Market Overview:

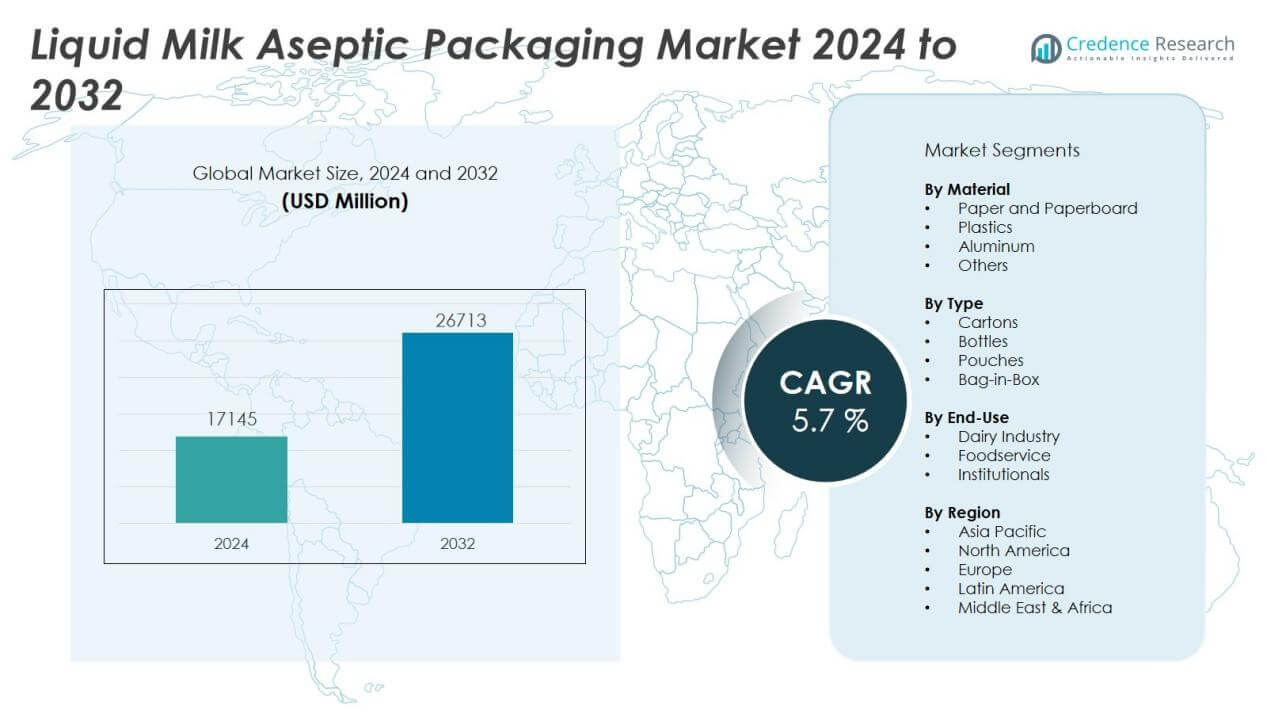

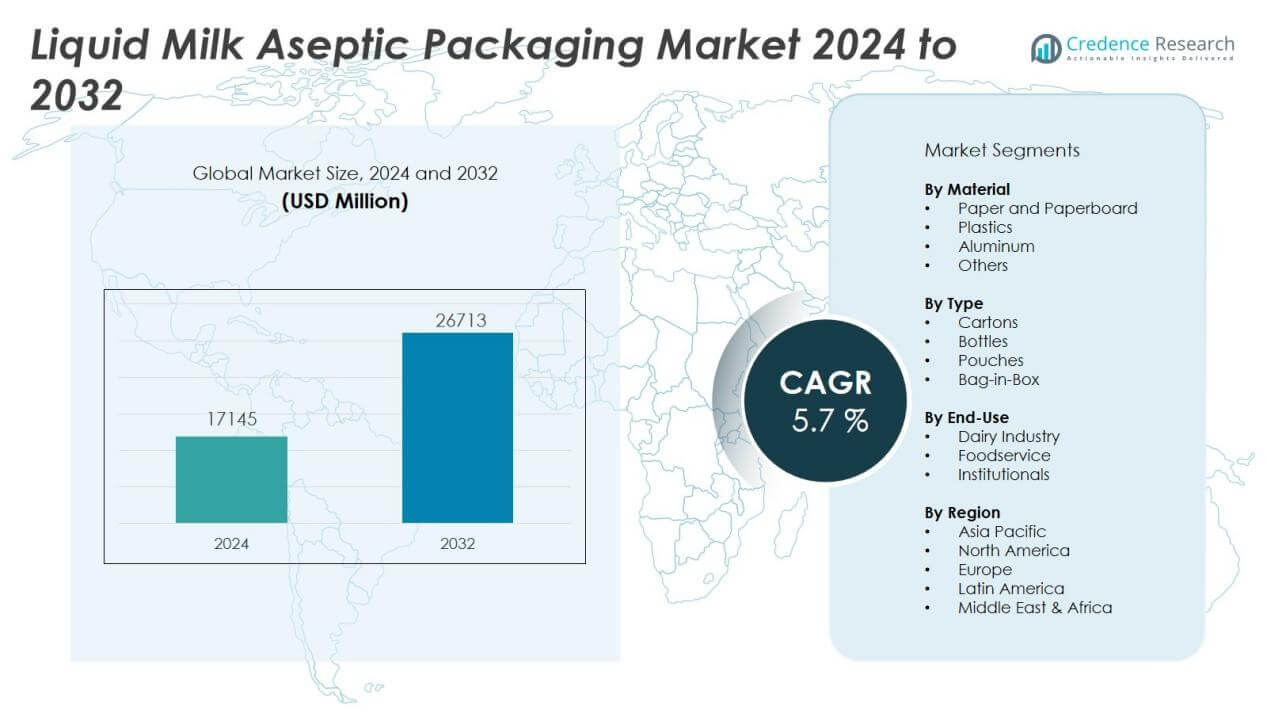

The liquid milk aseptic packaging market size was valued at USD 17145 million in 2024 and is anticipated to reach USD 26713 million by 2032, at a CAGR of 5.7 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Liquid Milk Aseptic Packaging Market Size 2024 |

USD 17145 million |

| Liquid Milk Aseptic Packaging Market, CAGR |

5.7 % |

| Liquid Milk Aseptic Packaging Market Size 2032 |

USD 26713 million |

Key drivers fueling market growth include the rising preference for convenient, ready-to-consume dairy options and heightened awareness regarding food safety. Stringent regulations surrounding product hygiene, coupled with consumer demand for minimally processed and preservative-free milk, are prompting manufacturers to invest in aseptic solutions. Ongoing advancements in packaging materials—such as multilayer laminates and high-barrier films—support enhanced product integrity, while automation in filling and sealing processes improves scalability for large-scale dairies.

Regionally, Asia Pacific leads the liquid milk aseptic packaging market, supported by growing urban populations, increased per capita milk consumption, and expanding middle-class demographics in countries such as China and India. Europe and North America follow, driven by established dairy industries, strong regulatory frameworks, and consumer emphasis on product freshness and sustainability, with key players including Amcor plc, Berry Global Inc, Sonoco Products Company, Tetra Pak, Stora Enso, SIG, and Mondi.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The liquid milk aseptic packaging market reached USD 17,145 million in 2024 and will rise to USD 26,713 million by 2032.

- Consumer demand for shelf-stable, ready-to-consume dairy drives market expansion across all major regions.

- Asia Pacific leads with a 48% share, fueled by urbanization, higher milk consumption, and investment in logistics.

- Europe holds 26% share, driven by strict food safety standards and high adoption of sustainable packaging.

- North America commands 17% share, supported by advanced manufacturing and growing demand for premium, convenient dairy products.

- High initial investment and technical complexity limit adoption by small and medium-sized producers.

- Regulatory pressure and supply chain disruptions challenge market stability, but innovations in packaging materials and cold chain infrastructure provide new growth opportunities.

Market Drivers:

Rising Demand for Shelf-Stable Dairy Products Accelerates Market Growth:

The liquid milk aseptic packaging market gains momentum from increasing global demand for shelf-stable dairy products. Consumers value packaging formats that extend product freshness and eliminate the need for refrigeration, supporting convenient storage and transportation. Food safety concerns and busy lifestyles further strengthen the preference for aseptic-packaged milk. Manufacturers recognize the advantage of distributing dairy to remote locations without risking spoilage. This demand continues to drive innovation and adoption within the sector.

