Market Overview

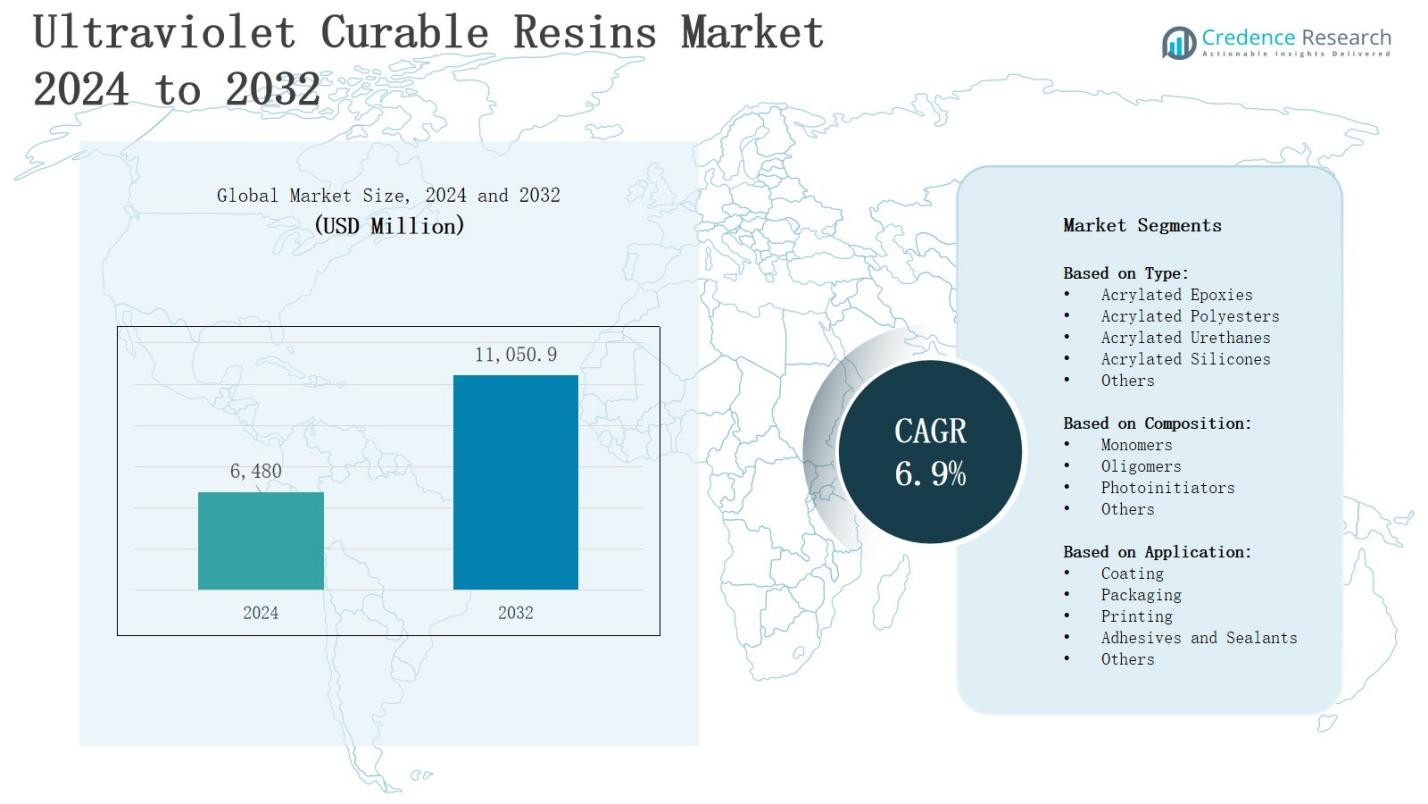

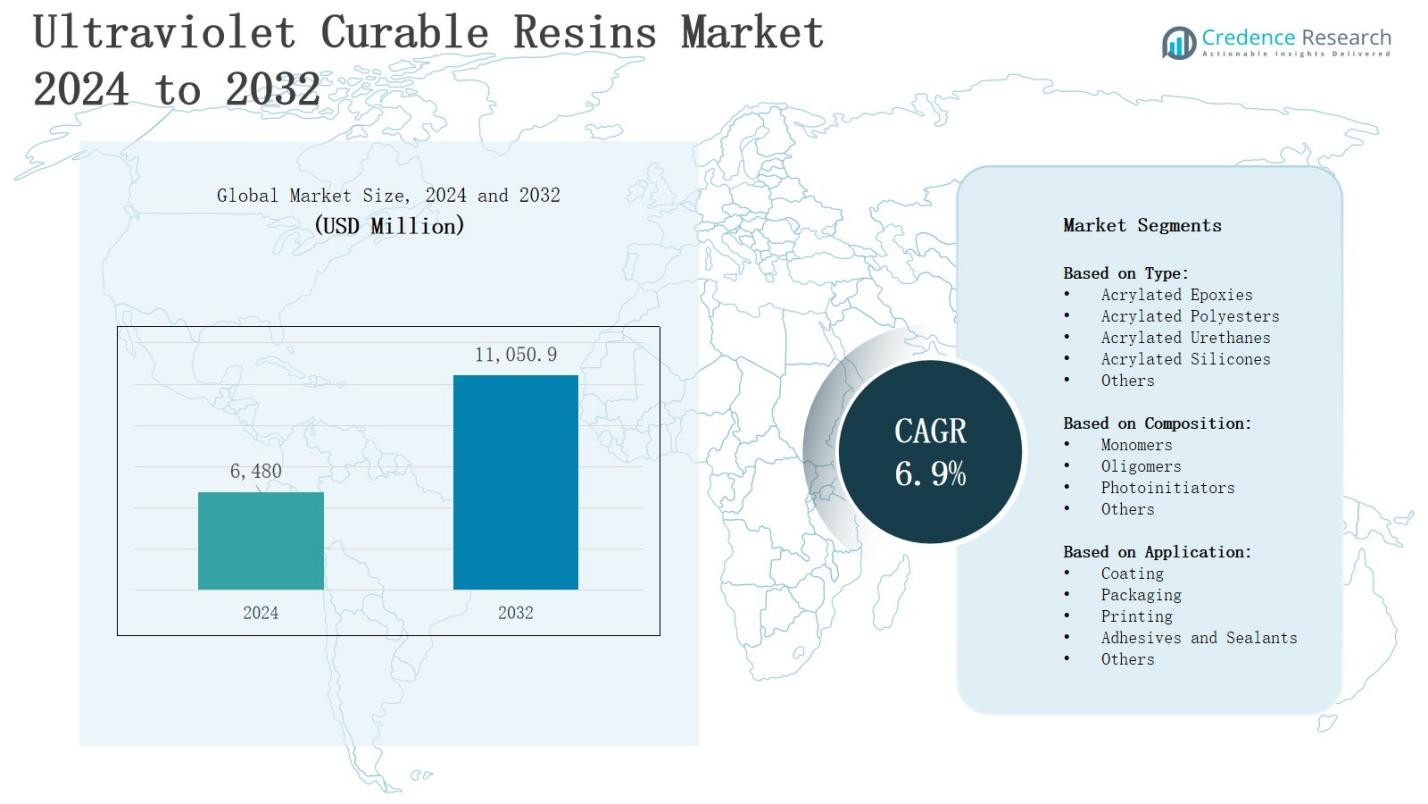

The ultraviolet curable resins market is projected to grow from USD 6,480 million in 2024 to USD 11,050.9 million by 2032, registering a CAGR of 6.9% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Ultraviolet Curable Resins Market Size 2024 |

USD6,480Million |

| Ultraviolet Curable Resins Market, CAGR |

6.9% |

| Ultraviolet Curable Resins Market Size 2032 |

USD 11,050.9 Million |

The ultraviolet curable resins market is driven by rising demand for eco-friendly coatings and adhesives that enable low VOC emissions, rapid curing, and high durability. Expanding applications in electronics, automotive, packaging, and 3D printing strengthen adoption due to superior chemical resistance and cost efficiency. Growing emphasis on sustainable manufacturing and energy savings supports market growth. Key trends include increased use of bio-based UV resins, advancements in LED-curing technology for energy-efficient processes, and integration in high-performance applications such as optical films, medical devices, and industrial coatings, positioning the market for steady expansion across diverse end-use industries.

