Market Overview:

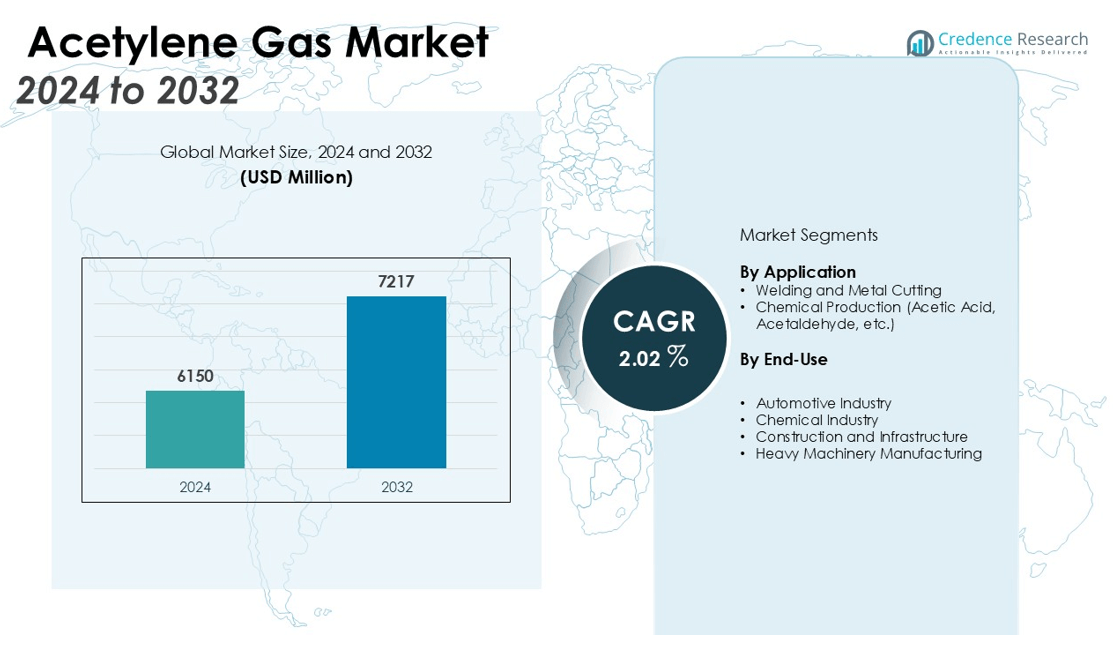

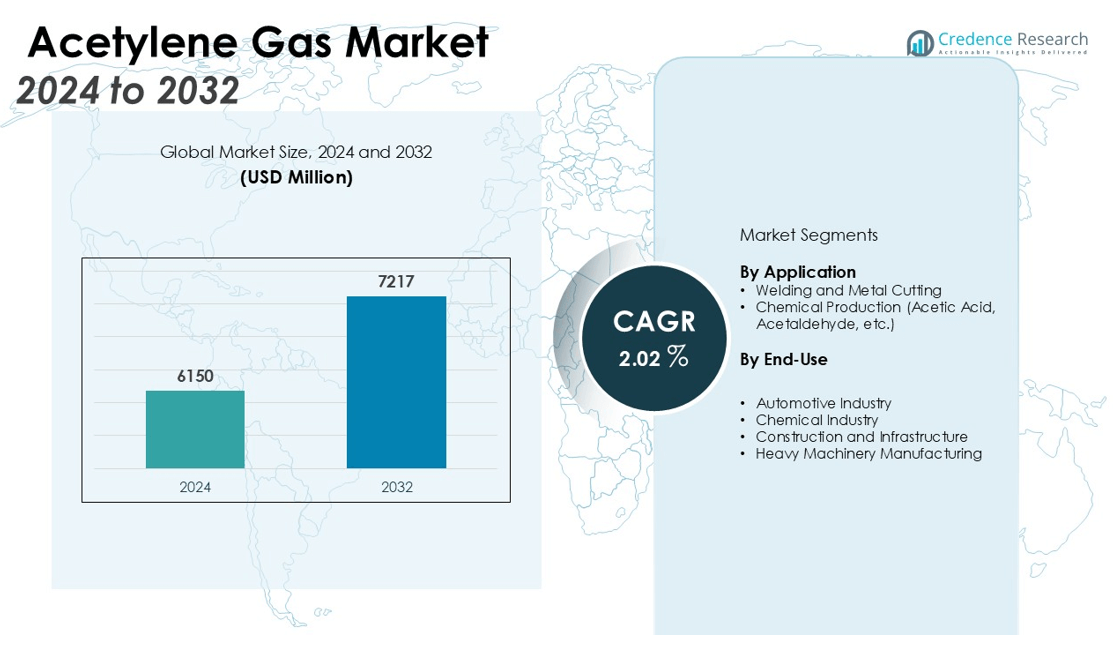

The Acetylene Gas Market size was valued at USD 6150 million in 2024 and is anticipated to reach USD 7217 million by 2032, at a CAGR of 2.02% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Acetylene Gas Market Size 2024 |

USD 6150 million |

| Acetylene Gas Market, CAGR |

2.02% |

| Acetylene Gas Market Size 2032 |

USD 7217 million |

Key drivers of the Acetylene Gas Market include the rise in industrial applications, particularly in welding and metal cutting operations. The demand for acetylene in the production of chemicals like acetic acid and acetaldehyde is also boosting market growth. Furthermore, acetylene’s use as a key component in the production of synthetic materials, including plastics and rubber, supports its ongoing demand across multiple sectors. The growing trend toward automation and precision manufacturing also contributes to acetylene’s increased usage in various industries.

Regionally, North America holds the largest market share, driven by a robust industrial base in the United States, where acetylene is widely used in automotive and chemical manufacturing. The Asia-Pacific region is expected to exhibit the highest growth rate, attributed to rapid industrialization and the growing demand for acetylene in emerging economies like China and India. The increasing number of infrastructure projects and expanding manufacturing sectors in the region are expected to further accelerate market growth. Additionally, the surge in renewable energy projects in Asia-Pacific is also likely to boost the demand for acetylene in welding and construction applications.

Market Insights:

- The Acetylene Gas Market is driven by its widespread use in welding and metal cutting, with growing demand in automotive, construction, and metalworking industries.

