Market Overview

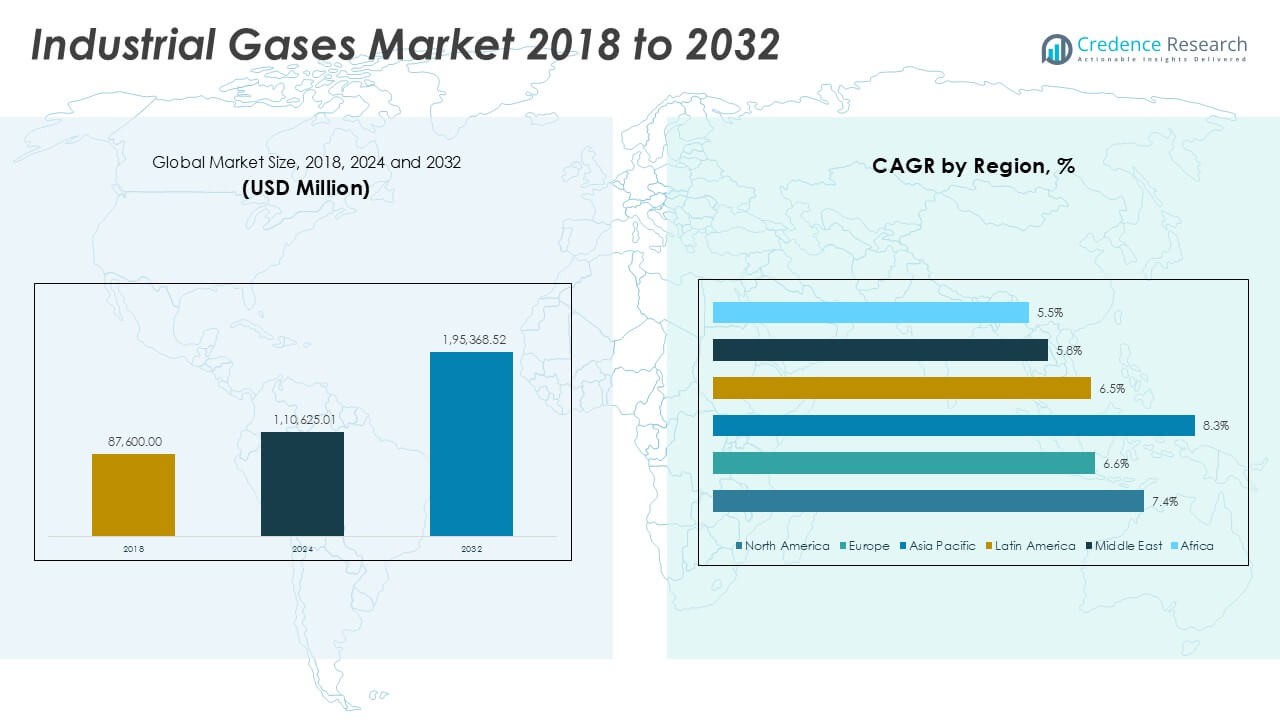

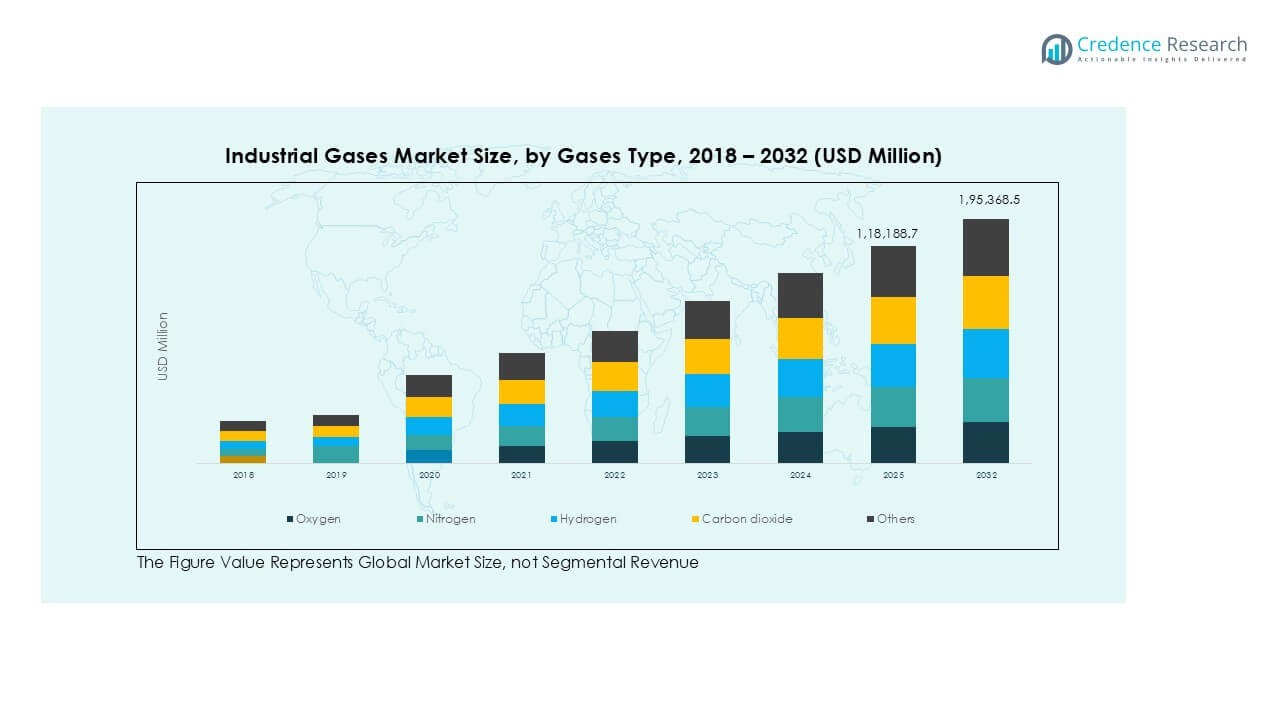

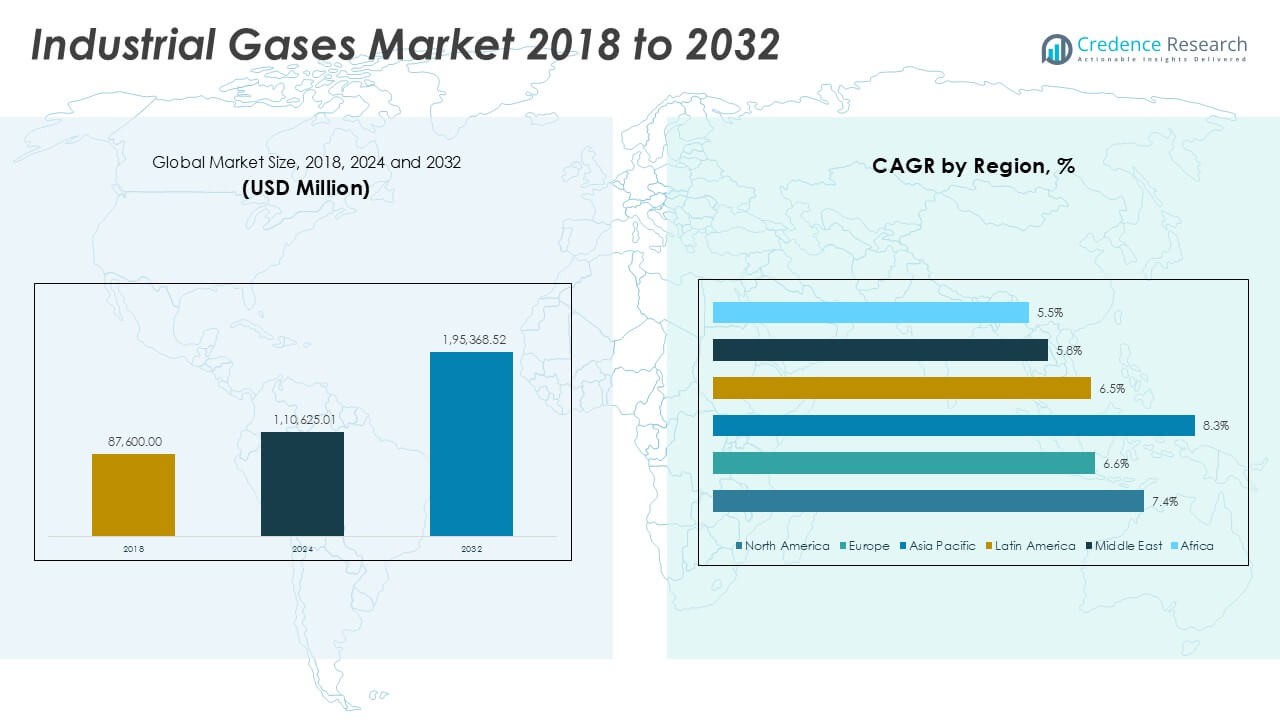

