Market Overview:

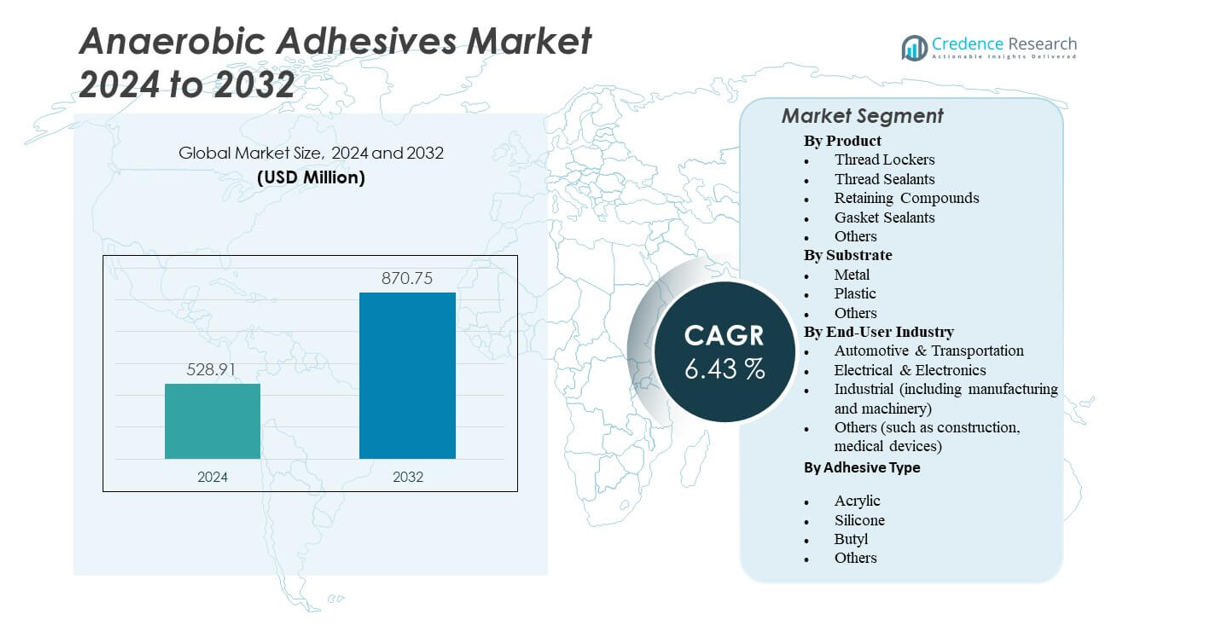

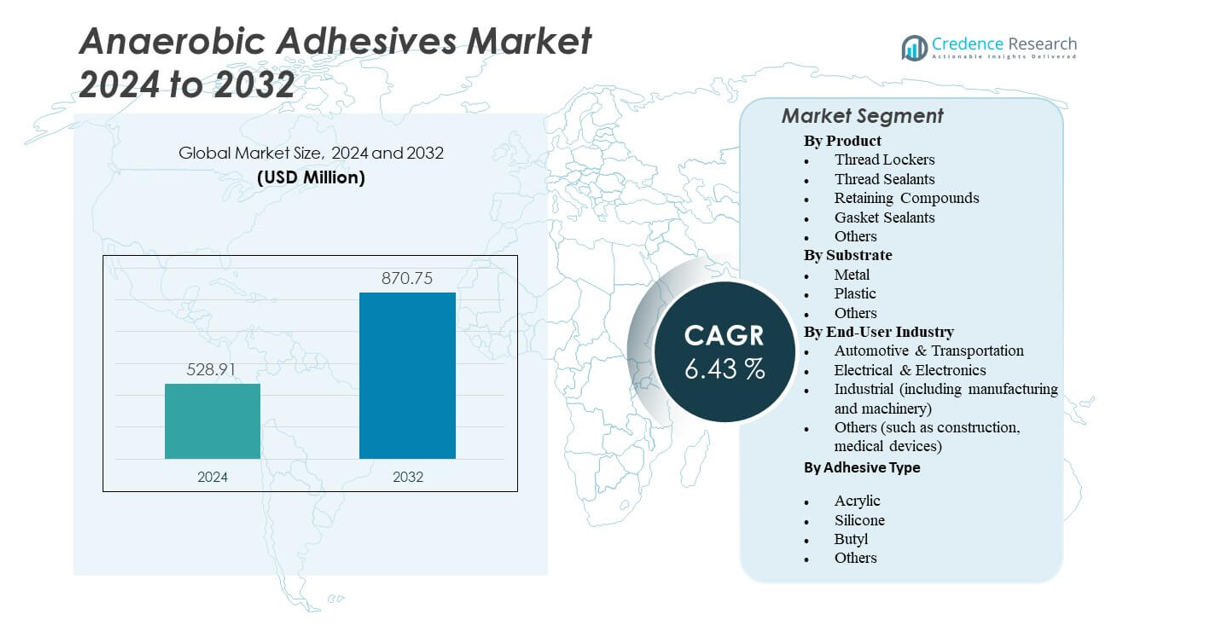

The Anaerobic Adhesives Market is projected to grow from USD 528.91 million in 2024 to an estimated USD 870.75 million by 2032, with a compound annual growth rate (CAGR) of 6.43% from 2024 to 2032.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Anaerobic Adhesives Market Size 2024 |

USD 528.91 million |

| Anaerobic Adhesives Market, CAGR |

6.43% |

| Anaerobic Adhesives Market Size 2032 |

USD 870.75 million |

Growth in this market is driven by increasing demand across automotive, aerospace, and industrial sectors. These adhesives offer superior resistance to vibration, leakage, and corrosion, making them ideal for mechanical assemblies and metal bonding. Manufacturers are focusing on sustainable, low-VOC formulations and improved curing efficiency to meet regulatory standards. Expanding applications in renewable energy, heavy machinery, and automated manufacturing further boost market growth, supported by advancements in dispensing systems and precision engineering.

North America leads the market due to its advanced manufacturing infrastructure and strong automotive and aerospace industries. Europe follows, supported by stringent environmental regulations and engineering excellence. Asia-Pacific is emerging rapidly with industrial expansion in China, India, and South Korea. Latin America and the Middle East show steady progress, driven by modernization efforts and increasing industrial investments.

Market Insights:

- The Anaerobic Adhesives Market was valued at USD 528.91 million in 2024 and is projected to reach USD 870.75 million by 2032, growing at a CAGR of 6.43%.

- Growth is driven by rising demand from automotive, aerospace, and industrial sectors for durable, vibration-resistant bonding solutions.

- Eco-friendly and low-VOC formulations are gaining traction to meet stringent environmental regulations and sustainability goals.

- High dependence on metal substrates and limited adhesion on plastics restrict some applications, acting as a market restraint.

- North America leads the market, supported by advanced industrial infrastructure and strong automotive and aerospace industries.

