Market Overview

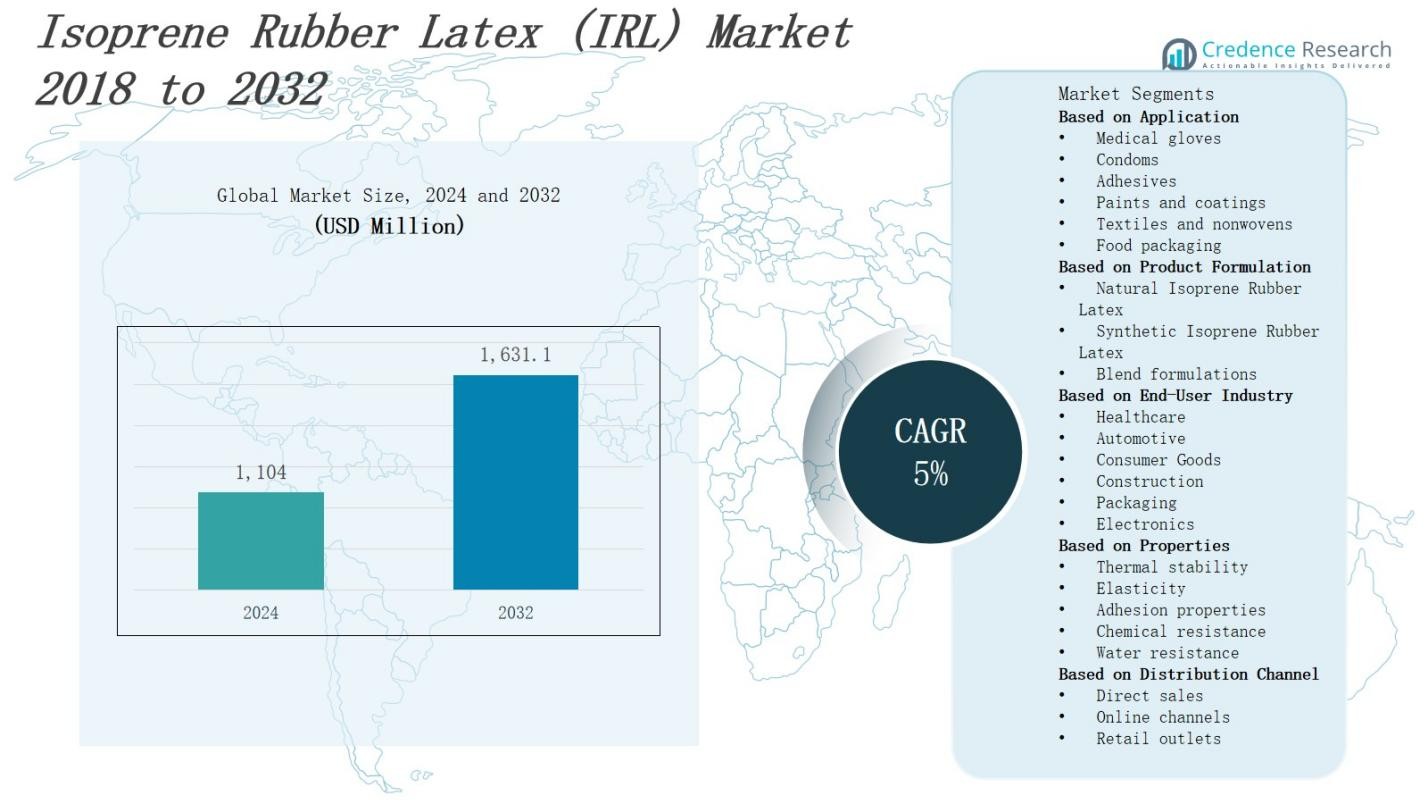

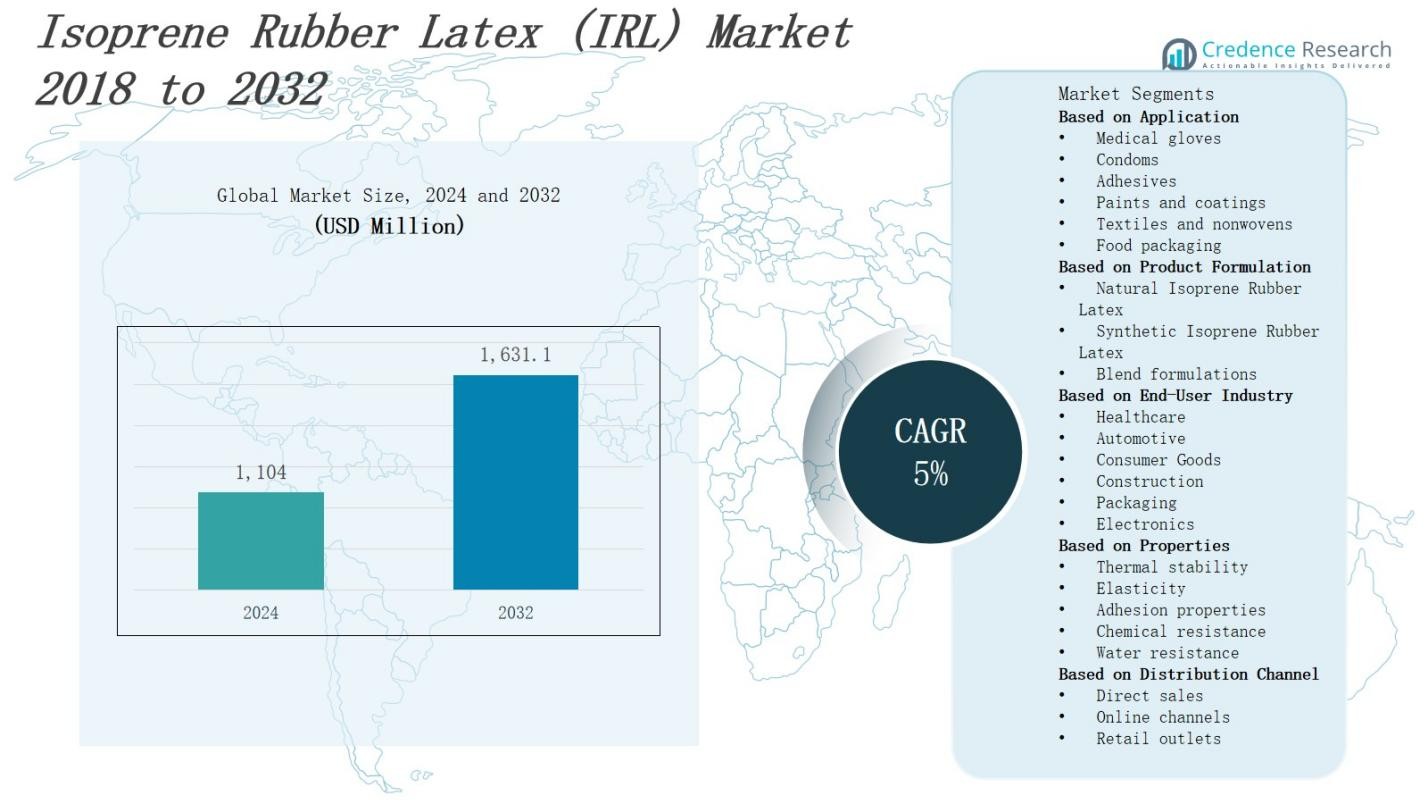

The Isoprene Rubber Latex (IRL) market is projected to grow from USD 1,104 million in 2024 to USD 1,631.1 million by 2032, registering a compound annual growth rate (CAGR) of 5%.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Isoprene Rubber Latex (IRL) Market Size 2024 |

USD 1,104 Million |

| Isoprene Rubber Latex (IRL) Market, CAGR |

5% |

| Isoprene Rubber Latex (IRL) Market Size 2032 |

USD 1,631.1 Million |

The Isoprene Rubber Latex (IRL) market grows steadily due to rising demand in medical, automotive, and consumer goods industries. Its superior elasticity, biocompatibility, and chemical resistance drive its preference over natural rubber in manufacturing gloves, condoms, and adhesives. Increasing awareness of latex allergies prompts innovation in hypoallergenic IRL products, expanding its application scope. Technological advancements enhance production efficiency and latex purity, lowering costs and improving quality. Additionally, growing automotive production and expanding healthcare infrastructure worldwide support consistent market growth. The shift toward sustainable and synthetic alternatives further boosts IRL adoption, aligning with evolving industry standards and regulatory requirements.

