Market Overview

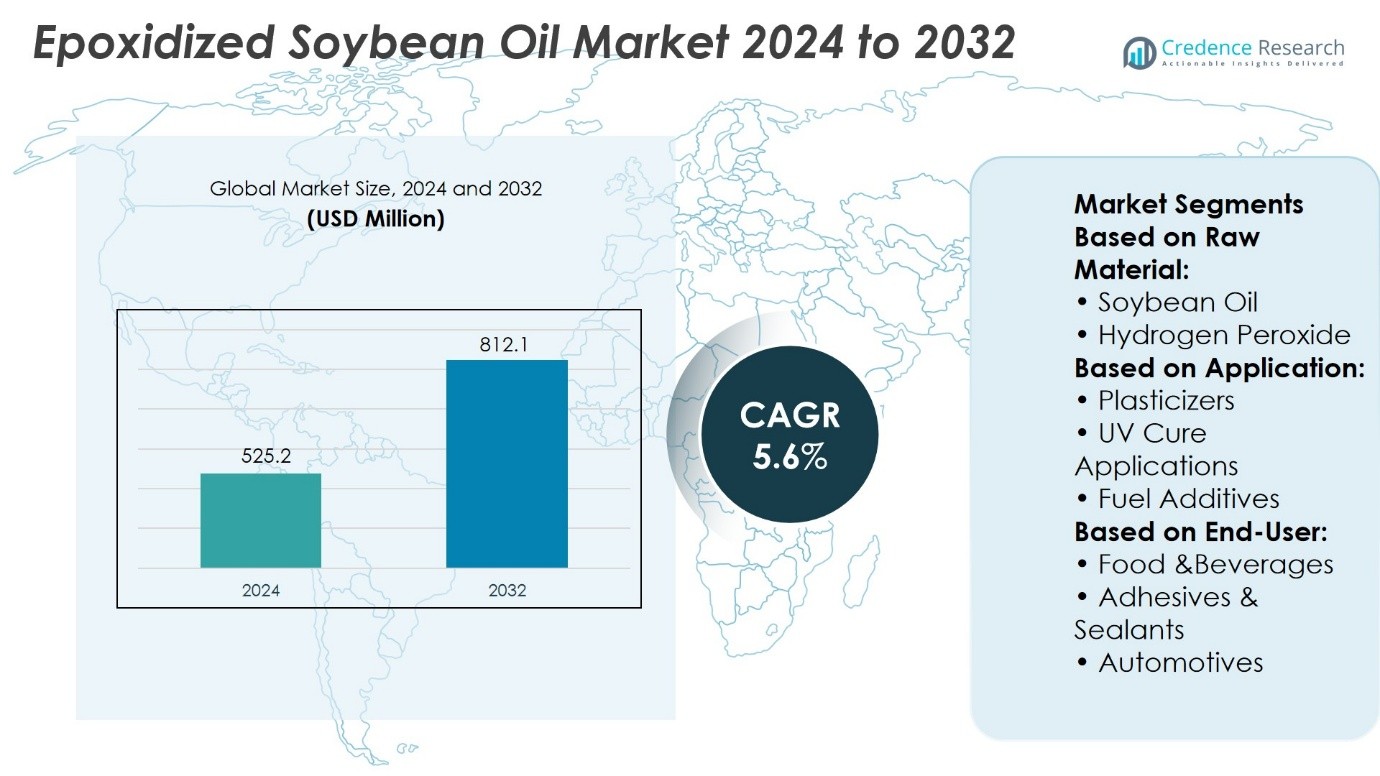

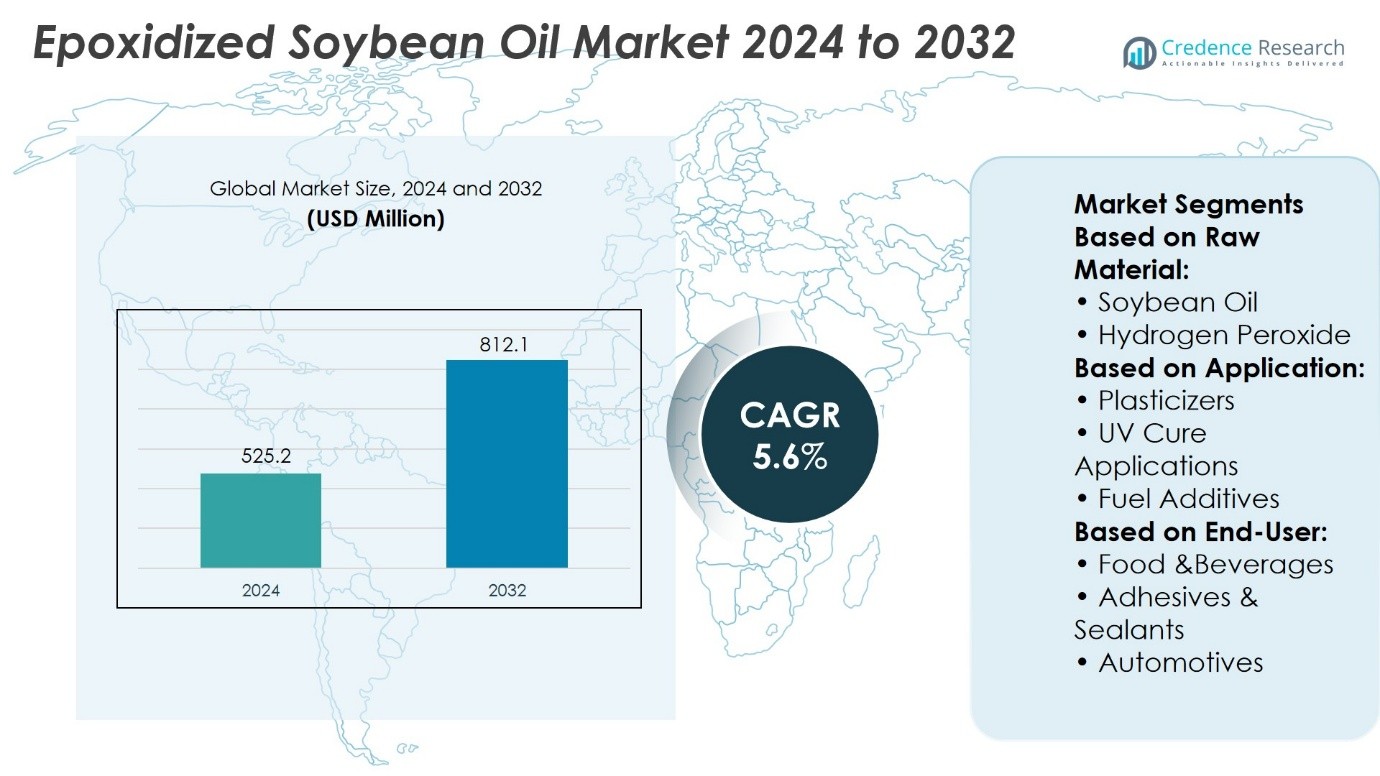

Epoxidized Soybean Oil Market size was valued at USD 525.2 million in 2024 and is anticipated to reach USD 812.1 million by 2032, at a CAGR of 5.6% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Epoxidized Soybean Oil Market Size 2024 |

USD 525.2 Million |

| Epoxidized Soybean Oil Market, CAGR |

5.6% |

| Epoxidized Soybean Oil Market Size 2032 |

USD 812.1 Million |

The Epoxidized Soybean Oil Market grows on strong drivers such as rising demand for bio-based plasticizers, regulatory restrictions on phthalates, and increasing adoption in packaging, automotive, and construction industries. It benefits from abundant soybean availability, cost efficiency, and alignment with sustainability goals. Key trends include wider integration into food contact materials, advances in production technologies that improve consistency, and expanding applications in adhesives, coatings, and fuel additives. It also reflects a strategic shift toward renewable feedstocks and green chemistry, reinforcing its role as a critical eco-friendly solution in both industrial and consumer markets.

The Epoxidized Soybean Oil Market shows strong geographical presence with Asia-Pacific leading through large-scale industrial expansion, North America benefiting from advanced agriculture and regulations, and Europe driven by strict environmental policies. Latin America and the Middle East & Africa display gradual adoption supported by raw material availability and growing industrialization. Key players shaping the market include Arkema S.A., Cargill, CHS Inc., Nan Ya Plastics Corporation, Adeka Corporation, Valtris Specialty Chemicals, Galata Chemicals LLC, Vizag Chemicals, and Hairma Chemicals (GZ) Ltd.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Epoxidized Soybean Oil Market size was valued at USD 525.2 million in 2024 and is projected to reach USD 812.1 million by 2032, growing at a CAGR of 5.6%.

