CHAPTER NO. 1 : INTRODUCTION 28

1.1.1. Report Description 28

Purpose of the Report 28

USP & Key Offerings 28

1.1.2. Key Benefits for Stakeholders 28

1.1.3. Target Audience 29

1.1.4. Report Scope 29

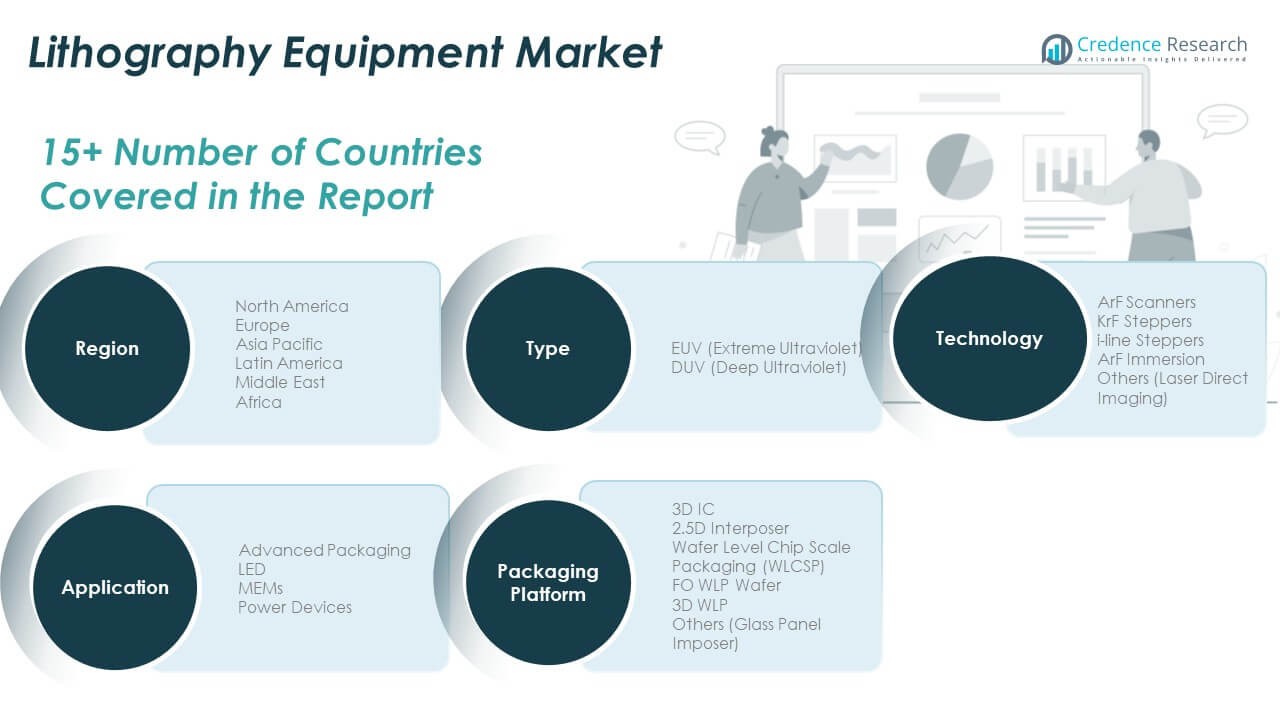

1.1.5. Regional Scope 30

CHAPTER NO. 2 : EXECUTIVE SUMMARY 31

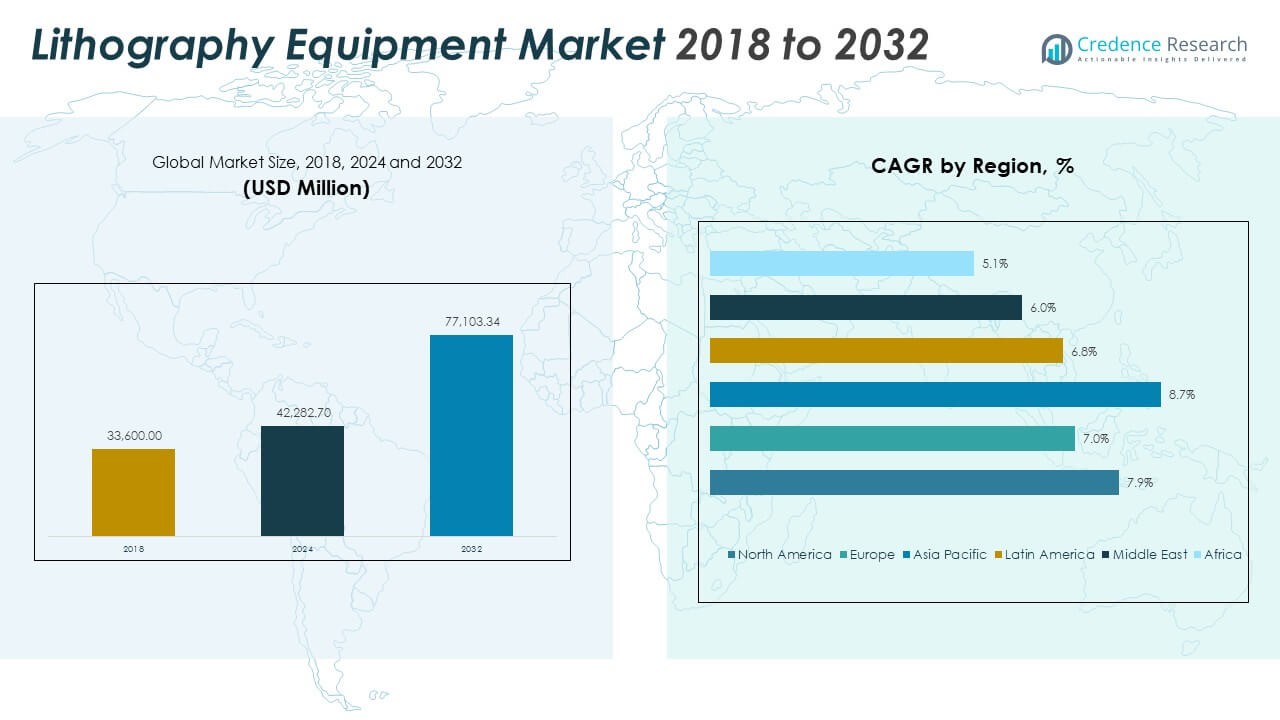

2.1. Lithography Equipment Market Snapshot 31

2.1.1. Global Lithography Equipment Market, 2018 – 2032 (USD Million) 32

CHAPTER NO. 3 : GEOPOLITICAL CRISIS IMPACT ANALYSIS 33

3.1. Russia-Ukraine and Israel-Palestine War Impacts 33

CHAPTER NO. 4 : LITHOGRAPHY EQUIPMENT MARKET – INDUSTRY ANALYSIS 34

4.1. Introduction 34

4.2. Market Drivers 35

4.2.1. Rising Demand for Advanced Semiconductor Nodes (≤7 nm) 35

4.2.2. Expansion of AI, IoT, and Automotive Electronics 36

4.3. Market Restraints 37

4.3.1. Extremely High Equipment Cost 37

4.4. Market Opportunities 38

4.4.1. Market Opportunity Analysis 38

4.5. Porter’s Five Forces Analysis 39

CHAPTER NO. 5 : ANALYSIS COMPETITIVE LANDSCAPE 40

5.1. Company Market Share Analysis – 2024 40

5.1.1. Global Lithography Equipment Market: Company Market Share, by Volume, 2024 40

5.1.2. Global Lithography Equipment Market: Company Market Share, by Revenue, 2024 41

5.1.3. Global Lithography Equipment Market: Top 6 Company Market Share, by Revenue, 2024 41

5.2. Global Lithography Equipment Market Company Revenue Market Share, 2024 42

5.3. Company Assessment Metrics, 2023 43

5.3.1. Stars 43

5.3.2. Emerging Leaders 43

5.3.3. Pervasive Players 43

5.3.4. Participants 43

5.4. Start-ups /SMEs Assessment Metrics, 2023 43

5.4.1. Progressive Companies 43

5.4.2. Responsive Companies 43

5.4.3. Dynamic Companies 43

5.4.4. Starting Blocks 43

5.5. Strategic Developments 44

5.5.1. Acquisitions & Mergers 44

New Product Launch 44

Regional Expansion 44

5.6. Key Players Product Matrix 45

CHAPTER NO. 6 : PESTEL & ADJACENT MARKET ANALYSIS 46

6.1. PESTEL 46

6.1.1. Political Factors 46

6.1.2. Economic Factors 46

6.1.3. Social Factors 46

6.1.4. Technological Factors 46

6.1.5. Environmental Factors 46

6.1.6. Legal Factors 46

6.2. Adjacent Market Analysis 46

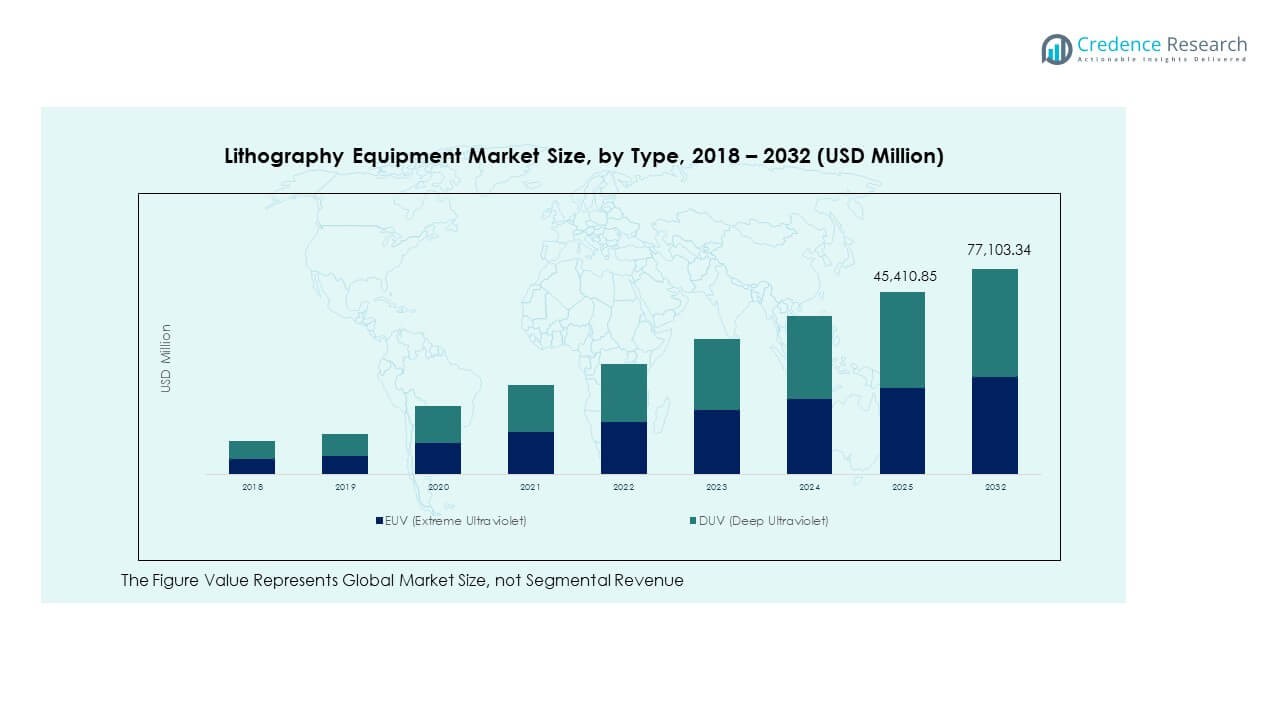

CHAPTER NO. 7 : LITHOGRAPHY EQUIPMENT MARKET – BY TYPE SEGMENT ANALYSIS 47

7.1. Lithography Equipment Market Overview, by Type Segment 47

7.1.1. Lithography Equipment Market Revenue Share, By Type, 2023 & 2032 48

7.1.2. Lithography Equipment Market Attractiveness Analysis, By Type 49

7.1.3. Incremental Revenue Growth Opportunity, by Type, 2024 – 2032 49

7.1.4. Lithography Equipment Market Revenue, By Type, 2018, 2023, 2027 & 2032 50

7.2. EUV (Extreme Ultraviolet) 51

7.2.1. Global EUV (Extreme Ultraviolet) Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 52

