Market Overview:

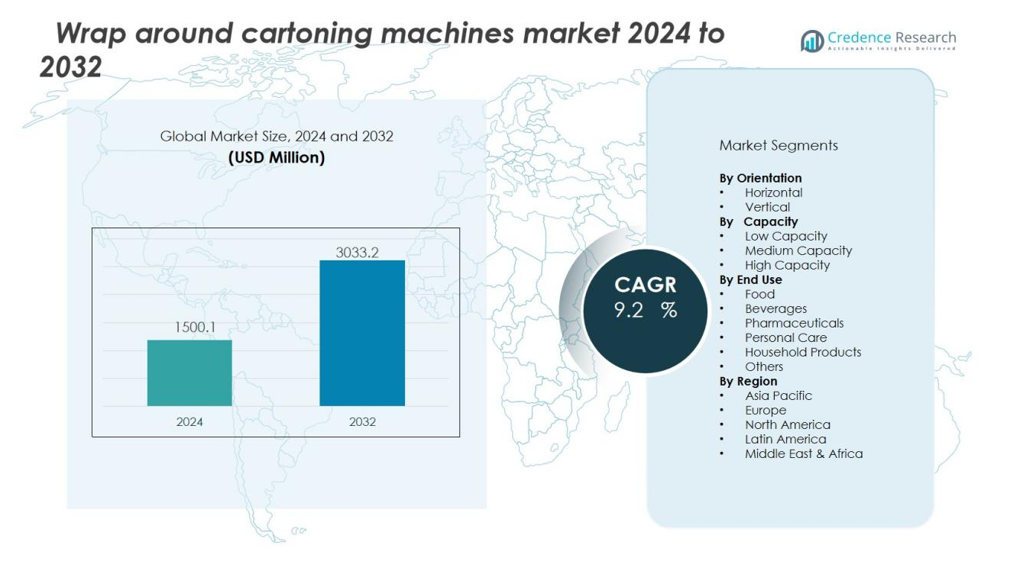

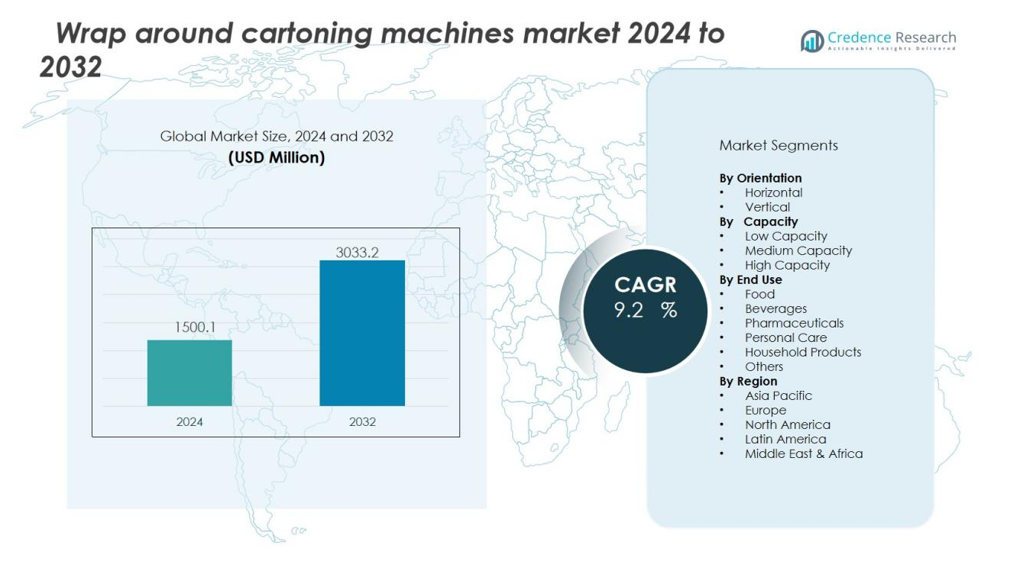

The Wrap-Around Cartoning Machines Market size was valued at USD 1500.1 million in 2024 and is anticipated to reach USD 3033.2 million by 2032, at a CAGR of 9.2 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Wrap Around Cartoning Machines Market Size 2024 |

