Market Overview:

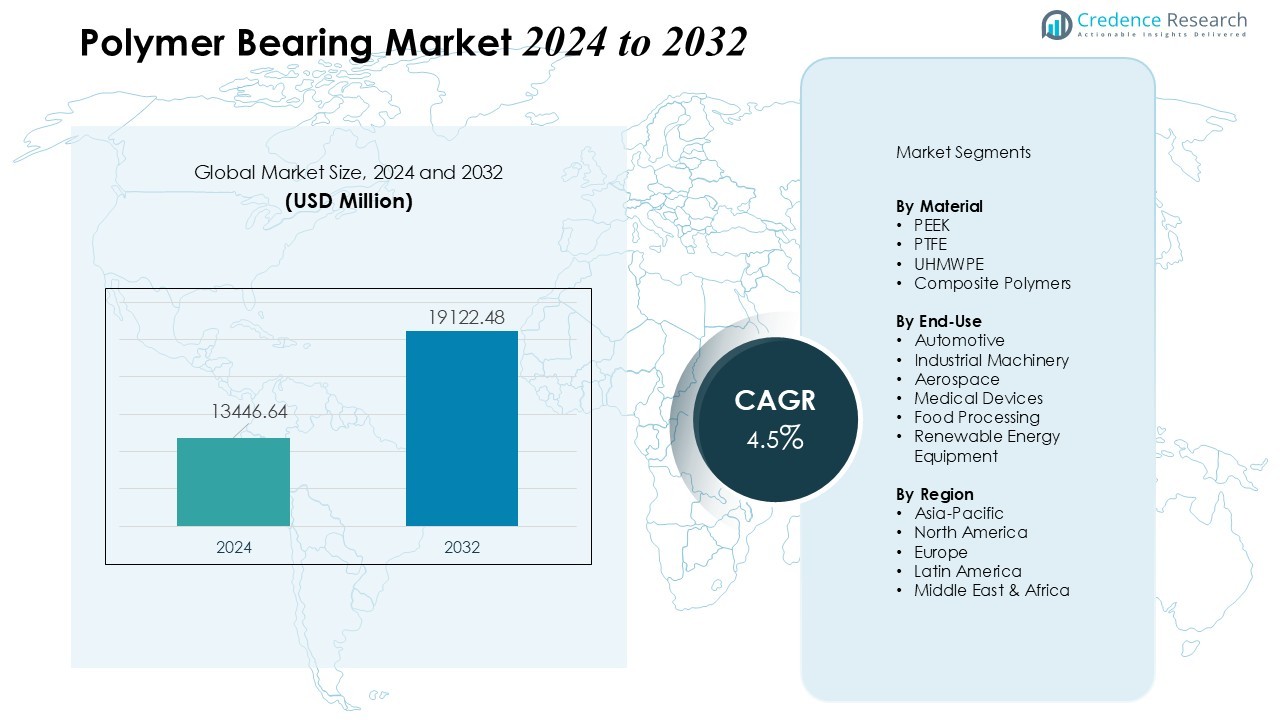

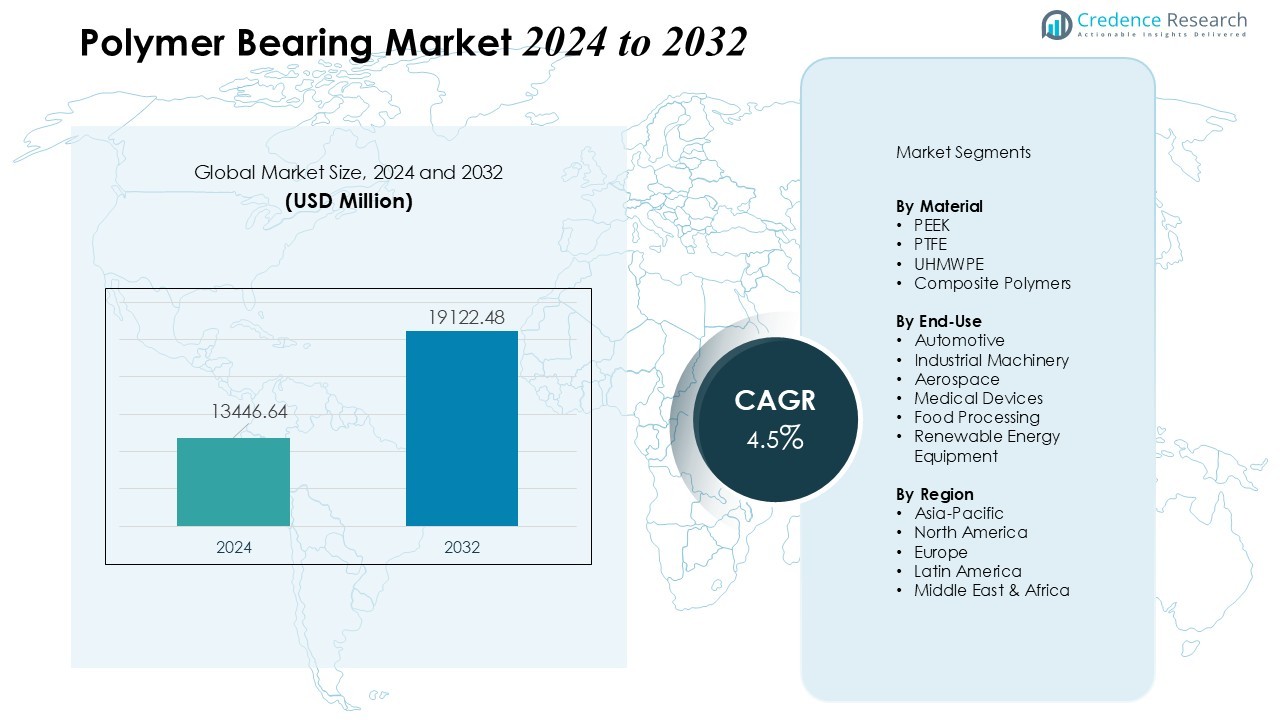

The Polymer Bearing Market size was valued at USD 13446.64 million in 2024 and is anticipated to reach USD 19122.48 million by 2032, at a CAGR of 4.5% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Polymer Bearing Market Size 2024 |

USD 13446.64 Million |

| Polymer Bearing Market, CAGR |

4.5% |

| Polymer Bearing Market Size 2032 |

USD 19122.48 Million |

Key drivers include the strong demand from automotive, industrial machinery, medical devices, and food processing sectors. Industries prefer polymer bearings due to their low friction, chemical resistance, and self-lubricating capabilities. Energy-efficient machinery and the push for maintenance-free components further support its penetration. Expanding automation, the rise of electric vehicles, and increased equipment modernization also widen application scope. It continues to benefit from technological advancements in high-performance plastics such as PEEK, PTFE, and UHMWPE.

Regionally, Asia-Pacific holds a significant share of the Polymer Bearing Market, driven by robust industrial production, growing automotive manufacturing, and increasing investment in machinery. North America and Europe maintain strong demand due to advanced engineering standards and early adoption of polymer components. Emerging markets in Latin America and the Middle East improve their presence with expanding manufacturing bases and infrastructure development. The global landscape remains competitive, supported by continuous material innovation and strategic industry collaborations.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Polymer Bearing Market was valued at USD 13,446.64 million in 2024 and is expected to reach USD 19,122.48 million by 2032, growing at a CAGR of 4.5%.

- Strong demand from automotive, industrial machinery, medical devices, and food processing sectors drives market growth due to low friction, chemical resistance, and self-lubricating capabilities.

- Energy-efficient machinery, maintenance-free components, expanding automation, and rising electric vehicle adoption further widen the market application scope.

- Asia-Pacific leads with 42% market share due to industrial production, automotive manufacturing, and machinery investment, while North America and Europe maintain strong demand, and Latin America and the Middle East show emerging growth potential.

- Technological advancements in high-performance polymers such as PEEK, PTFE, and UHMWPE support diverse industrial applications, including aerospace, renewable energy, and medical devices, enhancing operational efficiency and reliability.

Market Drivers:

Market Drivers:

Rising Demand for Lightweight and Durable Components in Automotive and Industrial Applications

The Polymer Bearing Market benefits from the increasing need for lightweight and durable components in automotive and industrial machinery. Manufacturers focus on reducing overall equipment weight while enhancing performance, making polymer bearings a preferred choice over traditional metal bearings. It offers high strength-to-weight ratio, corrosion resistance, and long service life, which improves operational efficiency. The trend towards electric vehicles further fuels adoption due to the requirement for low-friction, energy-efficient components. Industries investing in automation also favor polymer bearings for their reliability under continuous operation.

