Market Overview:

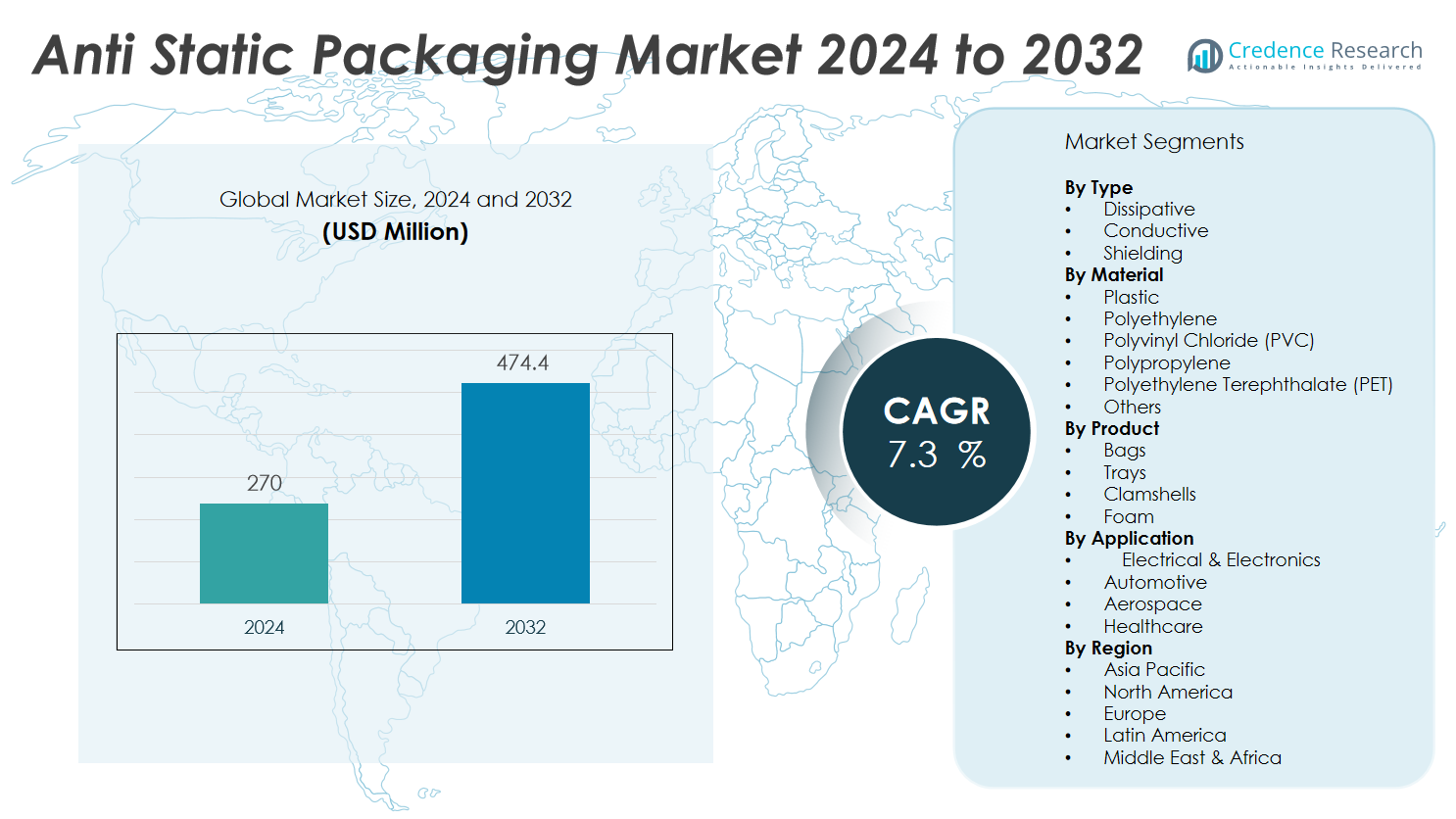

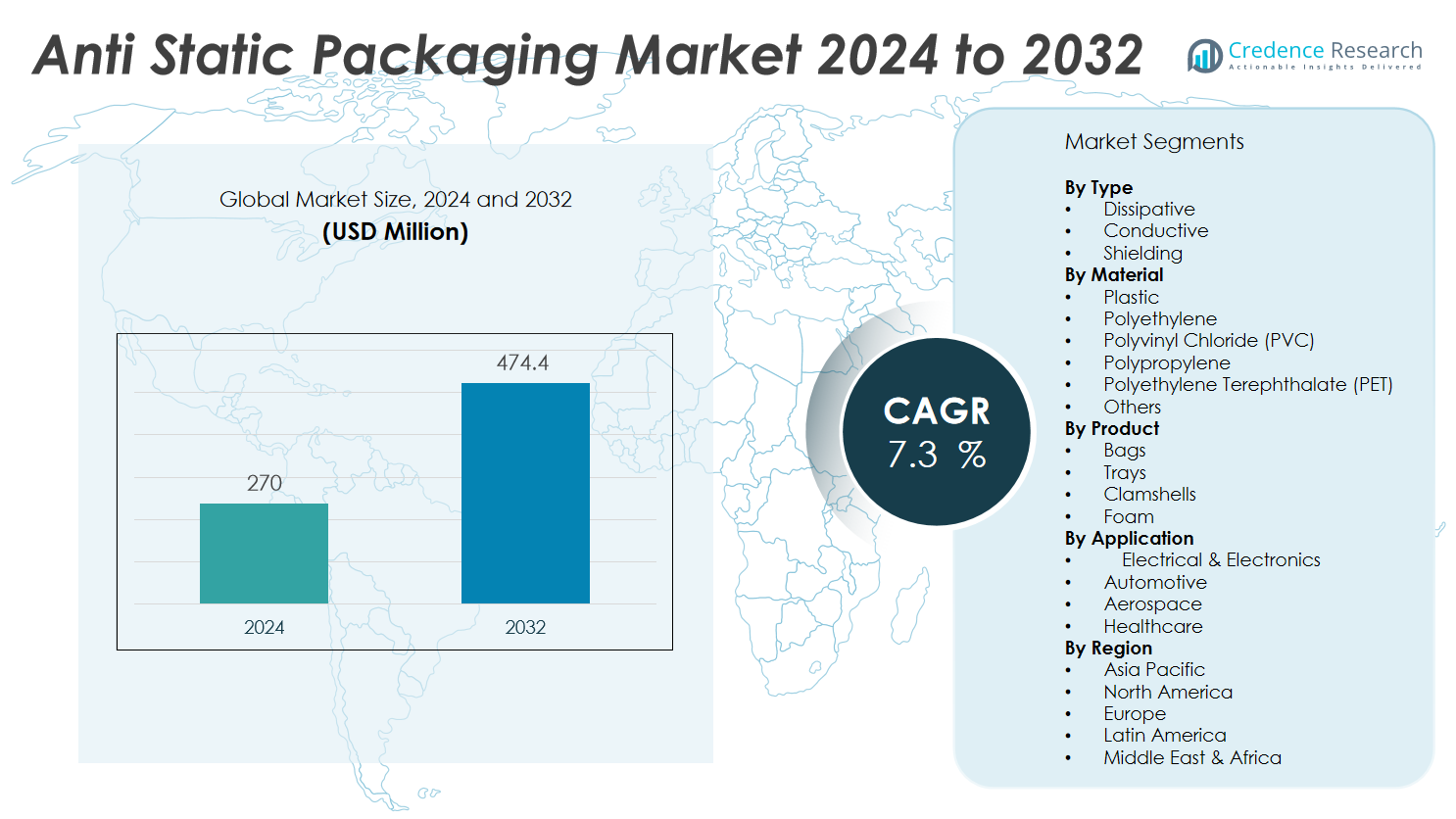

The Anti-static packaging market size was valued at USD 270 million in 2024 and is anticipated to reach USD 474.4 million by 2032, at a CAGR of 7.3 % during the forecast period (2024-2032).

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2024 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Anti-static packaging market Size 2024 |

USD 270Million |

| Anti-static packaging market, CAGR |

7.3 % |

| Anti-static packaging market Size 2032 |

USD 474.4 Million |

Key drivers propelling the market include the proliferation of consumer electronics, increased semiconductor production, and stricter regulatory standards regarding product safety and quality. Manufacturers are actively investing in the development of innovative materials, such as static dissipative plastics, conductive polymers, and advanced multi-layer films, to enhance packaging performance. The ongoing transition towards miniaturized, high-value components in sectors such as telecommunications, medical devices, and automotive electronics has also elevated the need for reliable anti-static protection. Furthermore, the expansion of e-commerce and global supply chains has intensified the demand for durable, tamper-evident, and cost-effective anti-static packaging formats, including bags, trays, clamshells, and bubble wraps.

