Market Overview

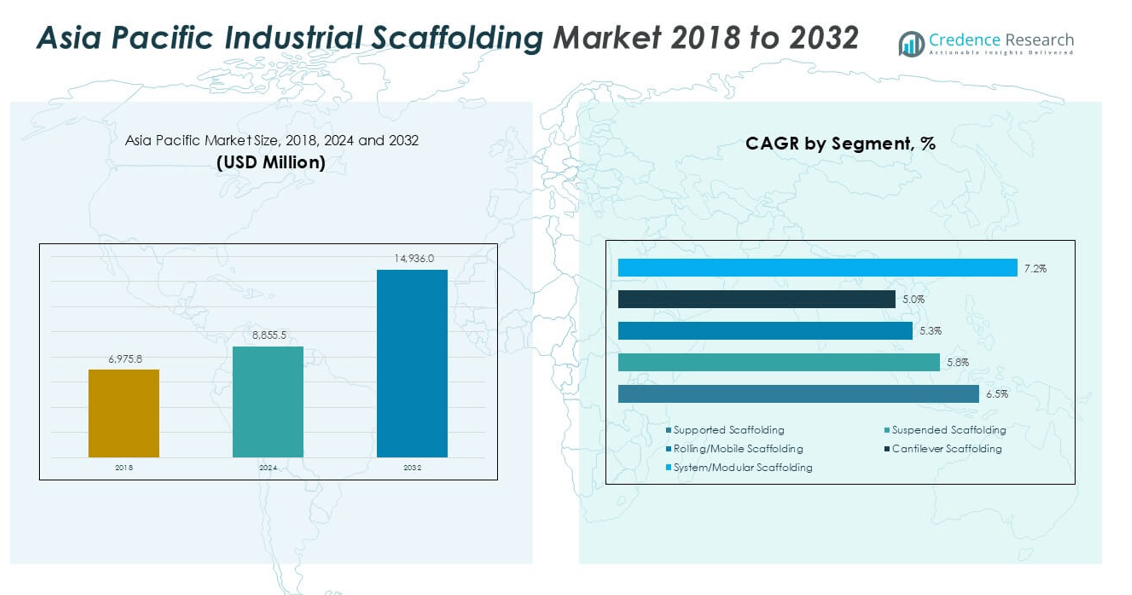

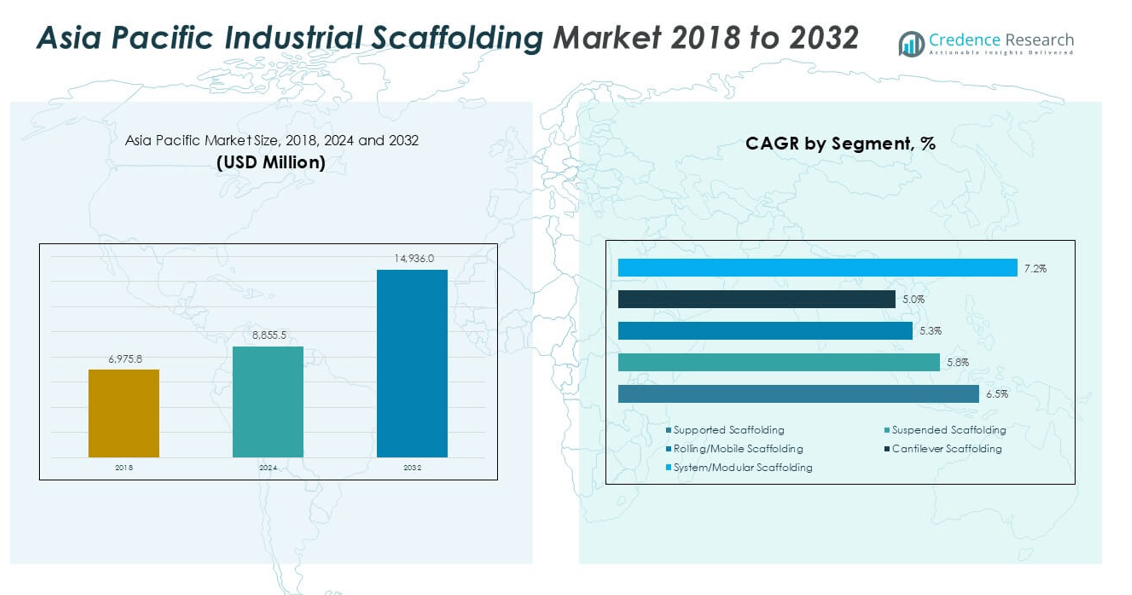

Asia Pacific Industrial Scaffolding market size was valued at USD 6,975.77 million in 2018, grew to USD 8,855.52 million in 2024, and is anticipated to reach USD 14,935.98 million by 2032, at a CAGR of 6.75% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Asia Pacific Industrial Scaffolding Market Size 2024 |

