CHAPTER NO. 1 : GENESIS OF THE MARKET

1.1 Market Prelude – Introduction & Scope

1.2 The Big Picture – Objectives & Vision

1.3 Strategic Edge – Unique Value Proposition

1.4 Stakeholder Compass – Key Beneficiaries

CHAPTER NO. 2 : EXECUTIVE LENS

2.1 Pulse of the Industry – Market Snapshot

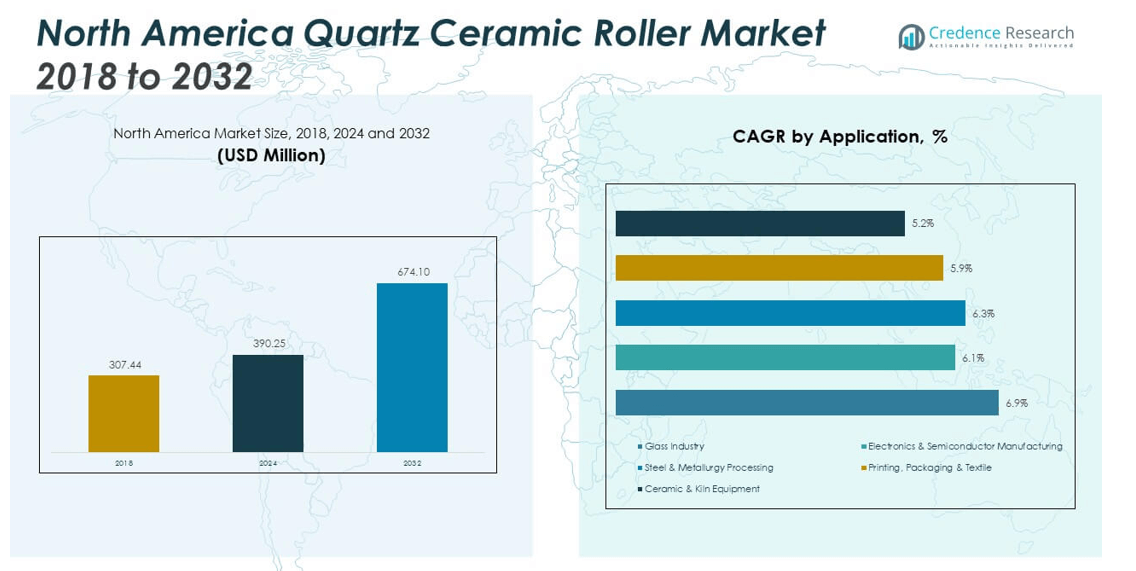

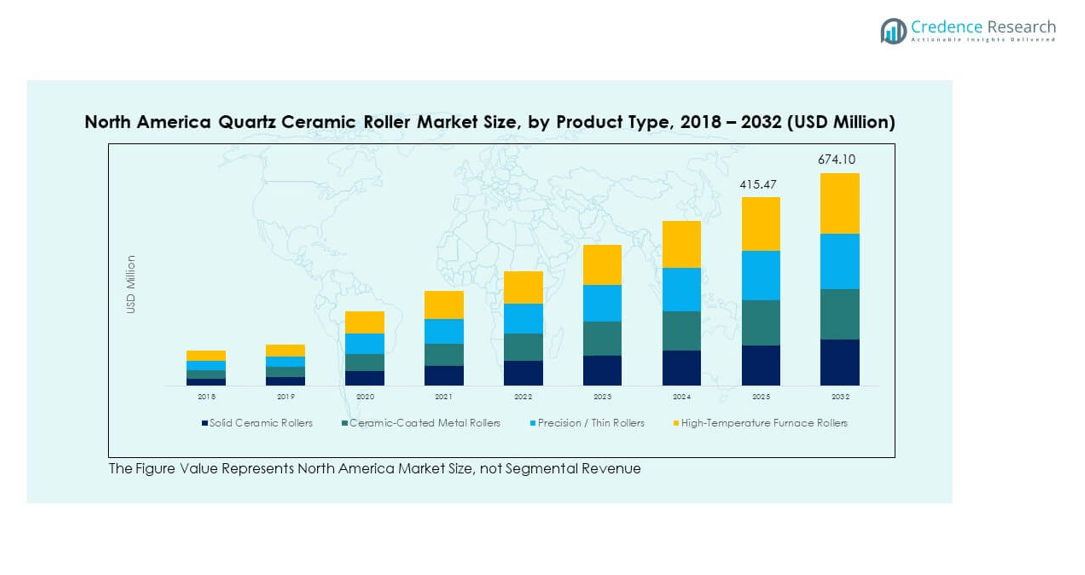

2.2 Growth Arc – Revenue Projections (USD Million)

2.3. Premium Insights – Based on Primary Interviews

CHAPTER NO. 3 : NORTH AMERICA WOUND DEBRIDEMENT MARKET FORCES & INDUSTRY PULSE

3.1 Foundations of Change – Market Overview

3.2 Catalysts of Expansion – Key Market Drivers

3.2.1 Momentum Boosters – Growth Triggers

3.2.2 Innovation Fuel – Disruptive Technologies

3.3 Headwinds & Crosswinds – Market Restraints

3.3.1 Regulatory Tides – Compliance Challenges

3.3.2 Economic Frictions – Inflationary Pressures

3.4 Untapped Horizons – Growth Potential & Opportunities

3.5 Strategic Navigation – Industry Frameworks

3.5.1 Market Equilibrium – Porter’s Five Forces

3.5.2 Ecosystem Dynamics – Value Chain Analysis

3.5.3 Macro Forces – PESTEL Breakdown

3.6 Price Trend Analysis

3.6.1 Regional Price Trend

3.6.2 Price Trend by product

CHAPTER NO. 4 : KEY INVESTMENT EPICENTER

4.1 Regional Goldmines – High-Growth Geographies

4.2 Product Frontiers – Lucrative Product Categories

4.3 Method Sweet Spots – Emerging Demand Segments

CHAPTER NO. 5: REVENUE TRAJECTORY & WEALTH MAPPING

5.1 Momentum Metrics – Forecast & Growth Curves

5.2 Regional Revenue Footprint – Market Share Insights

5.3 Segmental Wealth Flow – Product & Method Revenue

CHAPTER NO. 6 : TRADE & COMMERCE ANALYSIS

6.1. Import Analysis by Region

6.1.1. North America Wound Debridement Market Import Revenue By Region

6.2. Export Analysis by Region

6.2.1. North America Wound Debridement Market Export Revenue By Region

CHAPTER NO. 7 : COMPETITION ANALYSIS

7.1. Company Market Share Analysis

7.1.1. North America Wound Debridement Market: Company Market Share

7.2. North America Wound Debridement Market Company Revenue Market Share

7.3. Strategic Developments

7.3.1. Acquisitions & Mergers

7.3.2. New Product Launch

7.3.3. Regional Expansion

7.4. Competitive Dashboard

7.5. Company Assessment Metrics, 2024

CHAPTER NO. 8 : NORTH AMERICA WOUND DEBRIDEMENT MARKET – BY PRODUCT SEGMENT ANALYSIS

8.1. North America Wound Debridement Market Overview by Product Segment

8.1.1. North America Wound Debridement Market Revenue Share By Product

8.2. Gels

8.3. Ointments & Creams

8.4. Wound Irrigation Solution

8.5. Surgical Devices

8.6. Medical Gauzes

8.7. Ultrasonic Devices

8.8. Others

CHAPTER NO. 9 : NORTH AMERICA WOUND DEBRIDEMENT MARKET – BY METHOD SEGMENT ANALYSIS

9.1. North America Wound Debridement Market Overview by Method Segment