The ultraviolet curable resins market demonstrates strong geographical diversity, with Asia Pacific leading at 38% share, driven by large-scale manufacturing in China, Japan, South Korea, and India. Europe follows with 24%, supported by strict environmental regulations and advanced applications in automotive and packaging, while North America holds 21% with strong adoption in healthcare, electronics, and coatings. Latin America captures 8% share, and the Middle East & Africa account for 9%. Key players include Allnex GmbH, Arkema S.A., BASF SE, Covestro AG, Dymax Corporation, and Koninklijke DSM N.V.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The ultraviolet curable resins market is projected to grow from USD 6,480 million in 2024 to USD 11,050.9 million by 2032, registering a CAGR of 6.9%.

- Rising demand for eco-friendly coatings and adhesives with low VOC emissions, rapid curing, and durability drives widespread adoption.

- Expanding applications in automotive, electronics, packaging, 3D printing, and medical devices strengthen market penetration.

- Advancements in LED-curing technology and bio-based formulations enhance energy efficiency and sustainability.

- High raw material costs, supply chain risks, and technical limitations remain key challenges.

- Asia Pacific leads with 38% share, followed by Europe at 24%, North America at 21%, Latin America at 8%, and Middle East & Africa at 9%.

- Key players include Allnex GmbH, Arkema S.A., BASF SE, Covestro AG, Dymax Corporation, Eternal Materials Co. Ltd., IGM Resins B.V., Jiangsu Litian Technology Co. Ltd., Jiangsu Sanmu Group Co. Ltd., and Koninklijke DSM N.V.

Market Drivers

Rising Demand for Eco-Friendly and Sustainable Coating Solutions

The ultraviolet curable resins market gains momentum from increasing environmental regulations and consumer preference for sustainable products. It delivers low volatile organic compound emissions compared to traditional coatings, making it suitable for industries focused on green manufacturing. Governments encourage adoption through stricter environmental standards and incentives. Industries such as packaging, electronics, and automotive prefer UV resins for their eco-friendly attributes. Growing awareness of sustainability strengthens its role as a viable alternative to conventional materials.

- For instance, Covestro offers UV-curable resins containing up to 83% bio-based content derived from plant-based sources, enhancing sustainability in flooring and furniture coatings.

Expanding Applications Across High-Growth End-Use Industries

The ultraviolet curable resins market benefits from strong demand in diverse applications, including automotive coatings, electronics encapsulation, and advanced packaging. It provides superior adhesion, scratch resistance, and durability, which enhances product performance. Growth in 3D printing accelerates adoption, with UV resins offering precise curing for complex designs. Medical device manufacturers also integrate these resins for safe and durable applications. Expanding end-use industries ensure steady demand and broaden the scope of technological innovation.

- For instance, Allnex supplies UV curable resins for automotive coatings used in headlights, bumpers, and interior parts, delivering excellent weatherability and abrasion resistance while enabling faster curing processes under UV light.

Technological Advancements in Curing Processes and Equipment

The ultraviolet curable resins market experiences growth through innovations in curing technologies such as LED-based UV curing systems. It enables faster processing, lower energy consumption, and improved efficiency compared to traditional mercury lamps. LED curing expands possibilities for heat-sensitive substrates, driving adoption across electronics and flexible packaging. Manufacturers invest in research to enhance curing speed, depth, and uniformity. Technological progress ensures better performance and strengthens industry confidence in UV-curable resin solutions.

Growing Focus on Cost Efficiency and High-Performance Attributes

The ultraviolet curable resins market advances with rising demand for cost-effective and performance-oriented solutions. It offers shorter production cycles, reduced material waste, and lower energy requirements, aligning with industry cost-saving objectives. High chemical resistance and mechanical strength support use in demanding industrial applications. Manufacturers favor UV resins for scalability and adaptability across multiple substrates. These performance advantages combined with operational efficiency create strong incentives for wider market adoption across global industries.

Market Trends

Adoption of Bio-Based and Sustainable UV Resin Formulations

The ultraviolet curable resins market is witnessing a shift toward bio-based alternatives that align with global sustainability goals. It reduces reliance on petrochemical feedstocks and supports circular economy initiatives. Manufacturers develop renewable formulations derived from plant-based raw materials, offering comparable performance to synthetic variants. Growing demand for eco-friendly coatings in packaging, consumer goods, and medical devices accelerates this trend. Sustainability commitments from leading companies ensure wider acceptance of bio-based UV-curable solutions across industries.

