Market Overview

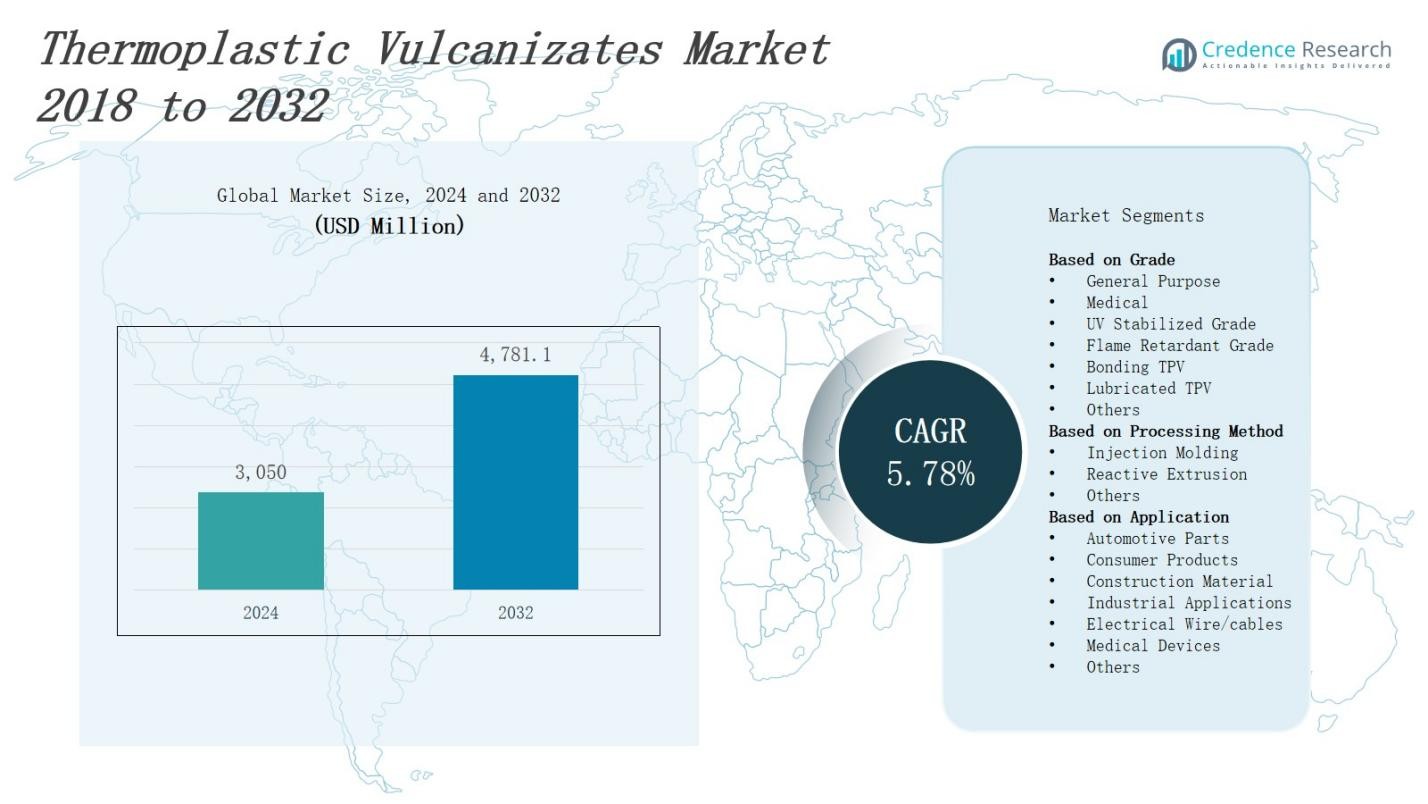

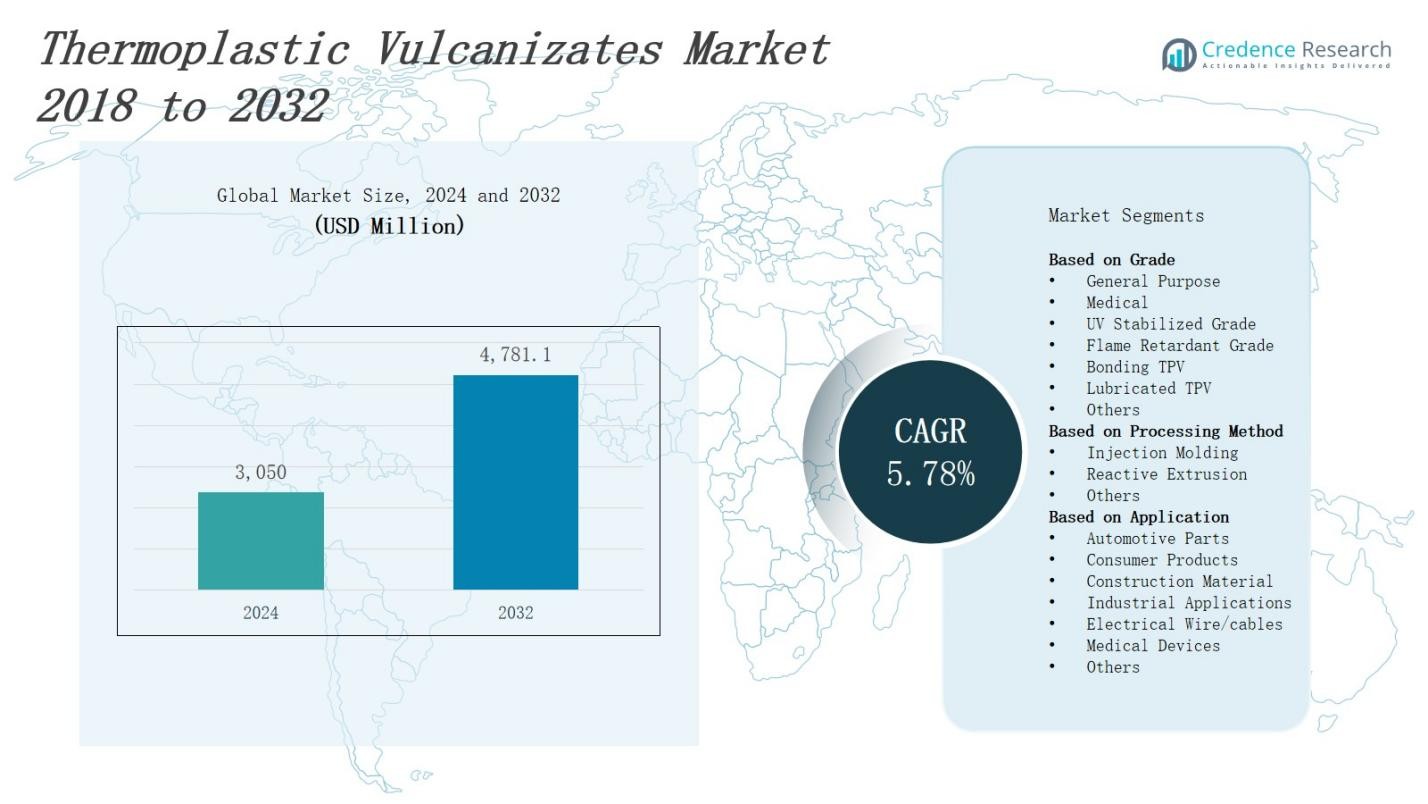

The thermoplastic vulcanizates market is projected to grow from USD 3,050 million in 2024 to USD 4,781.1 million by 2032, expanding at a CAGR of 5.78%.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Thermoplastic Vulcanizates Market Size 2024 |

USD 3,050 Million |

| Thermoplastic Vulcanizates Market, CAGR |

5.78% |

| Thermoplastic Vulcanizates Market Size 2032 |

USD 4,781.1 Million |

The thermoplastic vulcanizates (TPV) market grows driven by increasing demand for lightweight, flexible, and durable materials across automotive, construction, and consumer goods industries. Rising emphasis on sustainability encourages TPV adoption due to its recyclability and energy-efficient processing. Innovations in material formulations enhance thermal stability and chemical resistance, expanding application scope. Growing automotive production, especially electric vehicles, and infrastructure development boost market demand. Manufacturers focus on improving process efficiency and customizing TPV grades to meet specific industry needs. The trend toward replacing conventional elastomers with TPVs in various applications further supports sustained market growth and technological advancement.