USD 1500.1 million |

| Wrap Around Cartoning Machines Market, CAGR |

9.2% |

| Wrap Around Cartoning Machines Market Size 2032 |

USD 3033.2 million |

Key drivers influencing the wrap around cartoning machines market include the rising need for high-speed and flexible packaging machinery, growing consumer preference for packaged and branded goods, and the ongoing trend toward automation in manufacturing. Sustainability initiatives are also fueling demand, as these machines enable optimized material usage and eco-friendly packaging formats. In addition, advancements in robotics, servo technology, and intelligent control systems are enhancing performance, precision, and reliability, making these solutions highly attractive to end users seeking long-term operational efficiency.

Regionally, Europe and North America dominate the wrap around cartoning machines market, benefiting from strong adoption of advanced packaging technologies and stringent standards in food safety and pharmaceutical packaging. Asia-Pacific is expected to witness the fastest growth, led by rapid industrialization, rising consumption of packaged products, and expanding investments in manufacturing automation in countries such as China and India. Latin America and the Middle East & Africa are also emerging as potential markets, supported by growing retail and e-commerce activity.

Market Insights:

- The Wrap around cartoning machines market was valued at USD 1500.1 million in 2024 and is projected to reach USD 3033.2 million by 2032, growing at a CAGR of 9.2% during the forecast period.

- Rising automation in packaging is a key driver, with industries such as food, beverage, and pharmaceuticals adopting these machines to enhance speed, precision, and consistency while reducing labor costs.

- Flexibility and sustainability are strengthening demand, as machines capable of handling varied carton sizes and supporting eco-friendly packaging formats align with regulatory and consumer expectations.

- Europe holds 34% and North America 28% market share, driven by advanced packaging technologies and strict safety standards, while Asia-Pacific with 26% share is the fastest-growing region due to industrial expansion and rising packaged goods consumption.

- High capital costs, maintenance complexity, and supply chain volatility remain major challenges, yet opportunities are emerging through innovation in sustainable designs, cost-efficient models, and growth in emerging economies.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for Automation in Packaging Operations:

The Wrap around cartoning machines market is strongly driven by the global shift toward automation in packaging lines. Manufacturers in food, beverage, and pharmaceuticals are adopting automated systems to improve speed, accuracy, and consistency. These machines reduce labor dependency and minimize errors, which enhances overall efficiency. It also ensures that companies can meet growing consumer expectations for fast and reliable product delivery.

- For instance, Syntegon Technology introduced its automatic wraparound cartoner Elematic 3001, capable of handling up to 500 cartons per minute, significantly enhancing packaging efficiency for high-volume food and beverage producers.

Growing Preference for Flexible and Sustainable Packaging Solutions:

Flexibility and sustainability are key factors propelling demand in the Wrap around cartoning machines market. The machines can handle a wide variety of carton sizes and shapes, allowing producers to adapt quickly to changing packaging needs. Their ability to optimize material usage supports sustainability goals by reducing waste. It aligns well with increasing regulatory and consumer pressure for eco-friendly packaging solutions.

- For instance, Syntegon Technology developed a wrap-around cartoner for frozen foods that incorporates a glue-free locking system, reducing adhesive consumption by up to 50 kilograms annually per line.

Expansion of E-Commerce and Retail Distribution Channels:

The growth of e-commerce and modern retail formats directly supports the Wrap around cartoning machines market. Rising consumer demand for packaged goods requires efficient packaging technologies that protect products during storage and transport. These machines ensure sturdy packaging that extends shelf life and enhances product presentation. It creates opportunities for manufacturers to scale operations and meet high-volume distribution demands.

