Market Overview:

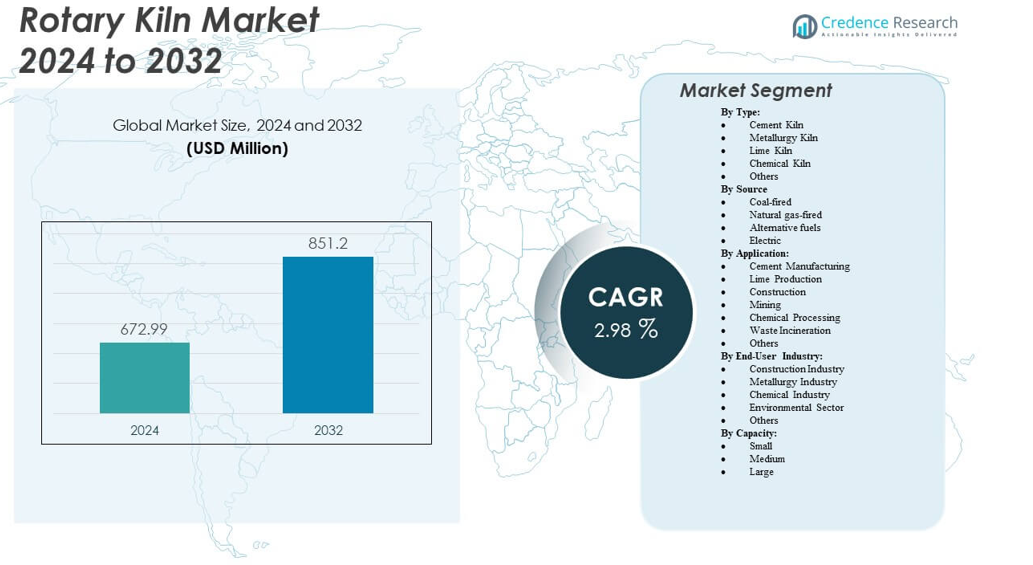

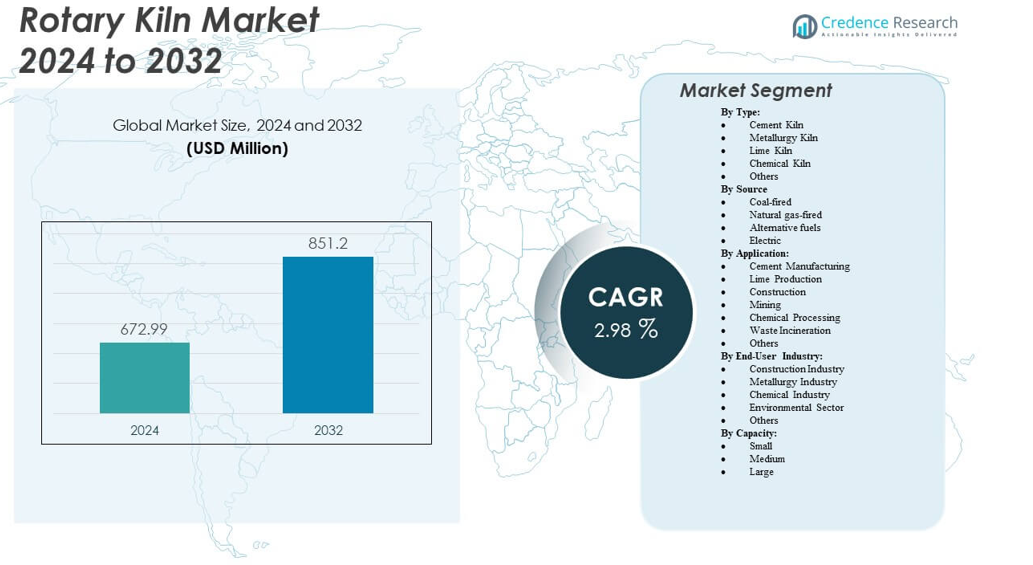

The Rotary Kiln Market is projected to grow from USD 672.99 million in 2024 to an estimated USD 851.2 million by 2032, with a compound annual growth rate (CAGR) of 2.98% from 2024 to 2032.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Rotary Kiln Market Size 2024 |