The thermoplastic vulcanizates market spans key regions including North America, Europe, Asia-Pacific, and the Rest of the World. North America leads with 35% market share, driven by strong automotive and sustainability focus. Europe holds 28%, supported by regulatory frameworks and advanced manufacturing. Asia-Pacific commands 30%, fueled by rapid industrialization and infrastructure growth. The Rest of the World accounts for 7%, with emerging demand in Latin America, the Middle East, and Africa. Leading players include Celanese Corporation, Mitsubishi Chemical, RTP, and Mitsui Chemicals, who drive innovation and global expansion across these regions.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The thermoplastic vulcanizates market is projected to grow from USD 3,050 million in 2024 to USD 4,781 million by 2032, at a CAGR of 5.78%.

- Increasing demand for lightweight, flexible, and durable materials across automotive, construction, and consumer goods sectors drives market growth.

- Emphasis on sustainability promotes TPV adoption due to recyclability and energy-efficient processing.

- Innovations in material formulations improve thermal stability and chemical resistance, expanding applications.

- Growing automotive production, especially electric vehicles, and infrastructure development boost TPV demand.

- Manufacturers focus on process efficiency and customized TPV grades to meet specific industry needs.

- The market benefits from replacing conventional elastomers with TPVs in multiple applications, supporting sustained growth and technological advancement.

Market Drivers

Rising Demand for Lightweight and Durable Materials

The thermoplastic vulcanizates market benefits from increasing demand for lightweight and durable materials, particularly in the automotive and construction sectors. Manufacturers prioritize materials that reduce vehicle weight to improve fuel efficiency and lower emissions. TPVs offer excellent flexibility combined with high strength, making them ideal for replacing traditional rubber components. Its durability under harsh environmental conditions further drives adoption. Industries seek materials that enhance product lifespan while maintaining performance, fueling sustained growth in TPV applications.

- For instance, ExxonMobil’s Santoprene TPV series has been used in HVAC systems to improve the durability and flexibility of seals, ensuring performance across a wide temperature range.

Growing Focus on Sustainability and Recyclability

Sustainability initiatives encourage the use of thermoplastic vulcanizates due to their recyclability and lower environmental impact compared to conventional elastomers. It supports circular economy principles by allowing reuse and reducing waste. Regulatory pressures push industries to adopt eco-friendly materials. TPVs require less energy in manufacturing, cutting overall carbon footprint. This aligns with corporate sustainability goals and consumer demand for greener products, strengthening the material’s position in various end-use sectors.

- For instance, BASF has implemented TPVs in automotive applications that contribute to weight reduction, helping manufacturers meet stringent emission regulations.

Advancements in Material Formulation and Processing

Continuous innovation in TPV formulations enhances thermal stability, chemical resistance, and processability, expanding its usability across industries. Manufacturers tailor it to meet specific requirements such as improved softness or stiffness. Enhanced processing techniques reduce cycle times and manufacturing costs, increasing efficiency. The ability to customize TPVs for diverse applications boosts their attractiveness to automotive, construction, and consumer goods manufacturers. This technological progress accelerates market penetration and application diversity.

Expansion of Automotive and Infrastructure Sectors

The growth of automotive production, especially electric vehicles, drives demand for thermoplastic vulcanizates due to their lightweight and insulating properties. It contributes to vehicle efficiency and safety improvements. Infrastructure development increases the need for durable construction materials, further supporting TPV use. Growing investments in these sectors create opportunities for TPV manufacturers to supply high-performance components. It helps industries meet evolving standards and performance expectations, supporting robust market growth.