Technological Advancements in Machine Design and Control Systems:

Continuous innovations in robotics, motion control, and sensor technologies are shaping the Wrap around cartoning machines market. Modern systems are equipped with advanced control panels and servo-driven mechanisms for greater precision. These features allow quick changeovers and higher production speeds, reducing downtime and operational costs. It positions the technology as a strategic investment for companies aiming to strengthen competitiveness in global markets.

Market Trends:

Integration of Smart Technologies and Digitalization in Packaging Systems:

The Wrap around cartoning machines market is witnessing a strong trend toward the integration of smart technologies that enhance efficiency and control. Manufacturers are embedding IoT-enabled sensors, data analytics, and remote monitoring features into packaging equipment to optimize performance. These innovations allow predictive maintenance, reduce downtime, and improve energy efficiency, which supports operational excellence. Digital control systems also enable faster adjustments in carton size and design, meeting the rising need for product differentiation. It creates a shift toward intelligent packaging solutions that deliver higher flexibility and real-time insights. Companies adopting these technologies gain a competitive advantage by aligning with Industry 4.0 practices and ensuring consistent quality standards across production lines.

- For instance, Bosch Packaging Technology integrated IoT-based condition monitoring into its cartoning systems, which helped reduce unplanned downtime by 18 hours per production line annually.

Growing Emphasis on Sustainable Packaging and Eco-Friendly Machinery Design:

Sustainability is emerging as a dominant trend in the Wrap around cartoning machines market, driving manufacturers to focus on eco-friendly packaging formats and machine designs. End users are increasingly selecting equipment that minimizes material consumption and supports recyclable or biodegradable packaging materials. Energy-efficient motors, lightweight designs, and optimized material flow are becoming standard features in modern systems. It reflects the growing alignment between regulatory frameworks and corporate sustainability goals. The rising demand for greener supply chains is prompting companies to integrate wrap around cartoning solutions that balance performance with environmental responsibility. This trend is reshaping the competitive landscape, with innovation in sustainability now acting as a key differentiator in procurement decisions.

- For instance, Bosch Packaging Technology’s variable-speed powertrain solutions have the potential to reduce energy consumption by up to 80 percent compared to previous models.

Market Challenges Analysis:

High Capital Investment and Maintenance Complexity:

The Wrap around cartoning machines market faces challenges linked to high upfront costs and ongoing maintenance requirements. Small and medium-sized manufacturers often hesitate to adopt these machines due to significant capital expenditure. Complex designs and advanced automation increase the need for skilled technicians, raising training and operational costs. It creates barriers to adoption in emerging economies where budget constraints limit modernization. Frequent upgrades and spare part replacements also add to the total cost of ownership. This financial strain slows adoption, particularly among companies with limited production volumes.

Customization Demands and Supply Chain Volatility:

Evolving consumer preferences and industry-specific needs are creating customization challenges in the Wrap around cartoning machines market. Manufacturers demand equipment that can handle diverse carton formats, quick changeovers, and high-speed production simultaneously. Meeting these requirements while maintaining affordability is difficult for suppliers. It also complicates design and lengthens delivery timelines. Supply chain disruptions and fluctuating raw material prices further increase uncertainty, affecting production and machine availability. These challenges pressure both equipment manufacturers and end users to balance efficiency, cost, and adaptability in a competitive market.

Market Opportunities:

Rising Adoption Across Emerging Markets and Expanding End-Use Industries:

The Wrap around cartoning machines market presents strong opportunities in emerging economies where industrialization and packaged goods consumption are accelerating. Food, beverage, and pharmaceutical industries in regions such as Asia-Pacific and Latin America are investing in advanced packaging systems to meet growing consumer demand. It creates scope for machine suppliers to offer cost-effective models tailored to regional requirements. Expanding e-commerce and retail networks are further boosting demand for durable, high-quality packaging. Government initiatives supporting automation and manufacturing modernization strengthen prospects for wider adoption. These factors open significant growth avenues for both global and regional equipment manufacturers.

