Market Overview

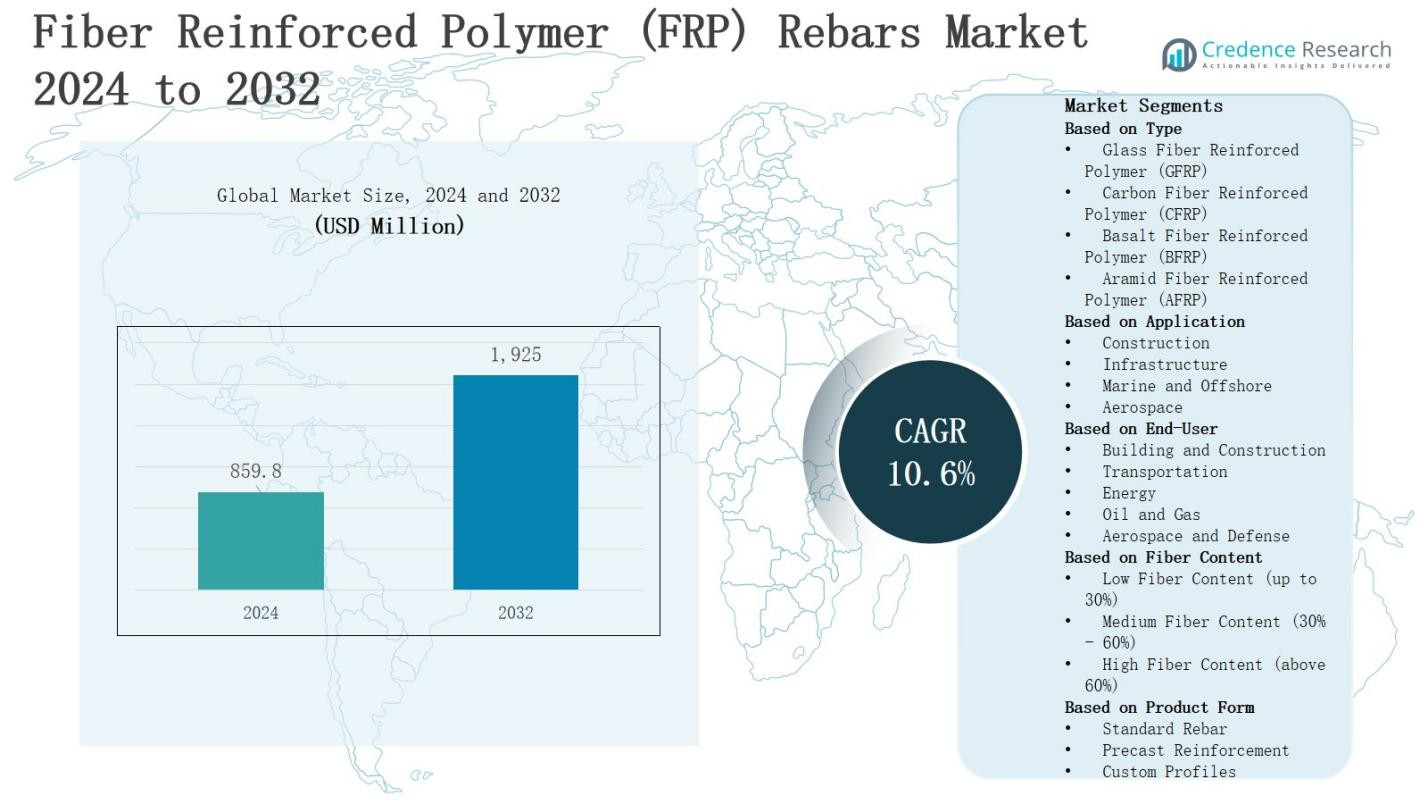

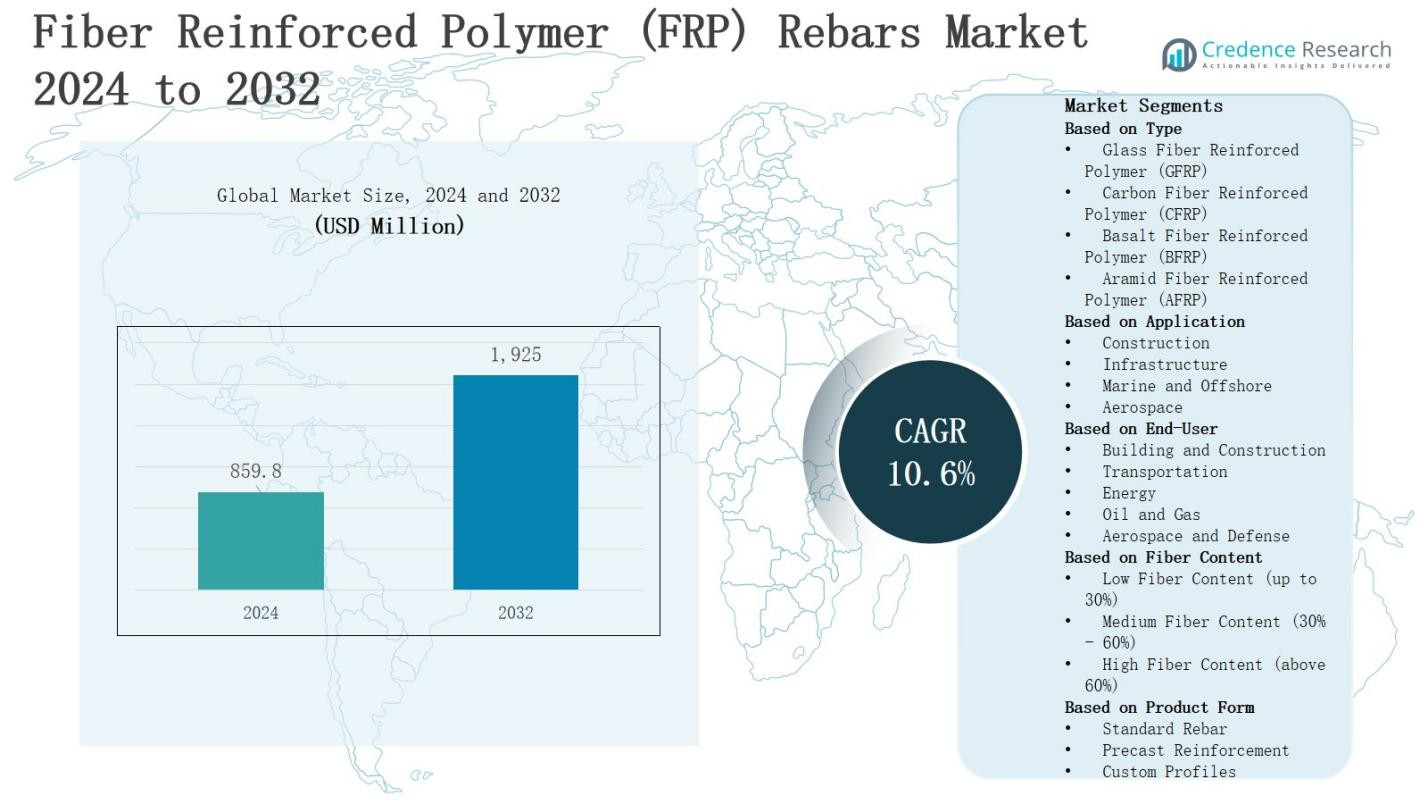

The Fiber reinforced polymer (FRP) rebars market is projected to grow from USD 859.8 million in 2024 to USD 1,925 million by 2032, registering a CAGR of 10.6% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Fiber reinforced polymer (FRP) rebars market Size 2024 |

USD 859.8 Million |

| Fiber reinforced polymer (FRP) rebars market, CAGR |

10.6% |

| Fiber reinforced polymer (FRP) rebars market Size 2032 |

USD 1,925 Million |

The fiber reinforced polymer (FRP) rebars market is driven by the rising demand for corrosion-resistant reinforcement in construction, increasing investments in infrastructure development, and the growing shift toward lightweight, high-strength materials to extend structure lifespan. Stringent regulations promoting sustainable and durable building solutions further boost adoption. Key trends include advancements in manufacturing processes for cost efficiency, integration of FRP rebars in marine and industrial structures, and the development of hybrid reinforcement systems combining FRP with traditional steel. Expanding applications in bridges, highways, and coastal projects underscore its potential to replace conventional materials in high-performance structural engineering.

The fiber reinforced polymer (FRP) rebars market spans North America, Europe, Asia-Pacific, and the Rest of the World, with North America leading through strong infrastructure investment, followed by Asia-Pacific’s rapid urbanization and Europe’s focus on sustainable materials. The Rest of the World, including Latin America, the Middle East, and Africa, shows steady growth through infrastructure modernization. Key players include Owens Corning, Schoeck International, Dextra Group, Pultron Composites, Pultrall, Sireg Spa, Kodiac Fiberglass Rebar, Marshall Composite Technologies, A.T.P Srl, Al-Arfaj Group, Fibrolux GmbH, and Internatio.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The fiber reinforced polymer (FRP) rebars market is projected to grow from USD 859.8 million in 2024 to USD 1,925 million by 2032, at a CAGR of 10.6%.

- Rising demand for corrosion-resistant reinforcement in construction and marine sectors is driving adoption, supported by its durability, lightweight properties, and low maintenance needs.

- Large-scale infrastructure projects, including bridges, highways, and metro systems, are increasing usage due to FRP’s high tensile strength and ease of installation.

- Advancements in resin systems, fiber alignment, and automated manufacturing are improving performance, cost efficiency, and customization.

- Challenges include high initial costs, limited economies of scale, and lack of global standardization in design codes and installation guidelines.

- North America leads with 32% share, followed by Asia-Pacific at 29%, Europe at 27%, and Rest of the World at 12%.

- Key players include Owens Corning, Schoeck International, Dextra Group, Pultron Composites, Pultrall, Sireg Spa, Kodiac Fiberglass Rebar, Marshall Composite Technologies, A.T.P Srl, Al-Arfaj Group, Fibrolux GmbH, and Internatio.

Market Drivers

Rising Demand for Corrosion-Resistant Reinforcement Solutions

The fiber reinforced polymer (FRP) rebars market benefits from increasing demand for corrosion-resistant alternatives to traditional steel reinforcement, particularly in marine, coastal, and industrial infrastructure. It offers superior durability in aggressive environments, reducing maintenance costs and extending service life. Growing awareness among engineers and contractors about its non-conductive and non-magnetic properties is boosting adoption. Governments and private developers are prioritizing materials that ensure structural longevity and safety in challenging conditions.

- For instance, FIBAR India extensively used GFRP rebars in the construction of the Indian Institute of Technology Hyderabad campus. This choice improved the structure’s resistance to corrosion in the humid Indian climate while also reducing carbon footprint and maintenance needs, supporting sustainable infrastructure development goals.

Expansion of Infrastructure Development Projects

Rapid urbanization and industrialization are creating sustained demand for advanced construction materials. The fiber reinforced polymer (FRP) rebars market is gaining traction in large-scale infrastructure projects such as highways, bridges, metro systems, and high-rise buildings. It delivers high tensile strength and lightweight benefits, enabling efficient handling and installation. Public and private investments in sustainable and resilient infrastructure are encouraging adoption, especially in regions with harsh climates and high corrosion risks.

- For instance, Jindal Advanced Materials reports that their FRP rebars provide superior tensile strength to traditional steel rebars while being over three times lighter, making them ideal for metro system construction and reducing dead load in buildings.

Shift Toward Sustainable and Lightweight Construction Materials

The global push for eco-friendly construction materials is influencing procurement strategies across the building sector. The fiber reinforced polymer (FRP) rebars market is supported by its lower environmental impact compared to steel, due to reduced maintenance needs and longer service life. It contributes to lighter structures without compromising strength, improving overall efficiency. Sustainability certifications and green building initiatives are further accelerating its integration in commercial, industrial, and public infrastructure projects worldwide.

Advancements in Manufacturing and Design Technology

Technological innovations in FRP production are enhancing performance, cost-efficiency, and customization options. The fiber reinforced polymer (FRP) rebars market benefits from improvements in resin systems, fiber alignment, and automated manufacturing processes that ensure consistent quality. It allows for tailored designs to meet specific engineering requirements, increasing its suitability for diverse applications. These advancements are reducing price gaps with steel, making FRP rebars more competitive and accessible for widespread use in construction sectors.

Market Trends

Growing Adoption in Transportation and Marine Infrastructure

The fiber reinforced polymer (FRP) rebars market is witnessing increasing integration in transportation and marine infrastructure due to its high corrosion resistance and lightweight nature. It is being deployed in bridges, coastal piers, and port facilities to enhance structural longevity under harsh environmental conditions. Engineers are leveraging FRP rebars to reduce maintenance costs and improve load-bearing capacity. Rising investments in transport connectivity and coastal protection are expanding its role in high-performance, long-life infrastructure projects globally.

- For instance, the Florida Department of Transportation (FDOT) has incorporated glass, basalt, and carbon FRP rebars in bridge decks, approach slabs, and prestressed concrete piles to combat corrosion in aggressive marine environments, boosting durability and reducing long-term repair expenses.

Integration with Hybrid Reinforcement Systems

A notable trend in the fiber reinforced polymer (FRP) rebars market is the development of hybrid reinforcement systems that combine FRP with conventional steel. This approach allows structures to benefit from both the corrosion resistance of FRP and the cost efficiency of steel. It is gaining traction in large-scale projects where selective reinforcement optimizes structural performance. Contractors and designers are increasingly specifying hybrid systems to achieve balance between durability, structural integrity, and project budget targets.

- For instance, Leung and Balendran’s research demonstrated that hybrid concrete beams reinforced with both steel and GFRP bars exhibited improved flexural capacity and contributed to better failure patterns, making hybrid reinforcement attractive for structural designs requiring enhanced performance.

Advances in Material Technology and Production Efficiency

Innovations in resin chemistry, fiber orientation, and automated manufacturing are significantly improving the mechanical properties and cost competitiveness of FRP rebars. The fiber reinforced polymer (FRP) rebars market is benefiting from production techniques that enhance tensile strength, bonding performance, and quality consistency. It is enabling broader customization to meet diverse application requirements in civil engineering. Improved scalability of manufacturing is supporting greater market penetration, particularly in regions with high infrastructure growth potential.

Expansion into Residential and Commercial Construction

The application of FRP rebars is expanding beyond industrial and infrastructure projects into residential and commercial construction. The fiber reinforced polymer (FRP) rebars market is gaining visibility among architects and builders seeking materials that meet green building standards and long-term durability goals. It is used in foundations, slabs, and structural walls to minimize lifecycle costs. Increasing awareness of its performance advantages is driving demand in private sector developments and urban redevelopment projects worldwide.

Market Challenges Analysis

High Initial Costs and Limited Price Competitiveness

The fiber reinforced polymer (FRP) rebars market faces challenges due to its higher upfront costs compared to traditional steel reinforcement. It requires advanced manufacturing processes and specialized raw materials, which increase production expenses. Many construction projects, particularly in cost-sensitive markets, prioritize immediate budget constraints over long-term savings. Limited economies of scale and slower adoption rates restrict the ability to reduce prices significantly. This cost disparity can hinder penetration in markets where cost efficiency is the primary procurement driver.

Lack of Standardization and Technical Awareness

The fiber reinforced polymer (FRP) rebars market is also constrained by insufficient global standardization in design codes, testing methods, and installation guidelines. It leads to hesitation among engineers, architects, and contractors who are more familiar with conventional materials. Limited technical knowledge about FRP’s long-term performance, load behavior, and compatibility with existing construction practices slows adoption. Inconsistent regulations across regions create uncertainty for suppliers and project planners. Expanding education, training, and industry-wide standards is essential to improve confidence and accelerate usage.

Market Opportunities

Rising Demand from Sustainable Infrastructure Development

The fiber reinforced polymer (FRP) rebars market has significant opportunities in sustainable infrastructure projects driven by global commitments to reduce carbon footprints and extend asset lifecycles. It offers corrosion resistance, lightweight properties, and reduced maintenance requirements, aligning with green building standards. Governments and private developers are investing in eco-friendly materials for bridges, highways, and coastal protection works. Increasing funding for resilient infrastructure in climate-vulnerable regions creates favorable conditions for adoption. It positions FRP rebars as a strategic material in next-generation construction.

Technological Advancements and New Application Segments

The fiber reinforced polymer (FRP) rebars market can expand through advancements in resin systems, fiber compositions, and automated manufacturing processes that improve performance and reduce production costs. It enables greater customization for specific structural requirements in industrial, commercial, and residential projects. Growth potential exists in emerging applications such as tunnel linings, offshore platforms, and earthquake-resistant structures. Collaborations between manufacturers, research institutions, and construction firms are expected to accelerate innovation. This technological progress can enhance competitiveness and broaden market penetration globally.

Market Segmentation Analysis:

By Type

The fiber reinforced polymer (FRP) rebars market is segmented into Glass Fiber Reinforced Polymer (GFRP), Carbon Fiber Reinforced Polymer (CFRP), Basalt Fiber Reinforced Polymer (BFRP), and Aramid Fiber Reinforced Polymer (AFRP). GFRP holds a major share due to its cost-effectiveness and balanced performance in construction and infrastructure projects. CFRP offers superior strength-to-weight ratio and is preferred in high-performance applications such as aerospace and defense. BFRP is gaining attention for its thermal resistance, while AFRP serves niche sectors requiring exceptional impact resistance.

- For instance, GFRP rebars are widely used in marine structures and bridges, such as a bridge in Kerala where GFRP was chosen for its corrosion resistance against the aggressive coastal climate.

By Application

In terms of application, the fiber reinforced polymer (FRP) rebars market covers construction, infrastructure, marine and offshore, and aerospace. Construction dominates due to rising adoption in residential, commercial, and industrial projects seeking corrosion-resistant reinforcement. Infrastructure projects, including bridges and highways, increasingly use FRP for longer service life. Marine and offshore applications benefit from its durability in saline environments, while aerospace leverages FRP’s lightweight and high-strength properties for structural efficiency and safety.

- For instance, in aerospace, companies like Boeing use carbon fiber reinforced polymers for structural components, benefiting from the material’s lightweight and high-strength properties to improve fuel efficiency and safety.

By End-User

The fiber reinforced polymer (FRP) rebars market serves building and construction, transportation, energy, oil and gas, and aerospace and defense. Building and construction lead the segment, driven by demand for sustainable and maintenance-free materials. Transportation projects use FRP for bridges, rail systems, and roads requiring high load capacity. Energy and oil and gas sectors integrate FRP in facilities exposed to harsh conditions, while aerospace and defense prioritize its performance advantages in mission-critical structures and components.

Segments:

Based on Type

- Glass Fiber Reinforced Polymer (GFRP)

- Carbon Fiber Reinforced Polymer (CFRP)

- Basalt Fiber Reinforced Polymer (BFRP)

- Aramid Fiber Reinforced Polymer (AFRP)

Based on Application

- Construction

- Infrastructure

- Marine and Offshore

- Aerospace

Based on End-User

- Building and Construction

- Transportation

- Energy

- Oil and Gas

- Aerospace and Defense

Based on Fiber Content

- Low Fiber Content (up to 30%)

- Medium Fiber Content (30% – 60%)

- High Fiber Content (above 60%)

Based on Product Form

- Standard Rebar

- Precast Reinforcement

- Custom Profiles

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America holds 32% share of the fiber reinforced polymer (FRP) rebars market, supported by advanced construction practices, strong infrastructure investment, and strict durability standards. The United States leads adoption due to large-scale bridge rehabilitation programs and coastal protection initiatives. It benefits from a well-established supply chain, robust R&D activity, and favorable government funding for sustainable materials. Canada focuses on using FRP in transportation and marine projects to address corrosion challenges. Growing awareness among contractors and engineers is further accelerating market penetration across both nations.

Europe

Europe accounts for 27% share of the fiber reinforced polymer (FRP) rebars market, driven by stringent environmental regulations and a strong emphasis on sustainable building materials. Countries such as Germany, France, and the UK are integrating FRP in transportation, industrial, and public infrastructure projects. It supports long-term cost savings through extended service life and minimal maintenance requirements. EU-funded research programs and cross-border collaborations are promoting technological advancements. The region’s established engineering expertise strengthens its position in the global market.

Asia-Pacific

Asia-Pacific commands 29% share of the fiber reinforced polymer (FRP) rebars market, fueled by rapid urbanization, infrastructure expansion, and government-led modernization initiatives. China, Japan, and India lead consumption, with high adoption in bridges, metro networks, and coastal developments. It benefits from lower manufacturing costs and increasing domestic production capacity. Public infrastructure investments and smart city projects are boosting demand. Rising acceptance of FRP in high-strength applications is positioning the region as a key growth hub.