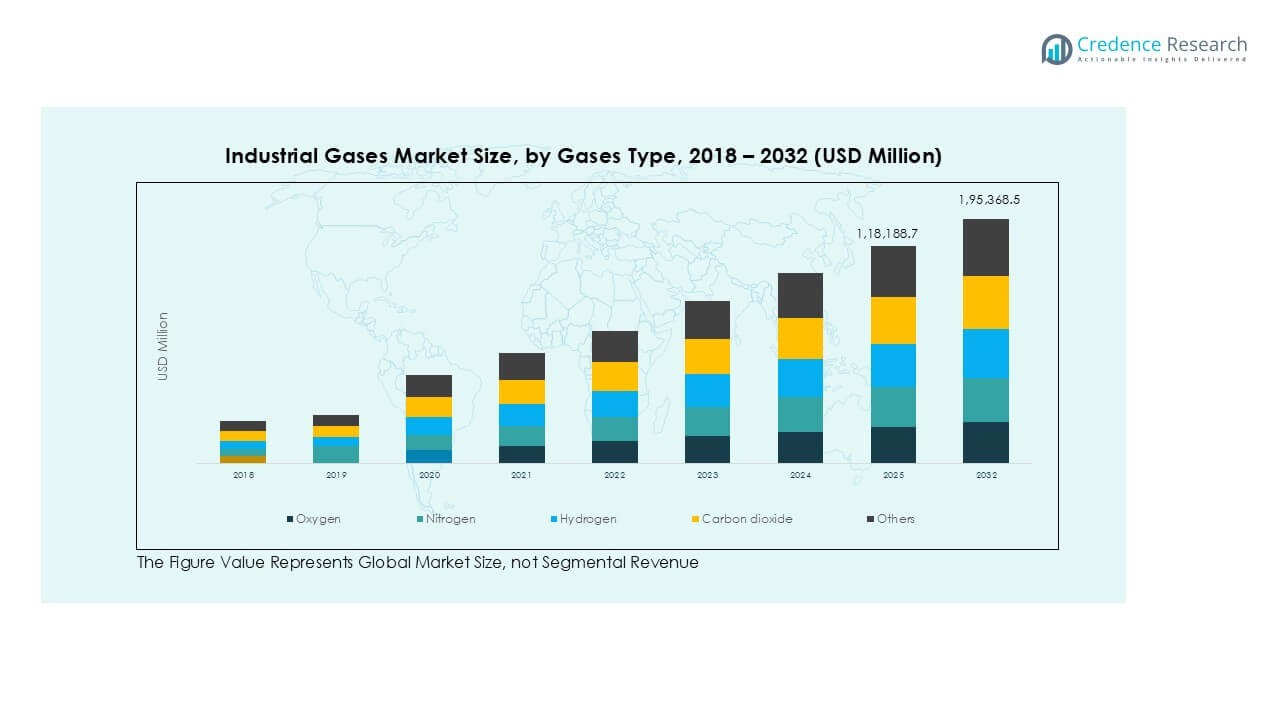

Global Industrial Gases market size was valued at USD 87.6 billion in 2018, increased to USD 110.62 billion in 2024, and is anticipated to reach USD 195.36 billion by 2032, at a CAGR of 7.44% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Industrial Gases Market Size 2024 |