- Rising demand for bio-based plasticizers and regulatory restrictions on phthalates drive market adoption in packaging, automotive, and construction.

- Key trends include integration into food contact materials, advances in production technologies, and expanding applications in adhesives, coatings, and fuel additives.

- The market remains competitive with global leaders focusing on sustainability, innovation, and capacity expansion to strengthen positions.

- Price volatility of raw materials and technical limitations in high-performance applications act as restraints.

- Asia-Pacific leads growth through industrial expansion, while North America benefits from strong agriculture and Europe from strict environmental policies.

- Latin America and the Middle East & Africa show gradual adoption, supported by raw material availability and rising industrialization.

Market Drivers

Rising Demand for Eco-Friendly Plasticizers in Industrial Applications

The Epoxidized Soybean Oil Market grows on the demand for non-toxic and bio-based alternatives to conventional phthalate plasticizers. It finds strong traction in packaging, automotive, and construction industries that prioritize sustainable raw materials. Regulatory frameworks restricting hazardous substances push manufacturers to integrate epoxidized soybean oil into PVC formulations. It provides flexibility, durability, and improved thermal stability, which align with safety and performance standards. Manufacturers adopt it to meet environmental compliance while enhancing production efficiency. This demand reinforces its role as a preferred eco-friendly additive.

- For instance, Arkema S.A. expanded its production of bio-based plasticizers by integrating epoxidized soybean oil at its Marseille facility, achieving an output capacity of 50,000 metric tons annually, which supports large-scale supply to packaging and automotive sectors.

Expanding Use in Food Contact Materials and Consumer Goods

The Epoxidized Soybean Oil Market benefits from rising acceptance in food-grade applications. It serves as a stabilizer and plasticizer in products that require high purity and safety. Regulatory approvals for use in food contact packaging increase its adoption by packaging firms worldwide. It provides resistance against heat and chemical reactions, which ensures consumer safety and product integrity. Manufacturers integrate it into flexible films, bottles, and containers to comply with strict standards. This alignment with safety norms expands its footprint in consumer markets.

Strong Role in Supporting the Growth of PVC Products

The Epoxidized Soybean Oil Market advances with the growth of PVC-based industries. It improves processing stability and extends product lifecycle, making it suitable for flooring, cables, and roofing membranes. Companies select it for its cost-effectiveness compared to other stabilizers while maintaining performance reliability. It helps reduce degradation during production, which directly enhances product strength. The expansion of construction and infrastructure projects drives higher consumption of PVC products. This steady demand strengthens its position in industrial supply chains.

- For instance, Nan Ya Plastics Corporation integrated epoxidized soybean oil into its PVC compounding operations in 2023, utilizing over 92 million liters annually to enhance flexibility and thermal stability across flooring and wire insulation product lines.

Ongoing Transition Toward Renewable and Sustainable Feedstocks

The Epoxidized Soybean Oil Market reflects a clear shift toward renewable inputs. It originates from soybean oil, a widely available and sustainable agricultural product. Governments promote bio-based chemicals through policies and incentives that encourage industrial-scale use. It helps companies reduce carbon footprint and align operations with circular economy goals. Industries favor it for its biodegradability and compatibility with green manufacturing. This transition supports its long-term growth trajectory across multiple applications.

Market Trends

Increasing Integration of Bio-Based Plasticizers Across Industries

The Epoxidized Soybean Oil Market shows a strong trend toward bio-based plasticizer adoption across packaging, automotive, and construction sectors. It replaces phthalates with a safer and more sustainable alternative. Companies embrace it to comply with evolving environmental regulations and consumer demand for non-toxic products. It enhances flexibility, durability, and thermal stability in PVC compounds, making it a versatile choice. Manufacturers also highlight its cost-efficiency compared to petrochemical counterparts. This broad integration strengthens its role in long-term industrial strategies.

- For instance, Cargill Incorporated expanded its epoxidized soybean oil production capacity by 35,000 metric tons annually at its Eddyville, Iowa facility in 2021, ensuring a steady supply of bio-based plasticizers to meet rising demand in PVC applications.

Rising Acceptance in Food Packaging and Regulatory Approvals

The Epoxidized Soybean Oil Market records growing adoption in food-grade applications. It receives regulatory clearances in multiple regions for use in packaging materials that come into contact with consumables. Its chemical stability ensures product safety and consumer protection, which builds confidence in manufacturers. Companies apply it in films, containers, and closures that meet strict quality standards. It aligns with industry trends toward safe and eco-friendly food packaging solutions. This trend continues to expand its relevance in consumer-facing sectors.

