Market Overview

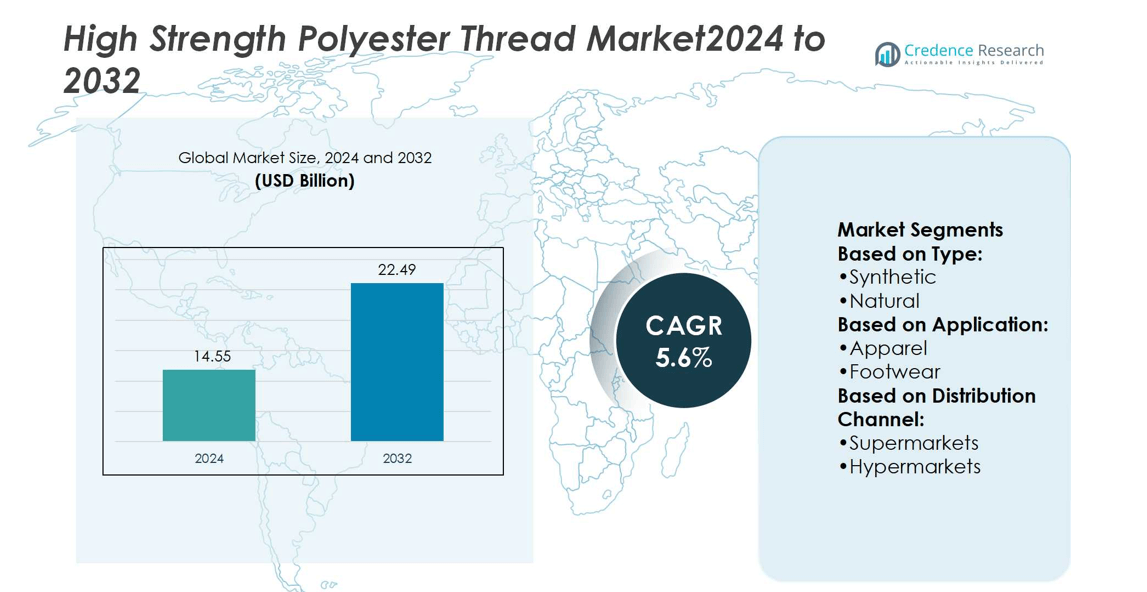

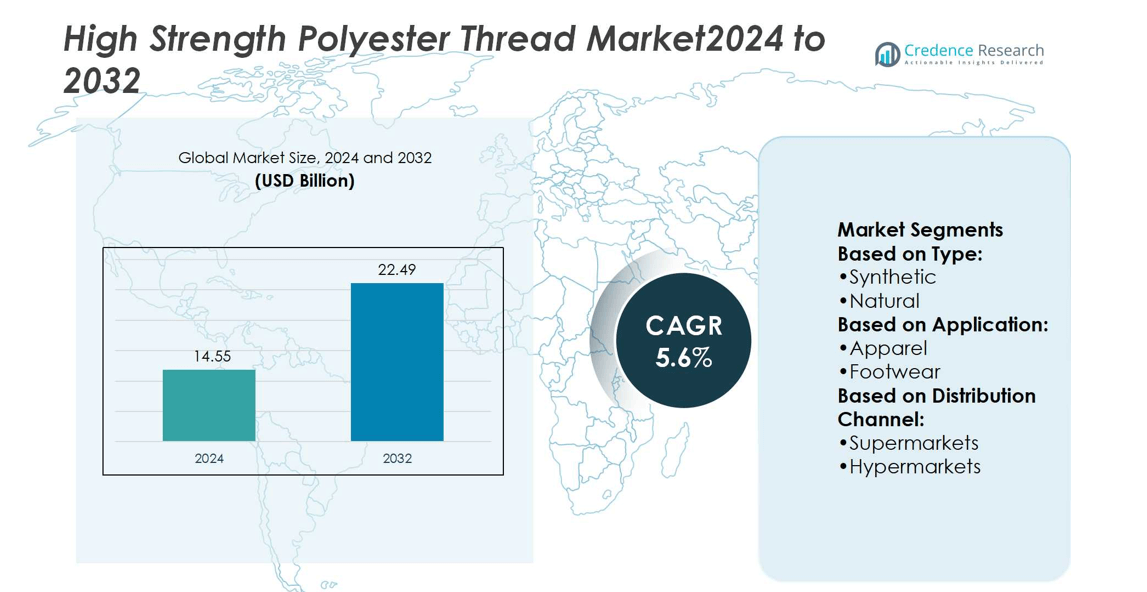

High Strength Polyester Thread Market size was valued at USD 14.55 billion in 2024 and is anticipated to reach USD 22.49 billion by 2032, at a CAGR of 5.6% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| High Strength Polyester Thread Market Size 2024 |

USD 14.55 billion |

| High Strength Polyester Thread Market, CAGR |

5.6% |

| High Strength Polyester Thread Market Size 2032 |

USD 22.49 billion |

The High Strength Polyester Thread Market grows through strong drivers and evolving trends shaping its expansion. Rising demand from apparel, footwear, and automotive industries fuels adoption due to the thread’s durability, tensile strength, and resistance to abrasion. Industrial applications in safety gear, upholstery, and technical textiles further support steady consumption. Sustainability trends push manufacturers toward recycled polyester and eco-friendly production processes. Advances in automation, digital monitoring, and coating technologies enhance product quality and efficiency. Growing interest in specialized variants, including UV-resistant and flame-retardant threads, highlights the market’s shift toward value-added solutions, ensuring its relevance across diverse global industries.

The High Strength Polyester Thread Market shows diverse geographical dynamics, with Asia Pacific holding the largest share due to strong textile manufacturing bases in China and India. North America and Europe contribute significantly, driven by automotive, apparel, and technical textile applications, while Latin America and the Middle East & Africa show steady growth from industrial and construction sectors. Key players strengthen market presence through innovation and sustainability initiatives, focusing on advanced thread properties to meet evolving global demand across multiple industries.

Market Insights