- For instance, Mitsubishi Chemical Corporation created DURABIO™, a bio-based polycarbonate resin derived from plant-based isosorbide. This transparent engineering plastic features superior optical properties, UV stability without yellowing, and high surface hardness, used for applications including optical films and cosmetic containers.

Advancements in LED UV-Curing Technology for Enhanced Efficiency

The ultraviolet curable resins market benefits from rapid adoption of LED UV-curing systems, which deliver energy savings and reduced operating costs. It enables precise curing for heat-sensitive substrates such as plastics and flexible electronics. LED technology provides longer equipment lifespan, consistent performance, and lower maintenance requirements compared to traditional mercury lamps. Growing investment in energy-efficient production lines accelerates this transition. The expanding role of LEDs strengthens the competitiveness of UV resin-based processes in multiple industries.

- For instance, Nichia launched high-efficiency UV LEDs with lifespans tens of thousands of hours longer than mercury lamps, minimizing downtime in industrial applications.

Integration in Additive Manufacturing and 3D Printing Applications

The ultraviolet curable resins market expands with rising use in additive manufacturing, particularly 3D printing technologies. It provides superior accuracy, faster curing, and strong mechanical properties for complex prototypes and functional components. Manufacturers leverage UV resins to produce detailed medical models, customized dental implants, and industrial parts. Growth in rapid prototyping and small-batch production drives widespread integration. Enhanced material properties and compatibility with advanced printers position UV resins as a key enabler in digital manufacturing.

Growing Penetration in High-Performance and Specialized Applications

The ultraviolet curable resins market evolves with increasing adoption in high-performance applications across automotive, electronics, and healthcare sectors. It offers scratch resistance, superior adhesion, and chemical durability that meet advanced performance standards. Emerging use in optical films, protective coatings, and microelectronics underscores its versatility. Industries adopt UV resins to enhance product lifespan and reduce maintenance costs. Rising demand for premium-quality finishes and functional coatings ensures continued growth in specialized and technologically advanced sectors.

Market Challenges Analysis

High Raw Material Costs and Supply Chain Vulnerabilities

The ultraviolet curable resins market faces significant pressure from fluctuating raw material costs and supply chain uncertainties. It relies heavily on specialty chemicals, photoinitiators, and oligomers, many of which are subject to volatile global pricing. Rising energy and transportation costs add to production challenges, limiting profitability for manufacturers. Dependence on limited suppliers for critical inputs heightens risks of shortages. Companies must balance cost optimization with quality assurance, making raw material sourcing a critical challenge for long-term growth.

Technical Limitations and Application Constraints Across Industries

The ultraviolet curable resins market encounters hurdles due to technical limitations that restrict its universal adoption. It struggles with depth of cure in thick or highly pigmented coatings, which impacts performance consistency. Sensitivity to oxygen inhibition during curing can reduce surface hardness and durability. High initial investment in UV-curing equipment poses barriers for small and medium enterprises. Limited awareness in emerging economies further slows penetration. Addressing these technical and adoption challenges remains crucial for sustained market expansion.

Market Opportunities

Rising Demand in Advanced Manufacturing and High-Growth Industries

The ultraviolet curable resins market holds strong opportunities in advanced manufacturing sectors such as electronics, automotive, and healthcare. It enables high-performance coatings, encapsulations, and adhesives that meet strict durability and safety standards. Growth in electric vehicles and miniaturized electronics increases demand for UV-curable solutions that deliver superior adhesion and resistance. Expanding medical applications, including dental materials and surgical instruments, further strengthen adoption. Industries seeking precision, efficiency, and sustainability provide a wide platform for future growth.

Expansion in 3D Printing and Sustainable Material Development

The ultraviolet curable resins market benefits from growing integration in 3D printing technologies and the development of bio-based formulations. It supports rapid prototyping and additive manufacturing by offering quick curing, dimensional accuracy, and strong mechanical properties. Rising adoption in customized healthcare devices, industrial parts, and consumer goods accelerates demand. Parallel efforts to create eco-friendly resins derived from renewable feedstocks open new avenues. Combining advanced manufacturing trends with sustainability initiatives creates strong opportunities for long-term expansion.