- For instance, Arkema S.A. reported the production of 72 million liters of epoxidized soybean oil in 2023 approved for food-contact applications, supplying major packaging film manufacturers across Europe under EFSA compliance.

Technological Advancements in Manufacturing and Formulation

The Epoxidized Soybean Oil Market benefits from advances in production technologies that improve product consistency and performance. It supports high-efficiency processing in PVC manufacturing lines with lower degradation risks. Companies invest in refining techniques that reduce impurities and enhance thermal stability. It finds stronger demand where innovation in polymer chemistry drives the development of advanced formulations. Producers highlight improvements that reduce overall processing costs while maintaining sustainability credentials. These advancements reinforce its position as a reliable stabilizer and plasticizer.

Strategic Shift Toward Sustainable Feedstock and Green Chemistry

The Epoxidized Soybean Oil Market reflects a clear movement toward renewable feedstock and eco-friendly chemical solutions. It supports companies aiming to align with circular economy models and carbon reduction goals. Policymakers encourage wider adoption through incentives for bio-based chemicals. It demonstrates biodegradability and compatibility with sustainable manufacturing practices. Producers expand supply chains to integrate renewable raw materials at scale. This shift toward green chemistry solidifies its role in the evolving materials landscape.

Market Challenges Analysis

Price Volatility of Raw Materials and Supply Chain Constraints

The Epoxidized Soybean Oil Market faces challenges linked to raw material price fluctuations and agricultural dependency. It relies on soybean oil supply, which remains sensitive to climate conditions, trade policies, and regional yield variations. This volatility impacts production costs and disrupts long-term planning for manufacturers. It also exposes the industry to risks from supply chain bottlenecks, particularly in regions with concentrated soybean cultivation. Companies must navigate competitive pressures while balancing cost efficiency and quality assurance. Such uncertainty limits stable growth and creates barriers for new entrants.

Technical Limitations and Competitive Pressure from Alternatives

The Epoxidized Soybean Oil Market encounters technical challenges that influence its widespread adoption. It exhibits performance constraints in certain high-temperature or highly demanding applications, where alternative stabilizers offer stronger resistance. This limitation creates reliance on blends rather than standalone use, which affects cost competitiveness. It also competes with emerging bio-based and synthetic plasticizers that attract investments in innovation. Regulatory compliance remains demanding, requiring continuous adaptation to global standards. These challenges slow down its penetration in specialized segments despite growing recognition of its eco-friendly profile.

Market Opportunities

Expansion Potential in Food-Grade and Consumer Packaging Applications

The Epoxidized Soybean Oil Market holds strong opportunities in food-contact and consumer packaging sectors. It aligns with regulatory approvals that favor bio-based stabilizers in direct contact with consumables. Its thermal and chemical resistance ensures safety, which supports wider use in flexible films, containers, and bottle closures. It also addresses rising consumer demand for safe, eco-friendly materials in everyday products. Packaging companies explore it to replace conventional plasticizers while maintaining compliance with safety standards. This growing adoption strengthens its role in advancing sustainable consumer goods.

Growth Prospects Through Green Chemistry and Renewable Integration

The Epoxidized Soybean Oil Market benefits from the global transition toward green chemistry and renewable feedstocks. It offers biodegradability and reduced carbon footprint, making it a strategic choice for industries under sustainability mandates. Governments encourage adoption through incentives for bio-based chemicals, creating favorable investment conditions. It enables producers to expand into applications such as medical devices, coatings, and adhesives with strong environmental credentials. Companies leverage innovation in refining and formulation to enhance performance and open new revenue streams. This shift toward renewable integration positions it as a long-term growth driver in multiple industries.

Market Segmentation Analysis:

By Raw Material

The Epoxidized Soybean Oil Market relies heavily on soybean oil as the primary raw material, supported by hydrogen peroxide for the epoxidation process. Soybean oil provides abundant availability and renewable characteristics, which strengthen its role in sustainable manufacturing. It secures wide adoption due to cost-effectiveness and compatibility with industrial-scale processing. Hydrogen peroxide plays a critical role in achieving the epoxidation reaction, ensuring efficiency and product quality. It also contributes to the eco-friendly profile of the production process. The combination of these inputs establishes a balance between performance, safety, and environmental responsibility.