USD 8,855.52 million |

| Asia Pacific Industrial Scaffolding Market, CAGR |

6.75% |

| Asia Pacific Industrial Scaffolding Market Size 2032 |

USD 14,935.98 million |

The Asia Pacific industrial scaffolding market is shaped by leading players such as PERI Group, Altrad Group, Tata Projects Ltd., Waco Kwikform, ULMA Construction, Zhejiang Huayuan Equipment Group, ACROW Formwork and Scaffolding, Pacific Scaffold, Nippon Scaffold Co., Ltd., Shimizu Corporation, Qingdao Scaffolding Import & Export, Shandong Shlomi Machinery, SK Form & Scaff India, and Dongguan Top Scaffold Equipment. These companies compete through modular solutions, rental services, and compliance-driven innovations. China leads the regional market with a 35% share, supported by large-scale infrastructure and energy projects, followed by India with 18% driven by rapid urbanization and industrial growth. Southeast Asia accounts for 13%, reflecting demand from oil, gas, and construction sectors, while Japan (12%) and Australia (8%) maintain stable growth through safety-focused adoption. Together, these regions and players define a competitive landscape balancing affordability, advanced technology, and regulatory compliance across the Asia Pacific scaffolding sector.

Market Insights

- The Asia Pacific industrial scaffolding market was valued at USD 8,855.52 million in 2024 and is projected to reach USD 14,935.98 million by 2032, growing at a CAGR of 6.75%.

- Market growth is driven by rapid urbanization, rising investments in oil, gas, and power sectors, and stricter safety regulations that boost adoption of modular and supported scaffolding systems.

- Trends highlight increasing demand for rental-based scaffolding services, lightweight aluminum structures for mobility, and modular systems that ensure faster assembly and compliance with safety standards.

- The competitive landscape includes global leaders such as PERI Group, Altrad Group, Tata Projects Ltd., and Waco Kwikform, alongside strong regional players in China and India focusing on cost-effective solutions.

- Regionally, China dominates with 35% share, followed by India at 18%, Southeast Asia at 13%, Japan at 12%, and Australia at 8%, while by type, supported scaffolding leads with the highest segment share.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Segmentation Analysis:

By Type of Scaffolding

Supported scaffolding holds the dominant share in the Asia Pacific industrial scaffolding market due to its widespread use across large-scale infrastructure and industrial projects. Its simple design, high load-bearing capacity, and adaptability for both vertical and horizontal expansion make it the preferred choice in construction and maintenance operations. The demand is reinforced by ongoing urbanization and industrial facility expansion in China and India. System/modular scaffolding is also gaining traction, driven by its ease of assembly and safety features, particularly in projects requiring quick deployment and compliance with international safety standards.

- For instance, the supported scaffolding segment accounted for about 40% of the global scaffolding market by type in 2023, showing its clear lead over other types.

By Application

The oil and gas industry accounts for the largest market share among applications, supported by extensive offshore and onshore exploration and refinery operations in Asia Pacific. Scaffolding is vital for construction, inspection, and maintenance activities in these facilities, ensuring worker safety and operational efficiency. Power generation, especially thermal and nuclear plants, also contributes significantly due to continuous maintenance and periodic shutdowns requiring large-scale access structures. Mining and metallurgy further drive adoption, as scaffolding supports heavy-duty environments in Australia and India, where large-scale extraction and smelting operations demand durable, safe platforms.

- For instance, nuclear facilities in China and India schedule major maintenance outages every 12–18 months, during which modular scaffolding systems are deployed to access reactor buildings and turbine halls safely.

By Material

Steel dominates the material segment with the highest revenue share, attributed to its superior strength, durability, and ability to handle heavy loads in industrial environments. Steel scaffolding is favored in oil, gas, and power projects that require long-term structural support under harsh conditions. Aluminum scaffolding is gaining steady growth due to its lightweight, corrosion resistance, and ease of transport, making it suitable for maintenance and mobile applications. Fiberglass and composite materials, while niche, are expanding in chemical and petrochemical plants where non-conductive and corrosion-resistant properties are essential to ensure worker safety and compliance with strict industry standards.