- For instance, Arla Foods Saudi Arabia adopted the SIG CFA 812 filling machine, achieving a capacity of 12,000 aseptic carton packs per hour, providing local production of long-life dairy with robust flavor and nutrient retention.

Regulatory Focus on Food Safety Boosts Adoption of Aseptic Technology:

Government agencies enforce strict regulations to maintain food safety standards in the dairy industry. The liquid milk aseptic packaging market responds to these mandates by adopting advanced aseptic technologies that prevent microbial contamination and reduce the need for preservatives. Manufacturers invest in sterilization and high-barrier materials to meet these requirements and reassure consumers. It enhances brand reputation and aligns with evolving regulatory frameworks. Stringent food safety policies support the sustained use of aseptic packaging solutions.

- For instance, Lothamilk Joint Stock Company in Vietnam implemented SIG’s aseptic filling machine that fills up to 24,000 packs per hour, enabling longer shelf life for milk without refrigeration or preservatives and expanded national distribution.

Innovation in Packaging Materials Improves Product Integrity and Sustainability:

The development of multilayer laminates, high-barrier films, and eco-friendly packaging solutions drives transformation in the liquid milk aseptic packaging market. These material innovations enable longer shelf life, superior protection from external contaminants, and compliance with environmental goals. Companies focus on reducing material waste while maintaining packaging efficiency and strength. It supports consumer and retailer expectations for sustainable, high-quality dairy products. Packaging innovation remains a core factor behind market growth.

Expansion of Cold Chain Infrastructure in Emerging Markets Spurs Demand:

Rapid urbanization and growing middle-class populations in emerging economies fuel the expansion of the liquid milk aseptic packaging market. Retailers and distributors invest in modern cold chain logistics to reach untapped regions and improve product access. The adoption of aseptic packaging solutions supports distribution in environments where refrigeration remains inconsistent or unavailable. It provides dairy producers with the flexibility to scale operations and serve broader markets. Market participants leverage this trend to secure long-term growth opportunities.

Market Trends:

Integration of Smart Packaging Technologies and Digitalization Enhances Market Appeal:

The integration of smart packaging technologies stands out as a prominent trend in the liquid milk aseptic packaging market. Brands deploy QR codes, RFID tags, and time-temperature indicators to enable real-time tracking and enhance transparency for consumers and supply chain partners. It provides end-users with valuable information regarding product origin, shelf life, and authenticity, fostering trust in packaged dairy products. The adoption of digital printing and variable data technology allows manufacturers to customize packaging, improve shelf appeal, and support marketing campaigns. Brands leverage these advancements to differentiate products and boost consumer engagement. The emphasis on connected packaging aligns with rising expectations for convenience, safety, and interactive experiences in the dairy sector.

- For instance, New Zealand’s Fonterra utilizes RFID technology to track up to 30,000 milk samples daily from farm to laboratory, enhancing traceability and minimizing errors throughout the supply chain.

Sustainable Packaging Materials and Circular Economy Practices Shape Industry Direction:

Sustainability initiatives increasingly influence the liquid milk aseptic packaging market, driving manufacturers to adopt recyclable, biodegradable, and renewable materials. Companies focus on reducing plastic content, lightweighting packaging, and introducing plant-based laminates to meet environmental goals. It enables brands to align with regulatory requirements and growing consumer awareness of ecological impact. The market witnesses a shift toward closed-loop supply chains, where post-consumer packaging is collected, recycled, and reused in new production cycles. Partnerships with recycling firms and investments in sustainable design strengthen market positioning. These trends reflect a long-term commitment to resource efficiency and environmental stewardship within the global dairy packaging industry.

- For instance, Pact Group’s collaboration with Circular Plastics Australia allows the recycling of up to 20,000 tonnes of used milk bottles annually into new packaging, keeping the equivalent of half a billion bottles in circulation rather than landfil.

Market Challenges Analysis:

High Initial Investment and Complex Technology Hinder Market Adoption:

The liquid milk aseptic packaging market faces challenges related to the high initial costs of equipment and facility upgrades. Manufacturers must allocate substantial capital for advanced filling lines, sterilization systems, and specialized packaging materials. It creates barriers for small and medium-sized dairy producers seeking entry into the market. Technical complexity further complicates integration, requiring skilled operators and rigorous maintenance protocols. Companies often experience extended payback periods, which can slow investment decisions. This factor limits the speed of widespread adoption, especially in developing regions.