The Isoprene Rubber Latex (IRL) market spans key regions including North America, Europe, Asia-Pacific, and the Rest of the World (Latin America, Middle East, and Africa). North America and Europe hold significant market shares due to advanced healthcare and stringent regulations, while Asia-Pacific drives rapid growth fueled by industrialization and expanding healthcare infrastructure. The Rest of the World shows emerging potential with increasing healthcare investments. Leading players such as Ansell Limited, Hartalega Holdings, JSR Corporation, and Kossan Rubber Industries actively operate across these regions, focusing on innovation, capacity expansion, and strategic partnerships to capture market opportunities.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Isoprene Rubber Latex (IRL) market is projected to grow from USD 1,104 million in 2024 to USD 1,631.1 million by 2032, registering a CAGR of 5%.

- Rising demand in medical, automotive, and consumer goods industries drives market growth, supported by IRL’s superior elasticity, biocompatibility, and chemical resistance.

- Innovation in hypoallergenic IRL products expands application scope amid increasing awareness of latex allergies.

- Fluctuations in raw material prices and supply chain disruptions present challenges, impacting production costs and margins.

- North America holds 30% market share due to advanced healthcare infrastructure and regulatory compliance, while Europe accounts for 25%, emphasizing sustainability and strict safety standards.

- Asia-Pacific leads growth with 35% market share, fueled by rapid industrialization, expanding healthcare infrastructure, and rising disposable incomes.

- The Rest of the World, including Latin America, the Middle East, and Africa, holds 10%, driven by increasing healthcare investments despite limited infrastructure and regulatory complexities.

Market Drivers

Growing Demand in Medical and Healthcare Applications

The Isoprene Rubber Latex (IRL) market experiences significant growth driven by increased demand for medical-grade products. It offers excellent elasticity, softness, and biocompatibility, making it ideal for manufacturing surgical gloves, catheters, and other medical devices. Rising global awareness about hygiene and infection control fuels demand in healthcare facilities. The latex’s hypoallergenic properties appeal to consumers sensitive to natural rubber allergens. Expansion of healthcare infrastructure, especially in emerging economies, supports sustained growth. Regulatory emphasis on safety and quality further promotes its adoption.

- For instance, Top Glove Corporation and Hartalega Holdings have expanded production capacity for IRL-based medical gloves, responding to increased demand for allergy-free, durable gloves amid heightened healthcare safety standards.

Expansion in Automotive and Industrial Sectors

The automotive industry’s growth directly influences the Isoprene Rubber Latex market due to its use in manufacturing durable seals, gaskets, and adhesives. It provides excellent resistance to heat, chemicals, and abrasion, meeting stringent automotive standards. Increasing vehicle production worldwide drives steady demand for IRL-based components. Industrial applications also benefit from its flexibility and durability, supporting equipment reliability. Rising investments in manufacturing modernization and lightweight materials promote the use of synthetic latex alternatives. The expanding industrial base in Asia-Pacific significantly boosts market prospects.

- For instance, DL Chemical’s recent completion of a large polyisoprene latex facility on Jurong Island, Singapore, which significantly boosts production capacity for synthetic latex materials used in automotive components and healthcare, reflecting the industry’s move toward hypoallergenic, durable synthetic alternatives.

Advancements in Production Technology and Quality Enhancement

Technological improvements in polymerization and compounding processes improve the purity and performance of IRL. It enables manufacturers to produce consistent, high-quality latex with tailored properties for specific applications. Cost-effective production techniques reduce raw material consumption and waste generation, enhancing profitability. Enhanced latex stability and shelf life allow broader distribution and storage options. Research and development efforts focus on developing eco-friendly and sustainable IRL variants to meet evolving environmental regulations. These innovations reinforce market competitiveness and product appeal globally.

Rising Focus on Sustainability and Allergy-Free Alternatives

The increasing preference for synthetic latex over natural rubber supports the Isoprene Rubber Latex market’s growth. It provides a viable alternative for consumers with latex allergies, reducing adverse reactions. The synthetic origin allows better control over allergen content, increasing its acceptance in sensitive applications. Growing environmental concerns drive manufacturers to adopt sustainable sourcing and production methods. Market players invest in bio-based IRL formulations to reduce carbon footprint. Consumer awareness about product safety and eco-conscious choices strengthens market demand for IRL products.

Market Trends

Increased Adoption of Hypoallergenic and Medical-Grade IRL Products

The Isoprene Rubber Latex (IRL) market shows a clear trend toward the development and adoption of hypoallergenic latex products, driven by rising concerns about latex allergies. Manufacturers focus on producing medical-grade IRL with reduced protein content to minimize allergic reactions. This shift enhances its use in healthcare and personal protective equipment, including gloves and catheters. Strict regulatory standards push companies to improve product safety and compliance. Growing consumer awareness about health and safety fuels demand for such specialized IRL products. The trend supports broader application across medical and hygiene sectors.