Market Overview

Rising Infrastructure and Industrial Investments

The Asia Pacific region witnesses significant investments in large-scale infrastructure, oil and gas facilities, and power generation projects. Supported scaffolding remains vital in construction and maintenance, ensuring worker safety and efficient operations. Expanding urbanization in China and India, combined with government-backed smart city initiatives, drives consistent demand. Industrial plants, including petrochemical and mining operations, rely on robust scaffolding solutions for installation, repair, and inspection, reinforcing growth. The steady expansion of heavy industries continues to accelerate market adoption across both emerging and developed economies in the region.

Stringent Safety Regulations and Compliance

Governments and industry bodies in Asia Pacific enforce strict safety standards for construction and industrial operations. Scaffolding systems that comply with international certifications gain higher adoption due to reduced accident risks and better worker protection. Industries such as oil, gas, and chemicals emphasize advanced modular scaffolding that improves safety during high-risk tasks. Frequent inspections, training programs, and stricter enforcement of Occupational Health and Safety (OHS) norms increase demand for durable, standardized scaffolding. Compliance requirements serve as a growth driver by pushing industries toward innovative and certified scaffolding solutions across multiple applications.

- For instance, governments have made mandatory safety regulations a key driver for high-quality scaffolding solutions, as noted in reports highlighting regulatory push in countries like China, India, Australia, and Southeast Asian nations.

Expansion of Oil, Gas, and Power Projects

Asia Pacific remains a hub for large-scale energy projects, including refineries, offshore platforms, and thermal and nuclear power plants. These facilities demand long-term scaffolding installations for construction, inspection, and regular maintenance. Countries like China, India, and Australia prioritize energy security, leading to steady capacity expansions and infrastructure upgrades. Shutdowns and turnarounds in oil and gas refineries require extensive scaffolding to support time-sensitive operations. The reliance of power plants and heavy industries on safe, high-load scaffolding reinforces the market’s expansion, establishing the energy sector as a critical growth driver.

Key Trends & Opportunities

Adoption of Modular and Lightweight Scaffolding

The shift toward modular scaffolding systems presents a strong growth opportunity across Asia Pacific. Modular solutions enable faster installation, reduced labor dependency, and enhanced safety, making them ideal for large projects with tight timelines. Aluminum scaffolding is also gaining popularity due to its lightweight design, which improves mobility for maintenance and repair operations. Companies investing in prefabricated and reusable systems capture cost efficiencies and compliance benefits. The adoption of modular and lightweight scaffolding aligns with industry needs for flexible, durable, and safe solutions in diverse industrial environments.

- For instance, a heavy-duty “kwikstage” bay used in Australia is certified to carry 675 kg per bay under the Australia/New Zealand AS/NZ 1576.3 standard.

Rental-Based Scaffolding Services

Temporary and rental-based scaffolding emerges as a prominent trend, especially in construction and shutdown projects. Renting scaffolding reduces capital expenditure for contractors and industrial operators while ensuring access to advanced systems. The rental model is particularly popular in Southeast Asia and India, where medium and small contractors focus on cost optimization. Service providers offering bundled solutions, including installation, dismantling, and safety supervision, strengthen their competitive position. This trend creates long-term opportunities for scaffolding companies to expand service portfolios and increase recurring revenue streams across key regional markets.

- For instance, the NORD company’s aluminum scaffolding towers have height options from 4 meters up to 12 meters per set with widths of 0.75 meters and 1.35 meters platforms, allowing medium contractors to rent rather than purchase for such variable heights.

Key Challenges

High Initial Setup and Maintenance Costs

Despite rising demand, the high cost of advanced scaffolding materials and modular systems presents a challenge. Steel scaffolding requires substantial investment in manufacturing, transport, and periodic inspections, which increases operational expenditure. Small and mid-sized contractors often prefer low-cost alternatives, limiting adoption of high-quality solutions. Additionally, maintaining compliance with safety regulations demands regular servicing, replacement of worn-out parts, and trained labor. These factors create cost pressures, particularly in developing markets where price sensitivity remains high, challenging widespread deployment of premium scaffolding solutions.

Shortage of Skilled Labor and Training Needs

Scaffolding operations demand trained workers for safe assembly, inspection, and dismantling. However, Asia Pacific faces a shortage of skilled labor, particularly in emerging economies. Improper installation increases accident risks, leading to downtime and compliance penalties. Companies must invest in training programs and safety workshops, adding to project costs and timelines. Rapid industrial growth in countries like India and Southeast Asia worsens the skills gap, creating reliance on subcontractors. The shortage of skilled manpower continues to challenge scaffolding deployment efficiency and limits scalability for large-scale industrial projects

Regional Analysis

China

China holds the largest share of the Asia Pacific industrial scaffolding market, accounting for over 35% in 2024. Rapid industrialization, continuous infrastructure development, and massive investments in energy and petrochemical plants drive demand. Government-backed projects such as high-speed rail, nuclear power plants, and urban redevelopment reinforce adoption of supported and modular scaffolding. The country’s strong presence in oil, gas, and steel industries further supports long-term deployment. Manufacturers also benefit from local production capabilities, which ensure cost efficiency and quick supply. China’s dominance is expected to remain strong due to sustained construction and industrial expansion.

