Market Overview

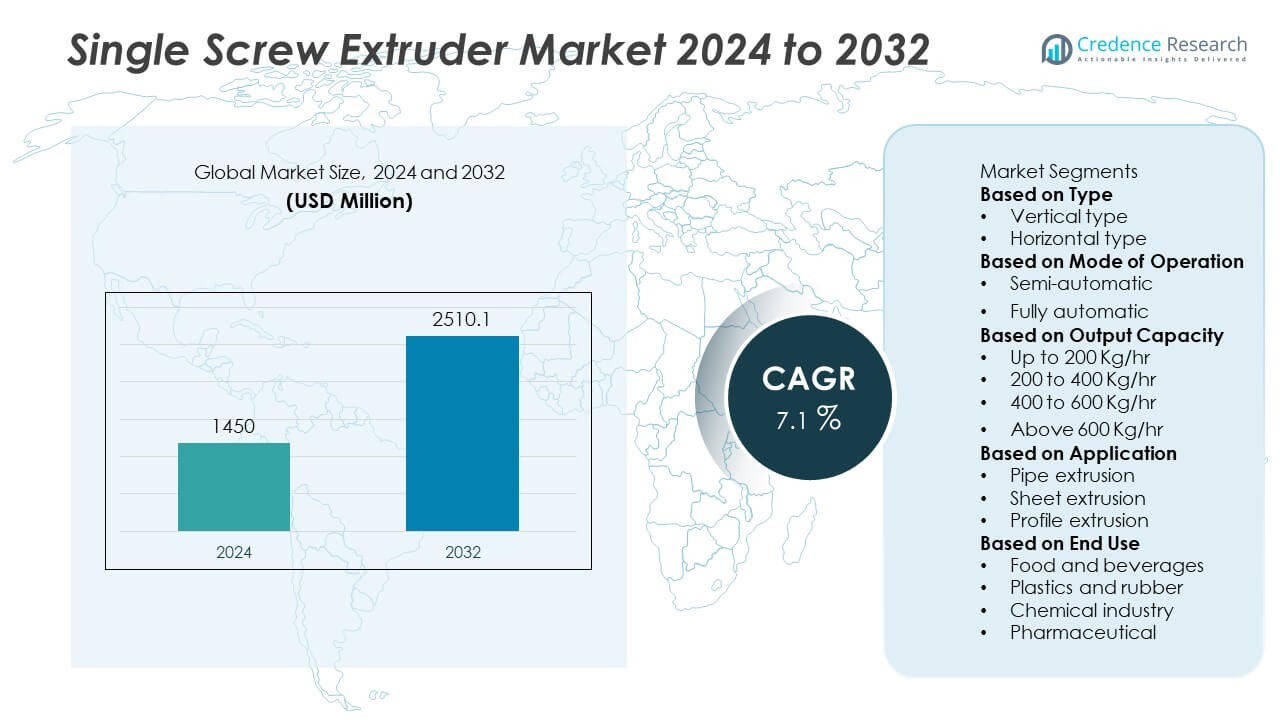

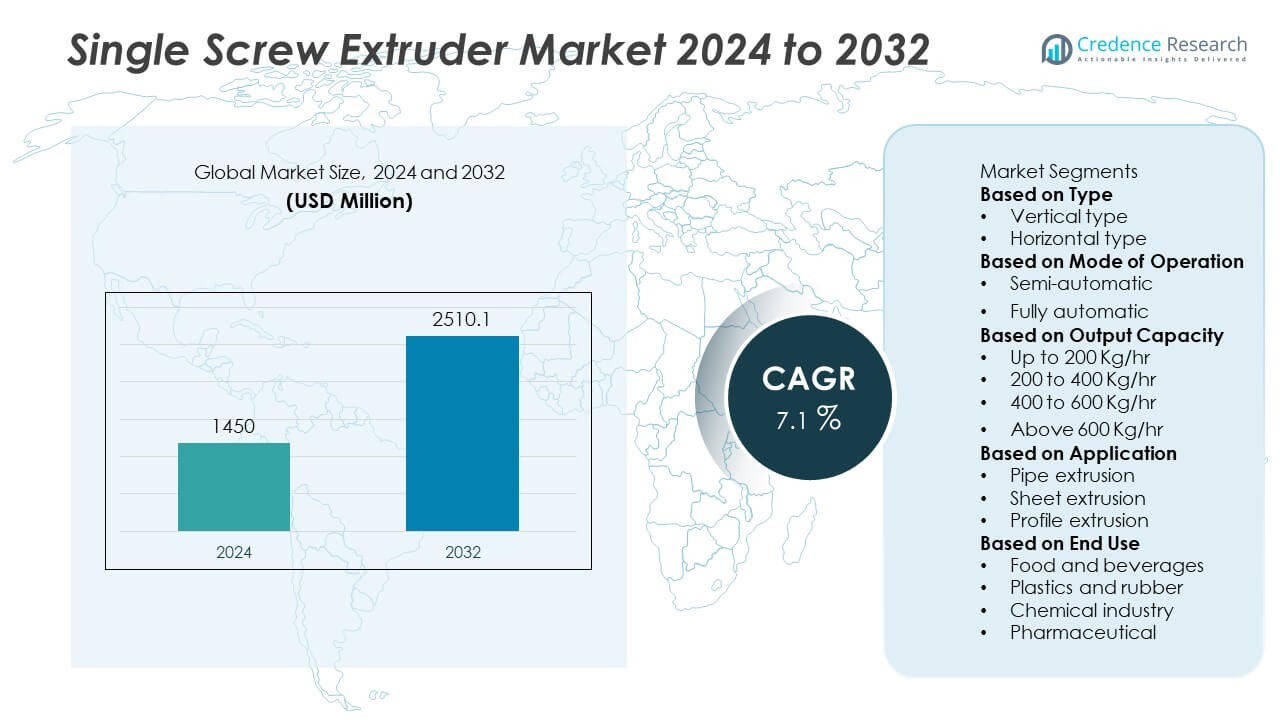

Single Screw Extruder Market size was valued at USD 1,450 million in 2024 and is anticipated to reach USD 2,510.1 million by 2032, at a CAGR of 7.1% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Single Screw Extruder Market Size 2024 |

USD 1,450 Million |

| Single Screw Extruder Market, CAGR |

7.1% |

| Single Screw Extruder Market Size 2032 |

USD 2,510.1 Million |

The Single Screw Extruder Market grows with strong drivers and evolving trends that highlight its role in plastics, packaging, and food processing industries. Rising demand for cost-effective extrusion equipment supports adoption across small and medium-scale manufacturers.

The Single Screw Extruder Market demonstrates strong geographical presence across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa, each region contributing through industrial growth and manufacturing priorities. North America shows steady demand supported by plastics and packaging industries, while Europe emphasizes advanced machinery and energy-efficient designs aligned with sustainability goals. Asia Pacific records the fastest expansion driven by large-scale polymer processing, automotive, and consumer goods manufacturing, supported by government-backed industrial programs. Latin America and the Middle East & Africa adopt extruders to strengthen local manufacturing, packaging, and infrastructure projects. Leading players shaping the market include Coperion, Buhler, Bausano & Figli, and American Extrusion International, who expand competitiveness through product innovation, automation integration, and advanced control technologies. Companies such as Extrudex and Boston Matthews also play a key role in providing specialized single screw extruder solutions tailored for regional and application-specific requirements.