Market Overview

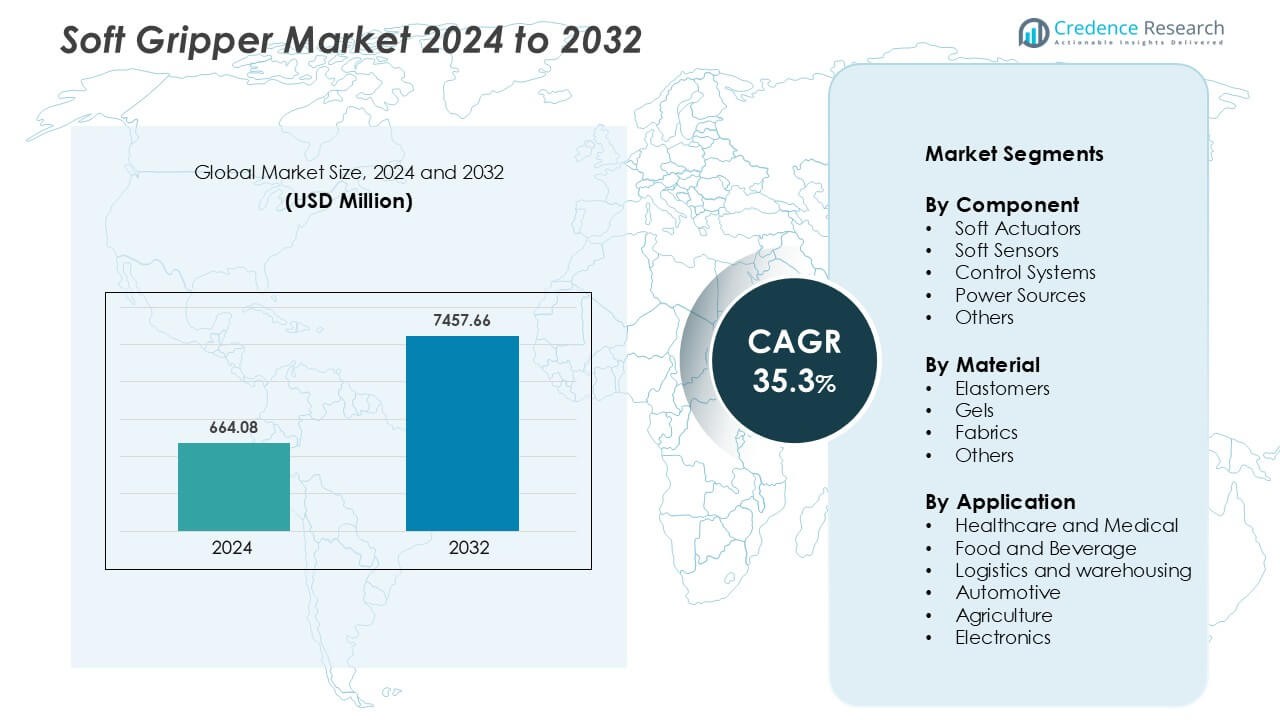

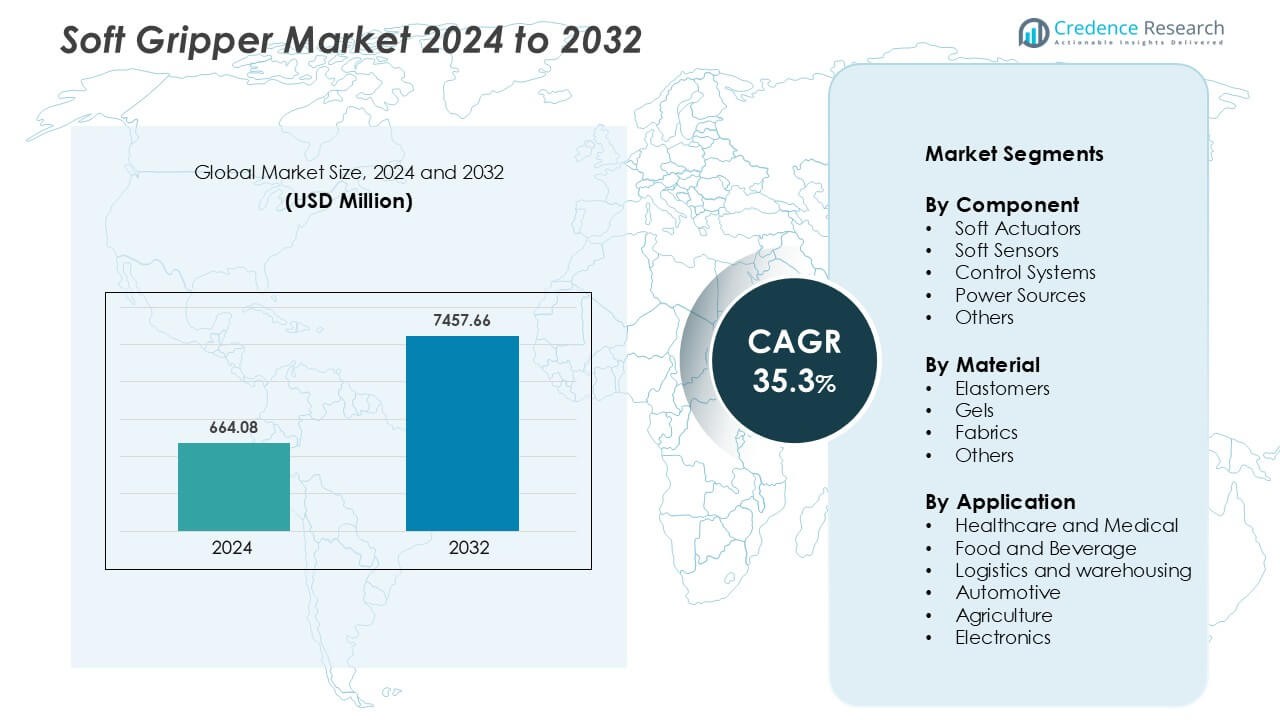

Soft Gripper Market was valued at USD 664.08 million in 2024 and is anticipated to reach USD 7457.66 million by 2032, growing at a CAGR of 35.3 % during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Soft Gripper Market Size 2024 |

USD 664.08 Million |

| Soft Gripper Market, CAGR |

35.3 % |

| Soft Gripper Market Size 2032 |

USD 7457.66 Million |

The Soft Gripper Market features strong competition among key players focusing on technological innovation and automation efficiency. Major companies including Soft Robotics, ABB, Piab AB, Robotiq Inc., OnRobot, SCHUNK GmbH & Co. KG, Festo, ATI Industrial Automation, Bastian Solutions, and KUKA lead the global landscape. These firms emphasize developing adaptive, AI-integrated gripping systems for precision handling in food processing, healthcare, and logistics industries. North America dominates the market with a 34% share, driven by advanced robotic integration, strong industrial automation infrastructure, and high adoption of collaborative robots. Continuous R&D and material advancements further reinforce regional leadership and competitive positioning.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights

- The Soft Gripper Market was valued at USD 664.08 million in 2024 and is projected to reach USD 7457.66 million by 2032, registering a CAGR of 35.3% during the forecast period.

- Rising demand for automation in food processing, packaging, and healthcare industries drives market growth, supported by the need for flexible and damage-free handling solutions.

- Increasing adoption of AI-integrated robotics and collaborative automation systems is shaping key market trends, enhancing precision and operational efficiency across sectors.

- The market is moderately competitive, with leading players such as ABB, Soft Robotics, OnRobot, SCHUNK GmbH & Co. KG, and Festo investing in material innovation and sensor-based control technologies.

- North America holds a 34% market share, followed by Europe with 28% and Asia-Pacific with 26%, while soft actuators lead the component segment due to their adaptability and dominance in industrial automation applications.

Market Segmentation Analysis:

By Component

Soft actuators dominate the Soft Gripper Market due to their ability to perform flexible and adaptive gripping operations. These actuators replicate human hand movements, allowing efficient handling of delicate or irregular objects. Their lightweight design and compliance with different shapes make them ideal for robotics and automation applications. The growing use of pneumatic and hydraulic actuation systems enhances precision and control in industrial and service robots. Additionally, advancements in soft sensors and control systems are improving responsiveness, enabling integration with AI-based robotic systems for enhanced performance and safety.

