Market Overview

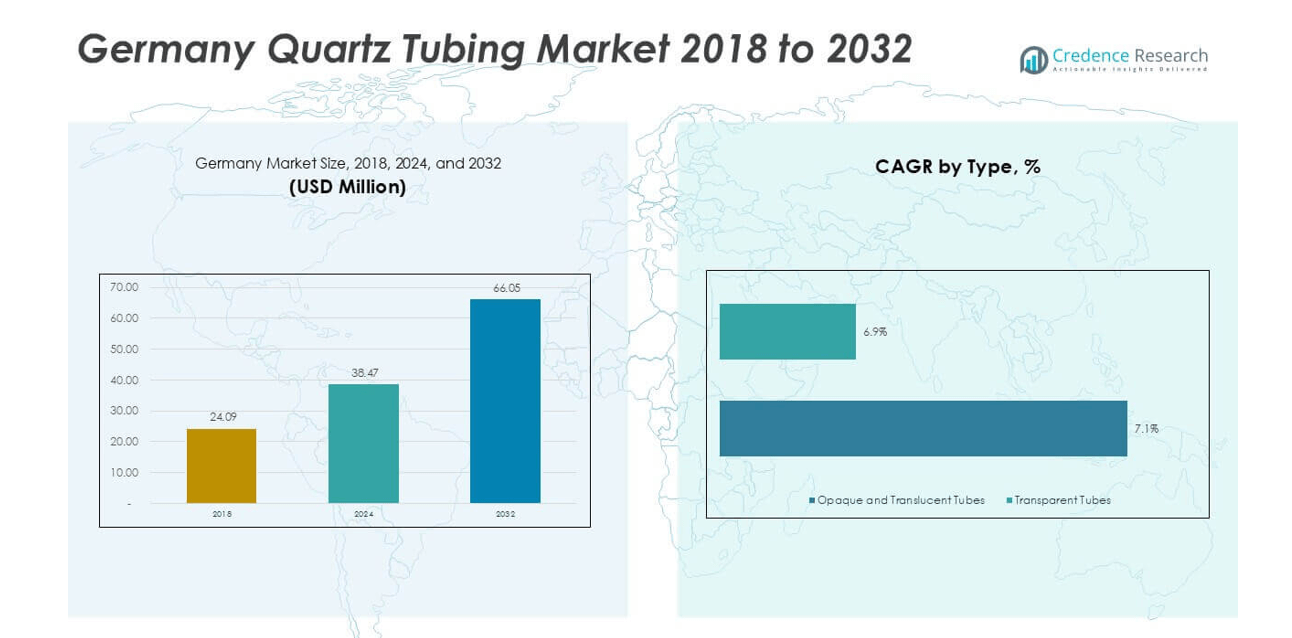

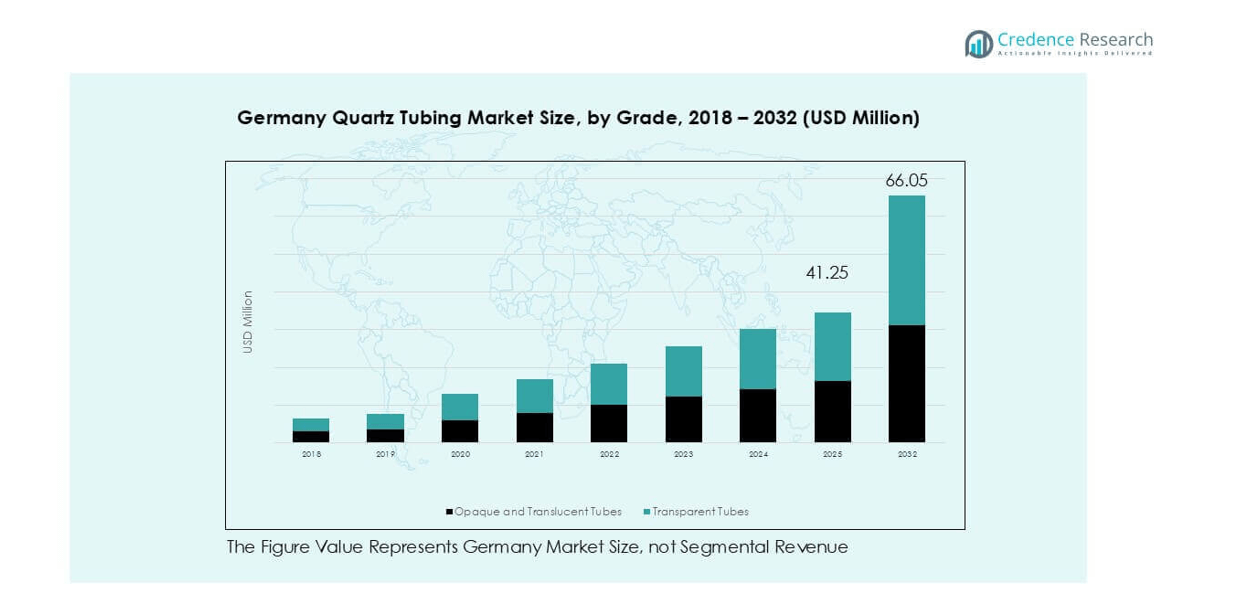

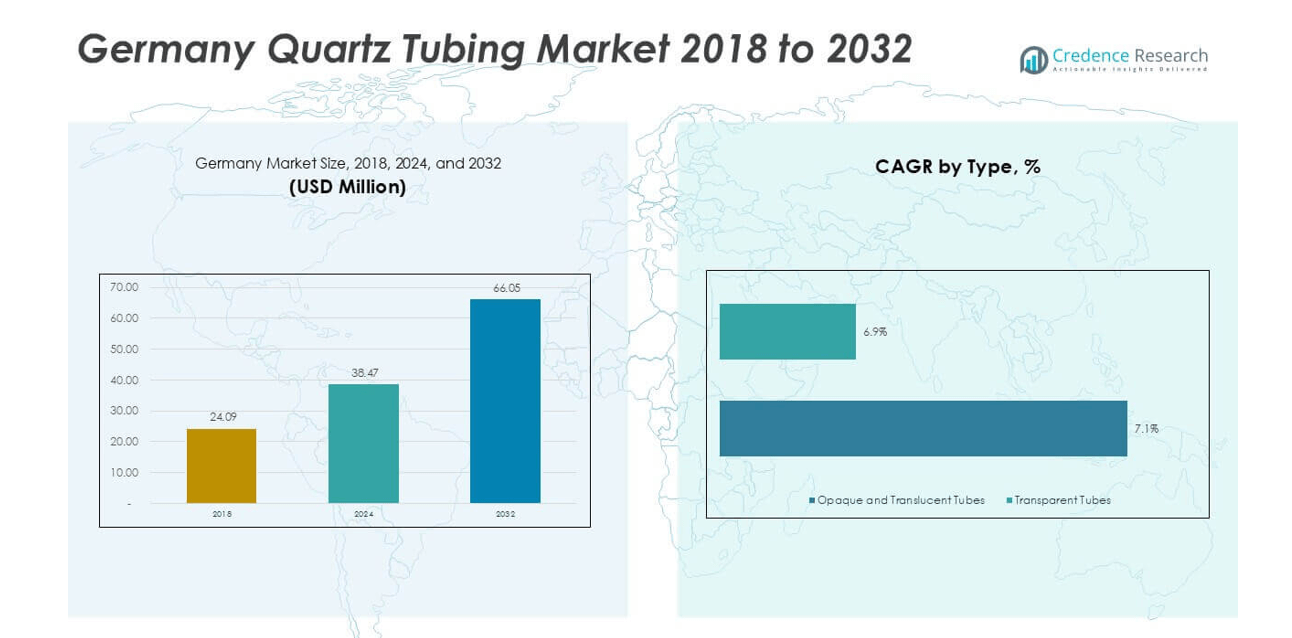

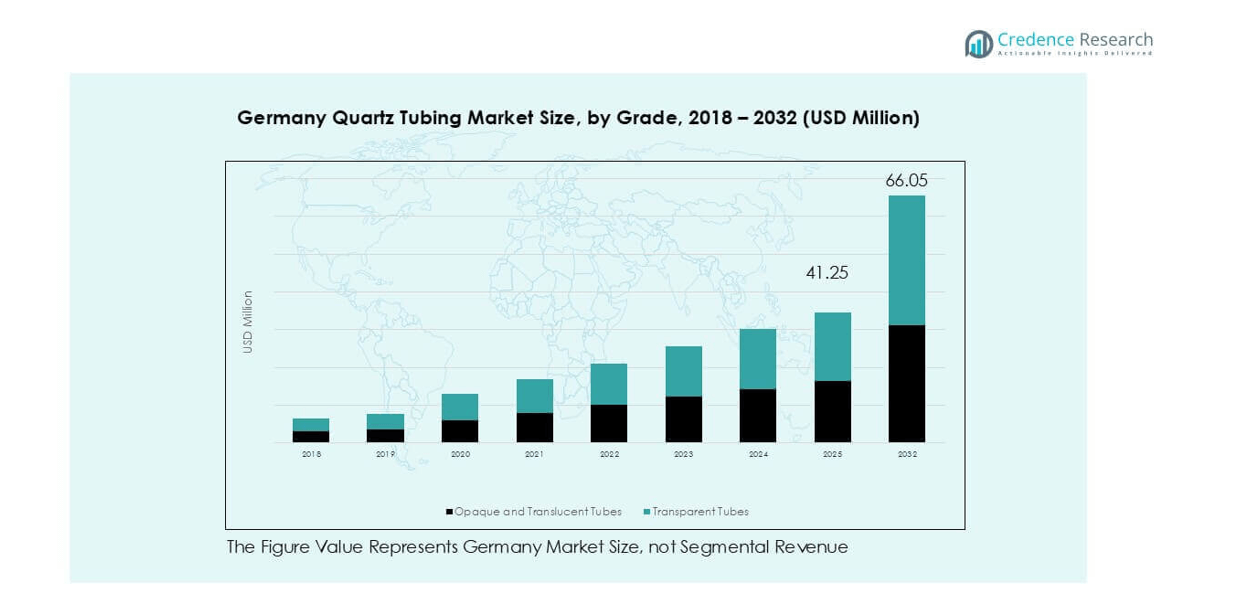

Germany Quartz Tubing market size was valued at 24.09 million in 2018 to USD 38.47 million in 2024 and is anticipated to reach USD 66.05 million by 2032, at a CAGR of 7.0% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Germany Quartz Tubing Market Size 2024 |

USD 38.47 million |

| Germany Quartz Tubing Market, CAGR |

7.0% |

| Germany Quartz Tubing Market Size 2032 |

USD 66.05 million |

The Germany quartz tubing market features a mix of global leaders and strong domestic suppliers. Heraeus, QSIL, GVB GmbH, and Raesch Quarz (Germany) GmbH lead through high-purity and customized offerings. WONIK Quartz Europe and TOSOH strengthen competition in semiconductor-grade tubing. These players focus on quality control, long-term OEM contracts, and local technical support. Southern Germany leads the market with a 38% share, driven by semiconductor and advanced manufacturing clusters. Western Germany follows with 28%, supported by chemicals and industrial processing. Northern Germany holds 22%, led by industrial demand. Eastern Germany accounts for 12%, reflecting emerging investments and expansion potential.

Market Insights

- The Germany quartz tubing market grew from USD 38.47 million in 2024 and is projected to reach USD 66.05 million by 2032, registering a CAGR of about 7.0% during the forecast period, supported by steady industrial and semiconductor demand.

