laser welding, and hot plate welding systems. Many companies are integrating automation and smart manufacturing technologies, allowing for higher throughput, minimal human intervention, and improved production consistency. This focus on automation aligns with the broader trend toward Industry 4.0, where real-time monitoring, predictive maintenance, and data-driven decision-making are becoming essential for improving production efficiency and reducing downtime. Energy efficiency and sustainability are key priorities for market players, leading to the development of welding technologies that consume less power and minimize environmental impact. As the Chinese market grows, competition intensifies with companies striving to offer versatile and customizable solutions that cater to a broad range of applications, including automotive, electronics, medical devices, and packaging. Companies also emphasize quality control and precision to meet the high standards required by industries like automotive and medical device manufacturing, where product reliability and performance are crucial. The market’s competitive dynamics reflect the ongoing push for technological advancements and operational efficiency.

Recent Developments

- In March 2025, Leister transferred its laser plastic welding business to Hymson Novolas AG, a subsidiary of Hymson Laser Technology Group Co. Ltd. The transition ensures continuity and further development of existing product lines, with a new Laser Technology Center established in Switzerland. Leister will now focus more on its core competencies: plastic welding (hot air, infrared) and industrial process heat.

- In February 2025, Herrmann continues to set industry standards with its ultrasonic welding solutions, particularly for medical devices and sensitive components. The company emphasizes individualized process development, intelligent process control, and digital quality monitoring for reproducible, high-strength welds. Herrmann will showcase new applications and integration options at K 2025, focusing on automation and sustainability in medical and packaging industries.

- In January 2025, Dukane highlighted its patented Q-Factor, Melt-Match®, Low Amplitude Preheat, and Ultra-High Frequency (260–400 Hz) vibration welding technologies, emphasizing their leadership in process control and diagnostics.

- In May 2024, Emerson launched the Branson™ GLX-1 Laser Welder, designed for the automated assembly of small, intricate plastic parts. The GLX-1 features a compact, modular design suitable for cleanroom environments, advanced servo-based actuation, and the ability to “un-weld” plastics for closed-loop recycling. It uses Simultaneous Through-Transmission Infrared® (STTlr) laser-welding technology for high efficiency, weld strength, and aesthetics. Enhanced connectivity, security, and data collection features support Industry 4.0 integration.

Market Concentration & Characteristics

The China Plastic Welding Equipment market exhibits moderate concentration, with several prominent players holding a significant share while a large number of smaller companies contribute to its diversity. The market is characterized by a mix of well-established multinational corporations and local players who offer a wide range of welding solutions. The leading companies focus on technological innovation, offering advanced systems such as ultrasonic, laser, and hot plate welding equipment to meet the demands of various industries, including automotive, electronics, medical devices, and packaging. These players often emphasize energy efficiency, automation, and sustainability to align with market trends. Despite the presence of large global companies, local players are also gaining ground by offering cost-effective solutions tailored to the specific needs of Chinese manufacturers. The competitive environment is dynamic, with companies continually innovating to enhance their product offerings, improve operational efficiency, and address the increasing demand for precision and high-quality welding solutions.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage

The research report offers an in-depth analysis based on Type, Application, Technology and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- China’s plastic welding equipment market is expected to witness continued growth, driven by the increasing demand from various industries, such as automotive, packaging, and construction.

- Technological advancements in welding processes, such as ultrasonic welding and laser welding, will continue to improve the efficiency and precision of plastic welding equipment.

- The rise in the production of electric vehicles (EVs) and lightweight components will drive demand for specialized plastic welding equipment, especially in the automotive sector.

- Government initiatives promoting sustainable manufacturing and green technologies will likely lead to the adoption of energy-efficient and eco-friendly plastic welding solutions.

- Increased investment in research and development (R&D) will help Chinese manufacturers develop more advanced plastic welding technologies, strengthening their competitive position in the global market.

- The expanding plastic packaging industry, particularly in food and beverage sectors, will contribute to steady demand for high-quality welding equipment.

- With a growing focus on automation, the demand for automated plastic welding equipment will rise, driven by the need for faster and more consistent production processes.

- Stronger regulations and standards concerning product safety and environmental impact will push manufacturers to upgrade their plastic welding equipment to comply with industry norms.

- As the Chinese manufacturing sector continues to modernize, the demand for integrated and smart plastic welding systems that enable better control and monitoring will increase.

- The global export potential for Chinese plastic welding equipment is set to grow, as the country’s technological advancements and cost-effective solutions attract international markets.