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Single Screw Extruder Market was valued at USD 1,450 million in 2024 and is projected to reach USD 2,510.1 million by 2032, growing at a CAGR of 7.1% during the forecast period.

- Rising demand for efficient polymer processing in industries such as packaging, construction, and automotive drives strong adoption of single screw extruders due to their cost-effectiveness and adaptability.

- The market reflects a clear trend toward automation, energy-efficient designs, and integration of advanced control systems that enhance precision, reduce waste, and optimize throughput.

- Competitive dynamics feature global players such as Coperion, Buhler, Bausano & Figli, American Extrusion International, and Extrudex, who strengthen market positions through technology upgrades, customized extruder designs, and service networks.

- Market restraints include high operational costs, wear-and-tear of screw components under continuous usage, and limited suitability for complex material processing compared to twin-screw extruders.

- Regional analysis highlights North America focusing on packaging and recycling, Europe emphasizing sustainable and high-performance extruders, Asia Pacific leading growth through large-scale plastics and automotive manufacturing, while Latin America and the Middle East & Africa gradually adopt extruders through industrial expansion.

- Long-term outlook suggests growing opportunities in biodegradable plastics processing, infrastructure-driven construction demand, and customized machinery solutions for emerging economies, reinforcing the role of single screw extruders in global manufacturing ecosystems.