Regulatory Compliance and Supply Chain Disruptions Affect Market Stability:

Strict regulatory requirements for aseptic packaging processes add pressure to maintain consistent product quality and traceability. The liquid milk aseptic packaging market encounters ongoing compliance challenges in response to evolving food safety standards across regions. It demands frequent updates to production processes and documentation, raising operational costs. Global supply chain disruptions—including shortages of packaging materials and delays in equipment delivery—affect production schedules. These issues can hinder the ability of manufacturers to meet demand reliably. Companies must address these obstacles to ensure uninterrupted supply and sustained growth.

Market Opportunities:

Expansion into Emerging Markets Unlocks Significant Growth Potential:

The liquid milk aseptic packaging market can capitalize on expanding opportunities in emerging economies. Rapid urbanization, rising incomes, and shifting dietary habits in Asia Pacific, Latin America, and Africa drive higher demand for packaged dairy products. It provides international dairy producers and packaging suppliers with a chance to establish a strong market presence. Investment in local manufacturing and distribution networks allows companies to overcome logistical barriers and meet evolving consumer preferences. Brands that tailor product formats to regional tastes can secure competitive advantages. This expansion supports sustained long-term growth for market participants.

Product Innovation and Sustainable Packaging Solutions Create Value:

Ongoing product innovation in packaging design and materials presents significant opportunities for the liquid milk aseptic packaging market. Companies that invest in biodegradable, recyclable, or renewable solutions can appeal to environmentally conscious consumers and comply with tightening regulations. It enables differentiation in crowded retail environments and fosters brand loyalty. The development of value-added features—such as easy-pour spouts or resealable closures—addresses convenience trends. Collaboration with technology providers and material suppliers accelerates time-to-market for new packaging formats. These initiatives position manufacturers to capture emerging demand and strengthen their market leadership.

Market Segmentation Analysis:

By Material:

The liquid milk aseptic packaging market segments by material into paper and paperboard, plastics, aluminum, and others. Paper and paperboard hold the dominant share due to their strong barrier properties, lightweight nature, and recyclability. Plastic materials, including polyethylene and polypropylene, support durability and flexibility, catering to high-volume packaging needs. Aluminum provides superior protection against light, oxygen, and moisture, making it ideal for markets where product integrity and extended shelf life remain priorities. Companies continue to innovate by integrating renewable and biodegradable materials to address sustainability demands.

- For instance, the Magical Mushroom Company has partnered with over 100 brands—including Stella McCartney and Selfridges—to replace fossil fuel-based packaging with Mushroom® Packaging.

By Type:

By type, the market divides into cartons, bottles, pouches, and bag-in-box formats. Cartons lead the segment, favored for their efficient storage, easy handling, and eco-friendly reputation. Bottles offer portability and resealable options, appealing to on-the-go consumers. Pouches and bag-in-box packaging solutions meet the requirements of bulk supply and food service sectors. Each type presents unique advantages in terms of convenience, storage, and shelf appeal, enabling dairy brands to target diverse consumer segments.

- For instance, Amcor, Stonyfield Organic, and Cheer Pack North America partnered to produce the first all-PE (polyethylene) spouted pouch for Stonyfield’s YoBaby yogurt, eliminating metallic film layers and reducing plastic use by more than five tons for every 10mm Vizi cap adopted.

By End-Use:

End-use segmentation focuses on the dairy industry, foodservice, and institutional sectors. The dairy industry dominates demand, leveraging aseptic packaging to ensure milk safety, prolong shelf life, and expand geographic reach. Foodservice providers and institutions value aseptic solutions for large-scale distribution and product consistency. It positions the liquid milk aseptic packaging market for sustained growth across retail and non-retail channels.

Segmentations:

By Material:

- Paper and Paperboard

- Plastics

- Aluminum

- Others

By Type:

- Cartons

- Bottles

- Pouches

- Bag-in-Box

By End-Use:

- Dairy Industry

- Foodservice

- Institutional

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

Asia Pacific :

Asia Pacific commands 48% share of the liquid milk aseptic packaging market, driven by strong dairy production and consumption in China, India, and Southeast Asian nations. Urbanization, population growth, and rising middle-class income fuel the shift toward packaged milk and modern retail channels. It benefits from major investments in advanced processing facilities and cold chain logistics. Government policies in China and India support the adoption of safe and hygienic packaging, enabling higher penetration of aseptic formats. Regional producers leverage local consumer insights to offer innovative packaging formats tailored to market preferences. Demand for shelf-stable and convenient dairy products drives ongoing growth and leadership in this region.