- Europe holds a significant share, with Germany, France, and the UK driving demand through engineering excellence and regulatory compliance.

- Asia-Pacific is emerging rapidly due to industrial expansion, automotive manufacturing hubs, and growing renewable energy and electronics sectors.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers

Growing Industrial Demand from Automotive and Aerospace Manufacturing

The Anaerobic Adhesives Market benefits from rising demand in automotive and aerospace production. High-performance adhesives replace mechanical fasteners, reducing weight and improving joint reliability. Manufacturers prefer these adhesives for their durability under heat, vibration, and mechanical stress. The automotive sector uses them for thread locking, shaft retention, and sealing critical components. Aerospace applications leverage anaerobic adhesives for enhanced vibration resistance and corrosion protection. Industrial assembly lines adopt automated dispensing systems to improve precision and reduce waste. The trend toward lightweight vehicles and fuel-efficient designs strengthens product demand. It continues to gain traction as industries prioritize cost efficiency and performance.

Increasing Shift Toward Eco-Friendly and Low-VOC Formulations

Sustainability drives innovation in the Anaerobic Adhesives Market through eco-friendly product development. Manufacturers invest in low-VOC formulations that meet strict environmental regulations. These adhesives reduce emissions without compromising bonding strength or shelf life. Regulatory frameworks in Europe and North America encourage the use of safer chemistries. Companies adopt renewable raw materials and cleaner production technologies. Consumer awareness of environmental impact supports the use of green adhesive products. The shift toward sustainability creates new competitive advantages for producers. It reinforces brand reputation and aligns with global decarbonization goals.

- For instance, GLUETEC’s WIKO anaerobic adhesives are PFAS-free, require no hazard labeling, and maintain high strength and vibration resistance, demonstrating eco-friendly performance in industrial hydraulics and precision engineering.

