Market Overview:

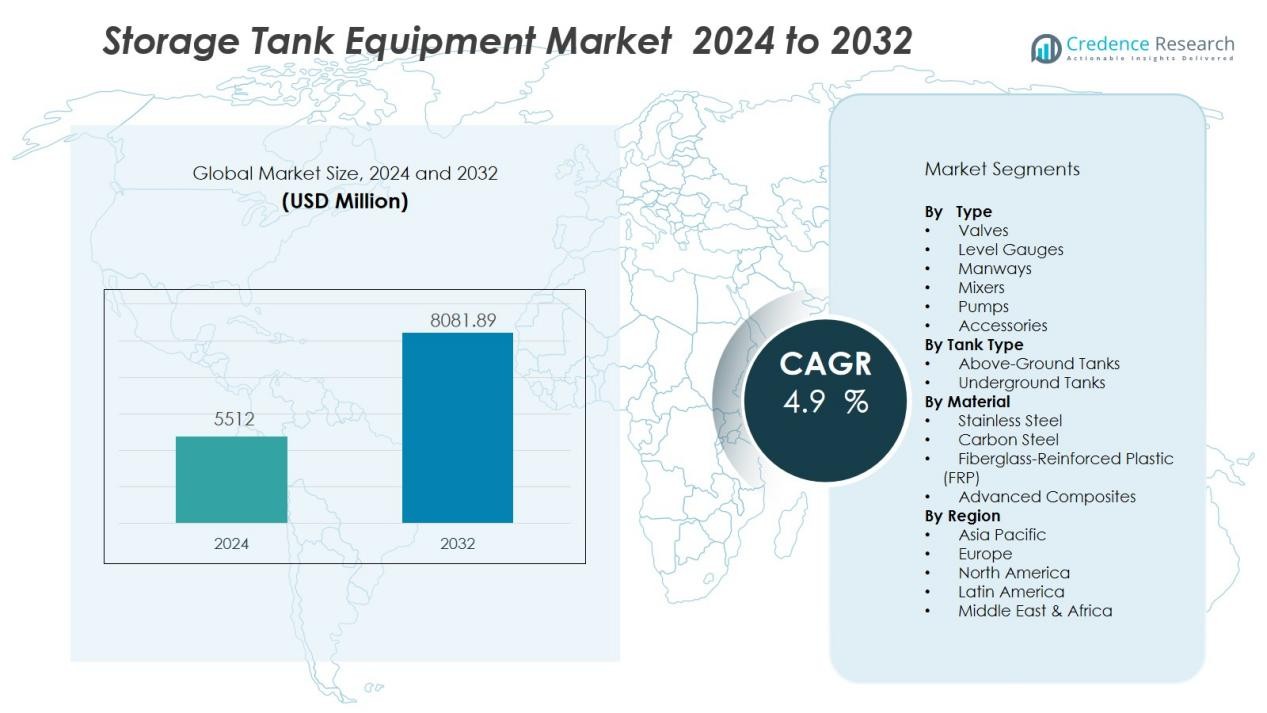

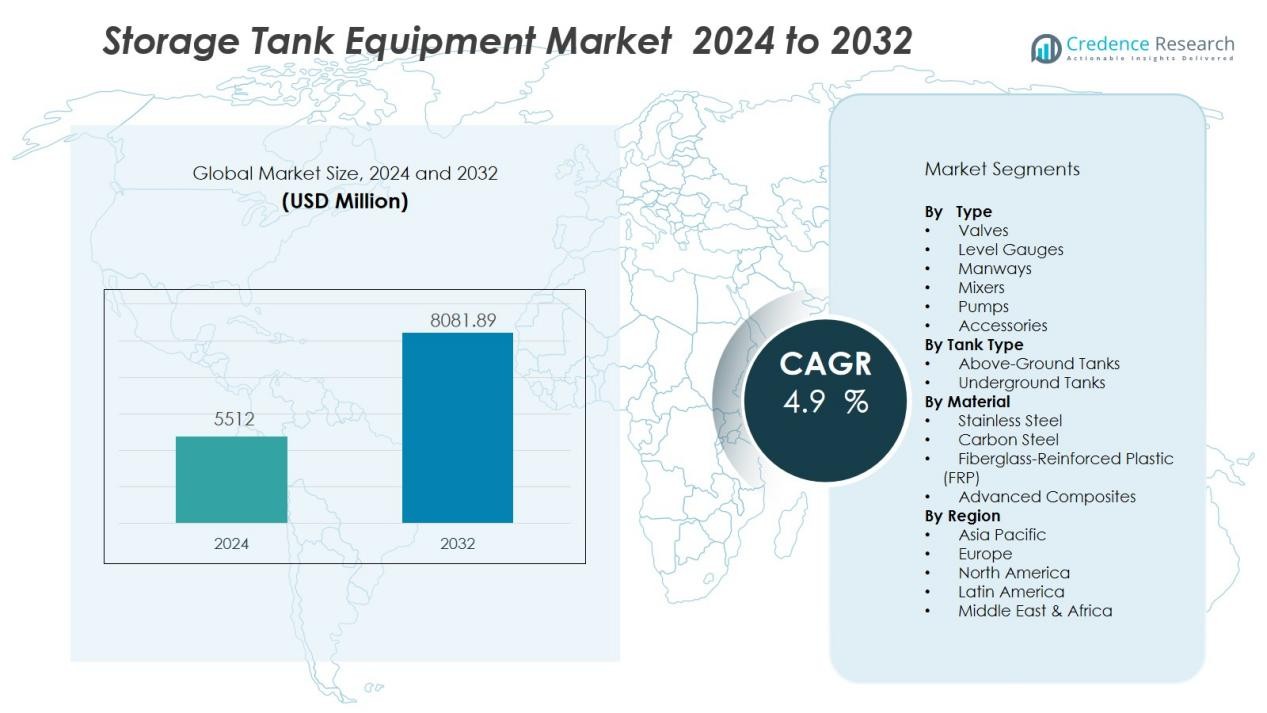

The Storage tank equipment market size was valued at USD 5512 million in 2024 and is anticipated to reach USD 8081.89 million by 2032, at a CAGR of 4.9 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Storage Tank Equipment Market Size 2024 |

USD 5512 Million |

| Storage Tank Equipment Market, CAGR |

4.9 % |

| Storage Tank Equipment Market Size 2032 |

USD 8081.89 Million |

Key drivers fueling the storage tank equipment market include stricter environmental regulations, growing focus on operational safety, and the adoption of advanced materials and technologies. Industries are investing in upgraded tank systems to comply with evolving standards, prevent leakage, and reduce operational risks. The shift towards automation and remote monitoring solutions is also enhancing market appeal, as companies seek to optimize asset management and improve overall operational efficiency.

Regionally, North America dominates the market due to significant infrastructure development, large-scale oil and gas projects, and early adoption of advanced equipment. Europe follows, supported by stringent environmental policies and modernization initiatives. The Asia-Pacific region is expected to register the fastest growth, driven by rapid industrialization, expanding manufacturing bases, and increasing investments in water and wastewater management across emerging economies such as China and India.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The storage tank equipment market was valued at USD 5,512 million in 2024 and is projected to reach USD 8,081.89 million by 2032, reflecting a CAGR of 4.9% during the forecast period.

- Stricter environmental regulations, operational safety requirements, and adoption of advanced materials are driving steady demand across multiple industries.