Europe :

Europe holds 26% share of the liquid milk aseptic packaging market, supported by a mature dairy sector and high standards for food safety. Regulatory frameworks emphasize product quality, traceability, and sustainability, compelling manufacturers to invest in state-of-the-art aseptic packaging solutions. It sees strong demand for eco-friendly materials and recyclable packaging formats. The presence of leading dairy processors in Germany, France, and the Netherlands ensures continuous innovation. Consumers in Europe display high awareness of food hygiene and environmental issues, reinforcing the use of advanced packaging technologies. Collaborative initiatives between brands and material suppliers drive progress toward circular economy goals.

North America :

North America accounts for 17% share of the liquid milk aseptic packaging market, with the United States as the primary contributor. The region benefits from advanced manufacturing infrastructure and a large consumer base seeking convenient, long-lasting dairy products. It experiences robust investments in packaging automation and digitalization to improve operational efficiency. Regulatory agencies prioritize food safety and traceability, prompting adoption of high-barrier and smart packaging formats. Trends in functional and flavored milk products stimulate demand for differentiated packaging. Market participants in North America continue to focus on product innovation and premiumization to address evolving consumer expectations.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- Amcor plc

- Berry Global Inc

- Sonoco Products Company

- Tetra Pak

- Stora Enso

- SIG

- Mondi

- DS Smith

- Ball Corporation

- Sealed Air

- ProAmpac

Competitive Analysis:

The liquid milk aseptic packaging market features intense competition among established global and regional players, including Amcor plc, Berry Global Inc, Sonoco Products Company, Tetra Pak, Stora Enso, SIG, and Mondi. These companies leverage strong R&D capabilities, advanced technology, and robust supply chains to maintain market leadership. It prioritizes product innovation by introducing sustainable materials, smart packaging features, and advanced barrier solutions. Leading firms invest in expanding manufacturing capacity and strategic partnerships to strengthen market reach. The competitive landscape requires continuous improvement in operational efficiency, regulatory compliance, and customer service. Companies differentiate themselves by focusing on quality assurance, cost competitiveness, and tailored solutions for dairy processors.

Recent Developments:

- In April 2025, Amcor plc completed its all-stock combination with Berry Global Inc., creating a global leader in consumer and healthcare packaging solutions.

- In April 2025, Berry Global Inc. is now part of Amcor plc following the completed all-stock business combination between the two companies.

- In June 2024, Sonoco announced an agreement to acquire Eviosys, Europe’s leading manufacturer of food cans, ends, and closures, for approximately $3.9 billion.

Market Concentration & Characteristics:

The liquid milk aseptic packaging market exhibits moderate to high concentration, with a handful of global players controlling a significant share alongside several regional competitors. It features prominent companies such as Tetra Pak, SIG Group, and Elopak, which lead in technology innovation, quality standards, and global reach. The market shows strong barriers to entry due to high capital requirements and complex regulatory compliance. It favors firms with established supply chains, advanced production capabilities, and a robust customer base. Product differentiation centers on sustainable materials, smart packaging features, and superior shelf-life performance, shaping the market’s competitive dynamics.

Report Coverage:

The research report offers an in-depth analysis based on By Material, By Type, By End-Use and By Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- Producers will adopt smart packaging features—such as QR codes and temperature indicators—to enhance transparency and consumer trust.

- Companies will invest in biodegradable and recyclable materials to reduce environmental impact and comply with stricter packaging regulations.

- Dairy manufacturers will expand aseptic operations into emerging markets to tap growing demand and improve distribution reach.

- Brands will introduce convenience-driven packaging formats, including resealable closures and easy-pour spouts, to attract busy consumers.

- Suppliers will integrate digital printing and variable data capabilities to enable customization and support marketing efforts on packaging.

- Manufacturers will implement closed-loop recycling partnerships to establish circular supply chains and drive sustainability.

- Industry leaders will explore plant-based and renewable laminate materials to minimize reliance on petrochemical-based packaging.

- Technology providers will develop modular filling lines that suit both small-scale producers and large dairy processors.

- Market stakeholders will strengthen cold chain infrastructure in remote and rural regions to support wider aseptic distribution.

- Companies will prioritize brand differentiation through transparent sourcing information, quality assurance, and unique packaging formats.