- For instance, IGUS developed iglide polymer bearings that operate without lubrication for over 10 million cycles in industrial automation setups.

Shift Towards Maintenance-Free and Self-Lubricating Solutions

Industries increasingly demand maintenance-free components to reduce operational downtime and maintenance costs. Polymer bearings provide self-lubricating properties, eliminating the need for external lubrication and minimizing wear. It ensures consistent performance in harsh environments, including chemical exposure, high humidity, and extreme temperatures. The ability to perform under challenging conditions enhances equipment lifespan and reduces replacement frequency. Growing focus on operational efficiency drives industries to replace conventional bearings with polymer alternatives.

- For Instance, RBC Bearings’ Fiberglide liners in self-lubricating bearings extend machinery lifespan and provide maintenance-free operation in industrial applications through integrated solid lubricants.

Expansion of Machinery and Equipment Manufacturing Across Emerging Economies

The Polymer Bearing Market experiences growth due to the expansion of machinery and equipment manufacturing in emerging regions. Countries in Asia-Pacific and Latin America are investing heavily in industrial infrastructure, boosting demand for high-performance components. It provides manufacturers with opportunities to meet rising local production requirements in automotive, construction, and processing industries. Increasing industrialization and mechanization create sustained demand for polymer bearings in new machinery setups. Emerging economies also attract foreign investment, supporting advanced component integration.

Technological Advancements in High-Performance Polymer Materials

Continuous innovation in polymer materials supports the growth of the market. New polymers such as PEEK, PTFE, and UHMWPE deliver enhanced load-bearing capacity, chemical resistance, and thermal stability. It allows manufacturers to produce bearings suitable for high-stress and high-speed applications. Advancements in material science expand application areas, including medical devices, aerospace, and renewable energy equipment. This drives adoption by offering performance improvements over conventional materials while maintaining cost efficiency.

Market Trends:

Growing Adoption of Polymer Bearings in Electric Vehicles and Renewable Energy Sectors

The Polymer Bearing Market demonstrates a strong trend toward adoption in electric vehicles (EVs) and renewable energy equipment. Manufacturers prefer polymer bearings for EVs due to their low friction, lightweight properties, and resistance to wear, which enhance energy efficiency and extend battery life. It finds increasing application in wind turbines, solar tracking systems, and other renewable energy machinery, where durability under variable loads and harsh environments is critical. Automotive and energy sectors prioritize components that reduce maintenance requirements and improve operational reliability. The demand for high-performance polymers such as PEEK and PTFE in these applications continues to rise. This trend encourages manufacturers to develop customized solutions that meet sector-specific requirements. The shift toward sustainable technologies further supports the integration of polymer-based components.

- For instance, SKF’s energy efficient deep groove ball bearings with polymer cages achieve over 30% reduction in power loss compared to standard bearings at speeds up to 16,000 r/min.

Integration of Advanced Materials and Customization in Industrial Applications

Industrial applications show a trend toward customized and advanced polymer bearing solutions. It incorporates high-performance polymers that withstand extreme temperatures, chemical exposure, and heavy loads. Industries such as aerospace, food processing, and medical devices increasingly require bearings tailored for specific operational conditions. The use of composite materials and reinforced polymers enhances strength, longevity, and reliability. Manufacturers also invest in precision engineering to optimize bearing performance for automated machinery and robotics. Adoption of simulation and testing technologies supports development of polymer bearings with improved tolerance and performance. This trend positions the market for continuous growth through material innovation and application-specific solutions.

- For instance, GGB Bearing Technology’s HI-EX metal-polymer composite bearings operate at up to 250°C with chemical resistance in steel production, achieving a maximum static load capacity of 140 MPa (150 MPa is a common application-specific estimate, but the official maximum static rating is 140 MPa).

Market Challenges Analysis:

High Material Costs and Limited Load-Bearing Capacity in Certain Applications

The Polymer Bearing Market faces challenges due to the high cost of advanced polymer materials. Polymers such as PEEK and UHMWPE provide excellent performance but require significant investment in raw materials and processing. It may limit adoption in cost-sensitive sectors where traditional metal bearings remain economically viable. Certain high-load or high-speed applications still demand metal alternatives due to the comparatively lower strength of some polymers. Manufacturers must balance performance benefits with cost efficiency to maintain competitiveness. The need for specialized manufacturing equipment further increases production expenses. This challenge slows widespread adoption in industries with tight budget constraints.