Rest of the World

The Rest of the World holds 12% share of the fiber reinforced polymer (FRP) rebars market, encompassing Latin America, the Middle East, and Africa. The Middle East is investing in corrosion-resistant materials for oil and gas infrastructure and coastal projects. Latin America is expanding adoption in transportation and energy sectors, especially in Brazil and Mexico. Africa shows gradual growth through donor-funded infrastructure projects. It benefits from increasing interest in lightweight, high-performance reinforcement solutions to meet long-term structural needs.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

Competitive Analysis

The fiber reinforced polymer (FRP) rebars market is characterized by a competitive landscape where global and regional players focus on product innovation, capacity expansion, and strategic partnerships to strengthen their market presence. Key companies such as Owens Corning, Schoeck International, Dextra Group, Pultron Composites, Pultrall, Sireg Spa, Kodiac Fiberglass Rebar, Marshall Composite Technologies, A.T.P Srl, Al-Arfaj Group, Fibrolux GmbH, and Internatio compete by offering diverse product portfolios tailored to infrastructure, construction, and marine applications. It emphasizes advancements in resin technology, fiber alignment, and automated manufacturing to improve strength, durability, and cost efficiency. Market leaders leverage their global distribution networks and technical expertise to secure large-scale contracts in transportation, energy, and industrial projects, while emerging players target niche applications to gain a competitive edge. Strategic collaborations with engineering firms, adherence to international quality standards, and investments in R&D remain crucial for sustaining growth and expanding market reach across regions.

Recent Developments

- In March 2023, Schoeck Bauteile GmbH introduced a new FRP rebar product to expand its portfolio and meet growing demand for advanced reinforcement solutions.

- In April 2025, MEIL Group entity Olectra entered the construction materials segment with the launch of a glass fiber reinforced polymer (GFRP) rebar, offering a durable and corrosion-resistant alternative to conventional steel reinforcement.

- In July 2025, Hughes Brothers introduced a next-generation FRP rebar incorporating carbon fiber technology, delivering enhanced strength and flexibility for demanding infrastructure projects.

- In 2025, Pultron Composites unveiled a marine-grade FRP rebar with improved corrosion resistance, ideal for applications exposed to saltwater and extreme stress environments.

Market Concentration & Characteristics

The fiber reinforced polymer (FRP) rebars market exhibits moderate to high concentration, with a mix of established global manufacturers and specialized regional producers. It is defined by strong competition among key players such as Owens Corning, Schoeck International, Dextra Group, Pultron Composites, Pultrall, and Sireg Spa, who leverage technological expertise, diversified product portfolios, and extensive distribution networks. The market is characterized by continuous innovation in resin systems, fiber compositions, and automated manufacturing processes to enhance performance, cost efficiency, and customization. It serves diverse end-use sectors, including construction, infrastructure, marine, energy, and aerospace, where corrosion resistance, high strength-to-weight ratio, and long service life are critical. Regulatory support for sustainable building practices, combined with rising infrastructure investments, is reinforcing its growth potential. Strategic partnerships, adherence to international quality standards, and capacity expansion are key competitive strategies adopted to strengthen market positioning and expand penetration across developed and emerging economies.

Report Coverage

The research report offers an in-depth analysis based on Type, Application, End-User, Fiber Content, Product Form and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Demand will rise with increasing adoption of corrosion-resistant materials in construction and infrastructure projects.

- Advancements in resin chemistry and fiber technology will improve product performance and cost efficiency.

- Integration in marine, offshore, and coastal projects will expand due to superior durability in harsh environments.

- Hybrid reinforcement systems combining FRP with steel will gain traction for optimized structural performance.

- Expansion of smart city and transportation projects will boost large-scale application.

- Standardization of design codes and testing methods will improve global adoption rates.

- Growing focus on sustainable and lightweight materials will support wider acceptance in green building projects.

- Investments in automated manufacturing will increase production capacity and reduce lead times.

- Rising use in energy, oil and gas, and industrial sectors will diversify revenue streams.

- Collaboration between manufacturers and research institutions will accelerate innovation and application development.