- For instance, Ansell has developed medical-grade IRL gloves with reduced protein content, significantly lowering allergic reactions in healthcare settings.

Expansion into Emerging Markets and Regional Growth Opportunities

Emerging economies in Asia-Pacific, Latin America, and Africa provide significant growth opportunities for the Isoprene Rubber Latex market. Rising healthcare investments and expanding automotive industries in these regions increase demand for synthetic latex products. It benefits from improving manufacturing infrastructure and growing urbanization. Local manufacturers increasingly adopt IRL to meet rising product standards and consumer expectations. The presence of favorable government policies and incentives supports market expansion. Regional growth contributes to a diversified global market footprint and sustained long-term growth prospects.

Technological Innovations Enhancing Latex Performance and Sustainability

Technological advancements drive the Isoprene Rubber Latex market by enhancing product performance and sustainability. Innovations focus on improving latex purity, elasticity, and resistance to environmental factors. It supports customization for specific industrial and medical applications. Research explores bio-based and eco-friendly IRL alternatives, aligning with stricter environmental regulations and consumer demand for sustainable products. Automation and process optimization reduce production costs and waste. These improvements increase product reliability and market competitiveness, encouraging wider adoption in various sectors.

- For instance, Zeon Corporation, which has introduced chemically resistant isoprene latex designed for aerospace elastomers and precision adhesives, offering improved durability and resistance for industrial applications.

Rising Integration of IRL in Automotive and Industrial Applications

The Isoprene Rubber Latex market observes growing integration in automotive and industrial sectors due to its superior mechanical and chemical properties. It finds increased use in seals, gaskets, adhesives, and vibration dampening components that require durability and heat resistance. Manufacturers leverage IRL to meet stringent automotive quality and safety standards. Industrial applications benefit from its resistance to abrasion and chemical degradation. The expanding electric vehicle segment also drives demand for advanced synthetic rubber materials. This trend highlights the market’s alignment with evolving industry requirements and technological progress.

Market Challenges Analysis

Volatility in Raw Material Prices and Supply Chain Constraints

The Isoprene Rubber Latex (IRL) market faces challenges from fluctuating raw material costs, which impact production expenses and profit margins. It depends heavily on petrochemical derivatives, making it vulnerable to global oil price volatility and supply disruptions. Inconsistent availability of high-quality isoprene monomers leads to production delays and increased operational costs. Supply chain complexities, including transportation bottlenecks and geopolitical tensions, further hinder steady material flow. Manufacturers struggle to balance cost control with maintaining product quality. These factors constrain market growth and create uncertainty in long-term planning for producers and buyers.

Regulatory Compliance and Environmental Concerns Limit Market Expansion

The IRL market encounters stringent regulatory frameworks aimed at controlling chemical emissions, waste management, and worker safety. It requires continuous investment to comply with evolving environmental and health standards across different regions. High compliance costs increase barriers for small and medium-sized manufacturers. Environmental concerns regarding synthetic latex production and disposal raise scrutiny from regulators and consumers. Limited recycling infrastructure for synthetic latex also challenges sustainability efforts. These regulatory and environmental pressures restrict market accessibility and necessitate innovation in cleaner, greener production technologies.

Market Opportunities

Growing Demand for Eco-Friendly and Sustainable IRL Products

The Isoprene Rubber Latex (IRL) market presents significant opportunities through the development of eco-friendly and sustainable latex variants. It can capitalize on increasing consumer and regulatory demand for biodegradable and low-emission materials. Innovations in bio-based isoprene production offer pathways to reduce environmental impact and dependence on fossil fuels. Companies investing in green manufacturing processes gain competitive advantages and access to environmentally conscious markets. Expansion of sustainability certifications and eco-labeling also encourages wider adoption. These trends open avenues for product differentiation and market expansion globally.

Expansion into New Applications and Emerging Regional Markets

The IRL market benefits from untapped applications in industries such as electronics, adhesives, and specialty coatings, where its unique properties provide functional advantages. It supports innovation in wearable devices, flexible electronics, and advanced adhesives, driving new revenue streams. Growing industrialization and healthcare infrastructure in emerging regions offer fertile ground for IRL market penetration. Investments in localized production facilities reduce costs and improve supply reliability. Strategic partnerships and collaborations facilitate market entry and product development. These opportunities enable sustained growth and diversification across geographies and end-use sectors.