Asia Pacific commands the largest share of the anti-static packaging market, driven by strong manufacturing activity and major electronics and semiconductor investments in China, Japan, South Korea, and Taiwan. Key players such as NEFAB GROUP, Bondline Electronics Ltd, ITB Packaging, LLC, Ficus Pax Pvt. Ltd., and Smurfit Kappa leverage this regional momentum. North America remains a key market due to advanced technology and leading electronics manufacturers. Europe sees steady demand, especially in automotive and aerospace sectors that require regulatory compliance and product reliability. Latin America and the Middle East & Africa show gradual growth, supported by infrastructure development and rising local manufacturing.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Insights:

- The Anti-static packaging market was valued at USD 270 million in 2024 and will reach USD 474.4 million by 2032.

- Demand for consumer electronics and increased semiconductor production drives robust market growth.

- Innovation focuses on static dissipative plastics, conductive polymers, and advanced multi-layer films.

- Miniaturization in telecom, medical, and automotive sectors elevates the need for reliable anti-static protection.

- E-commerce and global supply chains intensify demand for durable, tamper-evident, and cost-effective packaging.

- Asia Pacific holds the largest market share, with strong manufacturing activity and electronics investments.

- Key players include NEFAB GROUP, Bondline Electronics Ltd, ITB Packaging, Ficus Pax, and Smurfit Kappa.

Market Drivers:

Rising Demand from Electronics and Semiconductor Industries Fueling Adoption:

The anti-static packaging market benefits from significant growth in the global electronics and semiconductor sectors. The surge in demand for sensitive electronic devices, such as smartphones, tablets, and wearables, requires packaging solutions that prevent electrostatic discharge and maintain product integrity. It helps reduce the risk of damage during manufacturing, storage, and transportation, directly supporting quality and reliability. Growing consumer preferences for advanced electronics and ongoing innovation in chip design reinforce the need for robust anti-static protection. Major manufacturers rely on anti-static bags, trays, and films to safeguard microchips, PCBs, and memory devices. The expansion of electronics assembly plants in Asia Pacific further increases the use of anti-static packaging.

- For instance, Berry Global implemented over 2,500 Meech Hyperion ionizing bars across its 131 global manufacturing facilities, eliminating static issues in injection molding lines and ensuring safer packaging processes for more than 23,000 employees.

Expansion of E-Commerce and Complex Supply Chains Accelerating Market Growth:

Rapid e-commerce expansion and increasingly complex global supply chains support the widespread adoption of anti-static packaging market solutions. It ensures safe handling of electronic products shipped across long distances and through multiple distribution points. Brands and logistics providers prioritize tamper-evident, protective packaging formats to prevent returns and customer complaints related to ESD damage. The growth of online sales channels for consumer electronics highlights the necessity for effective packaging that preserves product quality. E-commerce has driven demand for cost-effective, durable, and lightweight anti-static materials. The need for reliable, scalable solutions across diverse logistics networks propels market growth.

- For Instance, Sealed Air Corporation introduced the NewAir I.B. Anti-Static Inflatable Film, the only inflatable cushioning meeting industrial specifications for electrostatic discharge, which can be produced at speeds over 16 meters per minute while ensuring electronics arrive safely through complex shipping cycles.

Stringent Regulatory Standards and Quality Assurance Driving Product Innovation:

Government regulations and industry standards for product safety and quality assurance drive investments in anti-static packaging market innovation. It enables compliance with strict guidelines set by regulatory agencies in key markets, including the U.S., Europe, and Asia. Manufacturers focus on developing packaging with advanced properties such as low triboelectric charge generation, high transparency, and recyclability. Compliance requirements motivate companies to test and certify their products for ESD protection, leading to higher adoption rates. The increasing importance of traceability and anti-counterfeiting measures also supports innovation in material science and design. These trends contribute to the continued evolution of the market.