USD 672.99 million |

| Rotary Kiln Market, CAGR |

2.98% |

| Rotary Kiln Market Size 2032 |

USD 851.2 million |

The primary drivers of the Rotary Kiln Market include the increasing demand for cement and lime in construction, industrialization, and infrastructure projects worldwide. Furthermore, environmental regulations and sustainability efforts are prompting the adoption of energy-efficient kilns with lower emissions. Technological advancements in rotary kiln design and the use of alternative fuels also contribute to market growth, as industries seek to reduce costs and environmental impacts.

Geographically, Asia Pacific dominates the Rotary Kiln Market, driven by large-scale industrialization in China and India. These regions lead in cement production and lime manufacturing, fueling the demand for rotary kilns. North America and Europe follow, with steady growth driven by replacement and modernization of existing kilns, as well as the need to comply with environmental regulations. Emerging markets in Latin America, the Middle East, and Africa are also showing increasing adoption of rotary kilns, spurred by infrastructure development and industrial growth.

Market Insights:

- The Rotary Kiln Market is projected to grow from USD 672.99 million in 2024 to USD 851.2 million by 2032, with a CAGR of 2.98%.

- Increasing demand for cement and lime in construction and infrastructure development drives market growth.

- Environmental regulations and the need for energy-efficient solutions are fueling demand for advanced rotary kilns.

- Technological advancements in kiln design and alternative fuel usage are key growth factors.

- Asia Pacific leads the market, driven by industrialization and cement production in China and India.

- North America and Europe show steady growth due to modernization and compliance with environmental standards.

- Emerging markets in Latin America, the Middle East, and Africa are expanding due to infrastructure projects and industrial growth.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for Cement and Lime Products

The increasing demand for cement and lime in construction and industrial applications is a significant driver for the Rotary Kiln Market. Rapid urbanization and industrialization in emerging economies are spurring infrastructure development. These products are essential for various sectors, such as construction, mining, and agriculture, boosting the need for rotary kilns. Cement production, in particular, plays a central role in the global economy, contributing to high demand for energy-efficient and high-capacity kilns. Manufacturers are focused on developing kilns that can handle large volumes to meet these demands effectively.

Technological Advancements in Kiln Designs

Innovations in rotary kiln designs are driving market growth by improving energy efficiency and reducing emissions. Kilns are now being developed with advanced features, including improved insulation, more efficient fuel consumption, and real-time monitoring systems. These technological enhancements not only improve kiln performance but also lower operational costs. By integrating automation and digital technologies, rotary kilns are becoming more reliable and easier to operate, making them an attractive option for manufacturers across various industries. This technological progress is expected to drive the continued expansion of the market.

- For instance, Metso Outotec’s Ferroflame LowNOx burner has been proven to deliver up to 80% reduction in nitrogen oxide emissions in pelletizing plants, using natural gas since 2019. This technology is part of Metso Outotec’s Planet Positive offering and has been independently verified, with performance confirmation in published news and statements from on-site clients.

Environmental Regulations and Sustainability Goals

Tightening environmental regulations regarding emissions and energy consumption are shaping the future of the Rotary Kiln Market. Governments worldwide are enforcing stricter standards for industrial operations, especially in sectors like cement and metallurgy, where kilns are widely used. Manufacturers are increasingly adopting kilns with lower emissions and improved energy efficiency to comply with these regulations. Sustainability goals, including reducing carbon footprints and improving resource management, further incentivize investments in advanced rotary kiln technologies that support eco-friendly practices and greener production.

- For instance, Holcim’s Carbon2Business project at its Lägerdorf, Germany cement plant is designed to capture more than 1.2 million tons of CO₂ emissions annually as part of an EU Innovation Fund-supported initiative. Cement production at this plant will transition to entirely net-zero by 2029 through dedicated carbon capture and utilization technology, documented in public project and government reports.