Technological Advancements in Adhesive Chemistry and Dispensing Systems

Continuous improvement in formulation technology enhances the performance of anaerobic adhesives. Research focuses on faster curing times, wider temperature tolerances, and superior metal adhesion. Smart dispensing systems optimize application accuracy and minimize product waste. The Anaerobic Adhesives Market leverages innovations like UV-curable hybrids and microencapsulation for controlled release. Automation in assembly lines improves production efficiency and consistency. Digital monitoring enables better quality control across high-speed operations. These technological advances expand applications in precision engineering and electronics. It fosters stronger partnerships between adhesive suppliers and OEMs.

- For instance, Technodigm™’s PCP-technology provides entirely metal-free, high-precision dispensing systems for anaerobic adhesives, achieving ±99% accuracy and repeatability in automated industrial assembly, ensuring reliable and stable manufacturing processes.

Expanding Applications in Renewable Energy and Heavy Engineering Sectors

The Anaerobic Adhesives Market sees growth in renewable energy and heavy machinery applications. Wind turbine assembly, powertrain systems, and industrial gearboxes rely on high-strength adhesives. These products ensure sealing integrity and resistance against extreme operating conditions. Manufacturers in construction and mining use them for thread locking in equipment. Energy infrastructure development in Asia and Europe boosts product consumption. Demand from green energy installations supports industry diversification. Companies focus on specialized adhesives for harsh environments. It strengthens product relevance in long-term energy and industrial expansion projects.

Market Trends

Integration of Smart Manufacturing and Digital Dispensing Systems

Industry 4.0 adoption transforms adhesive application processes through smart automation. Digital control systems manage curing times and bonding precision efficiently. The Anaerobic Adhesives Market integrates IoT-enabled dispensers for real-time monitoring. Predictive maintenance tools help minimize downtime and ensure consistent output. Robotics improve adhesive placement in complex assembly lines. Data analytics enhances operational decision-making and reduces material waste. Manufacturers gain flexibility in mass production through advanced process automation. It reflects a broader shift toward intelligent manufacturing ecosystems.

- For instance, Henkel inaugurated its Inspiration Center in Düsseldorf in 2022 with a €130 million investment, featuring 30 laboratories and supporting collaboration across more than 800 industry segments.

Rising Use of Anaerobic Adhesives in Electric Vehicle Assemblies

The transition to electric mobility increases adhesive demand for motor and battery assemblies. Anaerobic adhesives replace mechanical fasteners to ensure tight seals and improved heat management. The Anaerobic Adhesives Market benefits from this shift toward e-mobility and sustainability. Adhesive producers tailor solutions compatible with aluminum and composite substrates. EV manufacturers prefer them for lightweight and corrosion-resistant bonding. Battery housings and electric drive systems use these adhesives to enhance safety. The industry’s electrification trend accelerates new formulation development. It strengthens the market’s position in the clean energy value chain.

Product Customization and Expansion into Specialized Industrial Applications

Customization is becoming a major trend in adhesive design and performance. End users demand tailored formulations to meet sector-specific challenges. The Anaerobic Adhesives Market responds with hybrid adhesives suited for unique industrial needs. Precision manufacturing sectors prefer modified viscosities and curing rates. Aerospace and defense customers seek products with superior thermal stability. Small-scale fabricators look for cost-efficient multi-purpose options. Manufacturers collaborate with R&D partners to optimize adhesive behavior. It promotes innovation-led growth across industrial verticals.

Growing Investments in R&D and Sustainability-Oriented Production Processes

Manufacturers increase R&D budgets to develop sustainable and high-performance products. Research centers focus on extending product shelf life and curing efficiency. The Anaerobic Adhesives Market emphasizes non-toxic and recyclable formulations. Companies implement cleaner production lines to reduce carbon emissions. Industry partnerships enhance technology transfer and innovation pace. Regulatory frameworks drive continuous improvements in environmental performance. Strategic collaborations with universities accelerate eco-design developments. It aligns business growth with global environmental stewardship objectives.

- For instance, Huntsman uses renewable and recycled feedstocks in its polyurethane foams, with ISCC PLUS-certified processes that reduce carbon footprint and track scope-3 emissions.

Market Challenges Analysis

High Dependence on Metal Substrates and Limited Compatibility with Plastics

The Anaerobic Adhesives Market faces structural limitations due to metal substrate reliance. These adhesives require metal ions to initiate polymerization effectively. Their performance declines when applied to plastics or composite materials. Manufacturers struggle to achieve consistent curing in non-metal assemblies. The industry seeks chemical modifications to enhance adhesion on alternative surfaces. Diverse end-user requirements make universal solutions difficult to standardize. Companies invest in surface preparation techniques to expand usability. It remains a challenge to broaden application range without sacrificing bonding strength.

