Market Overview:

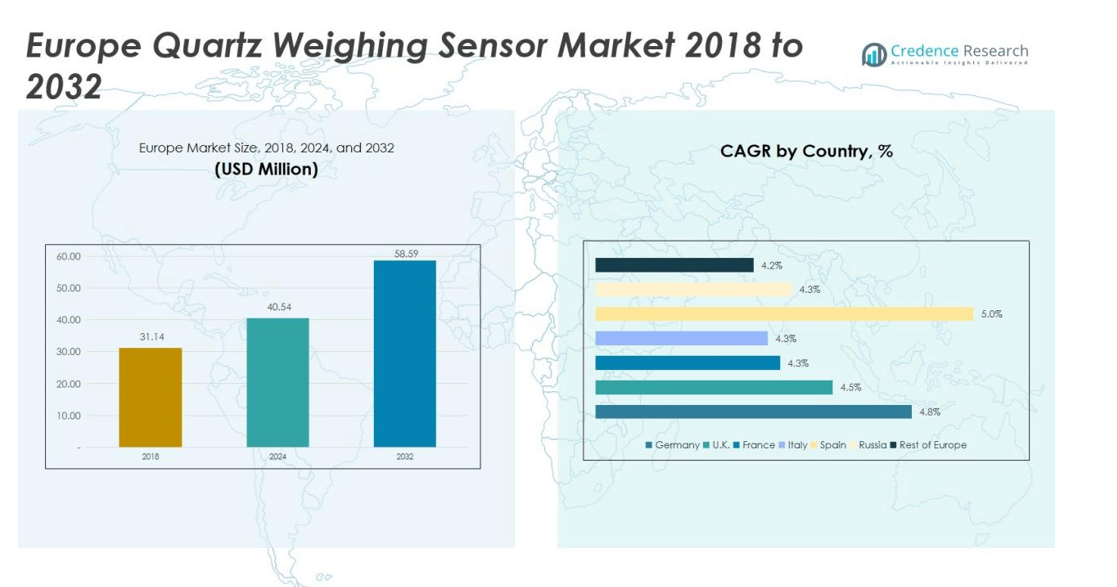

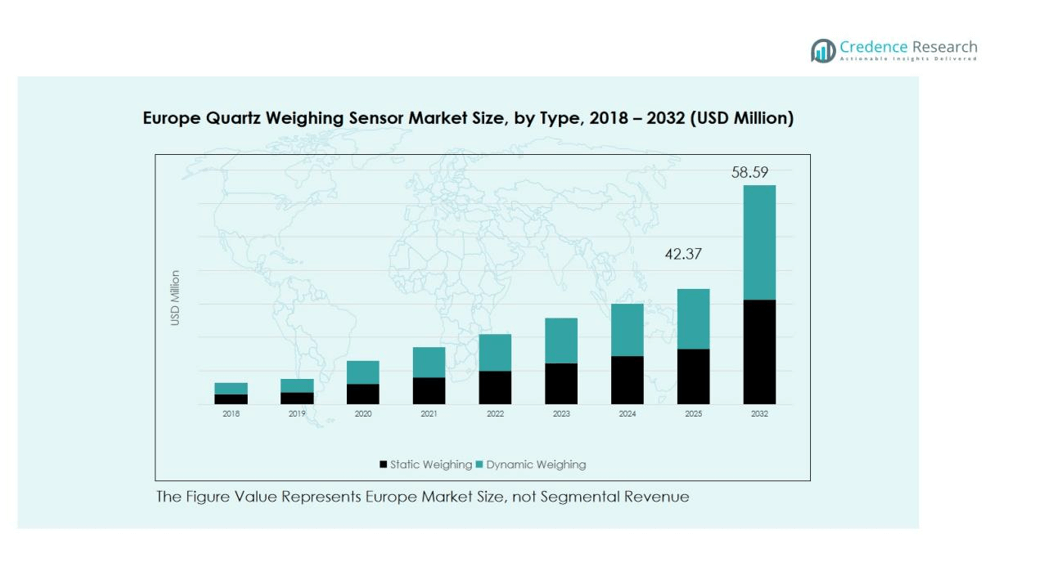

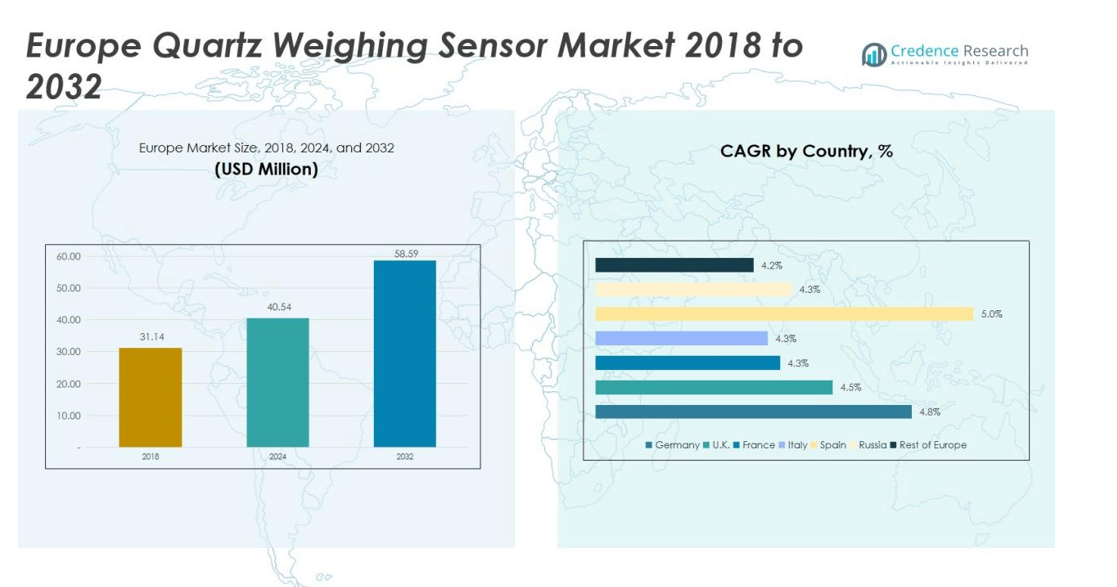

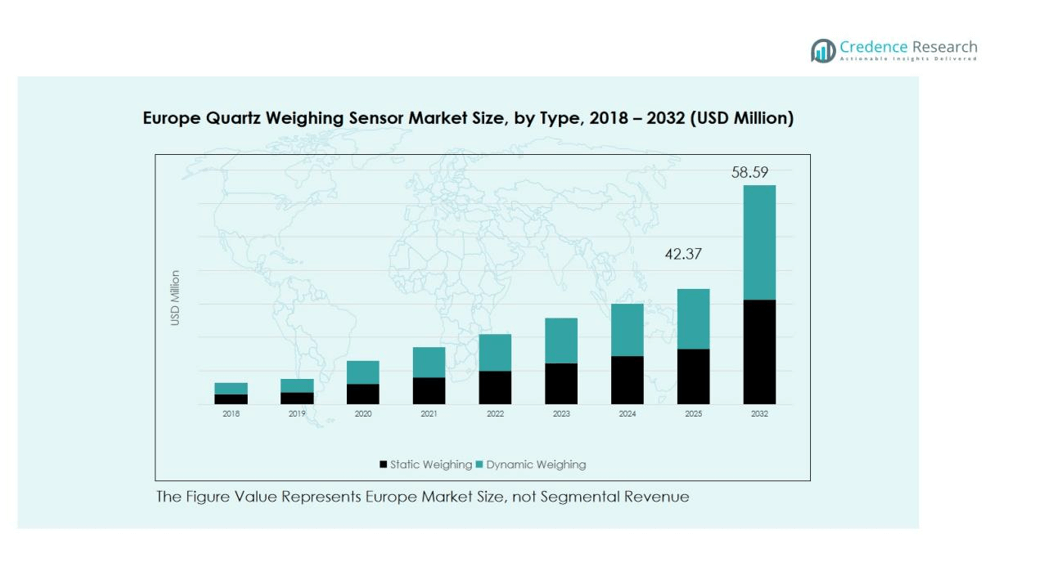

The Europe Quartz Weighing Sensor Market size was valued at USD 31.14 million in 2018 to USD 40.54 million in 2024 and is anticipated to reach USD 58.59 million by 2032, at a CAGR of 4.70% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Europe Quartz Weighing Sensor Market Size 2024 |

USD 40.54 million |

| Europe Quartz Weighing Sensor Market, CAGR |

4.70% |

| Europe Quartz Weighing Sensor Market Size 2032 |

USD 58.59 million |

The market is primarily driven by advancements in industrial automation, quality control, and laboratory applications. Increasing demand for accurate measurement systems in pharmaceuticals, chemical manufacturing, and food processing enhances the use of quartz-based weighing technologies. The sensors’ ability to deliver stable readings under temperature and vibration fluctuations further supports their integration into precision instruments and automated weighing systems. The rising trend toward IoT-enabled and smart weighing devices is also accelerating market expansion.