7.2.2. Global EUV (Extreme Ultraviolet) Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 52

7.3. DUV (Deep Ultraviolet) 53

7.3.1. Global DUV (Deep Ultraviolet) Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 54

7.3.2. Global DUV (Deep Ultraviolet) Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 54

CHAPTER NO. 8 : LITHOGRAPHY EQUIPMENT MARKET – BY APPLICATION SEGMENT ANALYSIS 55

8.1. Lithography Equipment Market Overview, by Application Segment 55

8.1.1. Lithography Equipment Market Revenue Share, By Application, 2023 & 2032 56

8.1.2. Lithography Equipment Market Attractiveness Analysis, By Application 57

8.1.3. Incremental Revenue Growth Opportunity, by Application, 2024 – 2032 57

8.1.4. Lithography Equipment Market Revenue, By Application, 2018, 2023, 2027 & 2032 58

8.2. Advanced Packaging 59

8.2.1. Global Advanced Packaging Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 60

8.2.2. Global Advanced Packaging Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 60

8.3. LED 61

8.3.1. Global LED Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 62

8.3.2. Global LED Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 62

8.4. MEMs 63

8.4.1. Global MEMs Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 64

8.4.2. Global MEMs Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 64

8.5. Power Devices 65

8.5.1. Global Power Devices Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 66

8.5.2. Global Power Devices Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 66

CHAPTER NO. 9 : LITHOGRAPHY EQUIPMENT MARKET – BY PACKAGING PLATFORM SEGMENT ANALYSIS 67

9.1. Lithography Equipment Market Overview, by Packaging Platform Segment 67

9.1.1. Lithography Equipment Market Revenue Share, By End-user, 2023 & 2032 68

9.1.2. Lithography Equipment Market Attractiveness Analysis, By End-user 69

9.1.3. Incremental Revenue Growth Opportunity, by End-user, 2024 – 2032 69

9.1.4. Lithography Equipment Market Revenue, By End-user, 2018, 2023, 2027 & 2032 70

9.2. 3D IC 71

9.2.1. Global 3D IC Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 72

9.2.2. Global 3D IC Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 72

9.3. 2.5D Interposer 73

9.3.1. Global 2.5D Interposer Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 74

9.3.2. Global 2.5D Interposer Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 74

9.4. Wafer Level Chip Scale Packaging (WLCSP) 75

9.4.1. Global Wafer Level Chip Scale Packaging (WLCSP) Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 76

9.4.2. Global Wafer Level Chip Scale Packaging (WLCSP) Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 76

9.5. 3D WLP 77

9.5.1. Global 3D WLP Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 78