Growing Penetration in Automotive, Healthcare, and Aerospace Applications:

Rising applications in automotive, healthcare, and aerospace industries support the sustained growth of the anti-static packaging market. It protects electronic components in modern vehicles, medical devices, and aircraft systems from ESD-related failures. The adoption of advanced driver-assistance systems (ADAS), IoT medical equipment, and avionics increases the importance of reliable anti-static protection. Strict quality control in these industries further compels suppliers to utilize certified packaging solutions. Leading players address specialized needs through customized anti-static formats for mission-critical applications. Market participants benefit from the expanding role of electronics in these high-value sectors.

Market Trends:

Integration of Sustainable and Recyclable Materials Reshaping Product Portfolios:

Sustainability trends shape the future direction of the anti-static packaging market, prompting manufacturers to develop recyclable and eco-friendly solutions. The industry witnesses a shift toward biodegradable films, water-based coatings, and non-toxic additives in response to tightening environmental regulations. It aligns with customer preferences for green packaging, supporting corporate sustainability targets and reducing landfill waste. Many leading companies have introduced product lines using recycled plastics or bio-based materials while ensuring compliance with electrostatic discharge standards. The push for sustainable materials encourages research into new polymers and composite structures, balancing ESD protection with environmental stewardship. It also creates opportunities for innovation in product design and raw material sourcing.

- For Instance, Palsgaard’s Einar® 601, a plant-based anti-static additive, enables efficient static decay time of less than 2 seconds when incorporated into LDPE films, supporting both recyclability and high ESD protection in mono-material packaging.

Adoption of Advanced Technologies and Customization to Meet Industry-Specific Needs:

Rapid technological advancements drive the adoption of anti-static packaging with enhanced functional properties, such as smart packaging and RFID-enabled formats. It enables real-time tracking, authenticity verification, and better supply chain management, particularly for high-value or sensitive electronic components. The market responds to sector-specific requirements by offering tailored solutions for automotive, healthcare, and aerospace industries. Increasing product miniaturization demands higher precision and specialized packaging to prevent ESD-related failures. Growth in automation and robotics within manufacturing facilities also spurs demand for packaging compatible with high-speed handling systems. The anti-static packaging market evolves through continuous improvements in product functionality, customization, and integration with digital supply chains.

- For instance, 3M’s RFID tags operate at 13.56MHz and come pre-programmed with a unique ID for every tag, enabling deployment of standardized real-time inspection and tracking systems across hundreds of industrial facilities.

Market Challenges Analysis:

Volatility in Raw Material Prices and Cost Pressures Impacting Profitability:

Fluctuating prices of key raw materials, such as conductive polymers and specialty plastics, create significant cost pressures for manufacturers in the anti-static packaging market. It forces companies to navigate unstable supply chains and manage sudden spikes in input costs. Limited availability of high-performance, sustainable materials further complicates procurement and production planning. Firms often struggle to balance price competitiveness with the need for quality and regulatory compliance. Cost-sensitive end users in sectors such as consumer electronics and automotive may delay adoption when prices rise. This volatility can restrict the ability of companies to invest in product innovation and capacity expansion.

Technical and Regulatory Complexities Hindering Widespread Adoption:

Meeting diverse technical requirements and regulatory standards remains a key challenge for the anti-static packaging market. It must deliver reliable electrostatic protection, comply with global safety norms, and meet environmental mandates. Complexities increase when customers demand specialized solutions for sensitive applications in medical, aerospace, or automotive industries. The need for certification and testing extends time to market and increases operational costs. Small and medium-sized enterprises often lack the resources to achieve compliance or invest in R&D. These hurdles may slow market penetration, especially in emerging economies.

Market Opportunities:

Emergence of High-Growth Sectors and Next-Generation Electronics Expanding Market Reach:

The anti-static packaging market stands to benefit from rising investments in high-growth sectors such as electric vehicles, 5G infrastructure, and advanced medical devices. It supports the safe handling of sensitive components, including lithium-ion batteries, high-frequency chips, and precision instruments. Growth in renewable energy technologies and the IoT ecosystem expands demand for robust ESD protection. Manufacturers who target emerging applications and niche markets can capture new revenue streams. Partnerships with technology leaders and OEMs offer opportunities for co-development and long-term supply agreements. This trend positions market players to address evolving customer requirements and secure a competitive edge.