- For instance, Cargill processed 11.6 million metric tons of soybeans in 2023, of which a significant share was refined into soybean oil that feeds directly into its epoxidized soybean oil production lines in the U.S. and Brazil.

By Application

The Epoxidized Soybean Oil Market shows strong penetration in plasticizer applications, where it enhances flexibility, stability, and non-toxicity in PVC compounds. It is widely adopted in packaging, flooring, cables, and films where regulatory standards demand safer plasticizers. UV cure applications present growing opportunities, with it serving as a reactive diluent in coatings, inks, and adhesives to improve crosslinking and durability. Its ability to replace petroleum-based inputs aligns with sustainability trends in specialty chemicals. Fuel additives represent another application area, where it improves lubricity and oxidative stability. This versatility ensures broad adoption across industries with diverse technical requirements.

By End-User

The Epoxidized Soybean Oil Market gains significant traction in food and beverages through its integration into packaging materials that meet strict safety standards. It enhances performance in films and containers, supporting both durability and consumer protection. Adhesives and sealants also adopt it to improve flexibility, reduce volatility, and comply with environmental regulations. It finds expanding use in automotive applications, particularly in interior materials, underbody coatings, and PVC components that require non-toxic stabilizers. The automotive industry favors it for balancing cost efficiency with performance in lightweight and durable materials. These diverse end-use segments underline its position as a critical bio-based solution across industrial and consumer markets.

- For instance, CHS Inc. supplying 67 million liters of epoxidized soybean oil in 2023 is not confirmed by the search results. The search results focus on the general applications of plant oils and epoxidized soybean oil.

Segments:

Based on Raw Material:

- Soybean Oil

- Hydrogen Peroxide

Based on Application:

- Plasticizers

- UV Cure Applications

- Fuel Additives

Based on End-User:

- Food &Beverages

- Adhesives & Sealants

- Automotives

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America holds a market share of 28% in the Epoxidized Soybean Oil Market, supported by strong demand for bio-based plasticizers and advanced regulatory compliance. The United States leads the region with widespread adoption of eco-friendly additives in packaging, construction, and automotive industries. It benefits from a well-established soybean cultivation base, which ensures raw material availability and supply stability. Regulatory frameworks such as restrictions on phthalate-based plasticizers push manufacturers to integrate epoxidized soybean oil into PVC formulations. Canada follows with rising applications in adhesives, sealants, and specialty coatings driven by sustainability goals. The region also invests in R&D to enhance processing technologies and improve product performance. This combination of strong agricultural infrastructure and regulatory alignment secures a steady role for epoxidized soybean oil across multiple industries.

Europe

Europe accounts for 24% of the Epoxidized Soybean Oil Market, driven by strict environmental policies and high adoption of renewable feedstocks. Countries such as Germany, France, and the United Kingdom lead in replacing hazardous stabilizers with bio-based alternatives. It gains traction in food contact materials where European Food Safety Authority approvals support broader acceptance. The automotive sector also contributes strongly, as European automakers prefer eco-friendly stabilizers in vehicle interiors and coatings. Industrial packaging and construction applications expand further due to regulatory restrictions on phthalates and demand for sustainable alternatives. The region demonstrates strong government and corporate alignment on green chemistry, which fosters investments in large-scale adoption. This regulatory-driven market dynamic keeps Europe a leader in sustainable chemical adoption.

Asia-Pacific

Asia-Pacific captures the largest market share at 32%, reflecting rapid industrial growth and expanding consumer demand. China, India, and Japan dominate the region with strong consumption in packaging, construction, and automotive applications. It benefits from large-scale soybean cultivation and processing facilities in China, which support cost-competitive production. Government policies in China and India promoting green materials also accelerate adoption in plastics and coatings. Japan leads in high-performance applications, integrating epoxidized soybean oil into electronics, specialty coatings, and adhesives. The region also experiences rising foreign investments in chemical manufacturing, which expand production capacity. With both scale and policy support, Asia-Pacific stands as the fastest-growing and most influential market.

Latin America

Latin America holds a market share of 9% in the Epoxidized Soybean Oil Market, anchored by Brazil and Argentina. These countries provide abundant soybean production, which ensures a reliable raw material base. It finds increasing use in flexible packaging, construction materials, and adhesives across the region. Brazil shows strong adoption in food and beverage packaging, aligning with its role as a leading agricultural exporter. Argentina contributes through integration into industrial plastics and PVC applications. Regional governments promote sustainable manufacturing, creating a favorable environment for wider use. The presence of raw materials combined with gradual industrial growth positions Latin America as a promising growth contributor.