- Oil, gas, and chemical sectors remain the primary end-users, supported by expansion projects and upgrades to enhance capacity, safety, and reliability.

- Automation, digitalization, and remote monitoring solutions are increasingly integrated, enabling real-time data tracking and predictive maintenance for storage systems.

- North America holds a 34% share of the global market, with strong demand from oil, gas, and water infrastructure sectors, followed by Asia-Pacific at 29% and Europe at 22%.

- The market faces challenges from complex regulatory compliance, high capital investment requirements, and operational risks such as tank failure and supply chain disruptions.

- Rapid industrialization in Asia-Pacific, Middle East, and Latin America is fueling equipment demand for new infrastructure in water, energy, and manufacturing, supporting the market’s long-term growth outlook.

Market Drivers:

Rising Demand Across Oil, Gas, and Chemical Industries Fuels Market Expansion:

The storage tank equipment market is witnessing strong demand from the oil, gas, and chemical industries, which require large-scale storage solutions for liquids and gases. Rapid growth in global energy consumption and increasing petrochemical production drive continuous investments in new tank infrastructure. Companies focus on upgrading their storage assets to improve capacity, safety, and operational reliability. The market benefits from expansion projects in both developed and emerging regions, supporting steady equipment sales.

- For instance, Bechtel was awarded a contract to build four crude-oil storage tanks at the TengizChevroil oil production facility in Kazakhstan, adding 500,000 barrels of tank storage capacity, showcasing their technical excellence in delivering large-scale tank projects efficiently.