Market Drivers

Rising Demand for Plastic Processing Across Packaging and Consumer Goods

The Single Screw Extruder Market grows steadily due to the rising use of plastic products in packaging, automotive, and consumer goods. Manufacturers prefer single screw extruders for their cost-effectiveness, reliability, and ability to handle a wide variety of thermoplastics. It enables high-volume production with consistent output, which is critical for packaging materials and disposable products. Growth in e-commerce and retail sectors fuels demand for flexible packaging that requires efficient extrusion equipment. Companies focus on lightweight and durable materials that extruders can produce at competitive rates. The expansion of consumer-driven industries reinforces adoption across global markets.

- For instance, Coperion reported that its latest ZSK extruder systems, deployed for polymer processing, achieved production rates exceeding 2,500 kg per hour of polyethylene films in 2024, strengthening its relevance in packaging applications.

Strong Adoption in Construction and Infrastructure Development

The Single Screw Extruder Market benefits from increasing use of extruded pipes, profiles, and sheets in construction projects. It plays a vital role in producing PVC pipes, window profiles, and insulation materials that support large-scale housing and infrastructure development. Rising investments in urban development and smart cities create consistent demand for cost-effective extrusion technologies. Construction firms require durable materials with high performance under varying environmental conditions, and extruders provide solutions at scale. Government-backed initiatives for affordable housing and modern infrastructure drive continued equipment utilization. The growth of construction-related applications positions single screw extruders as essential production tools.

- For instance, Bausano & Figli launched its new E-GO R single screw extruder line in 2024, designed for pipe extrusion, delivering up to 900 kg per hour of rigid PVC output, a benchmark that significantly supports construction material supply chains. The growth of construction-related applications positions single screw extruders as essential production tools.

Technological Advancements Enhancing Efficiency and Productivity

The Single Screw Extruder Market expands with innovations in screw design, temperature control, and automation. Advanced extruders improve mixing quality, reduce energy consumption, and minimize material wastage. It supports manufacturers in achieving higher efficiency while lowering operating costs. Integration of digital monitoring systems enables real-time process control and predictive maintenance. Producers adopt upgraded extruders to maintain competitiveness in cost-sensitive markets while meeting stricter quality standards. The combination of energy efficiency and automation strengthens long-term adoption across industries.

Expanding Applications in Food Processing and Recycling Sectors

The Single Screw Extruder Market gains momentum through its growing use in food extrusion and recycling. Food manufacturers rely on extruders for producing snacks, cereals, and pet food with precise texture and quality control. It also serves as a critical tool in recycling, converting plastic waste into reusable granules and compounds. Rising awareness of sustainability increases investment in recycling plants that depend on efficient extruders. The circular economy trend drives widespread adoption of equipment that supports material reuse. Expanding non-traditional applications diversify the market scope and ensure consistent demand beyond core industries.

Market Trends

Increasing Shift Toward Energy-Efficient and Sustainable Extrusion Systems

The Single Screw Extruder Market reflects a strong trend toward energy-efficient systems that reduce operational costs and environmental impact. Manufacturers develop extruders with optimized screw geometry and advanced heating systems to cut power consumption. It aligns with global sustainability goals as industries face stricter energy regulations. Adoption of eco-friendly extrusion processes supports reduced carbon footprints across plastics and packaging industries. Companies invest in equipment that balances high productivity with environmental responsibility. This transition strengthens the role of advanced extruders in meeting both economic and ecological objectives.

- For instance, Breyer GmbH introduced its energy-optimized single screw extrusion system in 2024, which reduced power usage by up to 22% while maintaining production output at 1,800 kg per hour for PET sheet extrusion, proving its efficiency in high-volume operations. This transition strengthens the role of advanced extruders in meeting both economic and ecological objectives.

Integration of Automation and Smart Control Technologies

Automation emerges as a defining trend in the Single Screw Extruder Market, enhancing process reliability and efficiency. Advanced extruders incorporate programmable logic controllers, IoT-based sensors, and real-time monitoring systems. It enables operators to track parameters, detect faults, and ensure consistent output quality. Predictive maintenance tools further reduce downtime and extend machine life. Automation also supports greater flexibility in handling diverse materials, expanding the range of applications. The adoption of smart-enabled extruders highlights the shift toward digitalization in industrial manufacturing.

- For instance, Boston Matthews launched its SMART PLC control system, providing operators access to recipe storage, alarms, data export, and network connectivity through its color touch-screen interface integrated on their single screw extruders.