- High Strength Polyester Thread Market size was valued at USD 14.55 billion in 2024 and is anticipated to reach USD 22.49 billion by 2032, at a CAGR of 5.6%.

- Rising demand from apparel, footwear, and automotive industries drives adoption due to strength and durability.

- Sustainability trends encourage the use of recycled polyester and eco-friendly production processes.

- Competitive landscape reflects focus on innovation, advanced thread properties, and global market expansion.

- Market restraints include raw material price volatility and growing competition from alternative fibers.

- Asia Pacific holds the largest share, supported by strong manufacturing bases in China and India.

- North America, Europe, Latin America, and Middle East & Africa show steady growth from industrial and technical textile applications.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers

Expanding Demand from Apparel and Footwear Industries

The High Strength Polyester Thread Market benefits from the rising demand in apparel and footwear industries. Growing consumer preference for durable clothing and high-performance sportswear drives consistent use of polyester threads. Strong stitch retention and resistance to abrasion make these threads a key choice for manufacturers. It supports high-speed sewing machines without compromising seam quality. The footwear sector requires reliable stitching material for sports shoes, casual wear, and industrial footwear. Expansion of fast fashion and premium sportswear brands further strengthens market adoption. Continuous innovation in thread design ensures sustained demand across these industries.

- For instance, spun polyester thread in Tex 60 size achieves breaking strength of around 2,120 centinewtons. Strong stitch retention and resistance to abrasion make these threads a key choice for manufacturers. It supports high-speed sewing machines without compromising seam quality.