Market Trends

Increasing Adoption of TPVs in Automotive Lightweighting Initiatives

The thermoplastic vulcanizates market experiences strong growth driven by the automotive industry’s shift toward lightweight materials. Automakers prioritize reducing vehicle weight to improve fuel efficiency and meet stringent emissions regulations. TPVs offer a combination of flexibility, durability, and weight reduction that supports these goals. It replaces heavier traditional rubber parts in seals, gaskets, and interior components. The demand for electric and hybrid vehicles further accelerates TPV adoption due to their thermal insulation and electrical properties.

- For instance, TPV Group Corporation has contributed to developing new high-strength steel and aluminum alloys for automotive seat components and chassis parts that reduce vehicle weight while maintaining load capacity.

Expansion into Construction and Building Applications

Construction and building sectors increasingly incorporate thermoplastic vulcanizates for their durability and resistance to environmental factors. TPVs provide superior performance in seals, weatherproofing, and piping systems. It withstands UV radiation, chemicals, and temperature variations, enhancing product lifespan. The market benefits from infrastructure growth worldwide, creating demand for high-performance materials that reduce maintenance costs. Growing awareness of sustainable construction materials supports wider TPV adoption, improving energy efficiency and environmental compliance.

- For instance, Dow’s Engage™ TPVs are used in roofing membranes that demonstrate extended UV resistance and flexibility in extreme weather conditions.

Innovations in Sustainable and Bio-Based TPVs

The thermoplastic vulcanizates market follows a trend toward sustainable and bio-based formulations to meet environmental regulations and consumer preferences. Manufacturers develop TPVs using renewable resources and recycled content, reducing reliance on fossil fuels. It improves eco-friendliness without compromising mechanical properties or durability. The trend toward green materials aligns with global efforts to lower carbon footprints across industries. This innovation broadens TPV applications in sectors with strict sustainability standards, including automotive and consumer goods.

Advancement in Processing Technologies Enhances TPV Versatility

Processing technologies evolve to improve TPV production efficiency, quality, and customization. It enables shorter cycle times and better integration with existing manufacturing lines. Advances in compounding and extrusion methods allow tailored mechanical and thermal properties for specific applications. The market benefits from increased design flexibility, supporting complex shapes and multi-material assemblies. These improvements reduce costs and expand TPV use in diverse industries, driving overall market growth and innovation.

Market Challenges Analysis

High Production Costs and Raw Material Price Volatility

The thermoplastic vulcanizates market faces challenges from high production costs linked to raw material price fluctuations. TPVs require specialized polymers and additives, which increase manufacturing expenses compared to traditional elastomers. Volatile prices of petrochemical feedstocks impact overall cost stability, affecting profit margins for manufacturers. It limits adoption in price-sensitive applications and regions. Companies must balance cost efficiency with product performance while exploring alternative materials and suppliers to mitigate risks and maintain competitive pricing.

Technical Limitations and Application-Specific Constraints

Thermoplastic vulcanizates exhibit limitations in certain high-temperature and heavy-load applications, restricting their use in some industrial sectors. It may not fully replace conventional rubber or thermoset elastomers in extreme conditions due to lower heat resistance or mechanical strength. This challenge slows market penetration in segments demanding superior performance under harsh environments. The market must invest in research and development to enhance TPV properties and expand its applicability. Collaboration with end users helps tailor formulations to meet specific technical requirements, supporting wider acceptance.

Market Opportunities

Growing Demand in Electric Vehicle and Renewable Energy Sectors

The thermoplastic vulcanizates market holds significant opportunities driven by the expanding electric vehicle (EV) industry and renewable energy applications. TPVs offer excellent electrical insulation, lightweight properties, and durability, making it ideal for EV components such as battery housings, seals, and cable sheathing. Rising investments in clean energy infrastructure create new avenues for TPV use in solar panels, wind turbines, and energy storage systems. It enables manufacturers to meet stringent performance and safety standards while supporting sustainability goals. The increasing shift toward electrification globally creates a favorable environment for TPV market expansion.