Market Segmentation Analysis:

By Type

The ultraviolet curable resins market is segmented into acrylated epoxies, acrylated polyesters, acrylated urethanes, acrylated silicones, and others. Acrylated epoxies hold strong demand due to their excellent chemical resistance and mechanical strength, making them suitable for industrial coatings and electronics. Acrylated urethanes gain traction in applications requiring flexibility, toughness, and adhesion. Acrylated polyesters find use in cost-sensitive sectors such as printing and packaging. Acrylated silicones cater to specialized needs where thermal stability and weather resistance are critical.

- For instance, epoxy acrylates are widely used as protective coatings and substrates in printed circuit boards, offering high electrical insulation and moisture resistance critical in electronics manufacturing.

By Composition

The ultraviolet curable resins market is divided into monomers, oligomers, photoinitiators, and others. Monomers are widely used due to their role in adjusting viscosity and curing performance across applications. Oligomers dominate the formulation structure, providing durability, hardness, and flexibility. Photoinitiators play a crucial role in initiating rapid polymerization under UV exposure, ensuring efficient curing. Demand for advanced oligomers and high-reactivity photoinitiators rises with the adoption of LED-curing technologies. Each composition segment contributes to balancing performance, cost, and sustainability goals.

- For instance, IGM Resins offers photoinitiators under brand names like Omnirad®, widely used for high-speed curing in electronics and packaging applications.

By Application

The ultraviolet curable resins market is classified into coating, packaging, printing, adhesives and sealants, and others. Coating applications remain dominant, supported by industries requiring scratch resistance, chemical durability, and eco-friendly solutions. Packaging emerges as a fast-growing segment with rising adoption of sustainable UV coatings in food and consumer goods. Printing benefits from faster curing speeds and high-quality finishes, especially in digital and flexographic processes. Adhesives and sealants expand use in automotive, electronics, and construction, ensuring strong market penetration.

Segments:

Based on Type:

- Acrylated Epoxies

- Acrylated Polyesters

- Acrylated Urethanes

- Acrylated Silicones

- Others

Based on Composition:

- Monomers

- Oligomers

- Photoinitiators

- Others

Based on Application:

- Coating

- Packaging

- Printing

- Adhesives and Sealants

- Others

Based on the Geography:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis

North America

The ultraviolet curable resins market in North America accounts for 21% of the global share, supported by strong adoption across automotive, electronics, and healthcare industries. It benefits from advanced manufacturing facilities and high investments in sustainable technologies. Regulatory support for low-VOC coatings drives the shift toward UV-curable solutions. Growth in 3D printing and industrial adhesives strengthens regional demand. The presence of key technology providers and material innovators enhances competitiveness. Strong R&D spending ensures continuous innovation and application expansion.

Europe

Europe holds 24% of the ultraviolet curable resins market, driven by strict environmental regulations and rising demand for eco-friendly materials. It witnesses strong use of UV-curable coatings in packaging, automotive, and printing sectors. The region emphasizes sustainable production practices, encouraging adoption of bio-based resin formulations. Demand for energy-efficient LED-curing systems grows rapidly in European industries. Local manufacturers focus on product innovation to meet specialized performance standards. Regional initiatives supporting carbon reduction goals provide long-term growth momentum.

Asia Pacific

Asia Pacific dominates the ultraviolet curable resins market with 38% share, led by rapid industrialization and large-scale manufacturing bases in China, Japan, South Korea, and India. It benefits from expanding electronics, packaging, and automotive sectors that prefer UV resins for their efficiency and durability. Rising infrastructure investments strengthen adoption across construction and coatings. The region sees strong demand for digital printing and advanced adhesives. Competitive pricing and high production capacity position Asia Pacific as the global leader in growth and innovation.

Latin America

Latin America represents 8% of the ultraviolet curable resins market, supported by steady demand in packaging, printing, and construction. It benefits from rising investments in modern manufacturing and infrastructure projects. Growing awareness of sustainable materials supports gradual adoption of UV-curable technologies. Brazil and Mexico lead regional demand, with printing and automotive coatings driving consumption. Limited local production capacity creates reliance on imports from global suppliers. Expanding industrial development offers untapped opportunities for UV resin manufacturers.