Innovation in Sustainable and Multi-Functional Machine Designs:

Sustainability-focused innovations present another key opportunity in the Wrap around cartoning machines market. Companies that develop machines capable of handling recyclable, biodegradable, and lightweight packaging materials can gain a competitive advantage. It allows end users to align operations with regulatory frameworks and environmental goals. Multi-functional machines that support faster changeovers and flexible carton formats are also in demand. Such innovations cater to industries seeking both efficiency and adaptability in packaging processes. By focusing on eco-friendly and versatile designs, manufacturers can strengthen their market presence and capture new customer segments.

Market Segmentation Analysis:

By Orientation:

The Wrap around cartoning machines market is segmented by horizontal and vertical orientations. Horizontal machines dominate due to their efficiency in handling high-speed production lines and compatibility with diverse carton formats. Vertical machines find demand in specific applications where space optimization and product type require vertical loading. It highlights the market’s adaptability in meeting the varied operational requirements of manufacturers across industries.

- For instance, Multivac wrap-around packaging line integrates both horizontal and vertical orientation, achieving an output of 150 cartons per minute, effectively addressing diverse product specifications and operational constraints.

By Capacity:

Segmentation by capacity includes machines designed for low, medium, and high-speed operations. High-capacity machines hold the largest share due to rising demand for mass production in food, beverage, and pharmaceutical sectors. Medium-capacity machines are preferred by mid-sized manufacturers seeking a balance of speed and cost efficiency. Low-capacity models continue to serve small-scale enterprises and niche product packaging. It reflects the market’s ability to address both large-scale industrial operations and smaller production needs.

- For example, Tetra Pak’s medium-speed aseptic filling machines process about 600 packages per minute, enabling mid-sized dairy producers to optimize both operational costs and output.

By End Use:

End-use segmentation includes food, beverages, pharmaceuticals, personal care, and other consumer goods. The food and beverage segment leads the Wrap around cartoning machines market, driven by global consumption of packaged goods and strict quality requirements. Pharmaceutical companies are rapidly adopting these machines to ensure precision, safety, and compliance. Personal care and household product industries are also increasing adoption to improve packaging efficiency and product presentation. It demonstrates the machine’s versatility in serving multiple industries with distinct packaging standards.

Segmentations:

By Orientation:

By Capacity:

- Low Capacity

- Medium Capacity

- High Capacity

By End Use:

- Food

- Beverages

- Pharmaceuticals

- Personal Care

- Household Products

- Others

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Europe and North America:

Europe holds 34% market share in the Wrap around cartoning machines market, while North America accounts for 28% market share. Both regions benefit from advanced manufacturing infrastructure, strict regulatory frameworks, and early adoption of automation technologies. The food, beverage, and pharmaceutical industries are key contributors, driving steady demand for efficient and reliable cartoning systems. It reflects the growing emphasis on sustainability, with companies seeking eco-friendly machine designs that reduce waste and energy consumption. Strong presence of global packaging equipment manufacturers in these regions further strengthens innovation and service capabilities. Continuous investments in R&D and Industry 4.0 integration ensure that Europe and North America remain leaders in high-value packaging solutions.

Asia-Pacific:

Asia-Pacific commands 26% market share in the Wrap around cartoning machines market, supported by strong growth in China, India, and Southeast Asian countries. The rising middle-class population and expanding urbanization drive higher consumption of packaged food, beverages, and personal care products. It creates a strong need for advanced packaging equipment to meet increasing production volumes. Regional manufacturers are investing in automation to remain competitive, while global players expand their presence to capture local demand. Government programs promoting manufacturing modernization also accelerate adoption. Asia-Pacific is expected to record the fastest growth, fueled by large-scale industrial expansion and export-oriented production.

Latin America and the Middle East & Africa:

Latin America holds 7% market share in the Wrap around cartoning machines market, while the Middle East & Africa capture 5% market share. These regions are witnessing rising demand for packaged goods due to expanding retail, e-commerce, and pharmaceutical sectors. It highlights opportunities for machine suppliers to introduce cost-effective and compact models suited to regional needs. Local manufacturers are gradually shifting from manual to automated packaging solutions to improve efficiency and quality. Infrastructure development and foreign investments in food and beverage industries further drive growth potential. Though adoption levels remain lower than other regions, increasing modernization and rising consumer demand position these markets as promising growth frontiers.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Mpac Group plc.