9.1.1. North America Wound Debridement Market Revenue Share By Method

9.2. Autolytic

9.3. Enzymatic

9.4. Surgical

9.5. Mechanical

9.6. Others

CHAPTER NO. 10 : NORTH AMERICA WOUND DEBRIDEMENT MARKET – BY WOUND TYPE SEGMENT ANALYSIS

10.1. North America Wound Debridement Market Overview by Wound Type Segment

10.1.1. North America Wound Debridement Market Revenue Share By Wound Type

10.2. Pressure Ulcers

10.2.1 Stage 1

10.2.2 Stage 2

10.2.3 Stage 3

10.2.4 Stage 4

10.2.5 Deep Tissue Injury

10.3. Diabetic Foot Ulcers

10.4. Venous Leg Ulcers

10.5. Burn Wounds

10.5.1 Second-degree (partial-thickness)

10.5.2. Third-degree (full-thickness) burns

10.5.3. Others

CHAPTER NO. 11 : NORTH AMERICA WOUND DEBRIDEMENT MARKET – BY END-USE SEGMENT ANALYSIS

11.1. North America Wound Debridement Market Overview by End-use Segment

11.1.1. North America Wound Debridement Market Revenue Share By End-use

11.2. Hospital (Inpatient)

11.3. Hospital (Outpatient)

11.4. Complex Wound Clinic

11.5. Leg Ulcer Clinic

11.6. Diabetic Foot Clinic

11.7. Walking-in Clinic

11.8. Podiatry Clinic

11.9. General Practitioners (GP) Surgery

11.11. Nursing Home

11.11. Home Health

11.12. Hospitalization at Home (HAD)

CHAPTER NO. 12 : NORTH AMERICA WOUND DEBRIDEMENT MARKET – BY PURCHASE SEGMENT ANALYSIS

12.1. North America Wound Debridement Market Overview by Purchase Segment

12.1.1. North America Wound Debridement Market Revenue Share By Purchase

12.2. Prescription

12.3. Over the Counter

12.4. Others

CHAPTER NO. 13 : NORTH AMERICA WOUND DEBRIDEMENT MARKET – COUNTRY ANALYSIS

13.1. North America Wound Debridement Market Overview by Country Segment

13.1.1. North America Wound Debridement Market Revenue Share By Region

13.2. North America

13.2.1. North America Wound Debridement Market Revenue By Country

13.2.2. Product

13.2.3. North America Wound Debridement Market Revenue By Product

13.2.4. Method

13.2.5. North America Wound Debridement Market Revenue By Method

13.2.6. End-use

13.2.7. North America Wound Debridement Market Revenue By End-use

13.2.8. Wound Type

13.2.9. North America Wound Debridement Market Revenue By Wound Type

13.2.10. Purchase

13.2.11. North America Wound Debridement Market Revenue By Purchase

13.3. U.S.

13.4. Canada

13.5. Mexico

CHAPTER NO. 14 : COMPANY PROFILES

14.1. Coloplast Corp

14.1.1. Company Overview

14.1.2. Product Portfolio

14.1.3. Financial Overview

14.1.4. Recent Developments

14.1.5. Growth Strategy

14.1.6. SWOT Analysis

14.2. Medline Industries

14.3. Smith & Nephew

14.4. ConvaTec Group PLC

14.5. Integra LifeSciences

14.6. B. Braun SE

14.7. Molnlycke Health Care AB

14.8. Lohmann & Rauscher

14.9. 3M

14.10. Schülke & Mayr GmbH (via distributors)

14.11. Cardinal Health

14.12. URGO MEDICAL

14.13. BD (Becton, Dickinson and Company)

14.14. DEBx Medical