Performance Limitations under Extreme Environmental Conditions

Polymer bearings can encounter performance limitations under extreme temperatures, heavy loads, or prolonged chemical exposure. It may deform or degrade under conditions beyond its design specifications, affecting operational reliability. Industries such as aerospace, mining, and heavy machinery require careful evaluation before replacing metal bearings with polymer alternatives. The necessity for precise design and material selection adds complexity to the production process. Limited awareness of these performance constraints among end-users can result in premature failures. Manufacturers invest in research to develop high-performance polymers capable of meeting stringent operational demands. Continuous material innovation remains crucial to overcoming these environmental and mechanical challenges.

Market Opportunities:

Expansion in Electric Vehicle and Renewable Energy Equipment Applications

The Polymer Bearing Market presents significant opportunities in electric vehicle (EV) and renewable energy equipment sectors. Manufacturers increasingly adopt polymer bearings for EVs due to their low friction, lightweight properties, and maintenance-free operation. It enables longer battery life and higher energy efficiency, meeting industry demands for sustainable transportation solutions. In renewable energy, polymer bearings support wind turbines, solar trackers, and hydroelectric systems by offering durability under fluctuating loads and harsh environmental conditions. Growing global investment in green energy infrastructure further drives market potential. The rising trend of electrification in transportation and industrial machinery expands avenues for polymer bearing integration.

Technological Advancements and Customization for Industrial Applications

Industrial applications provide opportunities through advanced material development and customized solutions. It leverages high-performance polymers such as PEEK, PTFE, and UHMWPE to meet specific operational requirements in aerospace, medical devices, and food processing equipment. Manufacturers can design bearings to withstand extreme temperatures, chemical exposure, and high-speed operations. Integration with automated machinery and robotics opens further growth prospects. Adoption of simulation, precision engineering, and composite materials enhances bearing performance and reliability. Continuous innovation in polymer technology positions the market to capture emerging industrial applications worldwide.

Market Segmentation Analysis:

By Material

The Polymer Bearing Market includes high-performance polymers such as PEEK, PTFE, UHMWPE, and composite materials. PEEK bearings lead due to superior mechanical strength, chemical resistance, and high-temperature tolerance. PTFE bearings are favored in applications requiring low friction and excellent wear resistance. UHMWPE bearings perform effectively under heavy loads and abrasive conditions. Composite polymer bearings gain adoption for customized solutions in specialized industrial machinery and medical devices. The choice of material influences durability, operational efficiency, and maintenance needs, driving market demand across sectors.

- For instance, Spark Fittings’ high-performance PTFE bearings deliver friction coefficients lower than traditional materials by a factor of 5-10 times, supporting high-speed operations with minimal wear.

By End-Use

The market serves automotive, industrial machinery, aerospace, medical devices, food processing, and renewable energy equipment. Automotive applications dominate due to the demand for lightweight, energy-efficient components in vehicles and electric mobility solutions. Industrial machinery and aerospace sectors adopt polymer bearings to enhance reliability, reduce maintenance, and extend service life. Medical and food processing industries prefer polymer bearings for corrosion resistance and compliance with hygiene standards. Renewable energy equipment, including wind turbines and solar trackers, increasingly utilizes polymer bearings for durability under fluctuating loads and harsh environmental conditions. It demonstrates the versatility of polymer bearings in meeting diverse operational and environmental requirements across industries.

- For instance, igus iglide bearings in RWenergy solar trackers resist dirt and sharp edges effectively. They maintain performance across a temperature range of –40°F to +266°F.

Segmentations:

By Material

- PEEK

- PTFE

- UHMWPE

- Composite Polymers

By End-Use

- Automotive

- Industrial Machinery

- Aerospace

- Medical Devices

- Food Processing

- Renewable Energy Equipment

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Strong Market Presence in Asia-Pacific Driven by Industrial Growth and Automotive Expansion

Asia-Pacific accounts for 42% of the global Polymer Bearing Market, reflecting robust adoption across industrial and automotive sectors. Rapid industrialization, growing automotive manufacturing, and expansion of machinery production drive demand. It benefits from high investments in infrastructure, energy, and manufacturing sectors, which require durable and low-maintenance bearing solutions. Countries like China, Japan, and India lead in polymer bearing consumption due to their industrial base and increasing focus on automation. Rising demand for electric vehicles and renewable energy equipment further supports growth. The region continues to attract global manufacturers seeking cost-efficient production and market access.