9.5.2. Global 3D WLP Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 78

9.6. Others 79

9.6.1. Global Others Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 80

9.6.2. Global Others Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 80

CHAPTER NO. 10 : LITHOGRAPHY EQUIPMENT MARKET – BY TECHNOLOGY SEGMENT ANALYSIS 81

10.1. Lithography Equipment Market Overview, by Technology Segment 81

10.1.1. Lithography Equipment Market Revenue Share, By Technology, 2023 & 2032 82

10.1.2. Lithography Equipment Market Attractiveness Analysis, By Technology 83

10.1.3. Incremental Revenue Growth Opportunity, by Technology, 2024 – 2032 83

10.1.4. Lithography Equipment Market Revenue, By Technology, 2018, 2023, 2027 & 2032 84

10.2. ArF Scanners 85

10.2.1. Global ArF Scanners Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 86

10.2.2. Global ArF Scanners Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 86

10.3. KrF Steppers 87

10.3.1. Global KrF Steppers Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 88

10.3.2. Global KrF Steppers Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 88

10.4. i-line Steppers 89

10.4.1. Global i-line Steppers Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 90

10.4.2. Global i-line Steppers Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 90

10.5. ArF Immersion 91

10.5.1. Global ArF Immersion Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 92

10.5.2. Global ArF Immersion Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 92

10.6. Others 93

10.6.1. Global Others Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 94

10.6.2. Global Others Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 94

CHAPTER NO. 11 : LITHOGRAPHY EQUIPMENT MARKET – REGIONAL ANALYSIS 95

11.1. Lithography Equipment Market Overview, by Regional Segments 95

11.2. Region 96

11.2.1. Global Lithography Equipment Market Revenue Share, By Region, 2023 & 2032 96

11.2.2. Lithography Equipment Market Attractiveness Analysis, By Region 97

11.2.3. Incremental Revenue Growth Opportunity, by Region, 2024 – 2032 97

11.2.4. Lithography Equipment Market Revenue, By Region, 2018, 2023, 2027 & 2032 98

11.2.5. Global Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 99

11.2.6. Global Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 99

11.3. Type 100

11.3.1. Global Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 100

11.4. Global Lithography Equipment Market Revenue, By Type, 2024 – 2032 (USD Million) 100

11.5. Application 101

11.5.1. Global Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 101

11.5.2. Global Lithography Equipment Market Revenue, By Application, 2024 – 2032 (USD Million) 101

11.6. End-user 102

11.6.1. Global Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 102