Growing Adoption of Alternative Fuels

The shift toward alternative fuels in industrial processes is a key factor driving the Rotary Kiln Market. Many industries, including cement and steel production, are moving away from traditional fossil fuels to more sustainable options. These alternative fuels, such as biomass, waste materials, and renewable energy sources, are being incorporated into rotary kilns to reduce greenhouse gas emissions and reliance on non-renewable resources. This trend aligns with global sustainability objectives and presents growth opportunities for companies involved in the design and manufacture of rotary kilns.

Market Trends:

Shift Towards Automation and Digitalization

The trend toward automation and digitalization is becoming more prevalent in the Rotary Kiln Market. Industrial operators are adopting smart technologies that provide real-time data on kiln performance, enabling better decision-making. Integrated sensors and monitoring systems offer continuous feedback on operational parameters such as temperature, fuel efficiency, and wear levels. This shift towards automated processes is improving kiln productivity and reducing human intervention, leading to safer and more efficient operations. Manufacturers are increasingly investing in these technologies to stay competitive and meet growing customer demands.

Focus on Energy-Efficient Kilns

Energy efficiency is a critical trend influencing the Rotary Kiln Market. With rising energy costs and growing concerns about environmental impact, energy-efficient rotary kilns are in high demand. Companies are looking for kilns that optimize energy consumption while maintaining high output levels. Innovations such as advanced heat recovery systems and better insulation materials are becoming integral to modern kilns, enabling them to reduce energy waste. This trend is not only cost-effective but also helps businesses meet sustainability targets and reduce their carbon footprint.

- For instance, AGICO’s electromagnetic heated rotary kiln, installed at a limestone processing plant in Shanxi, China, operates at temperatures up to 1100°C with a 6000 kW system. This installation has enhanced calcination efficiency and contributed to a significant reduction in energy consumption, showcasing the kiln’s effective environmental benefits.

Rising Demand for Customizable Solutions

As industries grow and diversify, there is an increasing demand for rotary kilns that offer tailored solutions for specific applications. Manufacturers are responding by providing customizable kiln designs that can handle varying production capacities, raw materials, and operating conditions. This trend is particularly prominent in industries like cement, chemicals, and metallurgy, where production requirements are unique. The ability to customize kiln configurations allows businesses to improve efficiency, reduce costs, and enhance their competitive advantage.

- For instance, FEECO International offers rotary kilns with sizes up to 4.6 meters in diameter and 30.5 meters in length, with capacities ranging from 1 TPH to 50 TPH. These kilns are tailored to meet specific process and material requirements in various industrial applications. FEECO’s engineering solutions include proprietary refractory lining, optimized shells, and automation controls, all designed to enhance performance and efficiency, as detailed on their official product page.

Integration of Advanced Materials in Kiln Construction

The integration of advanced materials in rotary kiln construction is transforming the industry. High-performance alloys, heat-resistant ceramics, and composite materials are being used to improve the durability and efficiency of kilns. These materials are designed to withstand extreme temperatures and harsh operating conditions, reducing wear and extending the lifespan of rotary kilns. As industries continue to push for higher performance and longer-lasting equipment, the demand for these advanced materials is expected to rise, further driving the Rotary Kiln Market.

Market Challenges Analysis:

High Initial Investment and Maintenance Costs

The high upfront costs associated with rotary kilns present a significant challenge for the market. The complex nature of kiln designs and the advanced materials required for construction contribute to elevated capital expenditures. Many small and medium-sized enterprises may find it difficult to afford the high initial investment needed for installation. Furthermore, maintenance and operational costs can also be substantial, particularly for older kilns that require frequent repairs. These factors can limit the adoption of rotary kilns in price-sensitive markets and pose barriers to market growth.