Japan

Japan contributes around 12% market share, with demand largely concentrated in maintenance and repair of aging infrastructure. The country emphasizes safety and regulatory compliance, encouraging adoption of modular and lightweight scaffolding solutions. Continuous refurbishment of nuclear plants and expansion of smart city projects sustain growth. High labor costs create strong preference for efficient and quick-to-assemble scaffolding systems. Japan’s advanced technology sector also drives innovation in scaffolding materials, with aluminum and composite platforms gaining traction. The market benefits from a mature industrial base and strong regulatory frameworks that prioritize worker safety and operational reliability.

South Korea

South Korea holds close to 9% of the regional scaffolding market, supported by strong shipbuilding, petrochemical, and power generation industries. The country invests heavily in offshore energy and large-scale industrial plants, creating steady demand for high-strength steel scaffolding. Government-backed infrastructure modernization projects further support adoption. South Korea’s safety-focused regulations and preference for modular scaffolding systems drive growth in industrial and construction sectors. Local firms also invest in rental-based scaffolding services to serve medium and small contractors. Growing emphasis on safety, combined with the country’s advanced manufacturing base, reinforces consistent demand for durable scaffolding systems.

India

India captures about 18% of the Asia Pacific scaffolding market, reflecting its rapid industrial and urban growth. Expanding oil refineries, large-scale power projects, and extensive urban infrastructure fuel adoption of supported and mobile scaffolding systems. The country’s construction boom, driven by government initiatives like Smart Cities Mission and industrial corridor projects, further accelerates demand. Price sensitivity remains high, but rental-based scaffolding models help smaller contractors access advanced systems. Safety awareness is improving, encouraging adoption of modular scaffolding solutions. India’s growing role as a regional industrial hub strengthens its market position, with double-digit growth projected over the next decade.

Australia

Australia accounts for around 8% of the market, led by mining, oil and gas, and infrastructure projects. Scaffolding demand is strong in large-scale mining operations and LNG facilities, where safety and durability are top priorities. The government’s continuous investment in transport and renewable energy infrastructure also supports market growth. Modular and steel scaffolding dominate usage, particularly in shutdowns and maintenance operations. Rental-based scaffolding services are increasingly popular due to cost advantages. Australia’s mature industrial base, combined with strict safety compliance, ensures steady adoption of advanced scaffolding systems, particularly in energy-intensive and heavy industry sectors.

Southeast Asia

Southeast Asia contributes nearly 13% market share, driven by infrastructure expansion in countries such as Indonesia, Vietnam, and Malaysia. Major oil and gas projects, port expansions, and industrial plant developments boost demand for scaffolding systems. Cost-sensitive contractors favor rental-based scaffolding services, while government-backed mega-projects encourage adoption of modular systems for safety and efficiency. The region’s rapid urbanization fuels construction of residential and commercial projects, creating consistent demand for mobile scaffolding. With increasing investments in chemical and power industries, Southeast Asia emerges as a high-growth region, offering strong opportunities for scaffolding providers and rental service operators.

Rest of Asia Pacific

The Rest of Asia Pacific, including smaller markets such as New Zealand and Taiwan, accounts for nearly 5% of total share. These markets see steady demand from power plants, construction projects, and industrial maintenance activities. Although smaller in scale, they emphasize high-quality, safety-compliant scaffolding due to strict regulations. New Zealand’s renewable energy projects and Taiwan’s semiconductor industry expansions contribute to niche demand for durable scaffolding. Contractors often prefer aluminum and modular solutions to meet safety and efficiency needs. While growth rates are modest, the region provides stable opportunities for specialized scaffolding providers.

