Market Overview:

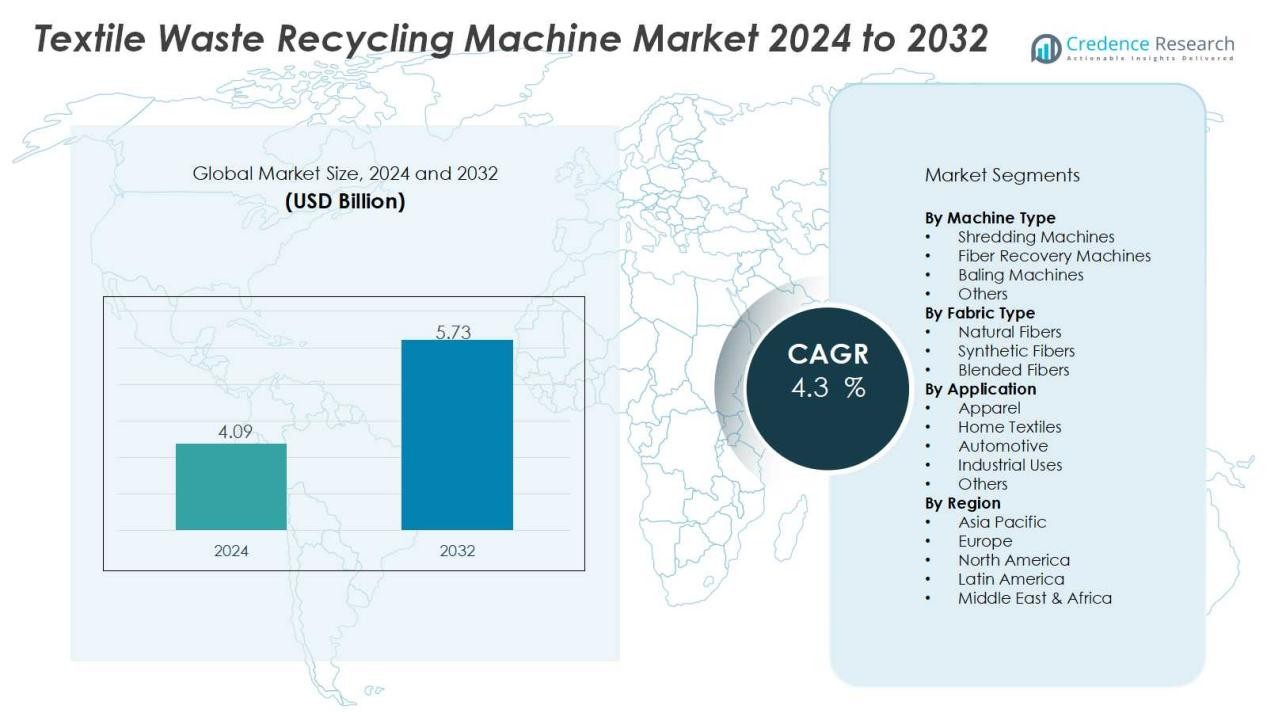

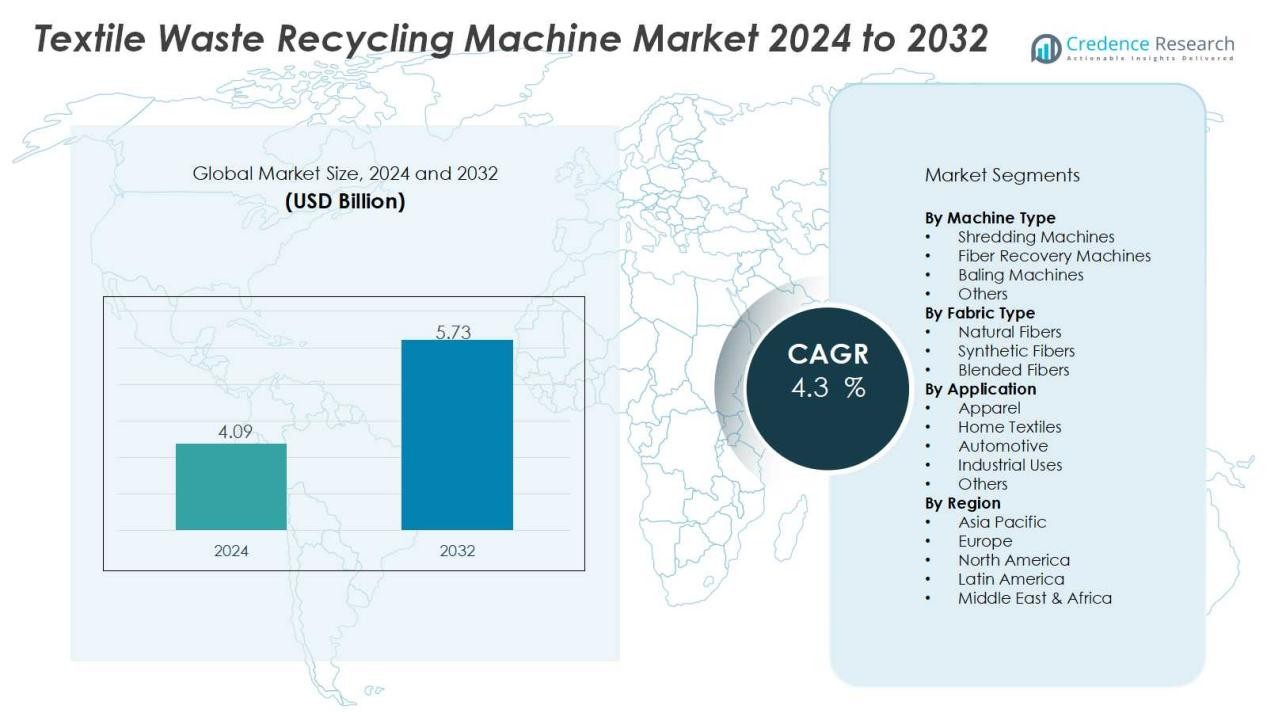

The textile waste recycling machine market size was valued at USD 4.09 billion in 2024 and is anticipated to reach USD 5.73 billion by 2032, at a CAGR of 4.3 % during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Textile Waste Market Size 2024 |

USD 4.09 Billion |

| Textile Waste Market, CAGR |

4.3 % |

| Textile Waste Market Size 2032 |

USD 5.73 Billion |

Key drivers include mounting textile waste volumes from fast fashion, industrial production, and post-consumer usage. Growing awareness of environmental impact and regulatory pressure on waste disposal are compelling industries to adopt recycling solutions. In addition, technological innovations in fiber separation, automated sorting, and energy-efficient recycling machines are improving performance, lowering costs, and boosting adoption across developed and developing economies. The rising demand for recycled fibers in apparel, home textiles, and industrial applications further strengthens market expansion.

Regionally, Asia-Pacific leads the market due to its large-scale textile manufacturing hubs in China, India, and Bangladesh, alongside strong government support for waste reduction initiatives. Europe follows with significant adoption, driven by strict sustainability regulations and high consumer awareness. North America demonstrates steady growth supported by advanced technologies and increasing brand commitments to circular supply chains, while Latin America and the Middle East & Africa show emerging opportunities with growing textile industries and supportive policy frameworks.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The textile waste recycling machine market was valued at USD 4.09 billion in 2024 and is expected to reach USD 5.73 billion by 2032 at a CAGR of 4.3%.

- Rising textile waste from fast fashion, industrial processes, and post-consumer use is driving machine adoption.

- Governments are enforcing strict waste disposal regulations, pushing industries to invest in recycling solutions.

- Technological advances in fiber separation, automated sorting, and energy-efficient systems are boosting adoption.

- Demand for recycled fibers in apparel, home textiles, automotive, and industrial applications is strengthening market growth.

- Asia-Pacific led with 45.6% share in 2024, supported by large-scale textile production and government initiatives.

- Europe followed with 27.3% share, while North America held 18.5% due to innovation and corporate sustainability commitments.