Steady Growth in North America Supported by Advanced Engineering and Technological Innovation

North America holds 28% of the global Polymer Bearing Market, driven by high adoption in aerospace, automotive, and medical equipment. It finds strong demand due to technological advancements and stringent engineering standards requiring high-performance polymer components. Manufacturers in the United States and Canada invest in research and development to improve bearing materials, durability, and operational efficiency. Demand for energy-efficient machinery and automation solutions fuels growth. Regulatory standards emphasizing performance and safety enhance opportunities. North America remains a competitive hub for innovation and material development.

Emerging Opportunities in Europe and Other Regional Markets

Europe contributes 18% to the global Polymer Bearing Market, driven by industrial modernization, renewable energy projects, and automotive innovation. It supports advanced applications in machinery, robotics, and transportation sectors. Manufacturers leverage high-performance polymers to meet operational requirements and sustainability goals. Other regions, including Latin America and the Middle East, represent 12% of the market and show emerging potential due to infrastructure development and industrial expansion. It offers opportunities for global suppliers to introduce high-quality polymer bearings to new markets. Increasing investments and technological adoption in these regions position the market for steady long-term growth.

Key Player Analysis:

- BNL Ltd.

- Boston Gear LLC

- Dotmar Engineering Plastic Products

- Igus Inc.

- Kashima Bearings, Inc.

- SKF Group

- Saint-Gobain S.A.

- Oiles Corporation

- NTN Corporation

- GGB Bearing Technology

- KMS Bearings, Inc.

- Waukesha Bearings

Competitive Analysis:

The Polymer Bearing Market exhibits a highly competitive landscape with several global and regional players focusing on innovation, product quality, and strategic partnerships. Leading companies such as SKF Group, Igus Inc., Saint-Gobain S.A., and Kashima Bearings, Inc. maintain strong market positions through continuous research and development of high-performance polymer solutions. It faces competition from both established manufacturers and emerging regional players offering cost-effective alternatives. Companies emphasize expanding product portfolios, improving material performance, and entering new geographic markets to enhance their presence. Strategic collaborations, mergers, and acquisitions support growth and technology advancement. The focus on customization for specific industrial applications, including automotive, aerospace, and renewable energy sectors, drives competitive differentiation. Continuous innovation in polymer materials and bearing design allows companies to meet evolving customer requirements and maintain a sustainable advantage in the market.

Recent Developments:

- In October 2023, Boston Gear launched the second generation SS700 Series Stainless Steel Worm Gear Speed Reducers.

- In February 2025, Igus Inc. acquired elko Verbindungstechnik GmbH, a cable assembly and harnessing specialist, to expand production capacities in drive technology and shorten delivery times for customers in southern Germany.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage:

The research report offers an in-depth analysis based on Material, End-Use and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and ITALY economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Polymer Bearing Market will continue expanding due to increasing adoption in automotive, aerospace, and industrial machinery sectors.

- Demand for lightweight, corrosion-resistant, and low-maintenance components will drive market growth globally.

- Electric vehicles and renewable energy equipment will emerge as key growth segments for polymer bearing applications.

- Technological advancements in high-performance polymers like PEEK, PTFE, and UHMWPE will enhance bearing durability and operational efficiency.

- Manufacturers will focus on customization to meet specific requirements of industries such as medical devices, robotics, and food processing.

- Automation and Industry 4.0 adoption will boost the need for precision-engineered polymer bearings in machinery and robotics.

- Emerging economies will present new opportunities due to industrial expansion, infrastructure development, and increased mechanization.

- Companies will increasingly invest in research and development to introduce innovative polymer bearing solutions for extreme environmental conditions.

- Strategic partnerships, mergers, and collaborations will strengthen market presence and support entry into new regional markets.

- Sustainability initiatives and energy efficiency goals will encourage industries to replace traditional metal bearings with environmentally friendly polymer alternatives.

Market Drivers:

Market Drivers: