Market Overview

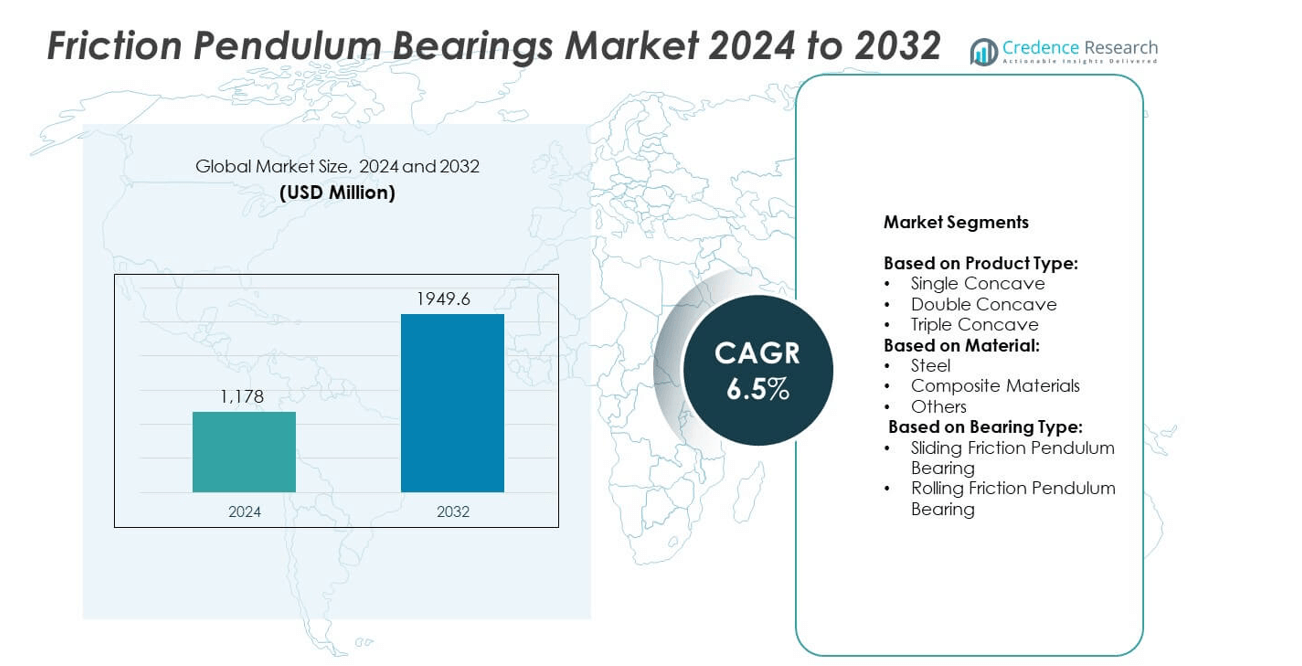

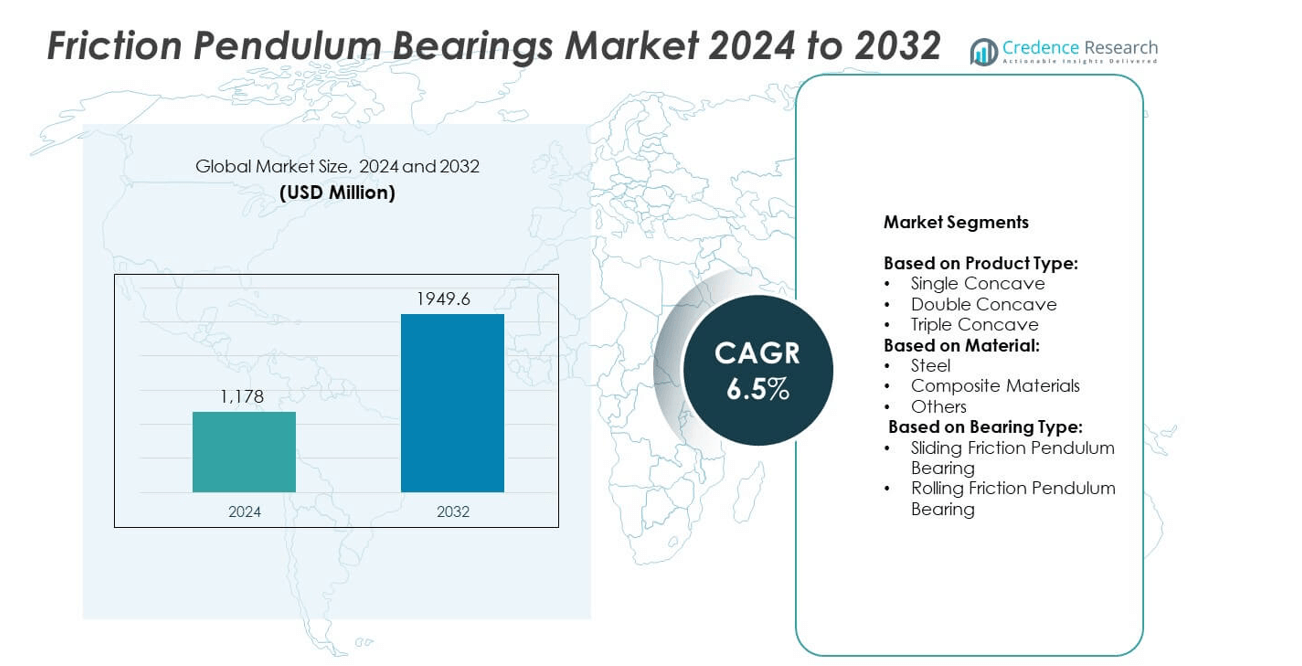

The Friction Pendulum Bearings market size was valued at USD 1,178 Million in 2024 and is expected to reach USD 1,949.6 Million by 2032, growing at a CAGR of 6.5% during the forecast period.

| REPORT ATTRIBUTE |

DETAILS |

| Historical Period |

2020-2023 |

| Base Year |

2024 |

| Forecast Period |

2025-2032 |

| Friction Pendulum Bearings Market Size 2024 |

USD 1,178 Million |

| Friction Pendulum Bearings Market, CAGR |

6.5% |

| Friction Pendulum Bearings Market Size 2032 |

USD 1,949.6 Million |

The Friction Pendulum Bearings market grows due to rising focus on seismic safety and resilient infrastructure. Governments enforce strict building codes, boosting adoption in bridges, hospitals, and public facilities. Demand rises from metro projects, airports, and industrial facilities in seismic zones. Manufacturers innovate with multi-concave designs and advanced materials to improve energy dissipation and durability. Integration of digital monitoring systems supports predictive maintenance. These factors collectively drive market expansion and strengthen confidence among engineers and project developers worldwide.

North America leads demand for friction pendulum bearings, driven by strict seismic safety codes and large-scale infrastructure projects. Europe follows with strong adoption in Italy, Turkey, and Greece for retrofitting schools and bridges. Asia-Pacific shows the fastest growth due to rapid urbanization and metro construction in Japan, China, and India. Key players include Zenith Technologies LLC (ZTech), WSP Group, Mabey Bridge, and NSK Ltd., focusing on innovative designs, material improvements, and collaborations to support resilient infrastructure development worldwide.

Market Insights