11.6.2. Global Lithography Equipment Market Revenue, By End-user, 2024 – 2032 (USD Million) 102

11.7. Technology 103

11.7.1. Global Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 103

11.7.2. Global Lithography Equipment Market Revenue, By Technology, 2024 – 2032 (USD Million) 103

CHAPTER NO. 12 : LITHOGRAPHY EQUIPMENT MARKET – NORTH AMERICA 104

12.1. North America 104

12.1.1. Key Highlights 104

12.1.2. North America Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 105

12.1.3. North America Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 106

12.1.4. North America Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 107

12.1.5. North America Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 108

12.1.6. North America Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 109

12.2. U.S. 110

12.3. Canada 110

12.4. Mexico 110

CHAPTER NO. 13 : LITHOGRAPHY EQUIPMENT MARKET – EUROPE 111

13.1. Europe 111

13.1.1. Key Highlights 111

13.1.2. Europe Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 112

13.1.3. Europe Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 113

13.1.4. Europe Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 114

13.1.5. Europe Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 115

13.1.6. Europe Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 116

13.2. UK 117

13.3. France 117

13.4. Germany 117

13.5. Italy 117

13.6. Spain 117

13.7. Russia 117

13.8. Belgium 117

13.9. Netherland 117

13.10. Austria 117

13.11. Sweden 117

13.12. Poland 117

13.13. Denmark 117

13.14. Switzerland 117

13.15. Rest of Europe 117

CHAPTER NO. 14 : LITHOGRAPHY EQUIPMENT MARKET – ASIA PACIFIC 118

14.1. Asia Pacific 118

14.1.1. Key Highlights 118

14.1.2. Asia Pacific Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 119

14.1.3. Asia Pacific Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 120

14.1.4. Asia Pacific Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 121

14.1.5. Asia Pacific Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 122

14.1.6. Asia Pacific Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 123

14.2. China 124

14.3. Japan 124

14.4. South Korea 124

14.5. India 124

14.6. Australia 124

14.7. Thailand 124

14.8. Indonesia 124

14.9. Vietnam 124

14.10. Malaysia 124

14.11. Philippines 124

14.12. Taiwan 124

14.13. Rest of Asia Pacific 124

CHAPTER NO. 15 : LITHOGRAPHY EQUIPMENT MARKET – LATIN AMERICA 125

15.1. Latin America 125

15.1.1. Key Highlights 125

15.1.2. Latin America Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 126

15.1.3. Latin America Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 127

15.1.4. Latin America Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 128

15.1.5. Latin America Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 129