USD 110.62 billion |

| Industrial Gases Market, CAGR |

7.44% |

| Industrial Gases Market Size 2032 |

USD 195.36 billion |

The global industrial gases market is led by Linde plc, Air Liquide S.A., Air Products and Chemicals Inc., Taiyo Nippon Sanso Corporation, and Messer Group GmbH, which collectively hold a major share through extensive production networks and long-term supply contracts. These players focus on expanding air separation units, hydrogen production facilities, and cryogenic storage infrastructure to meet growing industrial demand. Asia-Pacific leads the market with a 36% share, driven by rapid industrialization in China, India, and Japan, followed by North America at 28% with strong demand from manufacturing, healthcare, and clean energy sectors. Europe contributes 26%, supported by advanced manufacturing and green hydrogen projects. Regional players such as INOX Air Products and Gulf Cryo strengthen localized supply and distribution, ensuring consistent availability for industries like metallurgy, chemicals, and food processing, reinforcing the competitive and geographically diverse nature of the market.

Market Insights

- The global industrial gases market was valued at USD 110.62 billion in 2024 and is projected to reach USD 195.36 billion by 2032, growing at a CAGR of 7.44% during the forecast period.

- Growth is driven by rising demand for oxygen and nitrogen in steelmaking, chemical processing, and healthcare, along with increasing hydrogen adoption for clean energy projects worldwide.

- Key trends include rapid deployment of on-site gas generation units, cryogenic air separation plants, and green hydrogen projects supported by government incentives and net-zero commitments.

- The market is dominated by Linde plc, Air Liquide, Air Products and Chemicals Inc., Taiyo Nippon Sanso, and Messer Group, with regional players like INOX Air Products and Gulf Cryo strengthening local supply networks.

- Asia-Pacific holds 36% share, leading the market, followed by North America with 28% and Europe with 26%; oxygen accounts for the largest share by gas type.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segmentation Analysis:

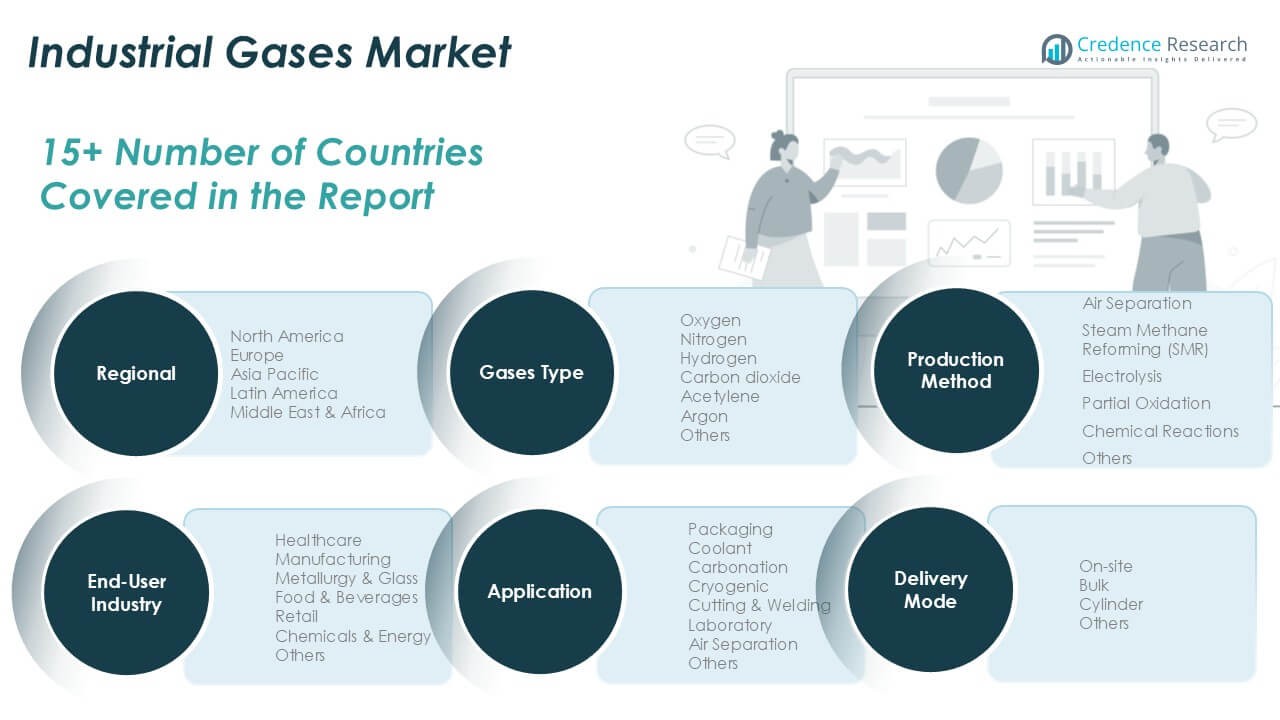

By Gases Type

Oxygen holds the dominant share of over 32% in the global industrial gases market in 2024, driven by its extensive use in steelmaking, healthcare, and chemical processing. Its demand is rising with growing medical oxygen requirements, particularly in hospitals and home healthcare. Nitrogen follows closely due to its role in inerting, blanketing, and food packaging applications. Hydrogen is gaining traction as a clean energy vector for fuel cells and green ammonia production. Carbon dioxide and argon see steady demand for carbonation, welding, and electronics manufacturing, while acetylene remains key for cutting and welding processes in heavy industries.

- For instance, in 2024, Linde India commissioned a new air separation unit in Ludhiana, Punjab, with a capacity of 250 tonnes per day.

By Application

Cutting & welding dominates the market with over 28% share in 2024, supported by rapid growth in construction, shipbuilding, and automotive fabrication. Oxygen-acetylene and argon-based shielding gases are widely used to enhance weld quality and productivity. Packaging applications are expanding, especially nitrogen flushing for food preservation and CO₂ use in carbonated beverages. Cryogenic applications are also increasing, with rising adoption of LNG and cold storage facilities. Laboratory and air separation applications contribute steadily, as research institutes and industrial plants invest in pure gas supply for experiments, quality control, and process optimization.

- For instance, in 2024, Nippon Gases was a supplier of argon to major European automotive plants for robotic welding operations. Argon is a key component in welding processes in the automotive industry, and Nippon Gases is a major industrial gas supplier in Europe.

By End-User Industry

Manufacturing accounts for the largest share at over 30% in 2024, driven by rising demand from metal fabrication, electronics, and chemical plants. Oxygen and nitrogen are widely used for combustion, inerting, and process efficiency improvement. The healthcare sector shows strong growth due to continuous demand for medical oxygen, especially in surgical and respiratory care. Food & beverages rely on industrial gases for carbonation, chilling, and packaging, ensuring product freshness and extended shelf life. Chemicals & energy applications are increasing with hydrogen use for refining and cleaner fuels. Metallurgy & glass industries remain steady consumers of oxygen and argon.

Key Growth Drivers

Expanding Manufacturing and Metal Fabrication

Rising global manufacturing output and infrastructure development are key drivers for industrial gases. Oxygen and acetylene demand is growing as welding and cutting activities surge across automotive, shipbuilding, and construction sectors. Rapid industrialization in Asia-Pacific further fuels consumption of nitrogen for inerting and process safety. Continuous investment in heavy industries and steel production strengthens gas consumption, making manufacturing the single largest consumer segment and ensuring sustained market expansion through 2032.

- For instance, Air Liquide commissioned a new Large Modular Air separation (LMA) unit with a 2,500 tonnes per day oxygen capacity.