- The Friction Pendulum Bearings market was valued at USD 1,178 Million in 2024 and is projected to reach USD 1,949.6 Million by 2032 at a CAGR of 6.5%.

- Growth is fueled by rising demand for seismic-resilient infrastructure, strict building codes, and public funding support.

- Key trends include adoption of double and triple concave designs, use of composite materials, and integration of digital monitoring systems.

- Leading players such as Zenith Technologies LLC (ZTech), WSP Group, Mabey Bridge, NSK Ltd., and Trelleborg AB focus on innovation and global project partnerships.

- High installation costs and limited awareness in emerging regions act as restraints, slowing market penetration in cost-sensitive projects.

- North America leads demand due to robust seismic codes, while Asia-Pacific shows fastest growth supported by urban infrastructure and government mandates.

- Europe and Latin America emphasize retrofitting of aging bridges and hospitals, and Middle East & Africa increase adoption in high-risk seismic zones.

Access crucial information at unmatched prices!

Request your sample report today & start making informed decisions powered by Credence Research Inc.!

Download Sample

Market Drivers

Growing Demand for Seismic Resilient Infrastructure and Safety Standards

The Friction Pendulum Bearings market is driven by the rising focus on earthquake-resistant infrastructure. Governments and private developers invest heavily in base-isolated structures to protect lives and assets. It provides a proven solution to minimize structural damage during seismic events. Urbanization in earthquake-prone regions like Japan, India, and California fuels adoption. Infrastructure projects such as bridges, hospitals, and government buildings specify these bearings to meet stringent codes. This trend strengthens market growth and adoption across public and private construction sectors.