- Semiconductor manufacturing acts as the main market driver, supported by power electronics, sensors, and equipment upgrades, while industrial processing sustains stable replacement demand across chemicals and thermal applications.

- Key trends include rising demand for high-purity transparent tubes, which hold nearly 62% segment share, and increased customization for semiconductor-grade applications, which account for around 48% of total demand.

- The competitive landscape features strong players such as Heraeus, QSIL, GVB GmbH, and Raesch Quarz, with competition based on purity, reliability, and long-term OEM partnerships rather than price.

- Regionally, Southern Germany leads with 38% share, followed by Western Germany at 28%, Northern Germany at 22%, and Eastern Germany at 12%, reflecting industrial concentration and investment patterns.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segmentation Analysis:

By Type

The Germany quartz tubing market shows clear dominance by transparent tubes. This sub-segment accounts for about 62% market share. Semiconductor and high-purity industrial processes strongly support this lead. Transparent tubes offer superior thermal stability and low impurity levels. These features suit diffusion, oxidation, and CVD processes. Strong demand from chip fabrication and precision equipment drives adoption. Opaque and translucent tubes hold the remaining share. These tubes mainly serve high-temperature industrial uses. Cost efficiency and mechanical durability support steady demand. However, purity limits restrict use in advanced semiconductor lines.

- For instance, Heraeus supplies transparent fused-quartz tubes with thermal expansion near 0.55 × 10⁻⁶/K and hydroxyl content below 10 ppm, supporting diffusion and CVD tools used in German semiconductor and precision-equipment plants.

By Application

Semiconductor applications dominate the Germany quartz tubing market with nearly 48% market share. Growth comes from wafer fabrication, power electronics, and sensor manufacturing. Quartz tubing supports high-temperature furnace processes with tight contamination control. Germany’s focus on domestic semiconductor capacity strengthens this segment. Industrial applications follow as the second-largest segment. Chemical processing and thermal equipment sustain stable demand. Lighting applications hold a smaller share. LED and specialty lamp uses support niche volumes. Efficiency improvements and equipment upgrades remain key growth drivers across applications.

- For instance, QSIL supplies semiconductor-grade quartz tubes with certified metallic impurities below 1 ppm and continuous-use stability above 1,050 °C, enabling clean oxidation and LPCVD processes in German wafer-fabrication facilities.

Key Growth Drivers

Expansion of Semiconductor Manufacturing and Equipment Upgrades

Germany’s expanding semiconductor ecosystem remains the strongest growth driver for quartz tubing demand. Chip fabrication relies on ultra-high-purity quartz tubes for diffusion, oxidation, and deposition steps. Advanced nodes require strict impurity control and thermal stability. Equipment upgrades increase replacement frequency for furnace tubes. Power electronics, automotive chips, and sensors add steady volume demand. Public incentives support domestic semiconductor capacity expansion. Local fabs prefer traceable and consistent material quality. Quartz tubing suppliers benefit from long-term supply agreements. Equipment OEM collaboration further strengthens demand visibility. Germany’s role in European chip sovereignty reinforces sustained consumption. Continuous process optimization also raises performance requirements. These factors together create strong, durable demand growth.

- For instance, Heraeus supplies semiconductor-grade quartz tubes with metal impurities below 1 ppm and continuous-use capability above 1,100 °C, supporting oxidation and LPCVD tools in German wafer-fabrication lines.

Localization of Supply Chains and Domestic Sourcing

Supply chain localization strongly supports the Germany quartz tubing market. End users aim to reduce reliance on overseas suppliers. Domestic sourcing improves delivery reliability and lead times. Local production supports rapid customization and technical support. Semiconductor and industrial customers value close supplier collaboration. Regulatory compliance also favors regional manufacturing. Government programs encourage strategic materials production. Local suppliers meet strict environmental and quality standards. Reduced logistics risk improves operational planning. After-sales service and process support strengthen supplier relationships. Localization improves quality assurance and supply continuity. These advantages drive long-term contracts and stable revenue growth.