Market Drivers:

Rising Textile Waste Generation and Environmental Concerns:

The textile waste recycling machine market is expanding due to growing textile waste from fast fashion, industrial processes, and post-consumer usage. Landfill accumulation and pollution issues are intensifying global demand for effective recycling solutions. Governments are imposing strict disposal regulations, pressuring manufacturers to adopt sustainable waste management practices. Recycling machines help reduce environmental impact by converting waste into usable fibers. This shift supports both ecological goals and industry compliance.

- For Instance,In May 2023, Lenzing announced a joint textile recycling project in Austria with partners including the Swedish pulp producer Södra. The goal of the project, named LIFE TREATS, is to reach an annual processing capacity of 50,000 metric tons of textile waste by 2027.

Technological Advancements Driving Efficiency and Adoption:

Innovations in textile waste recycling machines are transforming the industry through improved fiber separation, automated sorting, and higher energy efficiency. These advances make recycling processes faster, cost-effective, and more reliable. Companies are focusing on developing machines that handle diverse waste streams, including synthetic and blended textiles. It strengthens operational efficiency for textile manufacturers seeking sustainability integration. Enhanced machine performance is increasing adoption across global textile hubs.

- For instance, Andritz AG has engineered mechanical recycling machines capable of processing up to 2,000 kg of textile waste per hour, dramatically enhancing operational throughput for manufacturers focusing on sustainability.

Rising Demand for Recycled Fibers Across End-Use Industries:

The demand for recycled fibers in apparel, automotive, home textiles, and industrial uses is creating strong market momentum. Brands are increasingly integrating recycled materials into their product lines to meet sustainability commitments. Textile waste recycling machine market growth benefits directly from this demand surge. It ensures steady supply of high-quality recycled fibers that match performance standards. Growing consumer preference for eco-friendly products further supports this adoption.

Government Policies and Corporate Sustainability Commitments:

Strict government regulations on textile waste disposal are pushing industries toward recycling solutions. Incentives for recycling infrastructure and funding for innovation are strengthening the market landscape. Corporate commitments to circular economy practices align with these policies, driving machine investments. The textile waste recycling machine market benefits from sustainability goals set by leading global brands. It creates long-term growth opportunities across both developed and emerging regions.

Market Trends:

Integration of Automation and Digital Technologies in Recycling Processes:

The textile waste recycling machine market is witnessing strong momentum with automation, AI, and IoT integration. Smart recycling machines equipped with sensors and data analytics are enhancing sorting accuracy and operational efficiency. It reduces manual errors and increases throughput, enabling large-scale textile recycling to meet industrial demand. Robotics and vision systems are also being deployed to manage complex waste streams, including blended fabrics. Companies are investing in advanced machinery to achieve cost savings and meet rising sustainability requirements. These developments are transforming recycling operations from manual-intensive systems to technology-driven solutions.

- For instance, REDWAVE launched its modular REDWAVE TEX sensor-based sorting system in Europe, achieving real-time automated sorting for up to 5 target fractions in textile waste streams, while individual units have demonstrated throughput capacities above 3 metric tons per hour for shredded textiles since its deployment in May 2024.

Growing Focus on Circular Economy and Sustainable Manufacturing Practices:

Global textile brands are emphasizing circular economy models, driving adoption of recycling machines. The textile waste recycling machine market benefits from rising demand for recycled fibers in apparel, automotive, and industrial sectors. It supports corporate strategies to minimize virgin material use and reduce environmental footprints. Consumers are aligning with this shift by choosing products that contain sustainable and recycled textiles. Governments are also promoting eco-friendly practices through stricter waste regulations and incentives for recycling investments. The integration of recycled fibers into mainstream textile manufacturing highlights a long-term trend shaping the industry’s direction.

- For instance, ANDRITZ unveiled a fully automated industrial textile sorting and recycling line in June 2025, capable of sorting and processing up to 10,000 tonnes of pre- and post-consumer textile waste annually, enabling large-scale fiber recovery for use in automotive and insulation applications.

Market Challenges Analysis:

High Capital Costs and Operational Complexities Restraining Adoption:

The textile waste recycling machine market faces hurdles due to significant capital investment and maintenance costs. Small and medium-sized enterprises often struggle to adopt advanced recycling systems due to limited budgets. It creates a gap between large manufacturers and smaller players, slowing widespread adoption. Operational complexities, such as handling mixed fibers and blended textiles, add to the challenge. Companies must invest in skilled labor and advanced training, which raises overall expenses. These financial and technical barriers limit rapid market penetration.