Healthcare Sector Growth and Medical Oxygen Demand

The growing focus on public health and advanced medical infrastructure boosts the need for high-purity gases. Medical oxygen usage is increasing in hospitals, ambulatory centers, and homecare settings. The surge in respiratory disorders and critical care demand post-pandemic has accelerated investments in oxygen production and storage facilities. This is supported by government initiatives for emergency preparedness and reliable supply chains. Rising demand for nitrogen in cryopreservation and CO₂ for minimally invasive surgeries further strengthens healthcare-driven growth.

- For instance, Nippon Gases, a long-established supplier of medical gases in Europe, continued to provide oxygen and other essential medical supplies to hospitals in 2024 as part of its ongoing services.

Hydrogen Economy and Clean Energy Transition

Global decarbonization efforts and the push for cleaner fuels are creating strong opportunities for hydrogen. Governments and energy companies are investing in large-scale electrolysis plants and green hydrogen projects. Industrial gases suppliers benefit from the rising adoption of hydrogen in refining, ammonia production, and fuel cells for mobility applications. Supportive policies such as tax incentives and net-zero commitments encourage capacity expansions. This positions hydrogen as a critical driver of long-term growth for industrial gases providers worldwide.

Key Trends & Opportunities

Adoption of Cryogenic and On-Site Gas Generation

Industries are shifting toward on-site gas generation and cryogenic technologies to reduce logistics costs. Cryogenic air separation units are increasingly deployed near steel plants, refineries, and electronics manufacturing facilities to ensure continuous gas supply. This trend enhances operational efficiency and reduces dependence on bulk deliveries. Gas companies are also offering build-own-operate (BOO) models, creating recurring revenue streams and strengthening long-term customer relationships.

- For instance, Linde commissioned a 2,550 tonnes per day cryogenic Air Separation Unit (ASU) in Jamshedpur, India, to supply Tata Steel’s steel mill, not Vedanta’s smelter in Jharsuguda.

Growing Role of Digitalization and Automation

Digital tools, including IoT-enabled monitoring and predictive maintenance, are improving gas plant reliability and uptime. Real-time data analytics help optimize gas flow, reduce energy consumption, and maintain purity levels. This trend is accelerating as industries embrace Industry 4.0 principles, pushing gas suppliers to invest in smart distribution networks and automated filling stations. These advancements open opportunities for efficiency-driven differentiation.

- For instance, Air Liquide deployed its Avensis digital platform across 80 production sites, achieving 5% energy savings and monitoring over 1,000 process variables in real time.

Key Challenges

High Production and Distribution Costs

Industrial gases production is energy-intensive, especially cryogenic separation of air components. Rising energy prices directly impact production costs, reducing profit margins for suppliers. Distribution expenses also increase due to the need for specialized transport infrastructure, such as cryogenic tankers and pipelines. These cost pressures make it challenging for producers to maintain competitive pricing while sustaining capacity expansions.

Stringent Safety and Environmental Regulations

Compliance with safety standards and emission regulations poses challenges for gas producers. Storage and transport of gases like hydrogen and acetylene require robust safety measures to prevent accidents. Environmental rules aimed at reducing greenhouse gas emissions add additional compliance costs. Failure to meet regulatory requirements can result in fines, plant shutdowns, or reputational damage, making regulatory adherence a critical operational hurdle.

Regional Analysis

North America

North America holds a 28% share of the global industrial gases market in 2024, supported by strong demand from manufacturing, healthcare, and energy sectors. The U.S. leads regional consumption, driven by steel production, food packaging, and medical oxygen supply chains. Rising adoption of hydrogen for clean fuel initiatives, supported by federal funding under the Inflation Reduction Act, further boosts growth. Canada contributes with demand from oil sands processing and cryogenic applications in LNG. Investments in on-site air separation units and enhanced logistics infrastructure strengthen supply reliability, keeping North America a key revenue-generating region for global gas suppliers.