- For instance, OnRobot’s Soft Gripper supports a payload of 2.2 kg and handles grip dimensions from 11 mm to 118 mm, showcasing high adaptability for fragile object handling.

By Material

Elastomers hold the largest share in the material segment due to their high flexibility, stretchability, and resistance to deformation. These materials allow soft grippers to maintain structural integrity while adapting to variable shapes and weights. Their use in silicone-based and polyurethane-based formulations enhances tactile sensitivity and grip control. Growing demand for cost-effective, durable, and biocompatible materials further supports elastomer adoption in food handling and medical robotics. Gels and fabrics are also gaining attention for specialized applications that require high sensitivity or lightweight structural support.

- For instance, Piab AB’s piSOFTGRIP® employs food-grade silicone elastomer and can grip objects up to 50 mm in diameter, illustrating how elastomer materials enable reliable, hygienic handling of delicate items.

By Application

The food and beverage segment leads the market, driven by automation in packaging, sorting, and handling of delicate food products. Soft grippers provide a hygienic, non-damaging solution for handling fragile items like fruits, baked goods, and confectioneries. Their adaptability to varying product sizes and textures reduces mechanical waste and operational downtime. The healthcare and medical sector follows closely, utilizing soft grippers for surgical robotics and prosthetic devices. Increasing adoption in logistics, automotive assembly, and agricultural harvesting further strengthens the market’s growth trajectory across industries.

Key Growth Drivers

Rising Automation Across Manufacturing and Food Industries

The growing adoption of automation in manufacturing and food processing industries is a major driver for the soft gripper market. Soft grippers enable robots to handle delicate, irregularly shaped, or soft items without causing damage, which is essential in food packaging, electronics, and consumer goods sectors. Their flexibility and adaptability support high-speed operations, improving productivity and quality assurance. In food processing, soft robotic systems reduce contamination risks by replacing manual handling. The integration of soft grippers with vision systems and AI-driven control mechanisms further enhances precision and efficiency. As industries strive for greater automation and hygiene compliance, the demand for advanced gripping solutions continues to increase globally.

- For instance, Soft Robotics Inc. developed its mGripAI platform that integrates 3D vision and AI-based picking, capable of identifying and handling up to 120 items per minute in food automation lines.

Growing Adoption in Healthcare and Medical Robotics

Soft grippers are gaining traction in healthcare due to their biocompatibility and ability to handle fragile tissues and instruments. In surgical robots, soft grippers provide gentle, precise manipulation required for minimally invasive procedures. They also support rehabilitation robotics, prosthetics, and laboratory automation, where sensitivity and safety are paramount. The use of soft materials such as silicone and elastomers ensures patient safety and reduces mechanical strain on tissues. With advancements in soft actuators and smart sensors, medical robots now achieve higher dexterity and control. Growing healthcare automation and the rise of robotic-assisted surgeries are creating significant opportunities for soft gripper manufacturers to develop customized, sterilizable, and high-performance products.

- For instance, Ritsumeikan University developed a soft robotic gripper capable of safely grasping organs with forces below 0.3 newtons, improving precision in laparoscopic surgery.

Technological Advancements in Material Science and AI Integration

Innovations in soft materials and artificial intelligence are accelerating the performance and reliability of soft grippers. New-generation elastomers, hydrogels, and shape-memory polymers enable better elasticity, chemical resistance, and self-healing capabilities. These properties enhance the gripper’s lifespan and adaptability across industries. Integration with AI and machine learning allows soft grippers to identify object properties in real time, adjusting pressure and grip patterns automatically. Such smart automation minimizes product damage and energy consumption. Companies are also adopting sensor-embedded systems for self-calibration and predictive maintenance. As robotics evolves toward human-like dexterity, material and AI convergence will remain a core growth enabler for the soft gripper market.