Rising Raw Material Costs and Compliance with Safety Regulations

Volatility in petrochemical prices directly impacts adhesive production costs. Raw material constraints pressure manufacturers to balance cost and performance. The Anaerobic Adhesives Market must comply with REACH and EPA regulations. Achieving compliance raises formulation and certification expenses. Regional differences in chemical safety standards add complexity to global operations. Manufacturers adopt supply chain optimization to control expenses. Smaller producers face challenges maintaining profitability under strict compliance norms. It highlights the industry’s need for stable sourcing and standardized global frameworks.

Market Opportunities

Expansion into Electric Mobility, Renewable Energy, and Smart Assembly Sectors

Emerging industries present new growth pathways for anaerobic adhesive manufacturers. The Anaerobic Adhesives Market benefits from adoption in EVs, wind energy, and robotics. Lightweight bonding and vibration-resistant properties enhance energy system durability. Smart assembly lines use automated dispensing for precision sealing. Growth in electric powertrain manufacturing increases long-term adhesive demand. OEM collaborations drive customized adhesive development for high-voltage applications. Renewable energy projects encourage large-scale adhesive use in maintenance systems. It offers a profitable route for market diversification and innovation leadership.

Adoption of Bio-Based and Hybrid Adhesive Solutions for Sustainable Manufacturing

Manufacturers explore bio-based anaerobic formulations to reduce dependency on petrochemicals. These innovations align with global sustainability commitments and green certifications. The Anaerobic Adhesives Market experiences growing demand for low-carbon materials. Hybrid adhesives combining anaerobic and UV-curing technologies create new performance benchmarks. Environmentally conscious consumers influence purchasing decisions across industrial supply chains. Companies that integrate renewable sources improve brand perception and compliance readiness. Continuous R&D efforts improve biodegradability and performance balance. It paves the way for next-generation adhesive technologies built for circular economies.

Market Segmentation Analysis:

By Product

Thread lockers dominate the Anaerobic Adhesives Market due to their extensive use in securing fasteners against loosening from vibration. Thread sealants follow, providing reliable sealing for hydraulic and pneumatic fittings. Retaining compounds ensure structural integrity in cylindrical assemblies such as bearings and shafts. Gasket sealants gain traction for replacing traditional gaskets in automotive and industrial systems. Other specialized products cater to unique engineering applications that demand precise bonding and resistance to harsh environments. Each product category contributes to overall market growth through innovation and performance enhancement.

- For instance, Permatex High Performance Thread Sealant with PTFE cures rapidly and withstands pressures up to 10,000 psi in industrial hydraulic systems, according to its official technical datasheet.

By Substrate

Metal remains the leading substrate in the Anaerobic Adhesives Market, favored for its ability to trigger anaerobic curing through ion interaction. It supports strong adhesion in automotive, machinery, and aerospace components. Plastic usage grows steadily as manufacturers develop modified formulations that enable improved curing on non-metallic materials. Other substrates, including composites, offer niche opportunities for customized adhesives. The rising adoption of lightweight materials drives innovation toward universal bonding capabilities. It enhances versatility and extends market reach across varied industrial sectors.

By End-User Industry

The automotive and transportation sector holds the largest share of the Anaerobic Adhesives Market, driven by the demand for efficient thread locking and sealing. The electrical and electronics industry relies on these adhesives for precision bonding and insulation in compact devices. Industrial applications, including heavy machinery, use them for vibration resistance and equipment reliability. Other sectors, such as construction and medical devices, contribute through specialized applications requiring strength and durability. It ensures widespread adoption across diverse manufacturing ecosystems.

By Adhesive Type

Acrylic adhesives dominate the Anaerobic Adhesives Market due to their superior bonding strength and quick curing with metals. Silicone-based variants are gaining prominence for flexibility and chemical resistance in sealing and gasketing. Butyl adhesives find use in applications demanding elasticity and long-term moisture protection. Other adhesive types include hybrid formulations designed for performance under extreme operating conditions. It reflects the market’s commitment to material innovation and adaptability to evolving industrial requirements.