Stringent Environmental Regulations and Safety Standards Drive Upgrades:

Stringent regulations around emissions, leak prevention, and environmental protection push industries to invest in advanced storage tank equipment. Regulatory bodies enforce strict standards, prompting companies to upgrade aging tanks with double-walled designs, vapor recovery systems, and corrosion-resistant materials. This focus on compliance and risk mitigation elevates the need for technologically advanced tank solutions. The trend supports sustained market growth, especially in regions with rigorous regulatory frameworks.

- For instance, Sharp Tanks and Structurals P. Ltd. completed a project involving two full integrity double-walled storage tanks at Krishnapattanam Port, each with a capacity of 15,000 metric tons, meeting stringent safety and regulatory standards while enhancing operational efficiency.

Adoption of Digitalization, Automation, and Remote Monitoring Solutions:

Digital transformation is accelerating across storage operations, with companies integrating automation, smart sensors, and remote monitoring systems into tank infrastructure. The storage tank equipment market sees rising adoption of IoT-based devices for real-time data tracking and predictive maintenance. Automation enhances operational efficiency, reduces human error, and supports compliance with safety regulations. This transition to intelligent storage solutions creates new opportunities for equipment manufacturers and technology providers.

Rapid Industrialization and Infrastructure Development in Emerging Markets:

Emerging economies in Asia-Pacific, the Middle East, and Latin America are investing heavily in industrial infrastructure, including water treatment plants, manufacturing facilities, and energy storage projects. These investments fuel the demand for reliable and scalable storage tank equipment. Urbanization and increased focus on water management further accelerate market growth. The storage tank equipment market is well-positioned to benefit from ongoing infrastructure expansion in these high-growth regions.

Market Trends:

Integration of Smart Technologies and Automation in Storage Tank Systems:

The integration of smart technologies and automation stands out as a significant trend in the storage tank equipment market. Companies are adopting advanced sensors, IoT-enabled monitoring systems, and automated control mechanisms to enhance operational efficiency, improve safety, and enable predictive maintenance. These digital advancements allow real-time data collection and remote management of tank conditions, reducing the risk of leaks, overflows, and contamination. Smart technologies help operators comply with increasingly stringent safety and environmental regulations, while optimizing resource utilization. Equipment manufacturers are focusing on product innovation to meet customer demands for connected, user-friendly solutions. The shift toward digitalization is reshaping competitive dynamics and opening new avenues for value-added services in the market.

- For instance, Kawasaki Robotics supplied the ZT130S robot for spraying glass fiber reinforced plastic on double-walled cellar and underground storage tanks, automating a key manufacturing step and enhancing product consistency in storage tank production.

Growth of Sustainable Materials and Modular Designs for Flexible Applications:

Sustainability and adaptability are becoming central to new product developments in the storage tank equipment market. The adoption of eco-friendly, corrosion-resistant materials and coatings is growing, driven by environmental mandates and the need for longer equipment lifespans. Modular and customizable tank designs allow for easy installation, expansion, and integration into diverse industrial settings. This flexibility supports rapid project deployment and aligns with evolving infrastructure requirements in industries such as water treatment, food processing, and energy. Market participants are responding to customer preferences for low-maintenance, sustainable, and versatile equipment. These trends reinforce the market’s focus on lifecycle value and operational resilience, shaping future product development and procurement strategies.

- For Instances, CST Industries’ OptiBond™ Epoxy Coating System has been applied in bolted steel storage tanks in over 125 countries worldwide, known for extending tank life with its proprietary high-performance coating process.

Market Challenges Analysis:

Complex Regulatory Compliance and High Capital Investment Requirements:

Navigating complex regulatory compliance and meeting evolving industry standards present significant challenges for the storage tank equipment market. Companies must ensure adherence to strict environmental, safety, and quality regulations across various regions, which often differ by jurisdiction. Achieving compliance frequently demands significant capital investment in advanced technologies, certified materials, and continuous monitoring systems. Small and mid-sized enterprises may struggle to manage the high upfront costs associated with these upgrades. These regulatory and financial pressures can delay project timelines and limit market entry for new participants. Equipment providers must maintain ongoing investments in product development to satisfy both existing and emerging regulatory demands.