- SHIBUYA CORPORATION

- I.M.A. INDUSTRIA MACCHINE AUTOMATICHE S.P.A.

- Omori Machinery Co. Ltd.

- OPTIMA packaging group GmbH

- Coesia S.p.A.

- HANGZHOU YOUNGSUN INTELLIGENT EQUIPMENT CO., LTD

- Syntegon Technology GmbH

- Cama Group

- Douglas Machine Inc.

- Jacob White Packaging Ltd.

- Econocorp Inc.

Competitive Analysis:

Competitive Analysis

The Wrap around cartoning machines market is characterized by strong competition among global leaders and regional players, with a focus on automation, flexibility, and sustainability. Companies such as Mpac Group plc, SHIBUYA CORPORATION, and I.M.A. Industria Macchine Automatiche S.p.A. emphasize advanced engineering to deliver high-speed and reliable systems. Omori Machinery Co. Ltd. and OPTIMA packaging group GmbH strengthen their market position through innovation in modular and customizable designs. Coesia S.p.A. and Syntegon Technology GmbH leverage their global presence and R&D capabilities to expand across industries, particularly in food, beverage, and pharmaceuticals. Hangzhou Youngsun Intelligent Equipment Co., Ltd enhances competitiveness by offering cost-efficient solutions tailored for emerging markets. It reflects a balanced landscape where technology leadership, after-sales service, and sustainable machine designs are the key differentiators. Strategic collaborations, product innovation, and regional expansion continue to shape the competitive dynamics of this market.

Recent Developments:

- In May 2024, Mpac Group plc launched HORIZON, a robotic top load cartoning platform designed for modularity and flexibility across industries.

- In November 2024, IMA Life, part of the IMA Group, announced a strategic partnership with RheaVita to drive further technological development and commercial growth.

- In May 2025, OPTIMA packaging group GmbH joined as a new strategic investor in PulPac, a company specializing in sustainable Dry Molded Fiber technology.

Market Concentration & Characteristics:

The Wrap around cartoning machines market is moderately concentrated, with a mix of global leaders and regional players competing on technology, efficiency, and service offerings. It is characterized by strong demand from food, beverage, and pharmaceutical industries, where high-speed and reliable packaging is essential. Leading manufacturers focus on advanced automation, energy efficiency, and flexibility to handle diverse carton formats. Regional companies emphasize cost-effective solutions tailored to local production needs, which creates a balanced competitive environment. Continuous innovation in smart technologies, sustainability, and modular machine designs defines the market’s evolving landscape. Competitive differentiation often depends on after-sales support, customization, and integration capabilities, making service excellence a critical success factor.

Report Coverage:

The research report offers an in-depth analysis based on Orientation, Capacity, End Use and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- The Wrap around cartoning machines market will expand steadily, supported by rising global demand for packaged food, beverages, and pharmaceuticals.

- Manufacturers will prioritize automation and digital integration to enhance production efficiency and reduce downtime.

- Sustainability will shape future machine designs, with emphasis on recyclable materials and energy-efficient operations.

- The demand for flexible machines capable of handling multiple carton sizes will increase as product diversification grows.

- Adoption of smart technologies such as IoT, AI-driven monitoring, and predictive maintenance will accelerate across industries.

- Regional growth in Asia-Pacific and Latin America will create opportunities for global players to expand their presence.

- Partnerships between equipment suppliers and end users will rise, focusing on tailored solutions for specific industry needs.

- Compact and cost-effective models will gain traction among small and medium-sized manufacturers in emerging economies.

- The rise of e-commerce and retail distribution will fuel demand for durable, high-quality packaging systems.

- Continuous innovation in machine control systems and robotics will define competitiveness, enabling higher speed and greater precision.