15.1.6. Latin America Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 130

15.2. Brazil 131

15.3. Argentina 131

15.4. Peru 131

15.5. Chile 131

15.6. Colombia 131

15.7. Rest of Latin America 131

CHAPTER NO. 16 : LITHOGRAPHY EQUIPMENT MARKET – MIDDLE EAST 132

16.1. Middle East 132

16.1.1. Key Highlights 132

16.1.2. Middle East Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 133

16.1.3. Middle East Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 134

16.1.4. Middle East Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 135

16.1.5. Middle East Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 136

16.1.6. Middle East Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 137

16.2. UAE 138

16.3. KSA 138

16.4. Israel 138

16.5. Turkey 138

16.6. Iran 138

16.7. Rest of Middle East 138

CHAPTER NO. 17 : LITHOGRAPHY EQUIPMENT MARKET – AFRICA 139

17.1. Africa 139

17.1.1. Key Highlights 139

17.1.2. Africa Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 140

17.1.3. Africa Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 141

17.1.4. Africa Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 142

17.1.5. Africa Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 143

17.1.6. Africa Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 144

17.2. Egypt 145

17.3. Nigeria 145

17.4. Algeria 145

17.5. Morocco 145

17.6. Rest of Africa 145

CHAPTER NO. 18 : COMPANY PROFILES 146

18.1. ASML Holding NV (Netherlands) 146

18.1.1. Company Overview 146

18.1.2. Product Portfolio 146

18.1.3. Swot Analysis 146

18.1.4. Business Strategy 147

18.1.5. Financial Overview 147

18.2. Nikon Corporation (Japan) 148

18.3. Canon, Inc. (Japan) 148

18.4. EV Group (Austria) 148

18.5. Veeco Instruments Inc. (U.S.) 148

18.6. SUSS MicroTec SE (Germany) 148

18.7. Shanghai Micro Electronics Equipment (Group) Co. Ltd. (China) 148

18.8. Neutronix Quintel Inc. (U.S.) 148

18.9. JEOL Ltd. (Japan) 148

18.10. Onto Innovation (U.S.) 148

18.11. Company 11 148

18.12. Company 12 148

18.13. Company 13 148

18.14. Company 14 148

List of Figures

FIG NO. 1. Global Lithography Equipment Market Revenue, 2018 – 2032 (USD Million) 32

FIG NO. 2. Porter’s Five Forces Analysis for Global Lithography Equipment Market 39

FIG NO. 3. Company Share Analysis, 2024 40

FIG NO. 4. Company Share Analysis, 2024 41

FIG NO. 5. Company Share Analysis, 2024 41

FIG NO. 6. Lithography Equipment Market – Company Revenue Market Share, 2024 42

FIG NO. 7. Lithography Equipment Market Revenue Share, By Type, 2023 & 2032 48

FIG NO. 8. Market Attractiveness Analysis, By Type 49

FIG NO. 9. Incremental Revenue Growth Opportunity by Type, 2024 – 2032 49

FIG NO. 10. Lithography Equipment Market Revenue, By Type, 2018, 2023, 2027 & 2032 50