- For instance, QSIL operates European fused-silica production that delivers quartz tubing with diameter tolerances within ±0.1 mm and operating stability above 1,050 °C, enabling fast turnaround and consistent supply for German semiconductor and industrial customers.

Growth of High-Temperature Industrial Processing

Industrial processing remains a key demand driver for quartz tubing. Applications include chemical reactors, thermal treatment, and metallurgy. Quartz tubing offers excellent thermal shock resistance. High purity supports aggressive chemical environments. German industries prioritize durable and efficient materials. Energy efficiency upgrades increase furnace modernization. Replacement demand remains consistent across industries. Quartz tubing supports continuous high-temperature operation. Automation trends also favor reliable thermal components. Industrial users value long service life and performance stability. These factors sustain steady growth beyond semiconductor cycles.

Key Trends & Opportunities

Adoption of Advanced Manufacturing and Digital Quality Control

Advanced manufacturing creates new opportunities for quartz tubing suppliers. Automation improves dimensional accuracy and yield rates. Inline inspection detects micro-defects early. Digital traceability supports semiconductor compliance requirements. Process analytics reduce scrap and energy use. Customers favor suppliers with smart production lines. Precision forming supports tighter tolerance products. Digital quality data strengthens customer trust. These upgrades also lower operating costs. Technology adoption enhances global competitiveness. Suppliers investing in smart factories gain pricing power. This trend supports premium product demand.

- For instance, QSIL uses laser-based inline inspection systems that control tube diameter within ±0.1 mm and detect surface defects down to 50 µm, supporting semiconductor-grade quartz production.

Rising Demand for High-Purity and Customized Tubing

Customers increasingly demand application-specific quartz tubing. Semiconductor fabs request tighter purity thresholds. Custom diameters and wall thickness gain importance. Industrial users seek tailored thermal profiles. Small-batch customization creates differentiation opportunities. Engineering collaboration becomes a value-added service. Suppliers expand testing and metrology capabilities. Premium grades command higher margins. Customized solutions also strengthen customer retention. This trend favors technically advanced producers. Innovation-focused suppliers capture higher-value contracts.

- For instance, Heraeus supplies custom fused-quartz tubing with metallic impurities below 1 ppm and certified continuous-use stability above 1,100 °C, enabling tailored solutions for semiconductor and high-temperature industrial processes.

Key Challenges

High Production Costs and Energy Intensity

High production costs remain a key challenge. Quartz tubing manufacturing is energy intensive. Electricity and gas prices affect margins. Raw material purification adds cost pressure. Equipment maintenance requires skilled labor. Price-sensitive customers limit pass-through ability. Smaller producers face profitability strain. Compliance with environmental regulations increases expenses. Capital investment needs remain high. Cost volatility complicates long-term pricing strategies. These factors pressure operational efficiency. Suppliers must balance quality with cost control.

Technical Barriers and Stringent Quality Requirements

Meeting strict quality standards presents another major challenge. Semiconductor customers demand near-zero defect rates. Minor impurities can cause product rejection. Advanced testing raises operational complexity. Process control requires specialized expertise. Certification timelines can be lengthy. New entrants face high qualification barriers. Continuous audits increase compliance burden. Product failure risks damage supplier reputation. Scaling production without quality loss remains difficult. These constraints slow capacity expansion. Only technologically mature suppliers succeed long term.

Regional Analysis

Northern Germany

Northern Germany accounts for nearly 22% of the Germany quartz tubing market. Demand is driven by industrial processing, specialty chemicals, and thermal equipment manufacturing. The region benefits from strong port infrastructure, supporting raw material imports and equipment exports. Industrial users rely on quartz tubing for high-temperature reactors and process lines. Moderate semiconductor activity supports niche demand. Research institutes and applied technology centers also contribute to specialty requirements. Stable industrial investment sustains replacement demand. Northern Germany’s focus on process efficiency and durability supports steady, long-term consumption of quartz tubing products.