Expansion in Emerging Markets and Diversification of Applications

Emerging economies present lucrative growth prospects for the thermoplastic vulcanizates market due to rapid industrialization and infrastructure development. Increasing urbanization and consumer demand in Asia-Pacific, Latin America, and Africa drive the adoption of advanced materials like TPVs across automotive, construction, and consumer goods sectors. It offers potential for diversification into new applications, including medical devices, electronics, and packaging, where flexibility and durability are essential. Market players can capitalize on rising awareness of sustainable materials and tailor product offerings to meet regional requirements, enhancing penetration and competitive advantage.

Market Segmentation Analysis:

By Grade

The thermoplastic vulcanizates market segments by grade into general purpose, medical, UV stabilized, flame retardant, bonding, lubricated, and others. General purpose grades dominate due to broad applicability across automotive, construction, and consumer goods. Medical-grade TPVs cater to stringent hygiene and safety requirements in healthcare products. UV stabilized and flame retardant grades support outdoor and high-safety applications. Specialized bonding and lubricated TPVs improve processability and performance, enabling manufacturers to meet specific industry demands effectively.

- For instance, GLS Corporation’s general purpose TPVs are widely used in automotive door seals to enhance durability and flexibility.

By Processing Method

Injection molding leads the processing segment, favored for producing complex shapes with precision and speed. Reactive extrusion offers customization benefits by enabling dynamic vulcanization during polymer processing, enhancing material properties. Other methods serve niche applications with specific technical requirements. It allows manufacturers flexibility in production to optimize costs, quality, and efficiency. The choice of processing method influences TPV’s suitability for various industrial applications, driving market growth through tailored solutions.

- For instance, Teknor Apex utilizes high-efficiency injection molding with their Santoprene TPV grades, achieving cycle times significantly shorter than traditional rubber, enabling faster production of automotive sealing components with excellent durability.

By Application

Automotive parts constitute the largest application segment, driven by the demand for lightweight, durable components like seals, gaskets, and interior parts. Consumer products benefit from TPVs’ flexibility and aesthetics, expanding its use in household goods and sports equipment. Construction materials leverage TPVs for weather-resistant seals and piping. Industrial applications, electrical wire/cables, and medical devices also represent significant markets. TPVs’ adaptability supports diverse requirements, enhancing its penetration across industries and applications worldwide.

Segments:

Based on Grade

- General Purpose

- Medical

- UV Stabilized Grade

- Flame Retardant Grade

- Bonding TPV

- Lubricated TPV

- Others

Based on Processing Method

- Injection Molding

- Reactive Extrusion

- Others

Based on Application

- Automotive Parts

- Consumer Products

- Construction Material

- Industrial Applications

- Electrical Wire/cables

- Medical Devices

- Others

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

North America holds a significant share of 35% in the thermoplastic vulcanizates market, driven by strong automotive and construction industries. The region benefits from high consumer awareness of sustainable materials and stringent environmental regulations that encourage TPV adoption. Leading manufacturers invest heavily in research and development to produce advanced TPV grades suited for electric vehicles and renewable energy sectors. It supports a well-established supply chain and advanced processing technologies. Growing demand for lightweight, durable materials in medical devices and consumer products further fuels market expansion in the region.

Europe

Europe accounts for 28% of the thermoplastic vulcanizates market, supported by robust automotive production and infrastructure development. It emphasizes sustainability, pushing manufacturers to develop eco-friendly TPVs with improved recyclability and reduced carbon footprints. The presence of key automotive OEMs and strict regulatory frameworks for emissions and safety drive TPV demand in automotive and industrial applications. It benefits from government incentives promoting green technologies and circular economy models. Expansion in electrical wire and cable applications also contributes to market growth across European countries.

Asia-Pacific

Asia-Pacific commands 30% market share, fueled by rapid industrialization, urbanization, and rising disposable incomes. The region experiences growing demand for TPVs in automotive manufacturing, consumer goods, and construction materials. Emerging economies like China, India, and Southeast Asia invest heavily in infrastructure and automotive sectors, supporting TPV adoption. It attracts foreign investments and partnerships, leading to enhanced production capacities and technology transfer. The expanding electronics and medical device industries further increase the need for specialized TPV grades, accelerating regional market growth.