Rising Popularity of Compact and Modular Extruder Designs

The Single Screw Extruder Market shows increasing preference for compact and modular systems that provide operational flexibility. Industries with limited floor space adopt smaller extruders without compromising output quality. It allows quick installation and easy integration into existing production lines. Modular designs also enable manufacturers to upgrade or reconfigure equipment as demand evolves. These systems provide scalability for both small enterprises and large-scale producers. The emphasis on compact, adaptable machines supports market growth across diverse industries.

Expansion of Extruder Applications in Recycling and Specialty Polymers

The Single Screw Extruder Market demonstrates a growing trend toward recycling and processing of specialty polymers. Recycling industries deploy extruders to convert post-consumer plastic waste into reusable pellets. It addresses rising demand for sustainable materials in packaging and construction. Specialty polymers such as biodegradable plastics and engineered compounds also drive advanced applications. Manufacturers invest in extruders capable of handling complex formulations with consistent quality. This diversification into recycling and high-performance materials ensures long-term relevance across global markets.

Market Challenges Analysis

High Energy Consumption and Rising Operational Costs Restricting Wider Adoption

The Single Screw Extruder Market faces challenges linked to high energy consumption and operational expenses. Extrusion processes often require significant electricity and heating capacity, which increases production costs for manufacturers. It becomes a concern for small and mid-scale enterprises that operate under tight margins. Energy efficiency improvements in newer machines demand higher upfront investment, creating a barrier for cost-sensitive users. Maintenance and spare parts replacement further add to operating expenses. These financial pressures restrict adoption, especially in emerging markets where affordability remains critical.

Limitations in Material Processing Flexibility and Increasing Competition from Alternatives

The Single Screw Extruder Market also encounters constraints in handling advanced or multi-layered polymer formulations compared to twin-screw systems. It limits efficiency when processing complex materials that require intensive mixing or compounding. Industries producing specialty plastics often prefer alternatives with higher flexibility, reducing reliance on single-screw models. Growing competition from advanced extrusion technologies challenges manufacturers to differentiate their offerings. It requires continuous innovation in screw design and process optimization to remain competitive. The limited adaptability of traditional single-screw machines creates long-term challenges for sustained market growth.

Market Opportunities

Rising Demand in Packaging and Consumer Goods Driving New Growth Opportunities

The Single Screw Extruder Market benefits from strong demand in packaging and consumer goods sectors where cost efficiency and high throughput are critical. Manufacturers of films, sheets, and profiles prefer single screw machines for their simplicity, reliability, and lower capital requirements. It provides a practical solution for large-volume applications where precision compounding is not essential. Growth in food packaging, disposable products, and basic household goods expands opportunities for suppliers offering affordable and durable extruder models. Increasing demand for lightweight plastics in packaging strengthens reliance on these machines. Expanding consumer-driven markets in Asia and Latin America create new revenue streams for manufacturers.

Advancements in Energy Efficiency and Sustainable Material Processing Creating Scope

The Single Screw Extruder Market presents opportunities through innovations in energy-efficient designs and capability to handle bio-based and recycled polymers. New extruder models integrate advanced heating systems and optimized screw geometries that reduce energy use and improve output consistency. It enables cost savings for manufacturers while supporting global sustainability goals. The ability to process biodegradable plastics and recycled resins enhances market relevance in industries transitioning toward eco-friendly solutions. Demand from automotive, construction, and agricultural sectors for low-cost extrusion equipment broadens adoption. Companies investing in sustainable technologies gain stronger competitive positions and long-term growth potential.

Market Segmentation Analysis:

By Type

The Single Screw Extruder Market divides by type into horizontal and vertical extruders. Horizontal extruders dominate due to their wide use in plastic processing, packaging, and consumer goods manufacturing. It supports efficient continuous production with straightforward maintenance and high throughput. Vertical extruders serve niche applications such as laboratory testing, specialty materials, and compact installations. Their smaller footprint makes them suitable for space-constrained facilities. The combination of horizontal dominance and vertical niche adoption ensures the market caters to both large-scale industries and specialized sectors with diverse requirements.

- For instance, Coperion’s horizontal single-screw extruders achieve output capacities above 2,500 kg/h for polyolefin film production, while Breyer’s vertical compact systems for laboratory use deliver throughputs of 15–25 kg/h for high-performance polymers.