FIG NO. 11. Global Lithography Equipment Market for EUV (Extreme Ultraviolet), Revenue (USD Million) 2018 – 2032 51

FIG NO. 12. Global Lithography Equipment Market for DUV (Deep Ultraviolet), Revenue (USD Million) 2018 – 2032 53

FIG NO. 13. Lithography Equipment Market Revenue Share, By Application, 2023 & 2032 56

FIG NO. 14. Market Attractiveness Analysis, By Application 57

FIG NO. 15. Incremental Revenue Growth Opportunity by Application, 2024 – 2032 57

FIG NO. 16. Lithography Equipment Market Revenue, By Application, 2018, 2023, 2027 & 2032 58

FIG NO. 17. Global Lithography Equipment Market for Advanced Packaging, Revenue (USD Million) 2018 – 2032 59

FIG NO. 18. Global Lithography Equipment Market for LED, Revenue (USD Million) 2018 – 2032 61

FIG NO. 19. Global Lithography Equipment Market for MEMs, Revenue (USD Million) 2018 – 2032 63

FIG NO. 20. Global Lithography Equipment Market for Power Devices, Revenue (USD Million) 2018 – 2032 65

FIG NO. 21. Lithography Equipment Market Revenue Share, By End-user, 2023 & 2032 68

FIG NO. 22. Market Attractiveness Analysis, By End-user 69

FIG NO. 23. Incremental Revenue Growth Opportunity by End-user, 2024 – 2032 69

FIG NO. 24. Lithography Equipment Market Revenue, By End-user, 2018, 2023, 2027 & 2032 70

FIG NO. 25. Global Lithography Equipment Market for 3D IC, Revenue (USD Million) 2018 – 2032 71

FIG NO. 26. Global Lithography Equipment Market for 2.5D Interposer, Revenue (USD Million) 2018 – 2032 73

FIG NO. 27. Global Lithography Equipment Market for Wafer Level Chip Scale Packaging (WLCSP), Revenue (USD Million) 2018 – 2032 75

FIG NO. 28. Global Lithography Equipment Market for 3D WLP, Revenue (USD Million) 2018 – 2032 77

FIG NO. 29. Global Lithography Equipment Market for Others, Revenue (USD Million) 2018 – 2032 79

FIG NO. 30. Lithography Equipment Market Revenue Share, By Technology, 2023 & 2032 82

FIG NO. 31. Market Attractiveness Analysis, By Technology 83

FIG NO. 32. Incremental Revenue Growth Opportunity by Technology, 2024 – 2032 83

FIG NO. 33. Lithography Equipment Market Revenue, By Technology, 2018, 2023, 2027 & 2032 84

FIG NO. 34. Global Lithography Equipment Market for ArF Scanners, Revenue (USD Million) 2018 – 2032 85

FIG NO. 35. Global Lithography Equipment Market for KrF Steppers, Revenue (USD Million) 2018 – 2032 87

FIG NO. 36. Global Lithography Equipment Market for i-line Steppers, Revenue (USD Million) 2018 – 2032 89

FIG NO. 37. Global Lithography Equipment Market for ArF Immersion, Revenue (USD Million) 2018 – 2032 91

FIG NO. 38. Global Lithography Equipment Market for Others, Revenue (USD Million) 2018 – 2032 93

FIG NO. 39. Global Lithography Equipment Market Revenue Share, By Region, 2023 & 2032 96

FIG NO. 40. Market Attractiveness Analysis, By Region 97

FIG NO. 41. Incremental Revenue Growth Opportunity by Region, 2024 – 2032 97

FIG NO. 42. Lithography Equipment Market Revenue, By Region, 2018, 2023, 2027 & 2032 98

FIG NO. 43. North America Lithography Equipment Market Revenue, 2018 – 2032 (USD Million) 104

FIG NO. 44. Europe Lithography Equipment Market Revenue, 2018 – 2032 (USD Million) 111

FIG NO. 45. Asia Pacific Lithography Equipment Market Revenue, 2018 – 2032 (USD Million) 118

FIG NO. 46. Latin America Lithography Equipment Market Revenue, 2018 – 2032 (USD Million) 125

FIG NO. 47. Middle East Lithography Equipment Market Revenue, 2018 – 2032 (USD Million) 132