Limited Recycling Infrastructure and Quality Concerns of Recycled Fibers:

The absence of robust recycling infrastructure in many regions remains a key barrier to growth. The textile waste recycling machine market relies on efficient collection and segregation systems, which are often underdeveloped. It results in inconsistent feedstock quality and reduced machine efficiency. Concerns about the durability and performance of recycled fibers also challenge broader acceptance in premium applications. Manufacturers face difficulties in ensuring recycled fibers meet global quality standards. Without addressing these issues, market growth risks losing momentum despite strong sustainability demand.

Market Opportunities:

Expanding Demand for Sustainable Fibers Across Global Industries:

The textile waste recycling machine market holds strong opportunities due to rising demand for sustainable fibers in fashion, automotive, and home textiles. Brands are increasing their commitments to recycled materials, creating steady demand for advanced recycling solutions. It enables manufacturers to supply high-quality fibers that meet both performance and sustainability standards. Governments are also encouraging recycling investments through favorable policies and incentives. Growing consumer preference for eco-friendly products further strengthens the potential for recycled textiles. This trend positions recycling machines as essential tools in future manufacturing ecosystems.

Emerging Markets and Technological Advancements Creating Growth Potential:

Rapid industrialization in Asia-Pacific, Latin America, and Africa is generating significant opportunities for recycling machine adoption. The textile waste recycling machine market benefits from government initiatives promoting circular economy practices in these regions. It supports local industries in managing waste effectively while creating new revenue streams from recycled textiles. Advances in automation, fiber recovery, and digital monitoring are further enhancing efficiency and scalability. Companies that invest in innovative machines can capture new markets and expand their global footprint. This combination of regional growth and technological progress is set to reshape competitive dynamics in the sector.

Market Segmentation Analysis:

By Machine Type:

The textile waste recycling machine market is segmented into shredding machines, baling machines, fiber recovery machines, and others. Shredding machines hold a dominant role due to their ability to process large textile volumes efficiently. Fiber recovery machines are gaining traction for producing high-quality recycled fibers that meet industry standards. It supports industries aiming to reduce dependency on virgin raw materials. Baling machines continue to play a vital role in storage and transport of textile waste. Rising demand for integrated systems is driving innovation in this segment.

- For instance, Vecoplan’s VAZ 1700 industrial shredder is capable of processing up to 1,700 kg of mixed textile waste per hour. Its performance varies based on the material’s composition, and the company’s primary facility is located in Bad Marienberg, Germany.

By Fabric Type:

Segmentation by fabric type includes natural fibers, synthetic fibers, and blended fibers. Natural fibers such as cotton and wool dominate due to higher recycling feasibility and growing demand for eco-friendly textiles. The textile waste recycling machine market benefits from rising interest in synthetic fiber recycling, driven by polyester’s widespread use. It faces challenges with blended fibers, but advancements in separation technology are improving efficiency. Global brands are focusing on machines that handle complex blends to meet circular economy goals. This segment highlights the need for innovation and advanced sorting systems.

- For Instance,Gaomi Chengmai Environmental Technology Co., Ltd., which also uses the trademark Zhong Nuo, manufactures the Zn70K cotton waste recycling machine, which is capable of processing 350–500 kilograms of cotton waste per hour

By Application:

Key applications include apparel, home textiles, automotive, and industrial uses. Apparel leads due to increasing adoption of recycled fibers in fashion lines. The textile waste recycling machine market benefits from strong demand in home textiles, where sustainability is a growing priority. It is gaining traction in automotive and industrial applications, where recycled fibers enhance insulation and durability. Rising demand across multiple applications strengthens the need for efficient recycling solutions. This diversification supports steady long-term market growth.