Rising Adoption in Automotive and Industrial Applications

The High Strength Polyester Thread Market sees significant growth from automotive and industrial segments. Polyester threads provide high tensile strength, UV resistance, and thermal stability, making them suitable for seat belts, airbags, and upholstery. It also serves industrial uses such as protective clothing, tents, and safety gear. Automotive OEMs prioritize durability and safety, fueling large-scale adoption. The industrial sector depends on reliable stitching for heavy-duty fabrics and coated textiles. Increased production of vehicles and rising demand for industrial protective equipment create robust opportunities. Strong material properties establish polyester threads as a vital choice for these applications.

- For instance, FUJIX’s ‘KING POLYESTER’ 5 filament sewing thread (which corresponds to Tex 150) has a breaking strength of 120.3 newtons and is characterized by a high strength, appropriate elasticity, and good heat resistance.

Increasing Popularity in Home Furnishings and Upholstery

The High Strength Polyester Thread Market gains traction in home furnishing and upholstery. Polyester threads deliver high seam strength and long-lasting performance in curtains, sofas, mattresses, and outdoor furniture. It withstands exposure to sunlight, heat, and frequent use, maintaining quality over time. The rising trend of home décor upgrades supports wider use in both residential and commercial projects. Upholstery manufacturers prefer polyester threads for their colorfastness and ability to blend with various fabrics. The growth of interior design and demand for premium furnishing products provide further momentum. Sustainability efforts also drive adoption of recyclable polyester threads in this sector.

Technological Advancements and Sustainability Initiatives

The High Strength Polyester Thread Market expands through technological improvements and sustainability initiatives. Advanced manufacturing techniques produce threads with greater tensile strength, uniformity, and resistance to wear. It supports automation in textile production by enabling consistent performance at higher speeds. Manufacturers invest in eco-friendly production processes, including recycled polyester threads, to align with global sustainability goals. Growth in demand for green textiles strengthens the role of sustainable thread options. Brands leverage these innovations to reduce environmental impact while maintaining quality. Continuous R&D efforts ensure that polyester threads remain competitive against alternative materials in multiple industries.

Market Trends

Growing Preference for Sustainable and Recycled Threads

The High Strength Polyester Thread Market is witnessing strong momentum toward sustainable production. Manufacturers are increasingly adopting recycled polyester derived from post-consumer plastic waste. It reduces environmental footprint and supports circular economy initiatives across the textile industry. Global brands prioritize eco-friendly sourcing, driving demand for sustainable thread options. Rising awareness of environmental regulations encourages investment in green technologies. The push for recyclable packaging and apparel aligns with this trend. Sustainable polyester threads are becoming an essential part of supply chains worldwide.

- For instance, a future goal could be producing r-PET thread with enhanced tensile strength, which is a key challenge for recycled threads, while maintaining needle size compatibility (e.g., Nm 100-120). Manufacturers are actively working to close the performance gap between recycled and virgin materials.

Increasing Integration of Advanced Manufacturing Technologies

The High Strength Polyester Thread Market benefits from advanced production methods improving thread quality. Automated machinery and precision spinning deliver consistent tensile strength and superior uniformity. It supports efficient performance on high-speed sewing systems without breakage. Manufacturers adopt innovative coating techniques to enhance abrasion resistance and UV protection. Growing use of digital quality monitoring strengthens supply reliability. Automation also lowers costs and ensures large-scale capacity to meet global demand. These technological enhancements set new standards for industrial and consumer applications.

- For instance, Vardhman’s core-spun yarns, which are available in Polyester/Cotton blends, are produced in a wide count range (e.g., Ne 1/8 to Ne 1/100) allowing thread thicknesses suited for heavy-duty technical fabrics.

Rising Adoption Across Technical and Performance Textiles

The High Strength Polyester Thread Market expands through demand in technical and performance textiles. Protective clothing, industrial filters, and outdoor gear require strong and durable stitching solutions. It withstands exposure to harsh conditions, chemicals, and extreme temperatures. Increased investment in defense and aerospace textiles further strengthens thread consumption. Growth in sportswear and performance fabrics adds consistent demand for high-tensile materials. Polyester thread remains a preferred choice due to its strength-to-weight ratio. The trend highlights its growing role in specialized applications beyond traditional apparel.