Market Segmentations:

By Type of Scaffolding

- Supported Scaffolding

- Suspended Scaffolding

- Rolling/Mobile Scaffolding

- Cantilever Scaffolding

- System/Modular Scaffolding

By Application

- Oil & Gas Industry

- Power Generation (Thermal, Nuclear, Hydro)

- Mining & Metallurgy

- Chemical & Petrochemical Plants

- Others

By Material

- Steel

- Aluminum

- Fiberglass/Composite Materials

- Others

By Deployment

- Fixed Scaffolding

- Mobile/Rolling Scaffolding

- Temporary/Rental-Based Scaffolding

By Function

- Construction Access

- Maintenance & Repair (MRO)

- Shutdowns/Turnarounds

- Inspection & Cleaning Services

By Geography

- China

- Japan

- South Korea

- India

- Australia

- Southeast Asia

- Rest of Asia Pacific

Competitive Landscape

The Asia Pacific industrial scaffolding market is highly competitive, with both multinational corporations and regional players driving growth through product innovation, service expansion, and strategic partnerships. Leading companies such as PERI Group, Altrad Group, Tata Projects Ltd., Waco Kwikform, ULMA Construction, Zhejiang Huayuan Equipment Group, ACROW Formwork and Scaffolding, Pacific Scaffold, Nippon Scaffold Co., Ltd., Shimizu Corporation, Qingdao Scaffolding Import & Export, Shandong Shlomi Machinery, SK Form & Scaff India, and Dongguan Top Scaffold Equipment maintain a strong presence across the region. These firms compete by offering advanced modular scaffolding systems, rental-based services, and safety-compliant solutions tailored to industrial, construction, and energy sectors. Local manufacturers in China and India emphasize cost efficiency, while global firms focus on technological advancements and safety certifications. Strategic mergers, regional expansions, and service diversification remain central to gaining market share, ensuring a balance between affordability and high-quality, regulation-compliant scaffolding solutions across Asia Pacific.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- PERI Group

- Altrad Group (Asia-Pacific branches)

- Tata Projects Ltd. (India)

- Waco Kwikform (Australia, New Zealand)

- ULMA Construction (Asia offices)

- Zhejiang Huayuan Equipment Group (China)

- ACROW Formwork and Scaffolding Pty Ltd (Australia)

- Pacific Scaffold (Singapore)

- Nippon Scaffold Co., Ltd. (Japan)

- Shimizu Corporation (Japan)

- Qingdao Scaffolding Import & Export Co., Ltd. (China)

- Shandong Shlomi Machinery Co., Ltd. (China)

- SK Form & Scaff India Pvt. Ltd. (India)

- Dongguan Top Scaffold Equipment Co., Ltd. (China)

Recent Developments

- In July 2022, A major developer and provider of formwork and scaffolding systems, PERI Formwork Systems, Inc., has developed what would become a new industry standard for bridge construction. VPS ensures a safety and efficiency gap through a highly versatile system that is adjustable, rentable, and productive in forming bridge columns and caps.

- In July 2022, Doka, a key player in formwork solutions and services to the construction industry has taken its collaboration with the well-known American scaffolding company AT-PAC to the next level by making a significant investment in the US-based firm. The two companies first teamed up in 2020 to offer comprehensive solutions for building sites, and their partnership has only grown stronger since then.

- In July 2022, A Glasgow subsidiary named StepUp Scaffold UK from StepUp Scaffold Group in Memphis has completed the purchase of MP House ApS located near Copenhagen during July 2022. The company MP House stands as the dominant supplier of tools and equipment along with accessories to scaffolding operators based in Denmark.

- In April 2022, Layher Holding GmbH Co KG has introduced the Allround Scaffold, a name that reflects the company and perhaps represents the pinnacle of modular scaffolding solutions. The Modular Scaffolding System is essentially the Layher Allround Scaffolding. This system is comparable to Allround Performance, as it serves multiple purposes within a single framework. No matter how complex the designs, architectural styles, or strict safety standards may be, Allround Scaffolding consistently proves to be the quicker, safer, and more economical choice.

Report Coverage

The research report offers an in-depth analysis based on Type of Scaffolding, Application, Material, Deployment, and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The market will expand steadily with ongoing infrastructure and industrial development across the region.

- Supported scaffolding will remain the dominant type due to high load capacity and wide applicability.

- Modular scaffolding adoption will increase as industries prioritize safety, efficiency, and compliance.

- Rental-based scaffolding services will gain traction among cost-sensitive contractors and small firms.

- Oil and gas projects will continue to drive demand, supported by refinery expansions and offshore activities.

- Power generation projects, especially nuclear and thermal, will require large-scale scaffolding installations.

- Steel will retain the largest material share, while aluminum will grow for lightweight and mobile use.

- Southeast Asia and India will emerge as high-growth markets driven by urbanization and industrialization.

- Companies will invest in digital monitoring and advanced design solutions to improve safety and efficiency.

- Strategic partnerships and regional expansions will strengthen competition among global and local players.