Key Trends & Opportunities

Expansion of Collaborative Robotics (Cobots) Applications

Collaborative robots, or cobots, are increasingly using soft grippers for safe human-robot interactions in shared workspaces. These systems allow efficient handling of varied products without rigid end effectors, reducing injury risks. Soft grippers enhance cobot versatility in industries like logistics, electronics, and healthcare. The trend is fueled by small and medium enterprises (SMEs) investing in affordable automation solutions. Integration with lightweight materials and pneumatic control systems ensures flexibility and low maintenance. As cobots become mainstream in industrial and service environments, the adoption of adaptive soft gripping solutions is expected to expand rapidly.

- For instance, OnRobot’s Soft Gripper handles a maximum payload of 2.2 kg and adapts to objects with diameters ranging from 11 mm to 118 mm, providing flexible gripping without damaging items.

Emergence of Eco-Friendly and Biodegradable Gripper Materials

Sustainability has become a significant focus in robotics, driving demand for eco-friendly soft grippers. Manufacturers are developing biodegradable and recyclable elastomers that minimize environmental impact while maintaining strength and flexibility. These innovations align with regulatory pressures to reduce plastic waste and promote green manufacturing. Biodegradable silicone alternatives and plant-based polymers offer durability suitable for food-grade and medical applications. This trend not only supports sustainable production but also strengthens brand reputation for companies adopting green technologies. As industries move toward circular economy models, eco-friendly soft grippers present a major long-term growth opportunity.

- For instance, Festo developed bio-based elastomer materials derived from castor oil for its adaptive grippers, which maintain operational efficiency for over 5 million cycles.

Key Challenges

Limited Load-Bearing Capacity and Durability Issues

Despite their flexibility, soft grippers often struggle with limited load capacity and wear resistance. Their soft material composition restricts the handling of heavy or sharp-edged objects, which reduces applicability in high-load industrial settings. Continuous compression and stretching can lead to material fatigue, impacting operational lifespan. Additionally, exposure to heat, chemicals, or abrasives can degrade performance over time. These durability challenges raise maintenance costs and restrict adoption in harsh environments. Manufacturers are addressing this by developing reinforced elastomers and composite structures to improve tensile strength and reliability without compromising adaptability.

High Initial Integration Costs and Complex Control Systems

The implementation of soft grippers involves significant investment in robotics integration, control systems, and software. Unlike traditional grippers, soft systems require precise air pressure control, sensor calibration, and real-time feedback mechanisms. This increases both setup and maintenance complexity, especially for small manufacturers. Compatibility issues with existing robotic platforms can also delay deployment. Furthermore, the lack of standardized interfaces across vendors creates integration challenges. To overcome these barriers, companies are focusing on modular, plug-and-play designs that simplify installation. However, the high upfront costs and technical expertise required remain key obstacles to mass adoption.

Regional Analysis

North America

North America holds the largest share of the Soft Gripper Market, accounting for 34% of global revenue. The region’s dominance is driven by strong adoption of automation technologies in industries such as food processing, logistics, and healthcare. The U.S. leads the market due to advanced robotics research, high labor costs, and supportive government initiatives promoting automation. Key players are investing in AI-integrated soft gripping systems for industrial and service applications. Growing demand from packaging and warehousing sectors further strengthens North America’s leadership in deploying flexible and adaptive robotic handling solutions.

Europe

Europe captures 28% of the global soft gripper market, driven by strong manufacturing automation and the presence of leading robotics firms. Germany, Italy, and France lead adoption due to advancements in industrial robotics and food automation. The region benefits from EU-funded initiatives supporting human-robot collaboration and sustainable material innovation. European industries are rapidly integrating soft gripping technologies to comply with safety and hygiene regulations. The growing use of cobots in manufacturing and precision handling applications positions Europe as a key hub for innovation in soft robotic technologies.

Asia-Pacific

Asia-Pacific accounts for 26% of the soft gripper market, propelled by rapid industrialization and robotics adoption in manufacturing hubs like China, Japan, and South Korea. The region’s growth is fueled by expanding food processing, electronics, and automotive sectors. Rising labor costs and increasing automation in packaging and logistics drive higher demand for adaptive gripping solutions. Japan leads in soft robotics R&D, while China focuses on scalable, cost-efficient production. Investments in AI, smart sensors, and 3D printing technologies are strengthening Asia-Pacific’s role as a global center for soft robotic component manufacturing.

