Market Overview

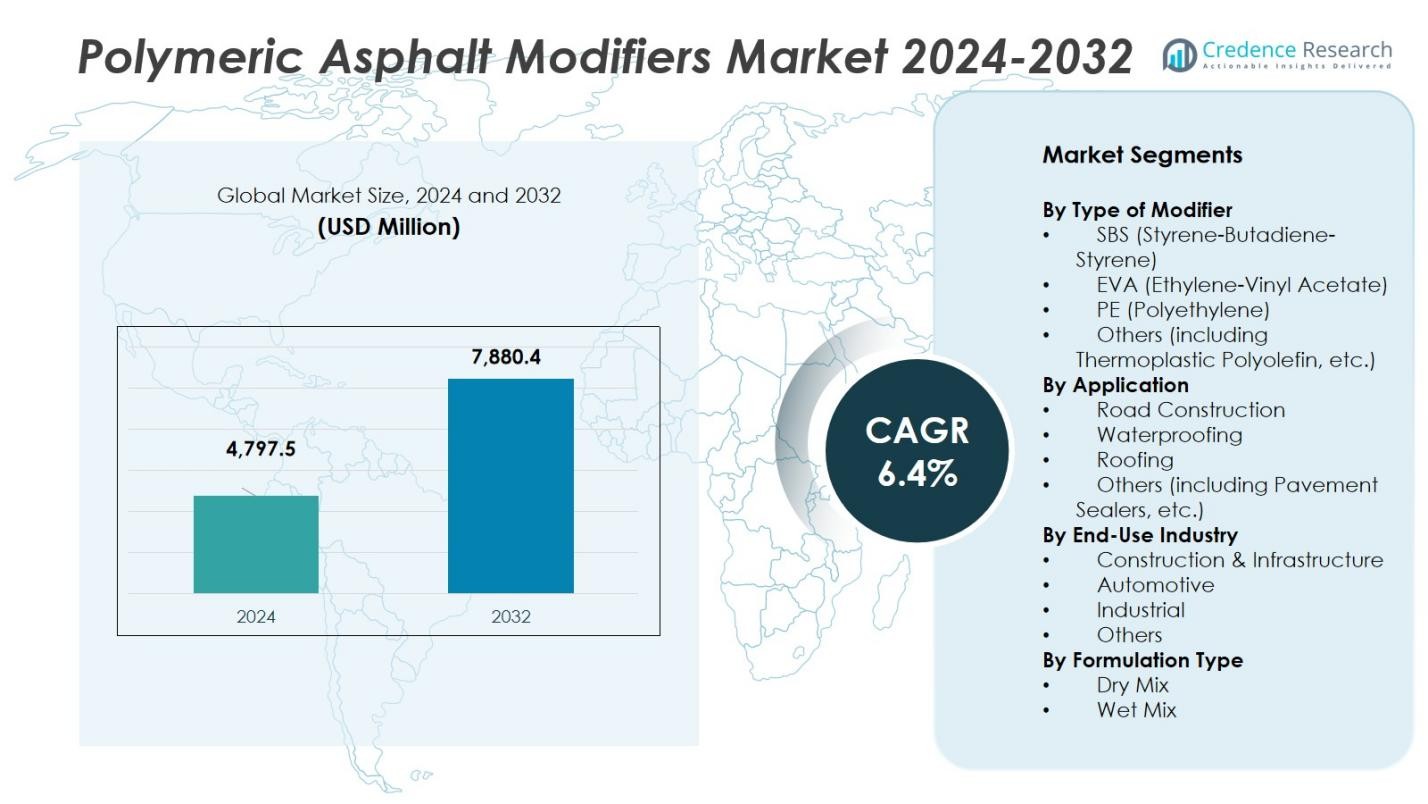

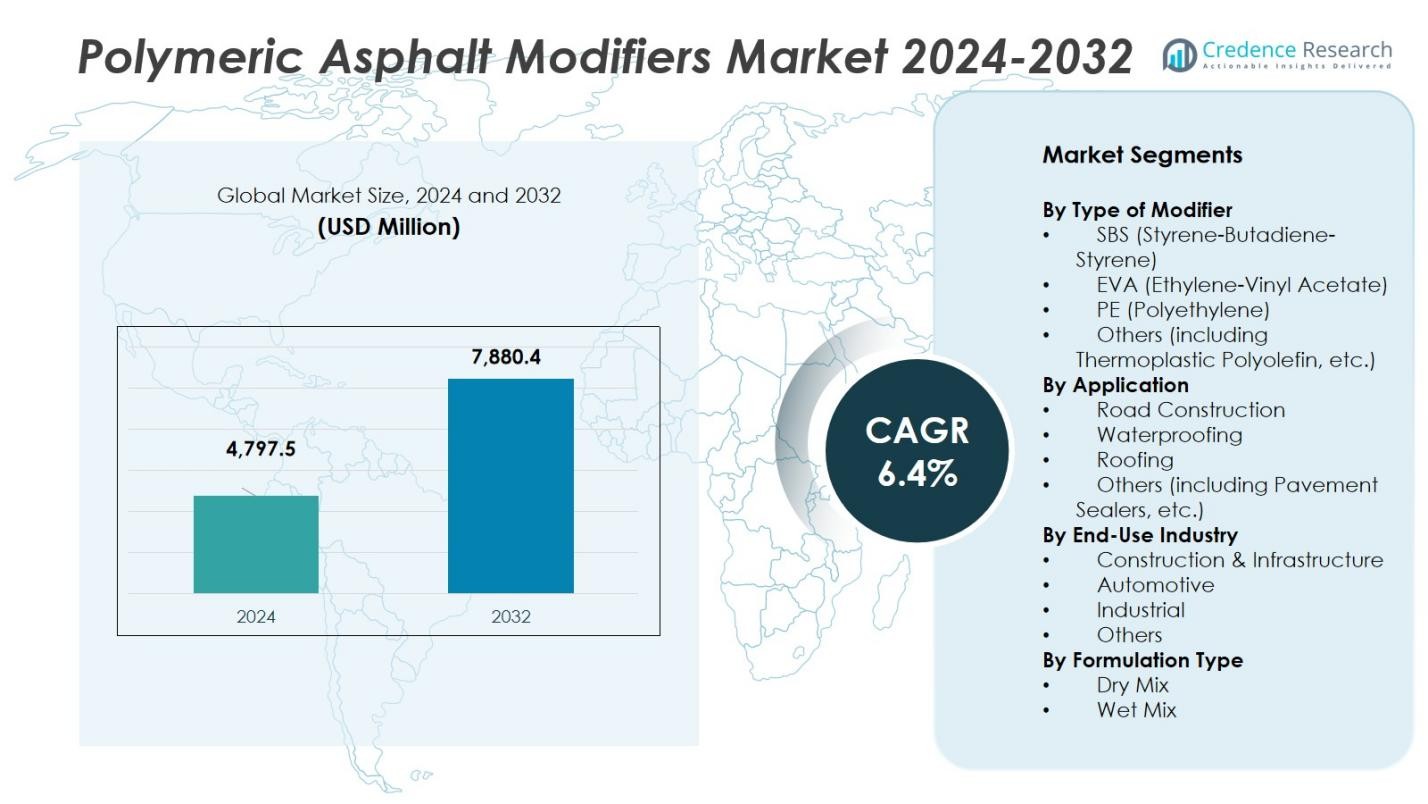

The Polymeric Asphalt Modifiers Market was valued at USD 4,797.5 million in 2024 and is projected to reach USD 7,880.4 million by 2032, growing at a CAGR of 6.4% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Polymeric Asphalt Modifiers Market Size 2024 |

USD 4,797.5 Million |

| Polymeric Asphalt Modifiers Market, CAGR |

6.4% |

| Polymeric Asphalt Modifiers Market Size 2032 |

USD 7,880.4 Million |

The Polymeric Asphalt Modifiers Market is dominated by key players such as Kraton Corporation, Arkema SA, BASF SE, Sinopec Corp, Evonik Industries AG, Dow Inc., and Ingevity Corporation. These companies are leading the market with their innovative product offerings, strategic partnerships, and continuous investments in research and development. Kraton Corporation and Arkema SA are prominent for their advancements in SBS, which is widely used in road construction and roofing. The market is primarily led by North America, holding around 30% of the global market share, followed by Asia Pacific with 35%. Europe accounts for 25%, while Latin America and the Middle East & Africa contribute smaller shares. The strong growth in infrastructure development and the rising demand for high-performance, sustainable materials drive market expansion, with these regions playing a pivotal role in adoption and innovation.

Market Insights

Market Insights

- The Polymeric Asphalt Modifiers Market was valued at USD 4,797.5 million in 2024 and is projected to reach USD 7,880.4 million by 2032, growing at a CAGR of 6.4%.

- Growth is fuelled by the rise in global infrastructure development, increased road‑construction activity, and the demand for high‑performance materials such as SBS which holds about 45% of the modifier type segment.