Segmentations:

By Machine Type:

- Shredding Machines

- Fiber Recovery Machines

- Baling Machines

- Others

By Fabric Type:

- Natural Fibers

- Synthetic Fibers

- Blended Fibers

By Application:

- Apparel

- Home Textiles

- Automotive

- Industrial Uses

By Region:

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

Asia-Pacific:

Asia-Pacific accounted for 45.6% market share in 2024, making it the global leader. The textile waste recycling machine market benefits from extensive textile production hubs in China, India, and Bangladesh. It is supported by strong government regulations promoting sustainable practices and waste reduction. Rising investments in recycling infrastructure and increasing export-oriented textile demand further drive machine adoption. Technological upgrades and partnerships with global players are enhancing machine availability and affordability. Strong manufacturing clusters and large consumer bases position Asia-Pacific for sustained dominance.

Europe:

Europe held 27.3% market share in 2024, supported by strict environmental regulations and strong consumer demand for eco-friendly textiles. The textile waste recycling machine market in this region is shaped by policies encouraging circular economy practices. It gains momentum from leading fashion and automotive industries integrating recycled fibers into mainstream applications. Governments provide incentives for recycling technologies, strengthening regional adoption. Growing collaborations between technology providers and textile brands are also fueling machine deployment. Europe remains a key region for premium recycling technologies and advanced waste management frameworks.

North America:

North America secured 18.5% market share in 2024, driven by technological innovation and strong sustainability initiatives. The textile waste recycling machine market benefits from rising corporate commitments to reduce textile waste. It is supported by advanced R&D centers and increasing adoption of automation in recycling processes. Growing demand for sustainable textiles across apparel and home furnishings accelerates machine installations. Policy initiatives focused on reducing landfill waste further enhance industry adoption. North America is positioned as a hub for innovation and premium recycling machine solutions.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- BLS Ecotech

- Leigh Fibers

- iinouiio

- Lenzing

- Patagonia

- Pistoni S.r.l.

- Martex Fiber

- RE TEXTIL Deutschland

- Textile Recycling International

- Renewcell

- Unifi

- Worn Again Technologies

Competitive Analysis:

The textile waste recycling machine market is defined by a mix of global manufacturers and regional specialists offering advanced recycling solutions. Key players include BLS Ecotech, Leigh Fibers, iinouiio, Lenzing, Patagonia, Pistoni S.r.l., Martex Fiber, and RE TEXTIL Deutschland. These companies compete by focusing on technology innovation, high-quality fiber recovery, and efficient waste processing systems. It strengthens their presence through product diversification, partnerships, and strategic expansion into emerging regions. Strong emphasis on automation, energy efficiency, and handling of blended fibers is shaping competitive strategies. Companies with advanced R&D capabilities and sustainable product portfolios are gaining higher visibility among textile producers. Competitive intensity is increasing as global brands demand scalable and eco-friendly recycling solutions, positioning leading players to drive market growth.

Recent Developments:

- In April 2023, BLS Ecotech and EcoEx collaborated to have BLS Ecotech’s plastic recycling project listed on the Verra Registry for Plastic Credit Certificate, supporting efforts toward verified recycling standards.

- In March 2024, Leigh Fibers acquired the operating assets of Martex Fiber and rebranded it as Revive Fiber, allowing expansion of textile recycling capacity with joint management of facilities in South Carolina and Texas.

Report Coverage:

The research report offers an in-depth analysis based on Machine Type, Fabric Type, Application and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- The textile waste recycling machine market will witness stronger adoption driven by fast fashion waste management needs.

- It will gain momentum from rising demand for recycled fibers across apparel, automotive, and industrial applications.

- Growing investments in advanced technologies such as automation, AI, and IoT will enhance machine efficiency.

- It will benefit from stricter global regulations encouraging sustainable textile production and recycling infrastructure development.

- Consumer demand for eco-friendly and recycled textiles will drive wider machine deployment across key regions.

- It will see expanding opportunities in emerging economies with rapid industrialization and textile production growth.

- Partnerships between machine manufacturers and textile brands will accelerate innovation and market penetration.

- It will experience rising demand for customized recycling solutions to handle diverse fiber types and blends.

- Global brands will increasingly integrate recycled fibers into mainstream collections, creating steady demand for recycling machines.

- It will remain central to achieving circular economy goals and reducing the environmental footprint of textiles.