Increasing Customization and Product Diversification

The High Strength Polyester Thread Market shows a trend toward customization and diversified offerings. Manufacturers provide threads in multiple colors, finishes, and specialized properties to meet niche demands. It allows alignment with fashion trends, branding needs, and industrial specifications. UV-resistant, water-repellent, and flame-retardant variants see increasing adoption. Rising consumer expectations for aesthetics and durability push companies to expand product portfolios. Advances in dyeing and finishing technologies enhance colorfastness and visual appeal. The growing focus on tailored solutions positions polyester thread as a versatile material across industries.

Market Challenges Analysis

Volatility in Raw Material Prices and Supply Constraints

The High Strength Polyester Thread Market faces challenges from fluctuating raw material costs. Polyester production depends heavily on petrochemical derivatives, making it vulnerable to oil price volatility. It creates uncertainty for manufacturers and directly impacts profit margins. Supply chain disruptions, including shipping delays and geopolitical tensions, further intensify cost pressures. Smaller producers struggle to maintain stable pricing in highly competitive markets. Frequent shifts in availability of raw materials complicate long-term planning for thread manufacturers. These factors hinder consistent growth and place pressure on industry participants to manage risks effectively.

Rising Competition from Alternative Materials and Sustainability Pressures

The High Strength Polyester Thread Market encounters strong competition from alternatives such as nylon, aramid, and biodegradable threads. Industries focused on sustainability adopt natural or compostable fibers to meet eco-friendly standards. It forces polyester thread producers to innovate and differentiate their products. Regulatory policies targeting plastic waste reduction increase the pressure on synthetic fibers. High investments in recycling and green technologies are required to remain compliant. Growing demand for environmentally responsible products influences purchasing decisions across end-use sectors. These challenges emphasize the need for innovation and sustainable practices to maintain market relevance.

Market Opportunities

Expansion in Technical Textiles and Industrial Applications

The High Strength Polyester Thread Market presents strong opportunities in technical textiles and industrial applications. Growing demand for protective clothing, safety gear, and automotive components creates a wide scope for adoption. It delivers strength, heat resistance, and durability, making it suitable for airbags, seat belts, and industrial upholstery. The aerospace and defense industries also rely on reliable stitching solutions for specialized fabrics. Expanding infrastructure and construction projects increase demand for heavy-duty textiles where polyester threads excel. Rising investment in advanced manufacturing strengthens the supply chain for industrial-grade products. This expansion reinforces the importance of polyester threads in high-performance sectors.

Advancements in Eco-Friendly and Value-Added Thread Variants

The High Strength Polyester Thread Market offers growth opportunities through eco-friendly and value-added product development. Manufacturers are investing in recycled polyester threads to meet sustainability targets and attract eco-conscious customers. It supports circular economy initiatives and compliance with stricter environmental regulations. Specialty variants such as flame-retardant, water-repellent, and UV-resistant threads gain traction in niche applications. The fashion and outdoor industries demand customizable solutions, opening avenues for product diversification. Technological innovation in dyeing and finishing enhances both performance and aesthetics. These advancements enable polyester threads to penetrate new markets while strengthening their role in traditional segments.

Market Segmentation Analysis:

By Type

The High Strength Polyester Thread Market is segmented into synthetic and natural types. Synthetic polyester thread dominates due to its superior tensile strength, durability, and resistance to abrasion. It performs well under harsh conditions, making it suitable for industrial textiles, automotive applications, and technical fabrics. Manufacturers prefer synthetic options for large-scale production because of their cost efficiency and reliability. Natural threads, though less common, find niche demand in eco-conscious applications where sustainability is prioritized. The segment balance highlights the prominence of synthetic variants while showing steady interest in natural alternatives. This dual presence ensures flexibility in meeting diverse end-user needs.