Innovation in Smart Packaging and Digital Supply Chain Integration Creating Value:

The integration of smart packaging technologies presents significant opportunities for the anti-static packaging market. It enables real-time tracking, enhanced product authentication, and automated quality control, meeting the needs of high-value and mission-critical electronics. Solutions featuring embedded sensors, QR codes, or RFID tags help optimize logistics and supply chain management. Digitalization and Industry 4.0 adoption accelerate the shift toward data-driven packaging formats. Companies that invest in R&D and digital infrastructure can differentiate their offerings and drive customer loyalty. These advancements unlock new business models and add measurable value across the product lifecycle.

Market Segmentation Analysis:

By Type:

The Anti-static packaging market segments by type into dissipative, conductive, and shielding categories. Dissipative packaging leads demand due to its versatility in protecting sensitive electronic components from ESD damage during storage and transit. Conductive packaging finds widespread use in environments where rapid charge transfer is necessary, such as semiconductor and automotive assembly. Shielding packaging offers advanced protection by blocking both static and electromagnetic interference, serving mission-critical applications in aerospace and healthcare.

- For instance, Vicor’s ChiP (Converter housed in Package) converters have demonstrated power densities up to 3kW/in³ and efficiency up to 98%, supporting next-generation electronic modules that operate reliably across challenging environments such as UAVs and ground vehicles.

By Material:

Material segmentation includes plastic, polyethylene, polyvinyl chloride (PVC), and others. Plastic dominates the anti-static packaging market, favored for its cost-effectiveness, durability, and adaptability across various formats. Polyethylene remains popular for lightweight, flexible bags and wraps. PVC and specialty polymers cater to applications requiring enhanced durability and chemical resistance, supporting innovation in material science.

- For instance, in 2023, LyondellBasell and AFA Nord established a mechanical recycling facility in Germany, capable of processing 26,000 metric tons of low-density and linear low-density polyethylene waste annually into high-quality materials suitable for flexible packaging.

By Product:

Product-wise, the market divides into bags, trays, clamshells, foams, and films. Bags represent the largest segment, driven by high-volume usage in consumer electronics and component distribution. Trays and clamshells secure and organize items during automated assembly and logistics operations. Foams and films offer tailored ESD protection for delicate devices, supporting custom requirements in high-value industries. It benefits from continuous innovation in product formats to address evolving end-user needs.

Segmentations:

By Type:

- Dissipative

- Conductive

- Shielding

By Material:

- Plastic

- Polyethylene

- Polyvinyl Chloride (PVC)

- Polypropylene

- Polyethylene Terephthalate (PET)

- Others

By Product:

- Bags

- Trays

- Clamshells

- Foam

- Films

- Boxes

By Application:

- Electrical & Electronics

- Automotive

- Aerospace

- Healthcare

- Defense & Military

- Industrial Equipment

- Others

By Region:

- Asia Pacific

- North America

- Europe

- Latin America

- Middle East & Africa

Regional Analysis:

Asia Pacific :

Asia Pacific holds a 46% share of the anti-static packaging market in 2024, supported by robust manufacturing infrastructure and significant investments in electronics production. China, Japan, South Korea, and Taiwan serve as global hubs for semiconductors and consumer electronics, creating sustained demand for advanced ESD protection. It benefits from favorable government policies, skilled labor, and access to raw materials. The rapid expansion of e-commerce and automotive industries also drives market growth in the region. Key manufacturers continue to invest in new production facilities and R&D centers. The high concentration of OEMs accelerates the adoption of specialized packaging formats.

North America :

North America accounts for a 24% share of the anti-static packaging market in 2024, led by strong presence of technology-driven industries and top electronics manufacturers. The United States dominates regional demand due to the scale of its semiconductor, aerospace, and healthcare sectors. It benefits from advanced R&D capabilities and a focus on developing sustainable packaging solutions. Market participants collaborate closely with OEMs to deliver certified products that meet rigorous safety and performance standards. The trend toward reshoring electronics manufacturing supports further market expansion. Investments in digital infrastructure and supply chain optimization contribute to ongoing demand for anti-static packaging.