- Acetylene’s role in producing chemicals like acetic acid and acetaldehyde supports its demand in global chemical production, particularly for plastics and solvents.

- Acetylene’s importance in producing synthetic materials such as plastics and rubber drives its growth in sectors like automotive, electronics, and construction.

- North America holds the largest market share due to strong demand in automotive and chemical sectors, while Asia-Pacific is poised for the highest growth rate driven by industrialization.

- Safety concerns and strict regulations surrounding acetylene’s production and transportation increase operational costs and can slow market growth.

- Supply chain disruptions and production limitations, including raw material shortages and transportation challenges, affect acetylene availability and market efficiency.

- North America holds 30%, Europe 25%, and Asia-Pacific 40% of the global acetylene market share, with expanding industrial sectors in these regions driving future growth.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Industrial Applications Drive Acetylene Gas Market Demand

The Acetylene Gas Market is significantly fueled by its widespread use in industrial applications, particularly in welding and metal cutting. Acetylene is an ideal fuel for oxy-acetylene welding due to its high flame temperature, making it essential for manufacturing and metalworking industries. The increasing demand for precision welding and cutting in sectors like automotive, construction, and heavy machinery is directly contributing to the market’s expansion. This demand is expected to continue rising as industrial sectors evolve and require advanced welding technologies.

- For instance, Air Liquide showcases its acetylene-oxygen combination that achieves a flame temperature of over 3150°C, providing optimal localized heating for high-precision industrial welding and cutting applications.