Latin America

Latin America holds 7% of the global market share, with growing applications in food processing, agriculture, and logistics industries. Brazil and Mexico are key contributors, supported by expanding industrial automation and local manufacturing initiatives. The adoption of soft grippers is increasing as companies modernize operations to improve efficiency and product quality. Government incentives promoting robotics in agriculture and packaging sectors further enhance growth potential. Despite slower technology penetration compared to developed regions, the region’s evolving automation landscape presents significant opportunities for soft gripper manufacturers targeting emerging markets.

Middle East & Africa

The Middle East & Africa region represents 5% of the global soft gripper market share, with growth driven by automation in food processing, healthcare, and logistics. The UAE, Saudi Arabia, and South Africa lead adoption through smart factory initiatives and investments in industrial modernization. Food and beverage companies are increasingly using soft grippers for safe, hygienic handling of packaged goods. The region’s growing focus on manufacturing diversification and robotics deployment supports steady market expansion. Ongoing infrastructure development and government-backed innovation programs are expected to further strengthen regional adoption

Market Segmentations:

By Component

- Soft Actuators

- Soft Sensors

- Control Systems

- Power Sources

- Others

By Material

- Elastomers

- Gels

- Fabrics

- Others

By Application

- Healthcare and Medical

- Food and Beverage

- Logistics and warehousing

- Automotive

- Agriculture

- Electronics

By Geography

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Competitive Landscape

The soft gripper market is highly competitive, driven by rapid advancements in robotics, automation, and material science. Soft Robotics and OnRobot lead the market with adaptive gripping technologies utilizing compliant materials and AI-based control systems for precision handling in food, electronics, and packaging industries. ABB and KUKA integrate soft grippers into collaborative robotic platforms, enhancing flexibility and safety in human-robot interaction. SCHUNK GmbH & Co. KG and Festo focus on pneumatic and elastomer-based grippers designed for high-speed industrial automation. Piab AB and Robotiq Inc. emphasize modular vacuum grippers suitable for irregular or fragile objects. ATI Industrial Automation strengthens its portfolio with sensor-integrated grippers offering force feedback and enhanced dexterity. Bastian Solutions advances end-of-arm tooling through custom automation and robotic integration services. Companies are investing in lightweight designs, 3D printing, and soft actuator technologies to improve adaptability, reduce maintenance, and meet growing demand for automation across diverse sectors.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

Recent Developments

- In September 2024, Researchers from the Japan Advanced Institute of Science and Technology (JAIST) have introduced an innovative soft robotic gripper named ROtation-based Squeezing grippEr (ROSE), designed to adapt to complex shapes, sizes, and the delicate nature of crops. This development addresses the challenges conventional robotic grippers face in agriculture, offering a versatile solution for efficient crop harvesting.

- In August 2024, The Singapore University of Technology and Design (SUTD) has developed a soft gripper designed for diverse functionalities across various industries. This design earned the prestigious Iron A’ Design Award, exemplifying SUTD’s approach of integrating design and technology in research to ensure relevance and facilitate the transition from lab prototypes to commercial products.

Report Coverage

The research report offers an in-depth analysis based on Component, Material, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Soft Gripper Market will witness strong growth driven by increased automation adoption across industries.

- Integration of AI and machine learning will enhance precision, adaptability, and predictive control in gripping systems.

- Demand for hygienic, food-grade soft grippers will expand with automation in food processing and packaging.

- Healthcare robotics will increasingly use soft grippers for surgical, prosthetic, and rehabilitation applications.

- Development of self-healing and shape-memory materials will improve product durability and flexibility.

- Collaborative robots using adaptive soft grippers will become more common in small and medium enterprises.

- Eco-friendly and recyclable elastomer materials will gain traction to support sustainability goals.

- Asia-Pacific will emerge as a key manufacturing hub with growing investments in robotics R&D.

- Modular, plug-and-play gripper systems will simplify installation and integration for industrial users.

- Continuous innovation in sensors and pneumatic systems will drive higher performance and efficiency.