Europe

Europe accounts for nearly 26% share of the market, driven by advanced manufacturing, chemical processing, and healthcare infrastructure. Germany, France, and the U.K. lead demand due to strong automotive, metallurgy, and pharmaceutical sectors. The European Union’s decarbonization targets are accelerating hydrogen adoption, with several green hydrogen hubs being developed across Germany and the Netherlands. Cryogenic and specialty gas applications are expanding in electronics manufacturing and R&D. Stringent environmental regulations and circular economy initiatives encourage energy-efficient gas production. This ensures Europe remains a mature but innovation-driven market with steady growth opportunities for industrial gas producers.

Asia-Pacific

Asia-Pacific dominates with a 36% market share, making it the fastest-growing region. China, India, and Japan lead demand, supported by rapid industrialization, urbanization, and expanding manufacturing bases. The region witnesses strong consumption of oxygen and nitrogen in steelmaking, electronics, and chemicals production. Government investments in LNG terminals, semiconductor fabs, and green hydrogen projects further boost demand. Food and beverage packaging and healthcare applications add to growth momentum. Presence of large-scale air separation units and cost-effective production facilities makes Asia-Pacific the most attractive region for capacity expansions and strategic partnerships among global and regional gas players.

Latin America

Latin America holds around 6% share of the global industrial gases market, driven by growth in metallurgy, oil & gas, and food processing industries. Brazil and Mexico lead demand, supported by expansion in automotive and steel manufacturing. Oxygen and acetylene consumption remains strong for welding and cutting applications, while nitrogen finds use in fertilizer production and oil refining. Regional players focus on expanding cryogenic storage and distribution infrastructure to improve supply reliability. Rising healthcare investment and adoption of packaged gases for medical use present additional opportunities, making Latin America a growing but developing market segment.

Middle East & Africa

Middle East & Africa capture nearly 4% market share, supported by robust demand from petrochemicals, refining, and power generation sectors. The Gulf countries, particularly Saudi Arabia and UAE, are investing heavily in green hydrogen and ammonia projects, which is expected to drive hydrogen demand over the next decade. Industrial gases are also crucial for desalination plants and enhanced oil recovery operations. South Africa contributes with demand from mining and metallurgy. Ongoing infrastructure projects, coupled with the push toward energy diversification, create opportunities for gas producers to expand supply capabilities across this emerging regional market.

Market Segmentations:

By Gases Type

- Oxygen

- Nitrogen

- Hydrogen

- Carbon Dioxide

- Acetylene

- Argon

- Others

By Application

- Packaging

- Coolant

- Carbonation

- Cryogenic

- Cutting & Welding

- Laboratory

- Air Separation

- Others

By End-User Industry

- Healthcare

- Manufacturing

- Metallurgy & Glass

- Food & Beverages

- Retail

- Chemicals & Energy

- Others

By Production Method

- Air Separation

- Steam Methane Reforming (SMR)

- Electrolysis

- Partial Oxidation

- Chemical Reactions

- Others

By Delivery Mode

- On-site

- Bulk

- Cylinder

- Others

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East

- Africa

Competitive Landscape

The global industrial gases market is highly consolidated, with leading players such as Linde plc, Air Liquide S.A., Air Products and Chemicals Inc., Taiyo Nippon Sanso Corporation, and Messer Group GmbH dominating global supply. These companies focus on large-scale air separation units, pipeline networks, and long-term supply contracts to serve major industries, including steel, chemicals, and energy. Strategic partnerships and joint ventures are common, enabling players to expand into emerging markets and secure hydrogen, carbon capture, and cryogenic technology projects. Regional players like INOX Air Products, Gulf Cryo, and SIAD S.p.A. strengthen localized distribution and meet country-specific demand. Investments in digital monitoring, automated gas generation, and sustainability initiatives enhance competitiveness. Mergers and acquisitions remain a key strategy to consolidate market share and optimize production capacity, while innovation in green hydrogen and low-carbon solutions positions key players for long-term growth under global decarbonization targets.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Linde plc (Ireland)

- Air Liquide S.A. (France)