Pressure to Meet Stringent Environmental Standards

Meeting stringent environmental standards is a considerable challenge for companies in the Rotary Kiln Market. Regulatory bodies are increasingly enforcing tighter emissions and efficiency requirements for industrial processes, particularly in sectors like cement and metal production. Companies must invest in technologies that reduce carbon emissions, improve energy efficiency, and comply with air quality standards. While advancements in kiln design are addressing some of these concerns, the continuous evolution of environmental regulations can create uncertainty for manufacturers trying to stay compliant with changing requirements.

Market Opportunities:

Expansion in Emerging Markets

Emerging economies present significant growth opportunities for the Rotary Kiln Market. Countries in Asia-Pacific, the Middle East, and Africa are investing heavily in infrastructure and industrialization, which creates high demand for cement, lime, and other industrial products. As these markets continue to develop, the demand for rotary kilns will rise, especially in industries like construction, mining, and metallurgy. Manufacturers that tailor their offerings to meet the specific needs of these regions can tap into this growing market and expand their global footprint.

Advancements in Sustainable Technologies

The increasing focus on sustainability presents an opportunity for innovation in the Rotary Kiln Market. Manufacturers that invest in developing kilns with lower environmental impact will gain a competitive advantage. The adoption of alternative fuels, energy-efficient technologies, and carbon capture systems are some of the advancements that will drive the market forward. Companies that can offer environmentally friendly solutions while maintaining high performance will meet the growing demand for sustainable industrial processes, creating significant opportunities for market growth.

Market Segmentation Analysis:

By Type:

The Cement Kiln segment is a dominant force in the Rotary Kiln Market, driven by the high demand for cement in the construction industry. These kilns are critical for producing clinker, a key ingredient in cement production. The Metallurgy Kiln segment also holds substantial market share, serving the metal industry by processing ores at high temperatures to extract metals. Rotary kilns are crucial in metal production, including iron, steel, and non-ferrous metals. Lime Kilns are essential for producing lime products, primarily used in environmental management and industrial applications, and this segment benefits from growing demand in the water treatment and steel industries. Chemical Kilns, while smaller in share, are important for chemical processing, producing fertilizers, catalysts, and other chemicals. The Others segment includes specialized kilns used in unique applications, contributing to the diversity of the Rotary Kiln Market.

- For instance, FLSmidth’s ROTAX-2 rotary kiln was supplied to major cement producers for high-capacity clinker lines; a typical deployment includes a 7,000 tons-per-day output, advanced self-adjusting roller suspension, and requires no periodic axis realignment, as documented for projects in the Middle East and North Africa.

By Source:

The Coal-fired rotary kilns are widely used due to their established infrastructure and cost-effectiveness, particularly in regions with abundant coal supplies. Natural gas-fired kilns are gaining popularity as they provide a cleaner, more efficient alternative to coal. This fuel type is especially favored in regions with a focus on reducing environmental emissions. The rise of Alternative fuels such as biomass and waste materials is an emerging trend, driven by sustainability goals and the need for greener alternatives in industrial processes. Electric rotary kilns are increasingly used, particularly in industries seeking precise temperature control and minimal environmental impact, supporting the shift towards cleaner energy solutions in sectors like chemical processing and waste incineration.

- For instance, Heidelberg Materials North America began operating its newest cement kiln at the Mitchell, Indiana, plant in 2023, replacing three old kilns with one state-of-the-art line capable of 2.4 million tons of cement annually, with substantial reductions in energy usage and emissions per ton, representing the second-largest cement plant in North America.

By Application:

In Cement Manufacturing, rotary kilns are integral to producing high-quality clinker, essential for cement production, which drives their demand in the global construction sector. Lime Production is another key application, with rotary kilns used to produce quicklime and hydrated lime for industries such as steel manufacturing and water treatment. The Construction sector relies heavily on rotary kilns for the production of materials like cement and lime, essential for building infrastructure and housing. Mining applications use rotary kilns for ore roasting and beneficiation, playing a vital role in metal extraction processes. In Chemical Processing, rotary kilns are used to produce various chemicals, including sulfuric acid and soda ash, supporting the growth of the global chemical industry. Waste Incineration is another growing application, as rotary kilns offer an efficient solution for converting waste into energy, especially in municipalities and industries focused on sustainability.