Growth in Chemical Production Boosts Acetylene Gas Market

Acetylene plays a crucial role in the production of various chemicals, including acetic acid and acetaldehyde, which are essential in the manufacture of plastics, solvents, and other industrial chemicals. The global rise in chemical manufacturing and petrochemical industries is boosting acetylene demand. Its use as a raw material in the synthesis of vital chemicals supports its market position, especially as industries scale their production to meet increasing consumer demand for chemicals in various applications.

- For instance, the chemical company BASF operates a new acetylene plant at its Ludwigshafen site with the capacity to produce 90,000 metric tons of acetylene per year.

Demand for Synthetic Materials Spurs Market Expansion

Acetylene’s importance in producing synthetic materials like plastics and rubber drives significant growth in its market. These materials are essential in several sectors, including automotive, electronics, and construction. The increasing need for lightweight, durable, and flexible materials has bolstered acetylene’s use in the manufacturing of synthetic polymers. The rapid industrialization of emerging economies further accelerates its demand in these applications.

Regional Industrial Growth and Infrastructure Development

The expanding industrial and manufacturing sectors, particularly in North America and Asia-Pacific, significantly influence the acetylene market. North America remains the largest market for acetylene, with high usage in the automotive and chemical industries. The Asia-Pacific region is expected to experience rapid growth due to increasing infrastructure projects, industrialization, and a high demand for acetylene in developing economies like China and India. This growth is supported by the expanding construction, automotive, and manufacturing industries, further driving the market’s potential.

Market Trends:

Technological Advancements Enhance Acetylene Gas Production and Application

The Acetylene Gas Market is experiencing significant growth due to continuous advancements in production technologies. Innovations such as on-site generation systems are gaining traction, offering industries increased safety and cost-efficiency by reducing transportation risks associated with acetylene cylinders. These systems are particularly beneficial in remote locations and large-scale industrial operations, where centralized gas supply may be challenging. Furthermore, the integration of automation and sensor technologies in acetylene dispensing and monitoring systems is improving operational efficiency and safety standards across various applications.

- For instance, iGAS Technology Solutions developed a mobile on-site acetylene generation system for an offshore vessel that produces a continuous supply of 8kg of acetylene per hour, eliminating the dependency on traditional cylinder supplies.

Rising Demand from Emerging Economies Drives Market Expansion

Emerging economies, especially in the Asia-Pacific region, are significantly contributing to the growth of the Acetylene Gas Market. Countries like China and India are witnessing rapid industrialization, leading to increased demand for acetylene in sectors such as metal fabrication, chemical manufacturing, and construction. The expansion of infrastructure projects and the automotive industry in these regions are further propelling the need for acetylene gas. This surge is not only boosting market revenues but also encouraging investments in production facilities and distribution networks to meet the escalating demand.

- For instance, the scale of acetylene use in China’s chemical sector is demonstrated by facilities such as the Yushe Chemical Industry complex, which can produce 400,000 metric tons of PVC annually using acetylene as a primary feedstock.

Market Challenges Analysis:

Safety Concerns and Regulatory Challenges in Acetylene Gas Market

One of the primary challenges facing the Acetylene Gas Market is safety concerns. Acetylene is highly flammable and can be dangerous if not handled properly, posing risks during storage, transportation, and usage. Strict regulations around the manufacturing, storage, and transportation of acetylene increase operational costs for suppliers. Compliance with these safety regulations can also slow down the growth of the market, as industries must invest in specialized storage equipment, safety measures, and regular inspections. These safety issues may also lead to delays in the supply chain, affecting the timely delivery of acetylene.

Supply Chain and Production Limitations Impacting Market Growth

The Acetylene Gas Market faces challenges related to supply chain disruptions and production limitations. The gas is produced via complex chemical processes, requiring high infrastructure investment. Any disruptions in the production process, such as equipment breakdowns or shortage of raw materials, can impact acetylene availability. Additionally, the logistical costs of transporting acetylene to remote or large-scale industrial operations can be substantial, leading to market inefficiencies. These production and supply chain issues contribute to price volatility, which affects both producers and end-users of acetylene gas.