- The shift toward cold‑mix asphalt and the integration of recycled asphalt pavement are gaining traction, supporting the road construction application segment, which holds roughly 50% of the market.

- Volatile raw material prices and stricter environmental regulations are challenging the cost structure and uptake of polymer‑modified asphalts in price‑sensitive regions.

- Asia Pacific leads with about 35% of the market share, followed by North America at roughly 30% and Europe at about 25%, while Latin America and the Middle East & Africa account for the balance.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segmentation Analysis:

By Type of Modifier

The Polymeric Asphalt Modifiers market is primarily segmented by modifier type, with Styrene-Butadiene-Styrene (SBS) leading the segment, accounting for approximately 45% of the market share. SBS, known for its excellent elasticity and durability, is widely used in road construction and roofing applications. Ethylene-Vinyl Acetate (EVA) follows as a significant sub-segment with around 30% of the market share due to its lower cost and good compatibility with asphalt. Polyethylene (PE) is also gaining traction, accounting for around 15% of the market, particularly for low-temperature paving. The growing demand for durable and sustainable construction materials drives the market growth across these modifiers, with SBS maintaining its dominance.

- For instance, for Styrene-Butadiene-Styrene (SBS), Kraton Corporation is a key player, providing advanced SBS polymers used in major infrastructure projects such as Skanska AB’s paving in Sweden.

By Application

In the Polymeric Asphalt Modifiers market, road construction holds the largest share, accounting for nearly 50% of the market. This is driven by the increasing infrastructure development globally, requiring high-performance modifiers like SBS for enhanced durability and longevity. Roofing applications follow closely, contributing approximately 25% to the market, fueled by the demand for weather-resistant and energy-efficient roofing solutions. Waterproofing and other niche applications, including pavement sealers, make up the remaining 25%. Road construction remains the dominant application, reflecting the ongoing global investments in road infrastructure.

- For instace, Kraton’s styrenic block copolymers (SBC) are integrated into modified bituminous roofing membranes to improve flexibility, waterproofing, and thermal resistance, sustaining harsh climates and long service life.

By End-Use Industry

The construction and infrastructure sector dominates the Polymeric Asphalt Modifiers market, holding around 60% of the total market share. The growing demand for durable and high-performance road surfaces and roofing materials fuels the use of polymeric asphalt modifiers in this sector. Automotive and industrial applications contribute significantly, with automotive accounting for approximately 20%, and industrial uses covering about 15% of the market. The rising need for enhanced road conditions, especially in emerging economies, is driving the demand for polymer-modified asphalts in construction, with the construction & infrastructure sector maintaining its leadership position.

Key Growth Drivers

Increasing Infrastructure Development

The continuous expansion of infrastructure projects worldwide is a significant growth driver for the Polymeric Asphalt Modifiers market. Government investments in road construction, urban development, and transportation networks have surged in both developed and emerging economies. This growing demand for durable, high-performance materials to enhance the lifespan of roads and pavements directly boosts the adoption of polymeric asphalt modifiers. As road construction projects increase, especially in Asia Pacific and North America, the demand for modifiers such as SBS and EVA is expected to rise, further fueling market growth.

- For instance, the U.S. Department of Transportation employs EVA and SBS polymer modifiers in numerous interstate highway refurbishments to enhance durability against heavy traffic and extreme weather.

Demand for Sustainable and High-Performance Materials

The shift toward sustainable construction materials is one of the key factors driving the growth of the Polymeric Asphalt Modifiers market. Polymeric asphalt modifiers improve the durability, flexibility, and weather resistance of asphalt, reducing the frequency of maintenance and extending the lifespan of infrastructure. As the construction industry focuses on eco-friendly solutions, the market for high-performance modifiers like SBS and EVA, which offer environmental benefits through longer-lasting materials, is expected to expand significantly. The growing emphasis on reducing the environmental impact of construction activities further supports this trend.

- For instance, Dow’s ELVALOY™ polymers improve sustainability by enabling longer-lasting pavements, lowering lifecycle emissions.

Technological Advancements in Asphalt Modification

Advancements in polymer technology have paved the way for improved asphalt modifiers with enhanced performance characteristics. Innovations such as thermoplastic elastomers and advanced blending techniques have enabled the production of more efficient and durable polymeric asphalt modifiers. These technological improvements contribute to better compatibility, increased temperature resistance, and enhanced workability, meeting the evolving needs of the construction industry. As research and development continue, these innovations will create new opportunities for the adoption of polymeric asphalt modifiers across various applications, particularly in challenging environmental conditions.