By End-User Industry:

The Construction Industry is a major end-user of rotary kilns, particularly for cement and lime production, as global infrastructure development continues to increase. The Metallurgy Industry is another key end-user, with rotary kilns used to process ores and extract metals like iron and steel. As demand for metals rises in sectors such as automotive and construction, so does the need for rotary kilns. The Chemical Industry utilizes rotary kilns in the production of various chemicals, including fertilizers, catalysts, and specialty products. The Environmental Sector has become an important end-user due to the growing reliance on rotary kilns for waste-to-energy applications and hazardous waste disposal. Industries focusing on sustainable waste management and energy recovery rely on the efficiency of rotary kilns to meet regulatory standards.

By Capacity:

Small-capacity rotary kilns are used in niche applications where lower production volumes are sufficient. These kilns are commonly found in industries with smaller-scale operations, such as waste management and chemical processing. Medium-capacity kilns strike a balance between cost and performance, making them ideal for industries with moderate production needs like lime production and small-scale cement manufacturing. Large-capacity rotary kilns are essential for high-volume industrial production, particularly in cement manufacturing, steel production, and large-scale chemical processes. The demand for large kilns is driven by the need for continuous, high-output operations in industries that require the processing of large quantities of raw materials at high temperatures.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Segmentation:

By Type:

- Cement Kiln

- Metallurgy Kiln

- Lime Kiln

- Chemical Kiln

- Others

By Source

- Coal-fired

- Natural gas-fired

- Alternative fuels

- Electric

By Application:

- Cement Manufacturing

- Lime Production

- Construction

- Mining

- Chemical Processing

- Waste Incineration

- Others

By End-User Industry:

- Construction Industry

- Metallurgy Industry

- Chemical Industry

- Environmental Sector

- Others

By Capacity:

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia Pacific leads the Rotary Kiln Market with a 36.25% share in 2023. China and India drive capacity additions in cement and lime production. Government programs supporting infrastructure development and waste-to-energy initiatives are pivotal in boosting demand for rotary kilns. OEMs are localizing services and spare parts to minimize downtime, further enhancing the market’s growth. Efficiency retrofits are becoming more common due to increasingly stringent energy consumption goals. These factors contribute to Asia Pacific’s continued dominance, as the region remains a key hub for industrial production. The rising focus on environmental sustainability and adoption of alternative fuels also support the growth of the market in this region, cementing its position as the leader.

North America ranks second in the Rotary Kiln Market, holding a 20.3% share in 2023. The region is characterized by a growing demand for industrial kilns, particularly in cement and metallurgy. Europe’s rotary lime kiln submarket contributes to about 18% of the market, indicating a steady share. EU regulations accelerating fuel shifts and heat-recovery upgrades have spurred innovation in rotary kiln technology. EPA standards and other environmental policies encourage the use of digital controls and emission-reducing technologies. Non-cement applications, including mining and chemicals, are increasingly adopting rotary kilns, adding to the market’s overall growth. North America is poised to continue its growth as manufacturers focus on energy-efficient and sustainable kiln solutions.

Latin America maintains a smaller 4.5% share in the Rotary Kiln Market, with countries like Brazil and Mexico sustaining demand through public infrastructure projects. Refurbished units are gaining traction among cost-sensitive buyers, especially in industries like cement and lime. The region’s increasing industrial activity, particularly in mining and chemical processing, adds to rotary kiln demand. The Middle East & Africa account for 4.1%, driven by large-scale projects in the GCC countries and emerging demand in African nations. Mega-projects and infrastructure development in the Middle East support the adoption of large rotary kilns. Additionally, Africa is expanding its demand for lime and clinker production, while waste mandates offer new opportunities in incineration. The Rotary Kiln Market in these regions is expected to grow steadily, supported by regional infrastructure and energy projects.