By Mode of Operation

Segmentation by mode of operation includes automatic and semi-automatic extruders. Automatic systems lead the market due to their ability to deliver consistent quality, minimize human error, and optimize productivity through advanced control systems. It integrates automation technologies such as PLC-based monitoring and feedback mechanisms to improve efficiency and reduce downtime. Semi-automatic extruders continue to find adoption in small and medium enterprises due to lower costs and easier installation. The balance between advanced automation for large industries and cost-sensitive solutions for smaller manufacturers strengthens overall market adaptability.

- For instance, Boston Matthews’ SMART automatic single-screw extruders are equipped with PLC-controlled interfaces that reduce setup time by nearly 40% while maintaining extrusion speeds up to 300 rpm.

By Output Capacity

The Single Screw Extruder Market further divides by output capacity into low, medium, and high output extruders. Low-output models cater to specialized applications such as prototyping, laboratory-scale production, and customized material development. It offers flexibility for industries with limited batch sizes or experimental processing needs. Medium-output extruders record strong demand from packaging, consumer goods, and construction sectors where consistent quality and moderate volumes are required. High-output extruders serve industries such as automotive and large-scale film production, where efficiency and throughput are critical for cost competitiveness. This segmentation highlights the ability of single screw extruders to adapt across scales, from small laboratories to mass production environments.

Segments:

Based on Type

- Vertical type

- Horizontal type

Based on Mode of Operation

- Semi-automatic

- Fully automatic

Based on Output Capacity

- Up to 200 Kg/hr

- 200 to 400 Kg/hr

- 400 to 600 Kg/hr

- Above 600 Kg/hr

Based on Application

- Pipe extrusion

- Sheet extrusion

- Profile extrusion

Based on End Use

- Food and beverages

- Plastics and rubber

- Chemical industry

- Pharmaceutical

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America

North America accounts for 27% of the Single Screw Extruder Market, driven by strong demand across packaging, automotive, and construction industries. The United States dominates regional growth with its advanced plastics processing sector and high levels of automation in extrusion operations. Canada contributes through adoption in food packaging and consumer goods industries, while Mexico benefits from increasing investments in industrial manufacturing and automotive production. It reflects steady adoption due to technological maturity and the preference for energy-efficient extrusion machinery. Ongoing modernization of manufacturing facilities and the need for cost-efficient plastic processing systems further strengthen regional demand. North American manufacturers also emphasize sustainability, with single screw extruders adapted for recycled materials, enhancing long-term adoption.

Europe

Europe holds 25% of the Single Screw Extruder Market, supported by a robust base of automotive, construction, and packaging sectors. Germany leads the region with advanced extrusion technology for automotive components and industrial applications, while Italy and France strengthen demand through food processing and specialty packaging. The United Kingdom focuses on sustainable plastics and eco-friendly material processing. It reflects high adoption due to strict regulations on energy efficiency and recyclability, which drive industries to integrate modern extruders into production lines. European manufacturers adopt single screw extruders to meet sustainability targets while ensuring precision in high-volume production. Regional growth is further reinforced by investments in smart manufacturing and Industry 4.0 initiatives, which promote digital monitoring and real-time process optimization.

Asia Pacific

Asia Pacific commands the largest share at 32% of the Single Screw Extruder Market, fueled by rapid industrialization, infrastructure expansion, and large-scale manufacturing. China and India dominate demand with their expanding plastics, packaging, and construction sectors. Japan and South Korea contribute through precision engineering and electronics-related extrusion applications. Southeast Asian countries including Vietnam, Indonesia, and Thailand record rising adoption with growing investments in packaging and consumer goods manufacturing. It benefits from cost-effective production and government-backed industrialization programs that encourage machinery adoption. Asia Pacific’s leadership is reinforced by its role as a global hub for plastics processing and extrusion exports. Increasing demand for recycled plastics and sustainable extrusion solutions further supports long-term growth across the region.

Latin America

Latin America accounts for 8% of the Single Screw Extruder Market, with Brazil and Mexico as the primary contributors. Brazil’s packaging and food processing industries lead demand, while Mexico strengthens its position through automotive manufacturing and export-oriented production. Argentina and Chile also support growth with smaller-scale adoption in consumer goods and construction materials. It demonstrates moderate adoption due to limited capital investment in advanced manufacturing technologies compared to North America and Europe. However, the increasing push toward modernization and the rising need for cost-efficient extrusion solutions create opportunities for expansion. Partnerships with global suppliers improve technology access, enhancing regional competitiveness.