FIG NO. 48. Africa Lithography Equipment Market Revenue, 2018 – 2032 (USD Million) 139

List of Tables

TABLE NO. 1. : Global Lithography Equipment Market: Snapshot 31

TABLE NO. 2. : Drivers for the Lithography Equipment Market: Impact Analysis 35

TABLE NO. 3. : Restraints for the Lithography Equipment Market: Impact Analysis 37

TABLE NO. 4. : Global EUV (Extreme Ultraviolet) Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 52

TABLE NO. 5. : Global EUV (Extreme Ultraviolet) Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 52

TABLE NO. 6. : Global DUV (Deep Ultraviolet) Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 54

TABLE NO. 7. : Global DUV (Deep Ultraviolet) Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 54

TABLE NO. 8. : Global Advanced Packaging Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 60

TABLE NO. 9. : Global Advanced Packaging Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 60

TABLE NO. 10. : Global LED Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 62

TABLE NO. 11. : Global LED Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 62

TABLE NO. 12. : Global MEMs Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 64

TABLE NO. 13. : Global MEMs Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 64

TABLE NO. 14. : Global Power Devices Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 66

TABLE NO. 15. : Global Power Devices Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 66

TABLE NO. 16. : Global 3D IC Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 72

TABLE NO. 17. : Global 3D IC Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 72

TABLE NO. 18. : Global 2.5D Interposer Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 74

TABLE NO. 19. : Global 2.5D Interposer Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 74

TABLE NO. 20. : Global Wafer Level Chip Scale Packaging (WLCSP) Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 76

TABLE NO. 21. : Global Wafer Level Chip Scale Packaging (WLCSP) Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 76

TABLE NO. 22. : Global 3D WLP Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 78

TABLE NO. 23. : Global 3D WLP Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 78

TABLE NO. 24. : Global Others Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 80

TABLE NO. 25. : Global Others Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 80

TABLE NO. 26. : Global ArF Scanners Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 86

TABLE NO. 27. : Global ArF Scanners Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 86

TABLE NO. 28. : Global KrF Steppers Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 88

TABLE NO. 29. : Global KrF Steppers Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 88

TABLE NO. 30. : Global i-line Steppers Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 90

TABLE NO. 31. : Global i-line Steppers Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 90

TABLE NO. 32. : Global ArF Immersion Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 92

TABLE NO. 33. : Global ArF Immersion Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 92

TABLE NO. 34. : Global Others Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 94

TABLE NO. 35. : Global Others Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 94

TABLE NO. 36. : Global Lithography Equipment Market Revenue, By Region, 2018 – 2023 (USD Million) 99

TABLE NO. 37. : Global Lithography Equipment Market Revenue, By Region, 2024 – 2032 (USD Million) 99

TABLE NO. 38. : Global Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 100

TABLE NO. 39. : Global Lithography Equipment Market Revenue, By Type, 2024 – 2032 (USD Million) 100

TABLE NO. 40. : Global Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 101

TABLE NO. 41. : Global Lithography Equipment Market Revenue, By Application, 2024 – 2032 (USD Million) 101

TABLE NO. 42. : Global Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 102

TABLE NO. 43. : Global Lithography Equipment Market Revenue, By End-user, 2024 – 2032 (USD Million) 102

TABLE NO. 44. : Global Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 103

TABLE NO. 45. : Global Lithography Equipment Market Revenue, By Technology, 2024 – 2032 (USD Million) 103

TABLE NO. 46. : North America Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 105

TABLE NO. 47. : North America Lithography Equipment Market Revenue, By Country, 2024 – 2032 (USD Million) 105

TABLE NO. 48. : North America Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 106

TABLE NO. 49. : North America Lithography Equipment Market Revenue, By Type, 2024 – 2032 (USD Million) 106

TABLE NO. 50. : North America Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 107

TABLE NO. 51. : North America Lithography Equipment Market Revenue, By Application, 2024 – 2032 (USD Million) 107

TABLE NO. 52. : North America Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 108

TABLE NO. 53. : North America Lithography Equipment Market Revenue, By End-user, 2024 – 2032 (USD Million) 108

TABLE NO. 54. : North America Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 109

TABLE NO. 55. : North America Lithography Equipment Market Revenue, By Technology, 2024 – 2032 (USD Million) 109

TABLE NO. 56. : Europe Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 112

TABLE NO. 57. : Europe Lithography Equipment Market Revenue, By Country, 2024 – 2032 (USD Million) 112

TABLE NO. 58. : Europe Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 113

TABLE NO. 59. : Europe Lithography Equipment Market Revenue, By Type, 2024 – 2032 (USD Million) 113