Key Trends & Opportunities

Shift Toward Cold Mix Asphalt

One of the significant trends in the Polymeric Asphalt Modifiers market is the growing adoption of cold mix asphalt. This trend is driven by its cost-effectiveness and ability to be applied in low-temperature conditions, making it ideal for regions with cooler climates or for repairs requiring minimal disruption. Cold mix asphalt, enhanced by polymeric modifiers like SBS and EVA, provides better durability and flexibility, leading to improved pavement performance and longer lifespan. This shift offers a significant opportunity for market players to capitalize on the growing demand for cold mix asphalt solutions.

- For instance, companies like Kraton Corporation and Dow Chemical provide SBS and EVA-based polymer modifiers specifically formulated to enhance cold mix asphalt’s flexibility and durability, making it ideal for repairs and paving in cooler climates.

Integration of Recycled Materials

The integration of recycled materials in asphalt production is another emerging trend in the polymeric asphalt modifiers market. As sustainability becomes increasingly important, the use of recycled asphalt pavement (RAP) combined with polymeric modifiers helps reduce waste and the carbon footprint of road construction. This practice not only supports environmental goals but also offers a cost-effective solution for infrastructure projects. Companies focusing on developing innovative ways to enhance the performance of RAP with polymer modifiers will find substantial opportunities for growth in the market.

- For instance, MacRebur Ltd. specializes in incorporating recycled plastics, including polyethylene, into asphalt mixes, improving durability and stiffness while supporting circular economy goals

Key Challenges

Fluctuating Raw Material Prices

The volatile prices of raw materials, particularly petroleum-based products like styrene and butadiene, pose a significant challenge to the Polymeric Asphalt Modifiers market. These price fluctuations can increase production costs, affecting the overall pricing structure of modified asphalts. As a result, manufacturers may struggle to maintain profitability while offering competitive pricing to customers. This challenge may hinder market growth, especially in price-sensitive regions, and could force manufacturers to look for alternative raw materials or cost-efficient production processes to mitigate the impact of price volatility.

Environmental and Regulatory Concerns

Despite their performance benefits, polymeric asphalt modifiers, particularly those derived from petrochemical sources, face increasing scrutiny due to environmental and regulatory concerns. Stricter regulations on emissions and the environmental impact of asphalt products, including the disposal of polymer-modified asphalt, can limit the growth of the market. Manufacturers need to comply with these regulations while maintaining product quality, which may result in increased compliance costs. Moreover, the growing emphasis on sustainability requires market players to focus on developing more environmentally friendly alternatives without compromising performance.

Regional Analysis

North America

North America holds a significant share of the Polymeric Asphalt Modifiers market, accounting for nearly 30% of the global market. The growth in this region is primarily driven by the robust demand from the United States, where infrastructure development and road construction projects are substantial. The need for high-performance and durable materials in extreme weather conditions propels the adoption of polymer-modified asphalts, particularly SBS. Moreover, regulatory support for sustainable construction materials and increased investments in infrastructure maintenance contribute to the market’s expansion. As the demand for eco-friendly solutions grows, North America is expected to maintain its dominant position.

Europe

Europe represents a key market for polymeric asphalt modifiers, holding about 25% of the global market share. The demand for high-quality, long-lasting roads in countries like Germany, France, and the UK drives the adoption of modifiers such as SBS and EVA. The region’s emphasis on sustainable construction practices and stringent environmental regulations further propels the market. Additionally, significant investments in road infrastructure rehabilitation and new construction projects in Eastern Europe contribute to the overall market growth. Europe’s focus on advanced technology and the integration of recycled materials in asphalt production presents substantial opportunities in the coming years.

Asia Pacific

Asia Pacific is expected to witness the highest growth in the Polymeric Asphalt Modifiers market, holding around 35% of the global market share. The rapid industrialization, urbanization, and ongoing infrastructure projects in countries like China, India, and Japan are major drivers. Road construction is a key focus area due to rising transportation needs and government investments in infrastructure development. The growing adoption of polymer-modified asphalts in road repairs and new projects contributes to the market’s rapid expansion. Additionally, the demand for cost-effective, durable, and eco-friendly construction materials presents significant opportunities for market players in the region.