Key Player Analysis:

- FLSmidth & Co. A/S

- Metso Outotec

- Thyssenkrupp AG

- KHD Humboldt Wedag International AG

- CITIC Heavy Industries Co., Ltd.

- Jiangsu Pengfei Group Co., Ltd.

- NHI Group

- LNVT

- Feeco International Inc.

- Boardman LLC

- Harrop Industries Inc.

- Shanghai Minggong Heavy Equipment Co., Ltd.

- Henan Hongxing Mining Machinery Co., Ltd.

- Shanghai Tongli Heavy Machinery Co., Ltd.

- Ube Corporation

- Steinmüller Babcock Environment GmbH

- Dal Engineering Group

- Ansac Pty Ltd

- CHMP

- Prayon Group

Competitive Analysis:

Global OEMs and EPCs are engaged in a highly competitive Rotary Kiln Market, with companies like FLSmidth, thyssenkrupp, and Metso Outotec leading the charge by offering decarbonized process packages. These major players are focusing on reducing environmental impacts by incorporating energy-efficient technologies and advanced kiln designs. Chinese leaders such as CITIC and Jiangsu Pengfei have a strong foothold by offering large-scale turnkey solutions at competitive prices. KHD and UBE focus on specialized designs and brownfield revamps, capturing niche markets in regions with lower operational costs. U.S. firms, including FEECO, are leveraging their expertise in custom engineering and testing, emphasizing their capabilities in handling complex kiln requirements. Digital control, predictive maintenance, and fuel flexibility are now key differentiators in competitive bidding, ensuring operational efficiency and reducing downtime. Vendors that offer bundled solutions, including refractories, burners, and heat-recovery systems, are gaining an edge by improving ROI and increasing kiln performance. The Rotary Kiln Market rewards suppliers who can deliver a comprehensive solution, ensuring the lowest cost of ownership while meeting regulatory compliance and sustainability goals.

Recent Developments:

- In November 2025, FLSmidth & Co. A/S completed the divestiture of its cement business, which will now operate independently as Fuller Technologies following its acquisition by Pacific Avenue Capital Partners. This strategic transaction marks a turning point for the company, with Fuller Technologies positioned to innovate and grow within the rotary kiln and cement market segment by focusing on advanced lifecycle solutions and customer support for more than 1,400 cement plants globally.

- In December 2024, KHD Humboldt Wedag International AG signed a front-end engineering contract with Heidelberg Materials to plan a new oxyfuel rotary kiln at the Geseke plant. This partnership focuses on advancing carbon capture-ready kiln infrastructure, positioning both companies as leaders in renewable cement production and environmental compliance in rotary kiln technologies

Report Coverage:

The research report offers an in-depth analysis based on Type, Source, Application, End-User Industry and Capacity. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Rotary Kiln Market is expected to see increased demand driven by the ongoing growth of the cement and lime industries globally.

- Technological advancements, particularly in energy efficiency and emission reductions, will drive future adoption across industries.

- The shift towards alternative fuels and sustainable practices will be a significant factor in shaping future kiln designs and operation methods.

- As environmental regulations tighten, the market will witness an increase in digital control systems and predictive maintenance technologies.

- The rise of infrastructure and industrialization in emerging economies will create opportunities for rotary kiln adoption, especially in Asia-Pacific.

- With a greater emphasis on waste-to-energy solutions, the waste incineration application segment is projected to experience substantial growth.

- Energy costs and the demand for lower emissions will push for the development of more efficient kiln systems, providing market opportunities.

- The increasing focus on decarbonization and carbon capture technologies will lead to the development of eco-friendlier rotary kilns.

- Customization and flexibility in rotary kiln designs will be crucial to meeting the specific demands of diverse industries, including chemical and metallurgy.

- The expansion of industries such as mining, chemical processing, and metal production will support a steady demand for rotary kilns in the coming years.