Middle East & Africa

The Middle East & Africa account for 9% of the ultraviolet curable resins market, with growth fueled by infrastructure development and industrial diversification. It benefits from rising adoption of UV-curable coatings in construction, automotive refinishing, and packaging. The healthcare sector also contributes to demand through medical device applications. Limited manufacturing capacity presents opportunities for foreign entrants to expand presence. Investments in renewable energy and sustainable construction accelerate adoption. The region continues to evolve as a growing market for UV-curable technologies.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

Competitive Analysis

The ultraviolet curable resins market is highly competitive with global and regional players focusing on product innovation, strategic partnerships, and sustainable solutions to strengthen their positions. It is characterized by strong R&D investments aimed at improving curing efficiency, eco-friendly formulations, and performance attributes across diverse applications. Key companies such as Allnex GmbH, Arkema S.A., BASF SE, Covestro AG, and Dymax Corporation lead with advanced product portfolios serving industries including coatings, packaging, and electronics. Eternal Materials Co. Ltd., IGM Resins B.V., Jiangsu Litian Technology Co. Ltd., Jiangsu Sanmu Group Co. Ltd., and Koninklijke DSM N.V. emphasize regional expansion, cost competitiveness, and specialty applications to capture emerging demand. Companies increasingly adopt LED-curing compatible solutions and bio-based resin technologies to align with global sustainability goals. The market shows consolidation trends through mergers, acquisitions, and collaborations that enhance technological capabilities and distribution reach. Competition remains intense with players balancing innovation, scale, and pricing strategies to expand their share across high-growth regions and end-use sectors.

Recent Developments

- In 2023, Arkema Group expanded its UV-curable resin portfolio by launching bio-based formulations under its flagship brand, targeting electronics and packaging applications with sustainability focus.

- In July 2023, BASF unveiled acResin® ZeroPCF, a high-performance UV acrylic hotmelt resin with a zero-product carbon footprint, aligning with its ‘Together for Sustainability’ commitment.

- In April 2025, ALTANA’s ACTEGA/Cubic Ink® division enhanced its UV-curing resin capacity by scaling production and delivering its Cubic Ink® family to a U.S. medical technology client.

Market Concentration & Characteristics

The ultraviolet curable resins market demonstrates moderate to high concentration, with a few global players holding significant influence through technological expertise, extensive product portfolios, and wide distribution networks. It is characterized by strong competition where companies compete on innovation, cost efficiency, and sustainability-driven solutions. Leading firms such as Allnex GmbH, Arkema S.A., BASF SE, Covestro AG, and Dymax Corporation dominate through advanced UV-curable technologies and application-specific developments. Regional players like Eternal Materials Co. Ltd., IGM Resins B.V., and Jiangsu Sanmu Group Co. Ltd. strengthen competition by offering cost-effective solutions and focusing on regional demand. It is defined by high entry barriers due to the need for specialized raw materials, capital-intensive equipment, and technical expertise. The market also shows rising adoption of bio-based and LED-compatible resins, which reinforces innovation intensity. Its structure reflects consolidation trends, with mergers and partnerships enhancing global reach and reinforcing leadership in high-growth sectors.

Report Coverage

The research report offers an in-depth analysis based on Type, Composition, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The market will expand with stronger demand for eco-friendly, sustainable, and low-VOC coating solutions.

- Bio-based resin formulations will achieve wider adoption, supporting global sustainability initiatives and green manufacturing standards.

- LED-curing systems will increasingly replace mercury-based technologies, driving efficiency, durability, and cost-effective curing processes.

- Expanding 3D printing applications will create new opportunities, enhancing precision manufacturing and customized product development.

- Healthcare and medical device industries will adopt UV resins for reliable, durable, and high-performance applications.

- Electronics and packaging sectors will remain dominant, utilizing UV resins for durability, flexibility, and efficiency.

- Raw material innovations will enhance curing speed, mechanical strength, and chemical resistance for advanced applications.

- Regional manufacturers will intensify competition by offering affordable, scalable, and adaptable UV-curable resin solutions.

- Strategic mergers, acquisitions, and alliances will strengthen global reach, innovation capabilities, and market positioning.

- Industrial modernization in emerging economies will drive adoption of UV resins across multiple high-growth sectors.