Market Segmentation Analysis:

By Application

The Isoprene Rubber Latex (IRL) market sees the highest demand from medical gloves due to their superior elasticity and hypoallergenic properties. It supports manufacturing of condoms, adhesives, paints, coatings, textiles, nonwovens, and food packaging. Medical gloves maintain dominance driven by expanding healthcare needs and infection control measures worldwide. Adhesives and coatings benefit from IRL’s chemical resistance and durability, expanding use in industrial sectors. Food packaging and textiles increasingly adopt IRL for flexibility and safety, diversifying application scope across industries.

- For instance, Ansell Limited, a global leader in protective solutions, develops isoprene rubber gloves that provide superior comfort and allergy protection for medical professionals, meeting stringent international safety standards.

By Product Formulation

Synthetic Isoprene Rubber Latex gains significant market share due to its controlled quality and reduced allergen content. It complements natural IRL and blend formulations that combine properties to meet specific industry needs. The market favors synthetic variants for critical medical and industrial applications where consistency and safety are paramount. Natural IRL remains relevant in applications valuing biodegradability. Blend formulations offer tailored performance, enhancing flexibility in product design and application. This segmentation reflects ongoing efforts to balance performance with regulatory compliance.

- For instance, Asahi Kasei Chemicals produces synthetic polyisoprene rubber known for its purity and latex-free nature, making it ideal for medical gloves used worldwide with enhanced safety and elasticity.

By End-User Industry

Healthcare dominates the Isoprene Rubber Latex market, leveraging IRL in gloves, catheters, and other medical devices critical for patient safety. The automotive sector follows, utilizing IRL in seals, gaskets, and vibration-dampening components requiring heat and chemical resistance. Consumer goods and construction industries adopt IRL for adhesives, coatings, and flexible materials. Packaging and electronics show emerging interest, driven by innovation and demand for durable, flexible materials. These diverse end-user industries collectively propel market growth and foster continuous product development.

Segments:

Based on Application

- Medical gloves

- Condoms

- Adhesives

- Paints and coatings

- Textiles and nonwovens

- Food packaging

Based on Product Formulation

- Natural Isoprene Rubber Latex

- Synthetic Isoprene Rubber Latex

- Blend formulations

Based on End-User Industry

- Healthcare

- Automotive

- Consumer Goods

- Construction

- Packaging

- Electronics

Based on Properties

- Thermal stability

- Elasticity

- Adhesion properties

- Chemical resistance

- Water resistance

Based on Distribution Channel

- Direct sales

- Distributors and wholesalers

- Online channels

- Retail outlets

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

The North American region holds a significant share of the Isoprene Rubber Latex (IRL) market, accounting for 30% of the global market. It benefits from a well-established healthcare infrastructure and high adoption of advanced medical devices, which drive demand for IRL-based medical gloves and other products. The automotive industry’s focus on quality and safety standards further fuels market growth. Strict regulatory frameworks ensure product compliance and encourage innovation in hypoallergenic and sustainable latex formulations. The presence of leading manufacturers and ongoing research and development activities strengthen the region’s market position. Rising consumer awareness about latex allergies supports the shift toward synthetic IRL.

Europe

Europe contributes 25% to the global Isoprene Rubber Latex market, driven by stringent safety regulations and environmental policies. It emphasizes sustainable production and eco-friendly latex products, which encourages manufacturers to innovate in bio-based and hypoallergenic IRL formulations. The healthcare sector remains a major consumer, with expanding demand for disposable medical supplies. The automotive and industrial sectors adopt IRL for applications requiring durability and chemical resistance. Investments in research and regional collaborations enhance technology advancement. Rising demand for premium quality and compliance with REACH regulations support steady market growth in this region.

Asia-Pacific

Asia-Pacific represents the fastest-growing region in the Isoprene Rubber Latex market, capturing 35% of the global share. Rapid industrialization, expanding healthcare infrastructure, and increasing automotive production stimulate demand. Growing populations and rising disposable incomes increase consumption of medical gloves and consumer goods containing IRL. Local manufacturers invest in capacity expansion and technological upgrades to meet rising standards. Governments encourage healthcare modernization and industrial growth, boosting IRL adoption. Emerging economies such as China, India, and Southeast Asian countries drive significant market expansion and competitive pricing.