- For instance, MH lists recycled sewing thread in counts like 40/2 spun polyester, offered alongside their standard synthetic lines.The segment balance highlights the prominence of synthetic variants while showing steady interest in natural alternatives.

By Application

Apparel and footwear remain key application segments driving consistent demand. The apparel industry depends on polyester threads for strong seams, colorfastness, and compatibility with high-speed sewing. It supports the growing sportswear and performance clothing market, where durability and comfort are essential. Footwear manufacturers use polyester threads in sports shoes, industrial footwear, and casual designs due to their ability to withstand tension and stress. Rising fashion trends and consumer preference for long-lasting products further strengthen this segment. Both apparel and footwear collectively provide a stable foundation for market expansion. Their wide adoption underscores the essential role of polyester threads in consumer goods.

- For instance, Eddington’s product specifications for polyester thread confirm that it “Sticks at 440° to 445° Fahrenheit” and “Melts at 483° Fahrenheit and melts at 483°F, ensuring seam integrity under heat during high-speed sewing.

By Distribution Channel

Supermarkets and hypermarkets represent a critical distribution channel for high strength polyester threads. These outlets provide easy accessibility for small-scale buyers, tailoring units, and local manufacturers. It ensures visibility to a diverse customer base and drives impulse purchases through retail display. Large retail chains also expand product reach by offering multiple variants and brands under one roof. While bulk buyers rely on industrial suppliers, retail channels continue to serve a significant role in supporting small and medium-scale demand. Growth in organized retail networks worldwide enhances market penetration. This distribution structure reflects a balanced mix of large-scale supply and consumer-level access.

Segments:

Based on Type:

Based on Application:

Based on Distribution Channel:

- Supermarkets

- Hypermarkets

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America

North America holds 22% of the High Strength Polyester Thread Market. The United States leads consumption, supported by strong demand in automotive, apparel, and industrial textiles. It uses high-strength polyester threads in airbags, seat belts, and protective clothing. Canada supports demand through home furnishings and upholstery, while Mexico contributes via textile exports to the U.S. and global markets. Rising sustainability awareness encourages adoption of recycled polyester threads across retail and industrial applications. Strong supply chains and advanced manufacturing facilities strengthen the region’s position. The focus on innovation and compliance with safety standards ensures steady market growth in North America.

Europe

Europe accounts for 21% of the market. Germany, Italy, and the United Kingdom remain the top contributors, driven by demand in automotive interiors, high-end fashion, and furniture. The region emphasizes high performance, sustainability, and durability in textile production. Strict EU regulations encourage the use of eco-friendly polyester threads with advanced properties like UV resistance and abrasion protection. Southern Europe supports the fashion and footwear industries, while Eastern Europe adds capacity in industrial textiles. Growing preference for sustainable consumer products supports investment in recycled and advanced threads. Europe continues to balance innovation with strict quality standards, giving it a strong competitive advantage.

Asia Pacific

Asia Pacific dominates with 38% share of the global market. China and India drive growth through their large textile and apparel industries. The region benefits from low production costs, massive export capacity, and rising local consumption. Southeast Asian countries, including Vietnam and Bangladesh, contribute significantly with garment manufacturing for global brands. Japan and South Korea support technical textile applications in automotive, defense, and industrial sectors. Rising disposable incomes and expanding infrastructure projects boost demand for high-performance threads. Asia Pacific maintains its leadership through both volume production and expanding specialized uses across industries.

Latin America

Latin America represents 10% of the High Strength Polyester Thread Market. Brazil and Mexico are the largest markets, supported by apparel manufacturing, industrial textiles, and footwear production. Growth in regional automotive and construction sectors creates new opportunities for heavy-duty polyester threads. Export-oriented garment industries in Central America contribute to steady demand. Supply chain gaps and economic volatility limit rapid expansion, but the demand for durable, cost-effective stitching material remains high. Investments in modern textile manufacturing are gradually improving efficiency in the region.