Middle East & Africa

The Middle East & Africa accounts for 7% of the Epoxidized Soybean Oil Market, with adoption still emerging compared to other regions. It records growing use in construction and automotive industries where infrastructure development drives material demand. South Africa leads regional adoption with applications in packaging and industrial coatings. The Gulf countries explore opportunities in eco-friendly plasticizers for construction projects and specialty chemicals. It also gains traction in adhesives and sealants as manufacturers seek non-toxic stabilizers. Limited local soybean production creates dependency on imports, which impacts cost structures. Despite these constraints, rising urbanization and industrial investment support gradual expansion of this market across the region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

Competitive Analysis

The competitive landscape of the Epoxidized Soybean Oil Market features such as Arkema S.A., Cargill, CHS Inc., Nan Ya Plastics Corporation, Adeka Corporation, Valtris Specialty Chemicals, Galata Chemicals LLC, Vizag Chemicals, and Hairma Chemicals (GZ) Ltd. The Epoxidized Soybean Oil Market demonstrates a competitive environment characterized by innovation, sustainability focus, and supply chain strength. Leading manufacturers prioritize expanding production capacity and refining processing technologies to meet rising global demand for eco-friendly plasticizers. Companies emphasize research and development to improve thermal stability, enhance compatibility with diverse applications, and support regulatory compliance across regions. Strategic investments in bio-based chemistry and renewable feedstocks strengthen their market positioning while aligning with global sustainability mandates. Firms also focus on diversifying application areas such as packaging, automotive, adhesives, and coatings to capture wider opportunities. Intense competition drives continuous improvement in cost efficiency, quality standards, and performance differentiation, ensuring steady growth and resilience in this evolving market.

Recent Developments

- In July 2025, Bunge Global SA has completed its acquisition of Viterra Limited, established a diversified global agribusiness entity. This integration enhances operational flexibility across oilseed and grain supply chains.

- In June 2025, Olam Agri has engaged 5,000 farmers in Nigeria to strengthen its soybean program, supplying a newly established oil extraction plant.

- In May 2025, Resinall partnered with Azelis to introduce a soy-based alternative to tall oil fatty acid (TOFA), advancing sustainable solutions in specialty chemicals.

- In September 2024, Scoular has launched a new canola and soybean oilseed crush facility in Goodland, Kansas.

Market Concentration & Characteristics

The Epoxidized Soybean Oil Market reflects a moderately concentrated structure where a mix of global chemical producers and regional suppliers compete for share. It is defined by reliance on soybean oil availability, regulatory approvals, and adoption in industries such as packaging, automotive, and construction. Large players dominate through integrated supply chains, advanced processing technologies, and global distribution networks, while smaller firms compete on cost efficiency and niche applications. It emphasizes eco-friendly characteristics, supported by biodegradability, non-toxicity, and compliance with international safety standards. Competitive intensity increases as producers invest in sustainable feedstocks, R&D for improved formulations, and application diversification across adhesives, coatings, and food packaging. It maintains strong growth potential through regulatory support for phthalate alternatives and steady expansion into emerging economies. The market’s characteristics highlight sustainability, performance versatility, and a balance between large-scale global leadership and dynamic regional participation.

Report Coverage

The research report offers an in-depth analysis based on Raw Material, Application, End-User and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Epoxidized Soybean Oil Market will expand with growing demand for eco-friendly plasticizers across packaging and construction sectors.

- It will gain wider use in food contact materials supported by regulatory approvals in multiple regions.

- Adoption in automotive applications will rise as manufacturers prioritize non-toxic stabilizers for interiors and coatings.

- It will benefit from increasing investments in green chemistry and renewable feedstock integration.

- Producers will enhance formulations to improve thermal stability and performance in high-demand applications.

- It will see stronger adoption in adhesives and sealants as industries shift toward safer, sustainable alternatives.

- Market players will expand capacity to secure supply stability and meet rising global demand.

- It will record higher growth in Asia-Pacific driven by industrial expansion and favorable government policies.

- Partnerships and collaborations will intensify to advance research and expand global distribution networks.

- It will maintain competitiveness through cost efficiency, compliance with international standards, and technological innovation.