Rest of the World (RoW)

The Rest of the World holds 10% of the Isoprene Rubber Latex market share, with growth opportunities mainly in Latin America, the Middle East, and Africa. These regions witness increasing healthcare investments and gradual industrialization, creating new demand for IRL products. Challenges include limited manufacturing infrastructure and regulatory complexities, which slow market penetration. Efforts to improve healthcare access and product quality support rising consumption of medical gloves and related products. Strategic partnerships and technology transfers from established markets help expand IRL applications in this segment. Growing awareness of product safety enhances market prospects across these regions.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Kraton Corporation

- Zeon Corporation

- Shell plc

- Rubberex

- JSR Corporation

- Hartalega Holdings

- Ansell Limited

- Sibur

- Kossan Rubber Industries

Competitive Analysis

The Isoprene Rubber Latex (IRL) market presents a highly competitive environment characterized by leading global players prioritizing innovation, production capacity expansion, and strategic alliances. Key companies such as Ansell Limited, Hartalega Holdings, JSR Corporation, and Kossan Rubber Industries focus on enhancing product quality and meeting stringent regulatory requirements, especially within medical and industrial applications. It leverages continuous research and development efforts to improve latex purity, reduce allergenic content, and develop sustainable formulations. Advanced manufacturing techniques contribute to greater production efficiency and cost reduction. Regional market penetration and supply chain optimization serve as vital competitive advantages. Companies increase production capabilities in high-growth regions like Asia-Pacific to meet rising demand. Collaborations, mergers, and acquisitions enable firms to diversify offerings and strengthen market presence. The competitive landscape encourages development of synthetic and blended IRL variants tailored to niche applications. Pricing strategies and customer support services also differentiate market participants. Increasing emphasis on sustainability and regulatory compliance drives strategic decisions, aligning with evolving environmental policies and consumer expectations.

Recent Developments

- In April 2025, JSR Corporation completed the divestiture of its emulsions and fine chemicals businesses to Nippon Shokubai Co., Ltd.

- In 2024, Ansell Limited introduced the GAMMEX® PI Plus Glove-in-Glove™ System, earning the World of Safety & Health Asia Award.

- In 2025, SIBUR is finalizing tests on experimental tires made with synthetic rubber, aiming to replace natural rubber in tires.

Market Concentration & Characteristics

The Isoprene Rubber Latex (IRL) market demonstrates a moderately concentrated structure, with several key players commanding substantial market shares through strong brand presence, extensive distribution networks, and continuous innovation. It features prominent companies such as Ansell Limited, Hartalega Holdings, JSR Corporation, and Kossan Rubber Industries that invest heavily in research and development to enhance product quality, purity, and sustainability. Market participants compete on factors including product performance, cost efficiency, and regulatory compliance to maintain competitive advantages. The market’s moderate concentration encourages collaboration and strategic partnerships, fostering technological advancements and capacity expansion. Regional diversification enables players to mitigate risks related to raw material volatility and regulatory changes. This dynamic promotes steady growth while allowing emerging manufacturers opportunities to penetrate niche segments by offering specialized or cost-effective solutions. Overall, the market balances competitive intensity with innovation-driven collaboration, supporting sustained expansion and adaptation to evolving industry demands.

Report Coverage

The research report offers an in-depth analysis based on Application, Product Formulation, End User Industries, Properties, Distribution Channel and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Isoprene Rubber Latex market will grow steadily, driven by increasing demand in healthcare and automotive industries.

- Companies will prioritize developing hypoallergenic and environmentally friendly IRL products to meet consumer preferences and regulations.

- Advances in manufacturing technologies will enhance latex purity, improve quality, and reduce production costs globally.

- Emerging markets, especially in Asia-Pacific, will present substantial growth opportunities due to rapid industrialization.

- Sustainability initiatives will push the development and adoption of bio-based and recyclable isoprene rubber latex variants.

- Regulatory frameworks will continue to influence product innovation and market access across different geographic regions.

- Strategic collaborations and partnerships will strengthen companies’ product offerings and expand their international presence.

- Synthetic and blended IRL formulations will gain popularity for specialized industrial, medical, and consumer applications.

- Efficient supply chain management will become essential to mitigate raw material price fluctuations and ensure steady supply.

- Capacity expansions by key players will meet rising global demand and improve responsiveness to market changes.