Operational Risks and Supply Chain Disruptions Impact Market Stability:

Operational risks related to tank failure, corrosion, and leakage continue to impact the reputation and profitability of companies in the storage tank equipment market. Equipment malfunctions or substandard installations can lead to costly downtime, environmental hazards, and legal liabilities. The market also faces supply chain disruptions, driven by global shortages of raw materials and logistical constraints. These challenges create uncertainty in procurement and delivery schedules, affecting both manufacturers and end-users. Companies need robust risk management strategies and diversified supplier networks to maintain operational continuity and fulfill customer requirements.

Market Opportunities:

Expansion of Renewable Energy and Water Management Projects Creates New Demand:

The global transition toward renewable energy and sustainable infrastructure presents significant growth opportunities for the storage tank equipment market. Rapid investments in biofuel production, hydrogen storage, and utility-scale battery projects require advanced storage solutions that can safely manage diverse materials. Governments and private sectors prioritize water management, driving demand for tanks in desalination, wastewater treatment, and rainwater harvesting applications. These expanding sectors enable equipment providers to develop tailored products that address new technical and regulatory requirements. The focus on green infrastructure and circular economy practices supports steady long-term demand for innovative tank equipment.

Technological Innovation and Digital Solutions Drive Value-Added Services:

Technological advancements in automation, remote monitoring, and predictive analytics are opening new avenues for differentiation and value creation in the storage tank equipment market. Equipment manufacturers can offer integrated digital platforms that enable real-time performance tracking, proactive maintenance, and enhanced safety management. Customers increasingly seek solutions that reduce downtime, optimize asset performance, and simplify compliance reporting. Service providers who invest in R&D and digital transformation are well-positioned to capture new market segments and expand recurring revenue streams. The market’s shift toward smart, connected solutions encourages collaboration across the supply chain, fostering long-term business partnerships and customer loyalty.

Market Segmentation Analysis:

By Type:

The storage tank equipment market segments by type into valves, level gauges, manways, mixers, pumps, and accessories. Valves and level gauges account for significant market share, driven by their critical role in safety and process control across oil, gas, chemical, and water industries. Pumps and mixers are gaining traction in applications requiring continuous fluid management and homogenization, supporting process optimization in industrial and municipal settings.

By Tank Type:

Market segmentation by tank type includes above-ground and underground tanks. Above-ground tanks dominate the market due to easier maintenance, inspection, and lower installation costs. These tanks serve a broad range of industries, including petrochemicals, water treatment, and food processing. Underground tanks hold relevance in space-constrained or safety-sensitive environments, particularly for fuel storage at commercial sites and filling stations.

- For instance, CB&I (Chicago Bridge & Iron) achieved a major milestone by designing and constructing a 1.2 million-gallon API 620 low-pressure liquid storage tank for liquefied gases, demonstrating their capability to handle specialized above-ground storage applications requiring high structural integrity.

By Material:

The storage tank equipment market segments by material into stainless steel, carbon steel, fiberglass-reinforced plastic (FRP), and other advanced composites. Stainless steel leads the market due to its durability, corrosion resistance, and suitability for handling aggressive chemicals and high-purity liquids. Carbon steel finds widespread use in oil and gas storage for its strength and cost-effectiveness. FRP and composites are emerging as preferred materials in applications requiring lightweight, corrosion-proof solutions, especially in water and wastewater management.

- For instance, Nippon Steel developed WEL-TEN™780 steel plates characterized by high strength and superior toughness tailored for large liquefied CO2 tanks used in carbon capture and storage projects.

Segmentations:

By Type:

- Valves

- Level Gauges

- Manways

- Mixers

- Pumps

- Accessories

By Tank Type:

- Above-Ground Tanks

- Underground Tanks

By Material:

- Stainless Steel

- Carbon Steel

- Fiberglass-Reinforced Plastic (FRP)

- Advanced Composites

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

North America :

North America accounts for 34% of the global storage tank equipment market, making it the largest regional contributor. The United States drives market demand through its extensive oil, gas, and petrochemical sectors, while Canada supports growth with expanding water and wastewater infrastructure projects. The region’s focus on safety, compliance, and modernization initiatives accelerates adoption of advanced storage technologies. Regulatory agencies enforce strict standards for emissions control and tank integrity, prompting significant investments in upgraded equipment. Equipment manufacturers benefit from strong R&D capabilities and robust distribution networks. The presence of leading industry players and a mature end-user base sustains regional market dominance.