Middle East & Africa

The Middle East and Africa hold 9% share of the global market. The Gulf countries drive consumption in protective clothing, automotive upholstery, and construction applications. South Africa and Egypt contribute through textile and garment industries. It faces challenges from limited infrastructure and higher dependency on imports. Rising demand for industrial safety gear and defense textiles creates growth opportunities. Increasing focus on diversifying economies away from oil supports the development of manufacturing sectors. The region offers long-term potential, supported by growing consumer demand and expanding industrial applications.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Perfectex Plus LLC

- Leader Thread Corp.

- FUJIX Ltd.

- Canwil Textiles, Inc

- Vardhman Yarns & Threads Ltd.

- Ningbo MH Industry Co., Ltd.

- Eddington Thread Manufacturing Co.

- Gunze Limited

- L. Gore & Associates, Inc.

- Threads (India) Private Limited

Competitive Analysis

The High Strength Polyester Thread Market companies include FUJIX Ltd., Gunze Limited, Vardhman Yarns & Threads Ltd., Threads (India) Private Limited, Ningbo MH Industry Co., Ltd., Leader Thread Corp., Eddington Thread Manufacturing Co., W.L. Gore & Associates, Inc., Perfectex Plus LLC, and Canwil Textiles, Inc. The High Strength Polyester Thread Market is defined by intense competition, with companies focusing on innovation, sustainability, and product performance to strengthen their positions. Manufacturers emphasize developing eco-friendly and recycled thread variants to align with global sustainability goals. Investment in advanced manufacturing technologies ensures consistent quality, high tensile strength, and compatibility with modern high-speed sewing systems. Firms also pursue differentiation by offering specialized variants with properties such as flame resistance, UV protection, and water repellency. Expanding distribution networks, both through industrial supply channels and organized retail, increase accessibility across regions. Market participants actively explore growth opportunities in emerging economies where rising apparel, automotive, and industrial textile demand fuels consistent expansion.

Recent Developments

- In April 2025, Singer focuses on innovation and diversification, retaining its core black sewing machines with DSBB and SLBB while expanding into Husqvarna embroidery-cum-sewing machines and industrial machines with precision and 5000 stitches per minute speed.

- In July 2024, MANN’s new state-of-the-art production site in India promises a greener future for the thread industry. As A MAN has been present in India for more than 15 years, and has been offering high-quality sewing and embroidery threads for thriving apparel of India, footwear, and the leather market, by serving as the central hub for producing high-quality sewing thread across various applications.

- In May 2024, Coloreel, a pioneer in innovative thread dyeing technology, collaborated with Juki America, a leading provider of sewing solutions. This partnership marks a significant leap forward, opening real-time, on-demand thread dyeing capabilities to the sewing market for the first time, aiming for both precision and flexibility in their creations.

- In November 2023, Adrian Elliott, CEO of the apparel division at Coats Group, announced that, a thread and structural components manufacturer Coats Group received the Cradle-to-Cradle Certified Material Health Certificate for its eco-friendly sewing thread solutions with a commitment to safe, circular, and sustainable products.

Report Coverage

The research report offers an in-depth analysis based on Type, Application, Distribution Channel and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The market will see rising demand from apparel and footwear industries driven by durability needs.

- Automotive applications will expand with threads used in airbags, seat belts, and upholstery.

- Industrial textiles will adopt more high-strength polyester threads for safety and protective gear.

- Sustainability will guide growth with increasing production of recycled and eco-friendly threads.

- Technological innovations will improve tensile strength, abrasion resistance, and high-speed sewing compatibility.

- Asia Pacific will maintain dominance through large-scale manufacturing and export capacity.

- North America and Europe will emphasize premium quality and regulatory compliance.

- Latin America will grow steadily with expanding apparel and footwear manufacturing bases.

- Middle East and Africa will create opportunities through construction and protective clothing demand.

- Customization and value-added variants such as flame-retardant and UV-resistant threads will gain traction.