Regionally, Western Europe dominates the market, led by Germany, the UK, and France, where strong manufacturing bases and robust R&D capabilities drive technological adoption. Central and Eastern Europe are witnessing steady growth due to expanding industrial infrastructure and government initiatives supporting modernization. Continuous innovation and regional collaborations with sensor manufacturers strengthen Europe’s position as a global hub for advanced quartz weighing technologies.

Market Insights:

- The Europe Quartz Weighing Sensor Market was valued at USD 31.14 million in 2018, growing to USD 40.54 million in 2024, and projected to reach USD 58.59 million by 2032 at a CAGR of 4.70%.

- Western Europe held the largest share at 48% in 2024, driven by strong industrial automation and advanced manufacturing infrastructure.

- Germany accounted for 20% of the regional market, supported by leadership in precision engineering and high R&D investment.

- The U.K. held around 15% share, backed by growing demand from the pharmaceutical and research sectors.

- Central and Eastern Europe are the fastest-growing regions with a combined share of 22%, fueled by industrial modernization and government-backed digital transformation.

- Static weighing sensors dominated the type segment with 62% share in 2024 due to high accuracy and repeatability.

- Industrial applications led the market with 58% share, driven by adoption in pharmaceuticals, chemicals, and food processing industries.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers:

Rising Demand for High-Precision Measurement Systems

The Europe Quartz Weighing Sensor Market is driven by the rising need for high-precision measurement in industrial and scientific applications. Industries such as pharmaceuticals, food processing, and chemicals rely on accurate weighing to ensure quality and compliance. Quartz-based sensors offer superior stability, repeatability, and resistance to environmental variations, making them ideal for precision-based operations. It continues to gain adoption across laboratories and automated production setups due to their ability to maintain consistent performance under demanding conditions.

- For Instance, Mettler Toledo’s XPR microbalance models are utilized in European pharmaceutical labs, offering measurement repeatability as low as 0.1 µg.

Expanding Industrial Automation and Process Optimization

Rapid automation across European manufacturing sectors is boosting the demand for quartz weighing sensors. Smart factories and Industry 4.0 initiatives are emphasizing accurate and real-time measurement systems for production efficiency. Quartz sensors enable automated monitoring, calibration, and integration with digital control systems, supporting predictive maintenance and reducing operational errors. It strengthens process optimization, helping companies achieve higher output with improved resource utilization.

- For instance, the Kistler Group has deployed over 50,000 Lineas quartz piezoelectric sensors across automated Weigh-In-Motion systems worldwide, which achieve uniform sensitivity verification across the entire sensor length.

Technological Advancements and IoT Integration

Continuous advancements in sensor technology and IoT connectivity are propelling market growth. Modern quartz weighing sensors now feature enhanced response times, self-calibration, and digital signal processing for improved accuracy. Their integration with IoT platforms allows remote data analysis, system diagnostics, and predictive insights. It enables industrial operators to optimize equipment health and streamline workflow management through connected systems.

Growth in R&D and Manufacturing Capabilities Across Europe

Strong R&D capabilities and manufacturing innovation in countries such as Germany, France, and the UK are fueling market expansion. Leading companies are investing in miniaturized, energy-efficient, and vibration-resistant quartz sensor designs. The region’s focus on sustainable industrial modernization supports the development of reliable and durable weighing solutions. It benefits from collaborations between technology developers, research institutions, and industrial users, promoting continuous advancement in precision sensing technologies.

Market Trends:

Integration of Smart Technologies and IoT Connectivity

The Europe Quartz Weighing Sensor Market is witnessing strong adoption of IoT-enabled and smart weighing systems. Manufacturers are incorporating sensors with digital interfaces, allowing seamless data transmission, remote monitoring, and automated calibration. It enables industries to achieve real-time measurement accuracy and process control in critical applications such as pharmaceuticals, chemicals, and food processing. The trend aligns with Europe’s broader digital transformation goals under Industry 4.0. Miniaturization and improved temperature compensation features are also enhancing sensor performance and reliability. The growing preference for automated weighing and control systems supports the steady shift toward smart and connected industrial environments.

- For Instance, Mettler Toledo launched its IND360 automation terminal in December 2022. It delivers communication speeds of 960Hz as an automation transmitter, which Mettler Toledo advertises as 8 to 10 times faster than comparable weighing devices.