TABLE NO. 60. : Europe Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 114

TABLE NO. 61. : Europe Lithography Equipment Market Revenue, By Application, 2024 – 2032 (USD Million) 114

TABLE NO. 62. : Europe Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 115

TABLE NO. 63. : Europe Lithography Equipment Market Revenue, By End-user, 2024 – 2032 (USD Million) 115

TABLE NO. 64. : Europe Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 116

TABLE NO. 65. : Europe Lithography Equipment Market Revenue, By Technology, 2024 – 2032 (USD Million) 116

TABLE NO. 66. : Asia Pacific Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 119

TABLE NO. 67. : Asia Pacific Lithography Equipment Market Revenue, By Country, 2024 – 2032 (USD Million) 119

TABLE NO. 68. : Asia Pacific Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 120

TABLE NO. 69. : Asia Pacific Lithography Equipment Market Revenue, By Type, 2024 – 2032 (USD Million) 120

TABLE NO. 70. : Asia Pacific Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 121

TABLE NO. 71. : Asia Pacific Lithography Equipment Market Revenue, By Application, 2024 – 2032 (USD Million) 121

TABLE NO. 72. : Asia Pacific Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 122

TABLE NO. 73. : Asia Pacific Lithography Equipment Market Revenue, By End-user, 2024 – 2032 (USD Million) 122

TABLE NO. 74. : Asia Pacific Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 123

TABLE NO. 75. : Asia Pacific Lithography Equipment Market Revenue, By Technology, 2024 – 2032 (USD Million) 123

TABLE NO. 76. : Latin America Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 126

TABLE NO. 77. : Latin America Lithography Equipment Market Revenue, By Country, 2024 – 2032 (USD Million) 126

TABLE NO. 78. : Latin America Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 127

TABLE NO. 79. : Latin America Lithography Equipment Market Revenue, By Type, 2024 – 2032 (USD Million) 127

TABLE NO. 80. : Latin America Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 128

TABLE NO. 81. : Latin America Lithography Equipment Market Revenue, By Application, 2024 – 2032 (USD Million) 128

TABLE NO. 82. : Latin America Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 129

TABLE NO. 83. : Latin America Lithography Equipment Market Revenue, By End-user, 2024 – 2032 (USD Million) 129

TABLE NO. 84. : Latin America Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 130

TABLE NO. 85. : Latin America Lithography Equipment Market Revenue, By Technology, 2024 – 2032 (USD Million) 130

TABLE NO. 86. : Middle East Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 133

TABLE NO. 87. : Middle East Lithography Equipment Market Revenue, By Country, 2024 – 2032 (USD Million) 133

TABLE NO. 88. : Middle East Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 134

TABLE NO. 89. : Middle East Lithography Equipment Market Revenue, By Type, 2024 – 2032 (USD Million) 134

TABLE NO. 90. : Middle East Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 135

TABLE NO. 91. : Middle East Lithography Equipment Market Revenue, By Application, 2024 – 2032 (USD Million) 135

TABLE NO. 92. : Middle East Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 136

TABLE NO. 93. : Middle East Lithography Equipment Market Revenue, By End-user, 2024 – 2032 (USD Million) 136

TABLE NO. 94. : Middle East Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 137

TABLE NO. 95. : Middle East Lithography Equipment Market Revenue, By Technology, 2024 – 2032 (USD Million) 137

TABLE NO. 96. : Africa Lithography Equipment Market Revenue, By Country, 2018 – 2023 (USD Million) 140

TABLE NO. 97. : Africa Lithography Equipment Market Revenue, By Country, 2024 – 2032 (USD Million) 140

TABLE NO. 98. : Africa Lithography Equipment Market Revenue, By Type, 2018 – 2023 (USD Million) 141

TABLE NO. 99. : Africa Lithography Equipment Market Revenue, By Type, 2024 – 2032 (USD Million) 141

TABLE NO. 100. : Africa Lithography Equipment Market Revenue, By Application, 2018 – 2023 (USD Million) 142

TABLE NO. 101. : Africa Lithography Equipment Market Revenue, By Application, 2024 – 2032 (USD Million) 142

TABLE NO. 102. : Africa Lithography Equipment Market Revenue, By End-user, 2018 – 2023 (USD Million) 143

TABLE NO. 103. : Africa Lithography Equipment Market Revenue, By End-user, 2024 – 2032 (USD Million) 143

TABLE NO. 104. : Africa Lithography Equipment Market Revenue, By Technology, 2018 – 2023 (USD Million) 144

TABLE NO. 105. : Africa Lithography Equipment Market Revenue, By Technology, 2024 – 2032 (USD Million) 144