- Air Products and Chemicals, Inc. (United States)

- Taiyo Nippon Sanso Corporation (Japan)

- Messer Group GmbH (Germany)

- Iwatani Corporation (Japan)

- SOL Group (Italy)

- SIAD S.p.A. (Italy)

- Gulf Cryo (Kuwait)

- nexAir, LLC (United States)

- Goyal MG Gases Pvt. Ltd. (India)

- Universal Industrial Gases, Inc. (United States)

- INOX Air Products Ltd. (India)

- National Industrial Gas Plants (NIGP) (Saudi Arabia)

- Bhagawati Oxygen Ltd. (India)

- Cryogenic Industrial Solutions, LLC (United States)

- Ellenbarrie Industrial Gases Ltd. (India)

- Yateem Oxygen (Bahrain)

- Axcel Gases (India)

Recent Developments

- In October 2024, Air Liquide announced to supply oxygen to LG Chem for their electric vehicle battery plant in the U.S. Supplying oxygen to LG Chem’s future cathode active material plant, the Group will be supporting the growth of the battery ecosystem in the U.S. This investment will increase the Group’s footprint in a key region and support the development of its industrial merchant market.

- In October 2024, Linde announced an agreement with Tata Steel to obtain and manage two additional Air Separation Units (ASUs) and enhance industrial gas supply to Tata Steel in Odisha, India. This arrangement will more than double Linde’s on-site capacity at Tata Steel’s Kalinganagar facility, where it presently runs two plants. The new ASUs, anticipated to be operational by 2025, will deliver oxygen, nitrogen, and argon to aid Tata Steel’s expansion project and cater to the local merchant market. Linde has additionally acquired renewable energy agreements to lower its scope emissions, in line with its 2035 GHG reduction goals.

- In July 2024, Air Liquide announced an investment of USD 104.914 million to support Aurubis AG, a major global provider of non-ferrous metals and one of the largest recyclers of copper worldwide, in Bulgaria and Germany. This investment will finance a new Air Separation Unit (ASU) in Bulgaria and the upgrading of four existing units in Germany. Besides supplying substantial amounts of oxygen and nitrogen for the rising copper and other metal production by Aurubis, these facilities will also assist in the growth of industrial merchant markets in both areas.

- In January 2024, Air Products, a company in industrial gases and clean hydrogen projects, announced the opening of its expanded Project Delivery Centre in Vadodara, India.

- In July 2023, Nippon Sanso Holdings Corporation announced that Matheson Tri-Gas, Inc, NSHD’s U. S. operating entity, has entered into a gas supply contract with PointFive to deliver oxygen for the carbon capture, utilization, and sequestration company’s inaugural Direct Air Capture (DAC*) facility in Texas. MATHESON will invest in and set up an Air Separation Unit to provide oxygen to “Stratos,” PointFive’s DAC facility currently under construction in Ector County, Texas. The oxygen is utilized in the DAC process to generate a pure stream of CO2, which is subsequently securely sequestered in geological reservoirs.

Report Coverage

The research report offers an in-depth analysis based on Gases Type, Application, End-User Industry, Production Method, Delivery Mode and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand for medical oxygen will continue to rise with expanding healthcare infrastructure worldwide.

- Hydrogen will gain strong traction as a clean energy fuel, supported by government decarbonization policies.

- On-site gas generation units will see higher adoption to reduce logistics costs and ensure supply reliability.

- Digital monitoring and IoT-enabled distribution networks will improve operational efficiency and reduce downtime.

- Investments in green hydrogen and carbon capture projects will strengthen sustainability initiatives.

- Asia-Pacific will remain the fastest-growing region, driven by industrial expansion in China and India.

- Advanced cryogenic technology will play a bigger role in LNG, electronics, and food applications.

- Strategic partnerships and acquisitions will help global players expand geographic reach and capacity.

- Specialty gases demand will grow with semiconductor and electronics manufacturing investments.

- Regulatory focus on safety and emissions will encourage innovation in low-carbon production methods.