Shift Toward Sustainable Manufacturing and Advanced Materials

Rising focus on sustainability and energy efficiency is shaping innovation in quartz weighing sensor design and production. Manufacturers are using eco-friendly materials and energy-efficient fabrication processes to meet European environmental standards. It supports market growth by aligning with regulations promoting green industrial practices. The development of compact and vibration-resistant sensors for harsh industrial environments is also gaining traction. Customization and modular design trends are allowing end-users to integrate weighing sensors into existing systems with minimal modification. The demand for durable, high-performance, and sustainable weighing solutions continues to drive technological evolution and product differentiation across the region.

- For instance, Wipotec developed Active Vibration Compensation (AVC) technology that reduces vibrations to one-tenth of their original value, equivalent to 20 dB attenuation, enabling precise weight measurements even in environments with significant floor vibrations below 10 Hz.

Market Challenges Analysis:

High Production Costs and Price Sensitivity Across Industries

The Europe Quartz Weighing Sensor Market faces challenges due to high production and material costs. Manufacturing quartz sensors requires precision engineering, advanced calibration, and quality control, leading to increased pricing. Many small and medium enterprises in Europe prefer low-cost alternatives, limiting widespread adoption. It struggles to balance performance with affordability in price-sensitive industrial applications. The cost of raw materials and specialized manufacturing equipment further restricts scalability. Continuous innovation is necessary to reduce costs while maintaining sensor reliability and accuracy.

Technical Complexity and Integration Barriers in Legacy Systems

Integrating advanced quartz weighing sensors into existing industrial setups remains a significant challenge. Many European factories still rely on older weighing systems that lack compatibility with modern digital and IoT-enabled sensors. It creates integration difficulties and raises the cost of upgrades or replacements. Technical expertise and specialized calibration skills are also required, which some users lack. Sensor performance can be affected by extreme vibration, temperature fluctuations, and electromagnetic interference in certain industrial environments. Overcoming these technical limitations is vital for expanding sensor adoption and improving operational efficiency.

Market Opportunities:

Rising Adoption of Automation and Smart Manufacturing Systems

The Europe Quartz Weighing Sensor Market presents strong opportunities through the growing shift toward automation and smart factories. Industries across Europe are investing in digital manufacturing technologies to enhance precision, efficiency, and traceability. It benefits from this transition, as quartz sensors enable accurate and real-time monitoring across automated processes. Demand is increasing in sectors such as pharmaceuticals, food production, and specialty chemicals, where precision and compliance are critical. The integration of weighing sensors with IoT and AI-based systems supports data-driven decision-making. Expanding government initiatives promoting Industry 4.0 adoption are creating favorable conditions for new product development and deployment.

Expansion in Emerging End-Use Sectors and R&D Collaborations

Emerging applications in aerospace, biotechnology, and semiconductor manufacturing offer new avenues for market growth. High-precision weighing is essential for advanced material development and nanotechnology research. It creates opportunities for sensor manufacturers to design specialized solutions tailored to scientific and industrial use. Collaborations between European research institutions and sensor developers are fostering technological innovation. Growing focus on miniaturized and energy-efficient sensors aligns with the evolving needs of precision-driven industries. Increasing investment in R&D and cross-industry partnerships continues to open new growth pathways across the region.

Market Segmentation Analysis:

By Type

The Europe Quartz Weighing Sensor Market is segmented into static and dynamic weighing sensors. Static weighing systems hold a dominant share due to their precision in laboratory and industrial measurement applications. These systems are preferred for processes that require high stability and accuracy under controlled environments. Dynamic weighing sensors are gaining traction in automated and continuous production lines. It benefits from increasing demand across manufacturing and logistics operations where real-time measurement and process optimization are essential.

- For Instance, For instance, Mettler-Toledo’s XPR micro-analytical balance series, widely used in laboratories, offers models with a readability of 1 µg (0.000001 g). They demonstrate exceptional repeatability, which is a key requirement for precision pharmaceutical and material testing.

By Application

Industrial applications represent the largest share of the market, supported by strong adoption in pharmaceuticals, chemicals, and food processing sectors. Aerospace and scientific research sectors are expanding rapidly, driven by the need for ultra-precise measurement and calibration. It is also seeing emerging use in electronics and material testing facilities, where reliability and responsiveness are critical. The growing use of sensors in R&D environments reinforces their importance in modern industrial ecosystems.