Middle East & Africa

The Middle East & Africa represent 8% of the Single Screw Extruder Market, supported by industrial expansion and infrastructure projects. Gulf nations including Saudi Arabia and the United Arab Emirates emphasize adoption in construction materials and packaging industries. African nations such as South Africa and Nigeria show growing demand driven by urbanization and consumer goods manufacturing. It reflects gradual adoption due to financial and infrastructure limitations, yet increasing investment in industrialization creates steady opportunities. Governments across the region prioritize diversification of economies beyond oil, which strengthens demand for plastic processing and extrusion machinery. Modular and cost-effective extruders gain traction, addressing the needs of small and mid-scale manufacturers in developing markets.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- CPM

- Boston Matthews

- Breyer

- Coperion

- Bausano & Figli

- Extrudex

- American Extrusion International

- Buhler

- BC Extrusion

- B&P Littleford

Competitive Analysis

The competitive landscape of the Single Screw Extruder Market is defined by established manufacturers such as American Extrusion International, B&P Littleford, Bausano & Figli, BC Extrusion, Boston Matthews, Breyer, Buhler, Coperion, CPM, and Extrudex, who compete through product innovation, technological expertise, and global presence. Coperion and Buhler lead with advanced extruder technologies designed for high throughput and precision in polymer processing, supported by strong service and distribution networks. Bausano & Figli and Breyer emphasize sustainable and energy-efficient extruder solutions that align with growing demand for eco-friendly plastics manufacturing. Boston Matthews and American Extrusion International cater to packaging and food industries with reliable, cost-effective machinery tailored for large-scale operations. CPM and B&P Littleford focus on modular designs and flexible extrusion systems that address varied industrial requirements, while BC Extrusion and Extrudex strengthen competitiveness by offering customized solutions for small and mid-scale manufacturers. Across the market, companies pursue strategies that include automation, digital control integration, and improved screw design for material efficiency. The focus on balancing cost-effectiveness with innovation, supported by after-sales service and technical expertise, defines competition and ensures that these players maintain strong positions across diverse end-use industries such as packaging, automotive, construction, and recycling.

Recent Developments

- In July 2025, Coperion Masterbatch producer Colorplasticchemie (cpc) enhanced its ZSK twin‑screw extruders by integrating C‑BEYOND digital platform for real-time cloud-based monitoring, improving OEE, energy consumption, and CO₂ tracking.

- In April 2025, Coperion Showcased the STS 75 Mc PLUS twin‑screw extruder at Chinaplas, featuring a specific torque of 13.6 Nm/cm³ and delivering up to 20% higher throughput, while improving product quality.

- In June 2024, CPM Introduced its Global eXtruder Technology (GXT) line of twin‑screw extruders—a standardized platform that lowers costs and accelerates deployment worldwide.

Market Concentration & Characteristics

The Single Screw Extruder Market reflects a moderately fragmented structure where global leaders and regional specialists compete through product differentiation, process optimization, and application-specific designs. It features strong participation from established companies including Coperion, Buhler, CPM, Bausano & Figli, and American Extrusion International, each leveraging technological expertise to deliver reliable and efficient extruders. Mid-sized firms such as Boston Matthews, Breyer, Extrudex, BC Extrusion, and B&P Littleford strengthen competitiveness by focusing on customized solutions for plastics, food processing, and industrial applications. The market emphasizes characteristics such as durability, energy efficiency, and adaptability to varied raw materials, supported by advances in automation and digital monitoring. It responds to growing demand across packaging, automotive, construction, and food sectors, where consistent output and low maintenance are critical. Strong focus on innovation, modular designs, and integration of IoT-enabled platforms defines the competitive concentration while ensuring adaptability across diverse end-user environments.

Report Coverage

The research report offers an in-depth analysis based on Type, Mode of Operation, Output Capacity, Application, End Use and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Market growth will align with rising demand for plastics in packaging, automotive, and construction industries.

- Energy-efficient and low-maintenance extruders will gain preference among manufacturers.

- Integration of automation and IoT-enabled monitoring will enhance process control and reliability.

- Customized extruder solutions will see higher adoption for specialized food and industrial applications.

- Advances in screw design and material handling will improve throughput and product quality.

- Emerging economies will drive demand through expanding manufacturing capacity and infrastructure projects.

- Recycling and circular economy initiatives will increase adoption of extruders for reprocessed materials.

- Compact and modular extruder systems will attract small and medium enterprises.

- Partnerships between global and regional players will expand technology access and market reach.

- Continuous investment in digital platforms and predictive maintenance tools will strengthen operational efficiency.