Market Opportunities:

Expansion of Industrial Applications Opens Opportunities in Acetylene Gas Market

The growing demand for acetylene in various industrial applications presents significant opportunities for market expansion. Industries such as automotive, construction, and metalworking increasingly rely on acetylene for welding, cutting, and manufacturing processes. As sectors adopt advanced technologies and increase their production capacities, the need for high-quality acetylene gas is expected to rise. This trend provides opportunities for manufacturers to innovate, introduce efficient production systems, and capture a larger share of the market. Expanding into emerging markets with high industrial growth further strengthens these opportunities, especially in regions like Asia-Pacific.

Sustainability Trends Create New Prospects for Acetylene Gas Market

Sustainability trends in manufacturing and infrastructure development offer new growth avenues for the Acetylene Gas Market. The push for greener, more energy-efficient industrial practices has led to an increased focus on reducing emissions in the manufacturing process. Acetylene’s ability to offer high energy output with relatively low carbon emissions positions it as a preferred choice for industries looking to meet stringent environmental regulations. Companies investing in cleaner, more sustainable technologies can capitalize on this opportunity by developing eco-friendly acetylene production methods and meeting the rising demand for sustainable solutions across global markets.

Market Segmentation Analysis:

By Application

The Acetylene Gas Market is primarily driven by its use in welding and metal cutting due to its high flame temperature, which makes it an ideal fuel for oxy-acetylene welding. This application leads the market, with significant demand from industries such as automotive, construction, and heavy machinery. Acetylene is also widely used in chemical production, especially in the manufacture of acetic acid and acetaldehyde, which further supports its market presence in plastics and solvents.

- For instance, oxy-acetylene welding technology, developed by French engineers Edmond Fouché and Charles Picard in 1903, revolutionized metal fabrication by achieving flame temperatures up to 3,500°C, sufficient to melt most common metals like steel.

By End-Use

The automotive industry holds the largest share of the acetylene market, utilizing acetylene for welding, cutting, and metalworking operations. The chemical industry follows closely, where acetylene is used as a raw material in producing various chemicals, including plastics, rubber, and solvents. Acetylene’s critical role in precision manufacturing and the growing demand for durable synthetic materials continue to boost its consumption across these industries. Furthermore, infrastructure and construction projects, particularly in emerging economies, are expected to further accelerate acetylene demand in the coming years.

- For instance, supporting the chemical industry, Shintech’s expansion in Plaquemine, Louisiana, included a new plant designed to produce 800,000 tons per year of vinyl chloride monomer, a key chemical derived from acetylene.

Segmentations:

By Application

- Welding and Metal Cutting

- Chemical Production (Acetic Acid, Acetaldehyde, etc.)

By End-Use

- Automotive Industry

- Chemical Industry

- Construction and Infrastructure

- Heavy Machinery Manufacturing

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

North America: Dominant Market Share Driven by Industrial Growth and Advanced Manufacturing

North America accounts for 30% of the global Acetylene Gas Market, with the United States being the dominant contributor. The region’s demand is driven by advanced industrial infrastructure, particularly in sectors such as chemicals, pharmaceuticals, and automotive. The increasing use of acetylene in welding and cutting processes, especially in construction and automotive manufacturing, further boosts market growth. It is expected that the market will continue to expand due to high manufacturing activities in the region, sustaining demand across various applications.

Europe: Strong Demand in Industrial Sectors, Including Automotive and Aerospace

Europe holds a 25% share of the global Acetylene Gas Market, with key players in countries such as Germany, France, and the United Kingdom. The demand for acetylene is significant in industrial applications, including metal cutting, welding, and chemical synthesis. The growth of automotive and aerospace industries contributes to this demand, as acetylene is crucial in precision welding and cutting processes. It is anticipated that the region’s industrial development and focus on advanced technologies will continue to drive acetylene demand in the near future.