- For Instance, Honeywell has delivered miniature inertial measurement units (MIMUs) to NASA for deep space mission instrumentation, including the OSIRIS-REx mission and the Artemis lunar program.

By Country

Germany leads the regional market, supported by its advanced manufacturing base and technological innovation. The U.K. and France follow, driven by growing investments in automation and precision engineering. Italy and Spain are witnessing steady growth supported by industrial modernization. It continues to expand in Russia and the Rest of Europe, where infrastructure development and smart factory adoption are increasing.

Segmentations:

By Type:

- Static Weighing

- Dynamic Weighing

By Application:

- Industrial Applications

- Aerospace

- Scientific Research

- Others

By Country:

- Germany

- K.

- France

- Italy

- Spain

- Russia

- Rest of Europe

Regional Analysis:

Western Europe Leading the Market Landscape

The Europe Quartz Weighing Sensor Market is led by Western Europe, driven by strong industrial and technological bases in Germany, the U.K., and France. Germany remains the largest contributor due to its advanced manufacturing infrastructure and commitment to automation. The U.K. benefits from growing adoption across the pharmaceutical and research sectors. France’s investments in precision measurement and process control systems strengthen its role in regional growth. It continues to witness robust demand from industries prioritizing accuracy, compliance, and operational efficiency.

Emerging Growth Across Southern and Central Europe

Southern Europe, including Italy and Spain, is showing steady progress supported by expanding industrial modernization and adoption of smart manufacturing systems. Italy’s strong automotive and food processing industries drive the deployment of precision weighing technologies. Spain is emphasizing process optimization in its chemical and material handling sectors. It benefits from European Union funding supporting digital transformation and automation. Central Europe also demonstrates potential growth with countries upgrading industrial facilities to meet international quality and efficiency standards.

Expansion Opportunities in Eastern and Northern Europe

Eastern and Northern Europe are emerging as promising regions for future market expansion. Russia and Poland are investing in industrial automation and testing facilities, supporting demand for quartz-based weighing systems. Nordic countries are focusing on high-end applications in biotechnology, research, and clean energy sectors. It benefits from strong innovation ecosystems and sustainability-driven policies. Continuous investments in infrastructure, smart factory development, and precision engineering create new opportunities for quartz sensor manufacturers across Europe.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

Competitive Analysis:

The Europe Quartz Weighing Sensor Market is characterized by moderate competition, with both global and regional players focusing on precision, reliability, and technological innovation. Key participants include TE Connectivity, Kistler Group, PCB Piezotronics, ChampionX, Enviko, and Zhengzhou Hengliang Tech Co., Ltd. These companies emphasize advanced sensor design, integration with IoT platforms, and improved temperature stability to enhance performance across industrial and laboratory applications. It continues to see strong investment in R&D, aimed at developing compact, high-sensitivity sensors for demanding environments. Strategic collaborations, product diversification, and regional expansions are common approaches adopted to strengthen market presence. Competition remains driven by technological differentiation and the ability to deliver customized weighing solutions aligned with evolving industrial automation trends in Europe.

Recent Developments:

- In October 2025, TE Connectivity announced it will host its 2025 Investor Day on November 20, 2025, in Philadelphia, where executive leadership will present strategic growth plans across global markets.

- In August 2025, The company announced India’s first real-time road quality assessment system, implemented on the Ganga Expressway project through smart measurement technologies supplied by Kistler.

Report Coverage:

The research report offers an in-depth analysis based on Type, Application and Country. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- The Europe Quartz Weighing Sensor Market will experience steady growth driven by industrial automation and digital transformation across key sectors.

- Rising adoption of IoT-enabled weighing systems will enhance precision monitoring and predictive maintenance capabilities.

- Manufacturers will focus on miniaturized, energy-efficient, and vibration-resistant sensor designs to meet modern industry requirements.

- Integration of sensors into AI-driven and cloud-based platforms will support real-time process optimization.

- Growing demand from pharmaceuticals, chemicals, and food processing industries will continue to drive large-scale deployment.

- Research and development activities will accelerate innovations in material science and sensor performance stability.

- Collaborations between manufacturers, research institutions, and automation firms will foster technology advancement.

- The shift toward sustainable and energy-efficient manufacturing will promote eco-friendly sensor production methods.

- Eastern and Central European countries will emerge as new growth hubs with industrial modernization initiatives.

- The market will remain competitive, with leading players focusing on product differentiation and strategic partnerships to strengthen regional presence.