Rest of the World

The Rest of the World region, including Latin America, Middle East, and Africa, holds a 7% share in the thermoplastic vulcanizates market. Economic development and infrastructure projects stimulate demand for advanced materials like TPVs in construction and automotive applications. Limited but growing awareness of sustainability drives gradual adoption of recyclable and lightweight materials. It faces challenges due to lower industrialization levels and less developed supply chains. Market players focus on strategic partnerships and local manufacturing to capture emerging opportunities and expand their footprint in these regions.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Biesterfeld

- Mitsubishi Chemical Group Corporation

- LCY

- SantopSeal

- Kumho Polychem

- Celanese Corporation

- FlexiShine Polyblends

- Bjørn Thorsen

- RTP

- Elastron TPE

- Mitsui Chemicals

- Apar Industries

Competitive Analysis

The thermoplastic vulcanizates market features intense competition among leading chemical and polymer manufacturers focused on innovation and capacity expansion. Key players invest in advanced R&D to develop high-performance, sustainable TPV grades tailored to automotive, construction, and medical applications. It fosters strategic partnerships and collaborations to enhance product portfolios and enter new geographic markets. Manufacturers emphasize process optimization to reduce costs and improve product quality. Competitive differentiation arises from proprietary technologies, customized solutions, and responsive customer support. The market’s dynamic nature pushes companies to continuously adapt to evolving industry standards and regulatory requirements, securing long-term growth and market share. Additionally, companies focus on expanding production capabilities in emerging markets to capitalize on growing demand and diversify their revenue streams, strengthening their global presence.

Recent Developments

- In December 2023, Biesterfeld AG and Celanese Corporation deepened their partnership to enhance their joint portfolio and enter new markets.

- In 2025, Teknor Apex and Goodyear Chemical unveiled new TPVs that incorporate styrenic elastomers to improve oil resistance and adhesion, aimed at applications like high-performance grips, seals, and diaphragms.

- In June 2025, Prism Worldwide launched a sustainable thermoplastic vulcanizate (TPV) formulation using revulcanized end-of-life tire rubber. This innovation enables up to 50% recycled content for injection and rotational molding applications, addressing odor, cost, and performance challenges for indoor vehicle and consumer product use.

- In August 2023, Teknor Apex launched the Starlink TPVs, emphasizing sustainability with up to 40% recycled content. The Sarlink RX 3100B Series contains post-industrial recycled content, enhancing processability and performance while expanding the company’s product portfolio.

Market Concentration & Characteristics

The thermoplastic vulcanizates market exhibits a moderately concentrated landscape dominated by a few key global players holding significant market shares. Leading companies focus on innovation, capacity expansion, and strategic partnerships to strengthen their competitive positions. It features high entry barriers due to the need for advanced technology, specialized raw materials, and compliance with stringent regulatory standards. The market favors manufacturers that offer customized TPV grades tailored to diverse applications such as automotive, construction, and medical industries. Product differentiation through proprietary formulations and sustainability initiatives drives competitive advantage. It also encourages continuous investment in research and development to improve performance and cost efficiency. The competitive dynamics promote technological advancements and faster adoption of TPVs, supporting steady market growth and increasing customer demand for high-quality, eco-friendly elastomer solutions worldwide.

Report Coverage

The research report offers an in-depth analysis based on Grade, Processing Method, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The thermoplastic vulcanizates market will expand due to rising demand in automotive lightweighting.

- Manufacturers will focus on developing more sustainable and recyclable TPV formulations.

- Advances in processing technologies will improve production efficiency and reduce costs.

- TPVs will see increased use in electric vehicle components and renewable energy applications.

- Emerging markets will offer significant growth opportunities for TPV adoption.

- Customization of TPV grades will support diverse application requirements across industries.

- Regulatory pressure will drive innovation toward environmentally friendly and safer materials.

- The market will benefit from growing infrastructure and construction projects worldwide.

- Collaboration between manufacturers and end users will accelerate product development.

- Continuous research will enhance TPV properties, expanding its industrial and consumer applications.