Latin America

Latin America holds a smaller share of the Polymeric Asphalt Modifiers market, accounting for about 7%. The growth in this region is driven by increasing infrastructure projects in countries such as Brazil and Mexico. The demand for polymeric asphalt modifiers in road construction and maintenance is rising due to the need for durable solutions that can withstand diverse climatic conditions. Additionally, the region’s focus on improving transportation infrastructure and reducing maintenance costs is expected to contribute to market expansion. Despite challenges such as economic fluctuations, the market in Latin America is projected to grow steadily in the coming years.

Middle East & Africa

The Middle East & Africa region contributes around 3% to the global Polymeric Asphalt Modifiers market, with substantial growth opportunities in key markets like Saudi Arabia, the UAE, and South Africa. The demand for polymer-modified asphalts is driven by major infrastructure projects, including the construction of roads, airports, and residential developments. The harsh climatic conditions in the region also drive the need for durable and high-performance asphalt materials. Government investments in infrastructure development, particularly in road construction and maintenance, are expected to fuel the market’s growth. With increased focus on sustainability, the region offers significant opportunities for polymeric asphalt modifiers.

Market Segmentations:

By Type of Modifier

- SBS (Styrene-Butadiene-Styrene)

- EVA (Ethylene-Vinyl Acetate)

- PE (Polyethylene)

- Others (including Thermoplastic Polyolefin, etc.)

By Application

- Road Construction

- Waterproofing

- Roofing

- Others (including Pavement Sealers, etc.)

By End-Use Industry

- Construction & Infrastructure

- Automotive

- Industrial

- Others

By Formulation Type

By Region

- North America

- Europe

- Germany

- France

- U.K.

- Italy

- Spain

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- South-east Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East & Africa

- GCC Countries

- South Africa

- Rest of the Middle East and Africa

Competitive Landscape

The Polymeric Asphalt Modifiers market is highly competitive, with key players such as Kraton Corporation, Arkema SA, BASF SE, Sinopec Corp, Evonik Industries AG, Dow Inc., and Ingevity Corporation leading the industry. These companies are focusing on strategic initiatives such as mergers and acquisitions, partnerships, and product innovations to strengthen their market position. Kraton Corporation and Arkema SA are recognized for their leadership in developing high-performance polymer modifiers, particularly SBS, which dominate the road construction segment. Meanwhile, BASF and Dow Inc. are leveraging their extensive research and development capabilities to introduce cost-effective, sustainable solutions. Competitive strategies also involve expanding production capacities, with a strong emphasis on meeting regulatory requirements and addressing the growing demand for eco-friendly solutions. As demand for polymer-modified asphalts rises, these key players are expected to invest heavily in expanding their product portfolios, improving supply chains, and driving technological advancements to maintain market leadership.

Key Player Analysis

- Evonik Industries AG

- Sinopec Corp

- Arkema SA

- BASF SE

- Kraton Corporation

- Dow Inc.

- Ingevity Corporation

- Heartland Paving Partners

- MacAdam Company

- Sasol

Recent Developments

- In April 2025, Kraton Corporation announced an across-the-board price increase for SBS grades, reflecting strategic moves in their polymer asphalt modifier business.

- In June 2025, Heartland Paving Partners announced the acquisition of MacAdam Company, broadening regional strength in the asphalt modifiers market.

- In October 2022, Kraton announced a collaboration with the asphalt pavement net zero initiative “The Road Forward,” highlighting their strategic partnership focus.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Report Coverage

The research report offers an in-depth analysis based on Type of Modifier, Application, End Use Industry, Formulation Type and Region. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The Polymeric Asphalt Modifiers market is expected to witness steady growth due to increasing infrastructure development and road construction projects globally.

- Demand for sustainable and high-performance materials will drive the adoption of polymer-modified asphalts in various applications.

- Technological advancements in polymer modification techniques will lead to enhanced product performance, catering to diverse environmental conditions.

- The growing focus on reducing road maintenance costs will further promote the use of durable polymer-modified asphalts.

- Asia Pacific is anticipated to remain the fastest-growing region due to rapid urbanization and significant infrastructure investments in countries like China and India.

- The integration of recycled materials in asphalt production will become more common as the industry adopts greener practices.

- Cold mix asphalt, enhanced with polymer modifiers, will see increased demand for cost-effective and efficient solutions.

- Increased government regulations and incentives for sustainable construction materials will support the growth of the polymeric asphalt modifiers market.

- Key players will continue to invest in R&D to introduce new, innovative products that offer better performance and environmental benefits.

- The market will likely experience consolidation, with mergers and acquisitions among leading players aiming to strengthen product portfolios and expand market reach.

Market Insights

Market Insights