Asia-Pacific: Rapid Industrialization and Growing Demand from Key Sectors

The Asia-Pacific region holds 40% of the global Acetylene Gas Market, with China, India, and Japan being major consumers. The rapid industrialization and rising demand from sectors such as automotive, steel, and chemicals are fueling market growth. Acetylene is increasingly used in welding and cutting applications, supporting infrastructure and metal fabrication projects. It is expected that the region will experience the highest growth rate due to expanding industrial activities and large-scale infrastructure projects.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Linde Group

- Toho Acetylene

- BASF SE

- SINOPEC

- Airgas

- Gulf Cyro

- China Petroleum and Chemical Corporation

- Sichuan Vinylon

- Praxair Technology Inc.

- Dow Chemical Company

Competitive Analysis:

The Acetylene Gas Market is highly competitive, with numerous global and regional players vying for market share. Key players in the market include major gas manufacturers such as Air Liquide, Linde Group, Praxair, and Messer Group. These companies dominate the market due to their extensive distribution networks, advanced technologies, and strong customer bases across various industries. Competition is driven by factors such as product quality, pricing strategies, and the ability to meet the growing demand from sectors like automotive, chemical, and construction. Innovation in production processes and the ability to offer customized acetylene solutions to meet specific industrial needs also play a critical role in maintaining a competitive edge. Market players are also focusing on expanding their presence in emerging markets, particularly in the Asia-Pacific region, where industrial growth is accelerating, thus providing significant growth opportunities for acetylene producers.

Recent Developments:

- In July 2024, BASF announced the expansion of its Xitavo soybean seed portfolio by adding 19 new products for the 2025 growing season.

- In April 2025, BASF and Mingyang announced a collaboration to develop advanced materials and technical solutions for Power-to-X projects.

- In February 2025, Linde announced it had secured a record number of new small on-site projects in 2024, signing 59 new long-term agreements to supply nitrogen and oxygen.

Market Concentration & Characteristics:

The Acetylene Gas Market exhibits moderate concentration, with a few major players holding significant market share, including companies like Air Liquide, Linde Group, and Praxair. These key players dominate due to their extensive global reach, advanced production capabilities, and well-established distribution networks. The market is characterized by a high level of competition, driven by technological advancements, pricing strategies, and customer demand across various sectors such as automotive, chemicals, and construction. Smaller regional players also contribute to the market dynamics by offering specialized services and tailored solutions. The ongoing industrialization in emerging economies, particularly in the Asia-Pacific region, is reshaping the competitive landscape by providing new opportunities for both large and small-scale producers. The Acetylene Gas Market’s growth is thus influenced by both the established leaders and the emerging players who cater to localized needs.

Report Coverage:

The research report offers an in-depth analysis based on Application, End-Use and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The global Acetylene Gas Market is expected to experience steady growth driven by increasing demand across various industrial applications.

- Welding and metal cutting remain the dominant applications, particularly in automotive, construction, and heavy machinery sectors.

- The chemical industry will continue to be a significant consumer, utilizing acetylene in the production of chemicals like acetic acid and acetaldehyde.

- The Asia-Pacific region is set to experience the highest growth rate, fueled by rapid industrialization and infrastructure development, especially in China and India.

- North America and Europe will show steady growth, supported by established industrial bases and advancements in technology.

- Advancements in production technologies, such as hydrocarbon pyrolysis, will enhance efficiency and reduce environmental impact in the market.

- The adoption of acetylene in renewable energy applications, such as fuel cells and power generation, is gaining attention.

- Evolving safety and regulatory standards will continue to influence acetylene production and distribution practices.

- The market remains moderately concentrated, with leading players such as Air Liquide, Linde Group, and Praxair maintaining a significant share.

- Ongoing research and development efforts will explore new applications for acetylene and improve production methods, ensuring sustained market growth.