Market Overview:

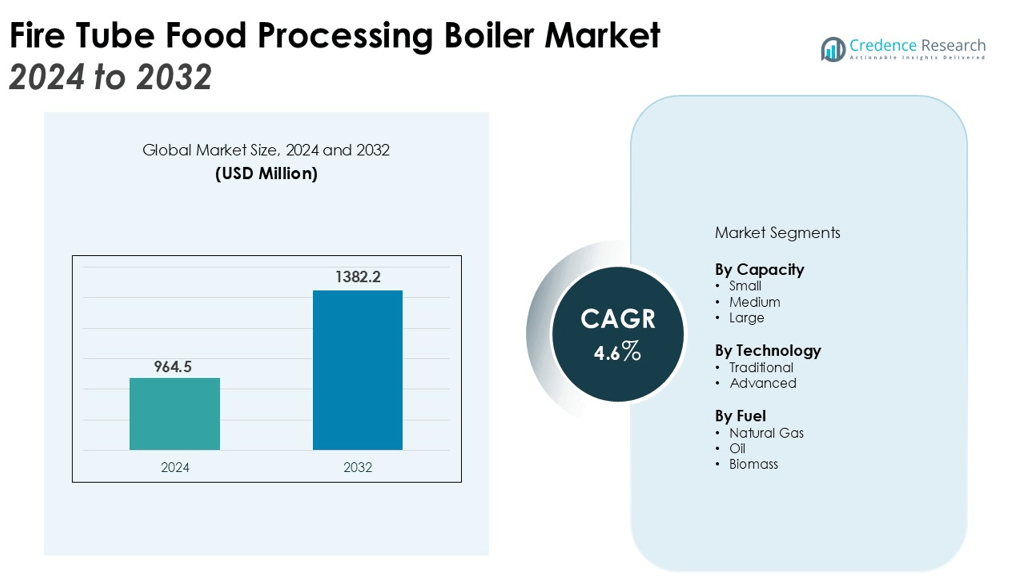

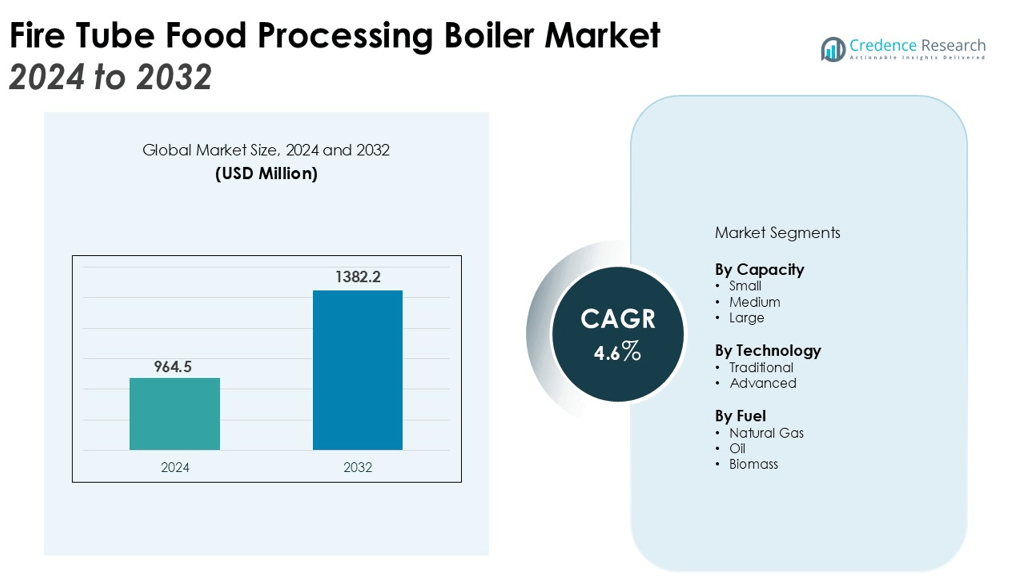

The Fire Tube Food Processing Boiler Market size was valued at USD 964.5 million in 2024 and is anticipated to reach USD 1382.2 million by 2032, at a CAGR of 4.6% during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Fire Tube Food Processing Boiler Market Size 2024 |

USD 964.5 million |

| Fire Tube Food Processing Boiler Market, CAGR |

4.6% |

| Fire Tube Food Processing Boiler Market Size 2032 |

USD 1382.2 million |

The market is driven by the rising demand for processed food globally, particularly in emerging economies. Additionally, the growing focus on sustainability and energy efficiency in industrial operations has propelled the adoption of fire tube boilers, known for their efficiency and cost-effectiveness. Technological advancements, such as automated control systems for optimized boiler operation, further contribute to the market’s growth. Strict food safety standards also drive the need for high-performance boilers to meet production requirements. The market is also supported by government initiatives and incentives aimed at promoting energy-efficient technologies in the food processing sector.

Regionally, North America and Europe dominate the market due to the established food processing sectors and stringent regulatory frameworks promoting energy-efficient systems. However, the Asia-Pacific region is expected to witness the highest growth, driven by rapid industrialization and increasing investments in the food processing industries in countries like China and India. This region’s growing focus on modernizing infrastructure and improving food safety standards boosts the demand for fire tube food processing boilers. Additionally, the expansion of food processing facilities in developing economies is further enhancing market prospects in the region.

Market Insights:

- The Fire Tube Food Processing Boiler Market was valued at USD 964.5 million in 2024 and is expected to reach USD 1382.2 million by 2032, growing at a CAGR of 4.6%.

- The rising demand for processed food globally, particularly in emerging markets, drives the need for efficient and reliable steam generation in food production.

- Energy efficiency and sustainability are key factors driving the adoption of fire tube boilers, with food processing plants seeking cost-effective and eco-friendly solutions.

- Technological advancements, such as automated control systems and improved combustion technologies, are enhancing boiler performance and operational efficiency.

- Strict food safety standards and regulations are increasing the demand for fire tube boilers to ensure compliance with sterilization, pasteurization, and other safety processes.

- North America holds 35% of the market, Europe holds 30%, and Asia-Pacific commands 25%, with the highest growth expected in Asia due to industrialization.

- The modernization of food processing infrastructure in Asia-Pacific and the increasing urbanization present significant market opportunities for fire tube boilers.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Growing Demand for Processed Food

The increasing global demand for processed food is a key driver for the Fire Tube Food Processing Boiler Market. As the food industry expands to meet the needs of a growing population, boilers that ensure efficient and reliable steam generation are in high demand. Fire tube boilers are widely used in food processing plants due to their ability to provide consistent heat and meet stringent production requirements. This trend is particularly evident in emerging markets, where rising disposable incomes and urbanization are boosting the consumption of packaged and processed food products.

- For instance, Babcock Wanson supplied its BWD30 fire tube boiler for IRC Cucina’s new central kitchen, which opened in September 2023, this system provides the large volumes of high-quality steam required for the facility’s industrial cookers.

Emphasis on Energy Efficiency and Sustainability

The growing focus on sustainability and energy efficiency is significantly impacting the Fire Tube Food Processing Boiler Market. Food processing facilities are increasingly adopting energy-efficient technologies to reduce operational costs and minimize their carbon footprint. Fire tube boilers are particularly favored for their ability to operate efficiently, lowering energy consumption and enhancing overall process performance. The adoption of these boilers aligns with global trends toward sustainability, where manufacturers seek to meet energy standards and reduce environmental impact.

Technological Advancements in Boiler Systems

Technological advancements are fueling growth in the Fire Tube Food Processing Boiler Market. Innovations such as automated control systems and improved combustion technology have enhanced the efficiency and reliability of fire tube boilers. These advancements enable better monitoring and control of boiler performance, optimizing energy usage and ensuring compliance with safety and quality standards. The increasing integration of smart technologies in industrial equipment further drives the demand for these boilers in modern food processing plants.

- For instance, the Babcock Wanson BWD series fire tube boiler incorporates a 3-pass design, this specific technological feature maximizes heat transfer from combustion gases, ensuring an efficient supply of high-quality dry steam for demanding food processing applications.

Regulatory Compliance and Food Safety Standards

Strict food safety standards are also driving the Fire Tube Food Processing Boiler Market. Governments worldwide are enforcing regulations that require food processing companies to ensure high levels of hygiene and product quality. Fire tube boilers help meet these regulations by providing consistent and reliable steam for sterilization, pasteurization, and other essential food safety processes. As food safety concerns grow, the demand for high-performance boilers to meet these stringent requirements continues to rise.

Market Trends:

Increasing Focus on Automation and Control Systems

One of the key trends in the Fire Tube Food Processing Boiler Market is the growing focus on automation and advanced control systems. Automation technologies enable food processing plants to optimize boiler performance by enhancing efficiency and minimizing human intervention. The integration of smart technologies, such as predictive maintenance systems and real-time monitoring, is becoming more common. These innovations allow for better control over steam production, improved energy management, and reduced operational downtime. As companies continue to prioritize operational efficiency, the demand for fire tube boilers equipped with automated control systems is expected to rise significantly.

- For instance, Cleaver-Brooks’ CBEX-3W firetube boiler integrates proprietary EX technology with an integral burner and economizer, generating steam up to 300 psig and offering up to 800 horsepower capacity with real-time monitoring via Prometha® IoT platform, ensuring precise control and reduced downtime.

Rising Investment in Food Processing Infrastructure

The expansion of food processing infrastructure, particularly in developing regions, is another important trend shaping the Fire Tube Food Processing Boiler Market. As countries like India, China, and Brazil experience rapid industrialization, there is a substantial increase in food production capacities. This growth requires the adoption of reliable and efficient boilers, such as fire tube systems, to meet the escalating demand for processed food. With governments encouraging investments in the food processing sector through incentives and subsidies, manufacturers are more inclined to modernize their equipment. This trend is expected to drive the adoption of fire tube boilers as part of larger industrial upgrades in these regions.Top of Form

- For instance, Bühler India’s UniLine rice mill system offers capacities up to 10 tons per hour, successfully deployed in multiple Indian food processing units to improve operational efficiency.

Market Challenges Analysis:

High Initial Investment and Maintenance Costs

One of the significant challenges in the Fire Tube Food Processing Boiler Market is the high initial investment and maintenance costs associated with these systems. While fire tube boilers are known for their efficiency, the upfront cost of installation can be substantial, especially for large-scale food processing facilities. This high capital expenditure can deter smaller manufacturers from adopting these systems. Additionally, regular maintenance is essential to ensure optimal performance, further adding to the operational costs. These financial barriers may limit the adoption of fire tube boilers, especially in cost-sensitive markets.

Stringent Regulatory Standards and Compliance Issues

The Fire Tube Food Processing Boiler Market also faces challenges related to compliance with increasingly stringent regulatory standards. Food safety regulations and environmental guidelines require manufacturers to meet specific operational criteria, which can be difficult for older boiler systems to adhere to. Retrofitting or upgrading existing boilers to comply with modern standards can be costly and complex. As governments implement tighter regulations to ensure food safety and environmental protection, companies must invest in advanced systems and technologies to meet these evolving requirements. This presents a significant challenge for manufacturers, particularly those in regions with rapidly changing compliance standards.

Market Opportunities:

Adoption of Energy-Efficient Solutions

The Fire Tube Food Processing Boiler Market presents significant opportunities through the growing demand for energy-efficient solutions. As energy costs continue to rise, food processing plants are increasingly focused on adopting technologies that reduce fuel consumption and operational expenses. Fire tube boilers, known for their energy efficiency, offer a promising solution for these facilities. The implementation of high-efficiency systems can help businesses comply with environmental regulations while improving their bottom line. With more food processing companies seeking to meet sustainability targets, the demand for energy-efficient fire tube boilers is expected to increase significantly.

Expansion in Emerging Markets

Emerging markets present a key opportunity for the Fire Tube Food Processing Boiler Market. Rapid industrialization and urbanization in regions such as Asia-Pacific, Latin America, and the Middle East are driving the growth of the food processing industry. These regions are investing heavily in modernizing their manufacturing facilities to meet rising food demand. Fire tube boilers, with their ability to deliver reliable steam and heat, are ideal for these expanding industries. As governments support infrastructure growth and food production, fire tube boilers will play a critical role in meeting these needs, opening up substantial growth opportunities for manufacturers in these regions.

Market Segmentation Analysis:

By Capacity

The Fire Tube Food Processing Boiler Market is segmented by capacity into small, medium, and large capacity boilers. Small capacity boilers are suitable for small-scale food processing facilities, while medium and large capacity boilers are designed for larger operations requiring higher steam output. The increasing demand for energy-efficient systems in large-scale production facilities is driving the adoption of medium and large capacity boilers, particularly in regions with high industrial activity.

By Technology

Fire tube boilers are available in both traditional and advanced configurations. Traditional models rely on manual control systems, whereas advanced fire tube boilers incorporate automated control systems that enhance performance monitoring and operational efficiency. The growing preference for automation and optimization in food processing plants is driving the shift towards advanced fire tube boilers, offering improved reliability and energy savings.

- For instance, Cleaver-Brooks offers advanced automation with its CB Master Panel, a control system capable of sequencing and managing the operation of up to 8 individual firetube boilers from a central interface.

By Fuel

Fire tube boilers in the food processing industry are powered by natural gas, oil, and biomass. Natural gas is the most widely used fuel due to its cost-effectiveness and availability, while biomass boilers are gaining popularity due to the increased demand for renewable energy sources. Oil-based boilers are typically found in regions where natural gas availability is limited. The shift towards more sustainable energy sources is influencing the preference for biomass and natural gas-powered fire tube boilers in food processing plants.

- For instance, an innovative biomass boiler project at a Frito-Lay facility, which uses wood waste for fuel, was supported with $1.6 million in funding from the U.S. Department of Energy to demonstrate its effectiveness in reducing natural gas consumption.

Segmentations:

By Capacity

By Technology

By Fuel

By Region

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis:

North America: Established Market with Strong Demand for Efficiency

North America holds a substantial share of the Fire Tube Food Processing Boiler Market, accounting for 35% of the global market. This dominance is driven by the region’s mature food processing sector and stringent regulatory standards. The U.S. and Canada have well-established food manufacturing industries, where the demand for efficient and reliable steam production systems is high. Fire tube boilers are widely adopted in these markets due to their proven efficiency and cost-effectiveness. The continuous push towards sustainability and energy efficiency is accelerating the adoption of these boilers. Furthermore, North America’s regulatory environment encourages investments in advanced technologies, which further supports the growth of the market.

Europe: High Focus on Sustainability and Compliance

Europe holds a significant 30% share of the Fire Tube Food Processing Boiler Market, influenced by its strong focus on sustainability and compliance with strict food safety standards. The European Union has stringent regulations regarding food processing and environmental impact, which drives the need for high-performance boilers. Fire tube boilers are favored in this region for their ability to meet energy efficiency requirements and ensure food safety in production processes. Countries like Germany, the UK, and France are major contributors to the market, with growing investments in energy-efficient and environmentally friendly technologies.

Asia-Pacific: Rapid Growth Driven by Industrialization

The Asia-Pacific region commands 25% of the Fire Tube Food Processing Boiler Market and is experiencing rapid growth due to industrialization and increasing investments in food processing industries. Countries like China, India, and Japan are modernizing their food manufacturing infrastructure to meet the growing demand for processed food. The adoption of fire tube boilers is accelerating in these regions as they seek efficient, reliable, and cost-effective solutions to meet production needs. The expanding middle class and increasing urbanization further fuel the demand for processed food, driving the growth of the market in this region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Fulton

- Babcock and Wilcox

- Babcock Wanson

- Hurst Boiler

- Thermax

- BM GreenTech

- Bosch Industriekessel

- Cochran

- Clayton Industries

- Johnston Boiler

- Miura America

- Cleaver-Brooks

- Forbes Marshall

- Hoval

Competitive Analysis:

The Fire Tube Food Processing Boiler Market is competitive, with key players like Bosch Thermotechnology, Viessmann, and Cleaver-Brooks leading through technological innovation and energy efficiency. These companies focus on enhancing performance with automated control systems and advanced combustion technologies. Additionally, they offer diverse product portfolios with various capacities and fuel options, including biomass and natural gas-powered boilers, aligning with sustainability trends. Regional players, particularly in Asia-Pacific, are gaining market share by offering cost-effective solutions tailored to local needs. As demand for energy-efficient and sustainable boilers increases, competition in the market is expected to intensify.

Recent Developments:

- In June 2025, Babcock & Wilcox announced an agreement to sell its Diamond Power International business to the Austrian company ANDRITZ for a purchase price of $177 million.

- In August 2025, Babcock Wanson launched its new energy-efficient PowerPack firetube boilers.

- In August 2025, BM GreenTech announced it had secured a RM95 million contract from Nefin V Power Sdn Bhd for an engineering, procurement, construction, and commissioning (EPCC) project.

Report Coverage:

The research report offers an in-depth analysis based on Capacity, Technology, Fuel and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Fire Tube Food Processing Boiler Market will continue to grow as the demand for processed food increases globally.

- The focus on energy efficiency and sustainability will drive the adoption of more advanced and energy-efficient fire tube boilers.

- Automation and smart control systems in fire tube boilers will become more prevalent, improving operational efficiency and reducing human intervention.

- Technological advancements will lead to further improvements in combustion systems, resulting in lower emissions and enhanced boiler performance.

- Governments will introduce stricter regulations on food safety and energy usage, encouraging the adoption of high-performance fire tube boilers.

- Emerging markets, particularly in Asia-Pacific, will see a rise in fire tube boiler demand due to rapid industrialization and food processing facility expansion.

- The growing middle class in developing countries will increase demand for processed food, further boosting market growth.

- There will be a shift toward renewable energy sources, with more food processing facilities opting for biomass-fired boilers.

- Competition among manufacturers will intensify as they seek to offer more cost-effective, sustainable, and technologically advanced boiler solutions.

- The market will see consolidation, with larger players acquiring regional firms to expand their product offerings and market presence.