Asia-Pacific :

Asia-Pacific holds a 29% share of the storage tank equipment market, supported by rapid industrialization and infrastructure expansion in China, India, and Southeast Asia. High demand for chemicals, refined fuels, and processed water propels investments in large-scale storage facilities and equipment. Governments invest in new manufacturing bases, energy projects, and smart city initiatives that require scalable and durable storage solutions. Rising population and urban migration fuel demand for reliable water supply and treatment infrastructure. The region’s competitive manufacturing landscape encourages cost-effective solutions and technology adoption. Local and international suppliers compete aggressively to capture new business in this high-growth market.

Europe :

Europe represents 22% of global demand, supported by well-established industrial sectors and progressive environmental policies. Countries such as Germany, the United Kingdom, and France prioritize modernization of existing storage infrastructure, focusing on safety, automation, and environmental compliance. Policy incentives and public-private partnerships accelerate market expansion in energy transition, circular economy, and water management projects. Equipment manufacturers leverage advanced engineering and digital technologies to address evolving regulatory requirements. Cross-industry collaboration supports innovation in materials and design, positioning Europe as a leader in sustainable storage tank solutions. The market reflects strong customer preferences for quality, reliability, and lifecycle value.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Balmoral Tanks

- Hansa Engineering

- ERGIL

- Franklin Electric

- Mass Tank Corp

- Nov

- OPW

- Kay Tank

- Potential Engineering

- Rainwater Equipment LLC

- PROTEGO

- Ramén Valves

- TEC Container Solutions

Competitive Analysis:

The storage tank equipment market features intense competition among global leaders and specialized regional players. Key companies such as Balmoral Tanks, Hansa Engineering, ERGIL, Franklin Electric, Mass Tank Corp, Nov, OPW, Kay Tank, Potential Engineering, Rainwater Equipment LLC, and PROTEGO drive market dynamics through continuous innovation and strategic expansion. The market rewards manufacturers that offer high-performance, durable solutions tailored to strict safety and environmental regulations. Companies invest in advanced materials, smart monitoring, and automation to differentiate their portfolios and address evolving customer demands. Partnerships, acquisitions, and local collaborations enable players to expand reach and strengthen service capabilities. The storage tank equipment market encourages a focus on research and development, lifecycle support, and rapid adaptation to regulatory and technological shifts, ensuring resilient market positions for those investing in customer-centric innovation.

Recent Developments:

- In March 2025, Balmoral Tanks announced a European market partnership with Global Tank Group A/S to collaborate on projects in renewable energy and wastewater treatment.

- In August 2025, ERGIL completed the fabrication of a custom multi-section pressure vessel for an aerodynamic testing tunnel.

- In March 2025 (expected): The acquisition of Barnes de Colombia S.A. by Franklin Electric is expected to close on or about March 1, 2025, pending regulatory approvals.

Market Concentration & Characteristics:

The storage tank equipment market features a moderate to high level of concentration, with several large multinational players holding significant market shares alongside numerous regional and specialized manufacturers. It is characterized by intense competition, ongoing technological innovation, and a strong emphasis on compliance with stringent safety and environmental standards. Leading companies focus on expanding product portfolios, integrating digital technologies, and forming strategic partnerships to strengthen market presence. The market supports a diverse customer base across oil and gas, chemicals, water treatment, and food industries, driving continuous demand for reliable, high-performance solutions. Innovation in materials, automation, and lifecycle services further shapes market dynamics and customer expectations.

Report Coverage:

The research report offers an in-depth analysis based on Type, Tank Type, Material, Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- Rising infrastructure investments across oil, gas, water, and chemical sectors will sustain long-term demand for advanced storage tank equipment.

- Increasing adoption of smart monitoring systems and automation will drive operational efficiency and safety across end-user industries.

- Regulatory requirements around emissions control, environmental protection, and safety compliance will encourage continuous product upgrades and technological advancements.

- Demand for modular and customizable tank designs will grow, supporting flexible deployment and rapid project implementation in diverse settings.

- Renewable energy, hydrogen storage, and biofuel sectors will offer new growth avenues, requiring specialized storage solutions and materials.

- Expansion of water and wastewater management initiatives will drive equipment demand in both developed and emerging markets.

- Manufacturers will invest in digital platforms for remote monitoring, predictive maintenance, and real-time data analytics to enhance service offerings.

- Competitive intensity will increase, with companies prioritizing R&D, product differentiation, and partnerships to secure market position.

- Sustainability trends will influence material innovation, emphasizing corrosion resistance, recyclability, and longer equipment life cycles.

- Emerging economies, especially in Asia-Pacific and Latin America, will play a key role in shaping future market opportunities through industrialization and urban infrastructure projects.