Southern Germany

Southern Germany dominates the market with about 38% market share. The region hosts major semiconductor fabs, equipment suppliers, and advanced manufacturing clusters. Bavaria and Baden-Württemberg drive strong demand for high-purity quartz tubing. Semiconductor, automotive electronics, and sensor production fuel volume growth. Customers require tight tolerances and strict quality control. Strong R&D intensity supports customized solutions. Public and private investments in chip manufacturing reinforce demand visibility. Southern Germany remains the key growth engine for premium and semiconductor-grade quartz tubing.

Western Germany

Western Germany represents around 28% of the market share. The region’s strength lies in chemicals, metallurgy, and industrial furnace manufacturing. Quartz tubing supports thermal processing, chemical reactors, and high-temperature testing. Dense industrial clusters ensure consistent replacement demand. Modernization of legacy plants drives incremental growth. Proximity to major OEMs supports long-term supply agreements. Energy efficiency upgrades increase demand for durable quartz components. Western Germany maintains stable demand driven by mature industrial infrastructure and continuous process optimization.

Eastern Germany

Eastern Germany holds approximately 12% market share. The region shows emerging growth potential supported by new industrial investments. Semiconductor expansion initiatives and research parks support rising demand. Government incentives encourage advanced materials manufacturing. Quartz tubing demand remains smaller but is growing steadily. Industrial applications dominate current consumption. Infrastructure development improves regional competitiveness. Local fabs and pilot lines increase demand for high-purity tubes. Eastern Germany offers long-term upside as capacity expansion and technology adoption progress.

Market Segmentations:

By Type

- Opaque and Translucent Tubes

- Transparent Tubes

By Application

- Industrial Applications

- Semiconductor

- Lighting

By Geography

- Northern Germany

- Southern Germany

- Western Germany

- Eastern Germany

Competitive Landscape

The Germany quartz tubing market shows a competitive landscape with both global leaders and strong regional players. Key suppliers, including GVB GmbH, Heraeus, and QSIL, hold leading positions through diverse product portfolios and high-purity offerings. Companies such as TOSOH and Aoxin Quartz focus on advanced material technology to serve semiconductor and industrial clients. Regional specialists like proQuarz GmbH and Raesch Quarz (Germany) GmbH emphasize customization and local service. Strategic partnerships with OEMs and long-term supply contracts secure stable revenue streams. Firms invest in quality control, digital production, and sustainable practices. Heraeus leverages brand strength, while WONIK Quartz Europe expands European reach. Smaller players differentiate with niche applications and rapid technical support. Price competition remains moderate due to high entry barriers and quality requirements. Innovation and supply reliability remain key success factors across the market.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- GVB GmbH

- Heraeus

- QSIL

- TOSOH

- Fudong Lighting

- Aoxin Quartz

- Sentro Tech

- proQuarz GmbH

- WONIK Quartz Europe

- Raesch Quarz (Germany) GmbH

Recent Developments

- In Jan 2025, Heraeus combined high-performance materials units into Heraeus Covantics to expand its technology leadership in high-purity quartz and fused silica products.

- In Nov 2024, Momentive Technologies promoted two long-serving executives into global quartz and ceramics leadership roles, strengthening its quartz business focus

Report Coverage

The research report offers an in-depth analysis based on Type, Application and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- Semiconductor capacity expansion will continue to drive demand for high-purity quartz tubing.

- Transparent quartz tubes will gain higher adoption due to advanced process requirements.

- Equipment modernization will increase replacement cycles for furnace and process tubes.

- Localization of supply chains will strengthen demand for domestic quartz tubing suppliers.

- Industrial processing will provide stable baseline demand across multiple end uses.

- Custom and application-specific tubing will see faster growth than standard products.

- Advanced manufacturing and digital quality control will improve supplier competitiveness.

- Environmental compliance will push investments in energy-efficient production methods.

- Long-term contracts with equipment OEMs will enhance revenue stability for key players.

- Eastern Germany will offer gradual growth opportunities as new investments materialize.