- For instance, Henkel’s LOCTITE 243 delivers medium strength threadlocking for various metal substrates and retains performance under high vibration, as confirmed in Henkel’s published technical sheet.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Segmentation:

By Product

- Thread Lockers

- Thread Sealants

- Retaining Compounds

- Gasket Sealants

- Others

By Substrate

By End-User Industry

- Automotive & Transportation

- Electrical & Electronics

- Industrial (including manufacturing and machinery)

- Others (such as construction, medical devices)

By Adhesive Type

- Acrylic

- Silicone

- Butyl

- Others

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Regional Analysis:

North America

North America holds the largest share of the Anaerobic Adhesives Market with 36% in 2024. The region benefits from advanced industrial infrastructure and high adoption across automotive, aerospace, and machinery sectors. The United States leads production and consumption due to its strong manufacturing base and focus on performance materials. Canada contributes through growing demand in energy and transportation applications. Investments in automation and smart assembly technologies support continuous market growth. It maintains strong competition among major players driven by innovation and sustainability goals. The region’s emphasis on R&D enhances product quality and environmental compliance.

Europe

Europe accounts for 30% of the Anaerobic Adhesives Market in 2024, driven by strict environmental regulations and expanding automotive manufacturing. Germany, France, and the UK are key contributors due to their engineering excellence and industrial innovation. The region’s focus on lightweight vehicle design promotes adhesive use over traditional fasteners. Demand for eco-friendly and low-VOC formulations aligns with EU sustainability targets. Industrial automation and renewable energy projects create additional adhesive applications. It continues to evolve through collaboration between material science companies and equipment manufacturers. High product standards and energy efficiency targets sustain regional growth momentum.

Asia-Pacific

Asia-Pacific holds 25% of the Anaerobic Adhesives Market in 2024 and represents the fastest-growing region globally. China, India, Japan, and South Korea drive expansion through rapid industrialization and infrastructure development. The rise of automotive production hubs and electronic manufacturing clusters supports large-scale consumption. Local manufacturers invest in cost-effective adhesive solutions tailored to regional requirements. Strong growth in renewable energy and construction further enhances demand. It offers significant potential for international players expanding distribution networks. Increasing government initiatives promoting sustainable industrial practices strengthen long-term market prospects across Asia-Pacific.

Key Player Analysis:

- Henkel AG & Co. KGaA (Loctite)

- 3M Company

- B. Fuller Company

- Permabond LLC

- ThreeBond Holdings Co., Ltd.

- Eastman Chemical Company

- Anabond Limited

- Cyberbond LLC

- Parson Adhesives, Inc.

- DELO Industrial Adhesives

- Kisling AG

- Hylomar Ltd.

- Loxeal S.r.l.

- ITW LLC & Co. KG

- Hernon Manufacturing

Competitive Analysis:

The Anaerobic Adhesives Market features strong competition among global and regional manufacturers focusing on performance innovation and application diversity. Leading companies include Henkel AG & Co. KGaA, 3M Company, Permabond Engineering Adhesives, H.B. Fuller, and ThreeBond Holdings. These players emphasize product development, automation compatibility, and low-VOC formulations to meet industry standards. Strategic mergers and partnerships expand distribution channels and strengthen customer engagement. The market sees continuous investment in R&D for hybrid and bio-based adhesive technologies. Emerging companies compete through niche applications and region-specific product lines. It maintains a dynamic structure driven by technological advancement and expanding industrial adoption.

Recent Developments:

- In October 2025, Henkel and Dow expanded their strategic partnership to reduce emissions in adhesive manufacturing, introducing low-carbon feedstocks and renewable electricity into Henkel’s production.

- In October 2025, DELO expanded its DELO-ACTIVIS line, launching DELO-ACTIVIS 330 for micro-dispensing (down to 4 µl), targeting integrated, energy-efficient production with up to 98% reduced carbon emissions. This aligns with DELO’s reported growth in the auto and semiconductor segments.

Report Coverage:

The research report offers an in-depth analysis based on Product, Substrate, End-User Industry and Adhesive Type. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook:

- Rising demand across automotive and aerospace industries will continue to drive product innovation.

- Increasing adoption of automation and precision manufacturing will boost adhesive consumption in assembly lines.

- Development of eco-friendly and low-VOC formulations will strengthen sustainability goals among producers.

- Expanding applications in renewable energy and heavy machinery will enhance market diversification.

- Advancements in digital dispensing and monitoring systems will improve efficiency and reduce material waste.

- Growing investments in electric vehicle manufacturing will support adhesive use in battery and motor components.

- Expanding industrial production in emerging economies will create new growth opportunities for manufacturers.

- Continuous R&D in hybrid and bio-based formulations will redefine product performance standards.

- Strategic collaborations between adhesive producers and OEMs will enhance customized product development.

- Rising environmental compliance requirements will encourage innovation in safe and regulatory-approved adhesives.