Europe:

Europe represents a 19% share of the anti-static packaging market in 2024, reflecting steady growth driven by stringent regulations and diversified end-user industries. Germany, France, and the UK lead regional consumption, particularly in automotive, aerospace, and medical device manufacturing. It benefits from high standards for product quality and safety, pushing suppliers to prioritize certified and eco-friendly materials. The focus on sustainability aligns with ongoing shifts toward recyclable packaging formats. Market players leverage partnerships and innovation to serve both established and emerging application segments. The evolving regulatory landscape continues to shape product development and adoption rates across the region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis:

- NEFAB GROUP

- Bondline Electronics Ltd

- ITB Packaging, LLC

- Ficus Pax Pvt. Ltd.

- Smurfit Kappa

- Freudenberg Performance Materials

- Cortec Corporation

- PakFactory

- TEGATAI

- TRICOR AG

Competitive Analysis:

The anti-static packaging market remains highly competitive, with a mix of global leaders and specialized regional suppliers addressing diverse industry requirements. Key players such as NEFAB GROUP, Bondline Electronics Ltd, ITB Packaging, LLC, Ficus Pax Pvt. Ltd., and Smurfit Kappa focus on innovation, quality, and tailored solutions to strengthen their positions. It features continuous investment in R&D to develop advanced materials and sustainable product lines. Leading companies emphasize partnerships with OEMs and end users, ensuring compliance with stringent safety and performance standards. The market rewards firms that deliver flexible production capabilities and rapid response to evolving customer needs. Strategic acquisitions and global expansion initiatives enable established players to broaden their geographic reach and capture new growth opportunities. Intense competition drives a focus on differentiation through technology integration, customized packaging formats, and customer service excellence.

Recent Developments:

- In July 2025, Nefab Group acquired Plasticos Flome, a Valencia-based company specializing in sustainable thermoforming and injection molding solutions, strengthening its position in Spain and Southern Europe for complete and sustainable packaging solutions.

- In April 2025, Freudenberg Performance Materials launched innovative fine denier spunbond nonwovens made from PET, PE, or PP, offering lightweight but strong solutions for construction and filtration applications, marketed under brands such as Filtura®

- In June 2025, Cortec introduced the world’s first certified industrially compostable VCI paper, reinforcing its sustainable leadership in protective packaging.

Market Concentration & Characteristics:

The anti-static packaging market features moderate concentration, with several global and regional players competing across diverse end-use industries. It includes established manufacturers with strong R&D capabilities, such as Smurfit Kappa, Desco Industries, and Sealed Air, alongside a large base of specialized suppliers focused on custom solutions. Leading companies differentiate through product innovation, material advancements, and compliance with strict regulatory standards. The market emphasizes rapid response to evolving customer needs in electronics, automotive, healthcare, and aerospace sectors. Intense competition drives continuous investment in capacity expansion, sustainability, and digital integration. It remains dynamic, with market participants pursuing strategic partnerships and acquisitions to strengthen their positions.

Report Coverage:

The research report offers an in-depth analysis based on Type, Material, Product, Application and Region. It details leading Market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current Market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven Market expansion in recent years. The report also explores Market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on Market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the Market.

Future Outlook:

- The anti-static packaging market will expand into emerging sectors such as electric vehicles, renewable energy, and advanced medical devices, driving diversified application demand.

- It will shift toward bio-based and fully recyclable materials to meet new environmental regulations and corporate sustainability goals.

- Manufacturers will invest in smart packaging features like embedded RFID tags, QR codes, and data sensors to enhance supply chain transparency and asset tracking.

- It will integrate with Industry 4.0 and automated handling systems to support high-speed production lines and improve operational efficiency.

- Suppliers will develop multi-layer, hybrid-material films to deliver tailored ESD protection for next-generation microelectronics.

- It will see rising deployment of anti-counterfeiting and authentication measures in packaging to secure sensitive products and high-value components.

- Companies will leverage digital platforms to offer customized packaging configurations and online ordering with faster lead times.

- It will align with extended producer responsibility frameworks, prompting manufacturers to offer take-back and recycling programs.

- It will expand its footprint in emerging markets such as India, Latin America, and Southeast Asia, driven by local electronics and semiconductor investments.

- It will witness growing consolidation through strategic acquisitions and joint ventures, enabling scale, geographic reach, and enhanced technological capabilities.