- For instance, Well-Link offers bearings with nominal vertical loads from 0.5 to 4000 tons, horizontal displacement of ±100 to ±1000 mm, and coefficient of friction between 0.01 and 0.05

Rising Investments in Smart Cities and Large-Scale Infrastructure Projects

Global investments in smart cities and transport networks are creating strong opportunities. The Friction Pendulum Bearings market benefits from increasing construction of metro stations, airports, and viaducts. It enhances structural resilience while reducing maintenance costs over the life cycle. Public-private partnerships accelerate deployment in developing nations with seismic risks. Funding support from multilateral banks and agencies encourages integration of advanced seismic isolation technology. Large infrastructure projects adopt these bearings to meet long-term durability requirements and ensure safety.

- For instance, in Japan-US research on Triple Friction Pendulum Bearings (TPBs), a five-story steel frame building specimen was excited 21 times using TPB system in tests, under real strong ground motions such as the 2011 Tohoku earthquake record.

Technological Advancements and Product Innovation Driving Adoption

Manufacturers are developing bearings with improved energy dissipation and load-carrying capacities. The Friction Pendulum Bearings market sees strong demand for double and triple concave designs. It allows buildings to withstand stronger quakes with minimal structural disruption. Research focuses on advanced composite materials to enhance wear resistance and service life. Digital monitoring systems are integrated for real-time performance tracking. These innovations increase confidence among engineers and regulators, encouraging broader adoption in critical infrastructure.

Regulatory Mandates and International Building Code Compliance

Compliance with global seismic design codes supports rapid market expansion. The Friction Pendulum Bearings market aligns with standards such as ASCE 7, Eurocode 8, and Indian IS codes. It ensures projects meet required safety levels for earthquake protection. Governments enforce building regulations for schools, hospitals, and bridges, boosting demand. Insurance firms encourage installation by offering lower premiums for isolated structures. Regulatory pressure combined with public safety awareness sustains long-term growth in multiple regions.

Market Trends

Adoption of Multi-Concave and Advanced Bearing Designs

The Friction Pendulum Bearings market is witnessing a clear shift toward double and triple concave designs. Engineers prefer these systems for their superior displacement capacity and energy dissipation. It enables structures to handle higher seismic forces without major damage. Multi-concave bearings also provide better re-centering after an earthquake. Research efforts focus on optimizing geometry for reduced friction losses. This trend improves performance and lowers lifecycle maintenance costs for critical infrastructure.

- For instance, the company JingTong Rubber Bridge Bearings produces vibration-resistant tensile friction pendulum bearings with a rated load capacity of 1,000 kN, coefficient of friction 0.05, and maximum displacement ±100 mm.

Integration of Digital Monitoring and Smart Sensors

Smart monitoring solutions are becoming common in seismic isolation projects. The Friction Pendulum Bearings market benefits from embedded sensors that track displacement, load, and wear. It allows asset owners to perform predictive maintenance and ensure long-term reliability. Real-time data helps engineers validate designs and improve safety protocols. Cloud-based systems offer centralized control and faster decision-making. Adoption of smart bearings supports the shift toward connected infrastructure.

- For instance, In tests done at the CCCC Highway Bridges National Engineering Research Centre, a friction pendulum bearing specimen with a design capacity of 10,000 kN was subjected to a vertical static force of 10,000 kN. The specimen was then tested under cyclic displacement cycles of 27 mm, 54 mm, and 81 mm to evaluate its rapid friction performance.

Growing Focus on Sustainable and Durable Material Selection

Material innovation is shaping the next generation of products. The Friction Pendulum Bearings market is seeing development of composite sliding surfaces and corrosion-resistant alloys. It increases lifespan while reducing replacement frequency. Manufacturers are reducing reliance on traditional steel-only components for better environmental performance. Coatings that resist extreme weather and chemical exposure gain traction. Demand grows for eco-friendly solutions that meet green building certifications.

Expansion in Emerging Economies with High Seismic Risks

Emerging markets are driving significant demand for base isolation systems. The Friction Pendulum Bearings market expands rapidly in Asia-Pacific, Latin America, and parts of the Middle East. It is supported by government programs focused on disaster-resilient infrastructure. Bridge construction, urban metro projects, and industrial facilities use bearings to safeguard assets. International suppliers form partnerships with local contractors to meet regional needs. Rising construction spending in earthquake-prone cities sustains this growth trend.

Market Challenges Analysis

High Initial Costs and Limited Awareness in Developing Regions

The Friction Pendulum Bearings market faces barriers due to high installation and material costs. Many infrastructure developers in emerging economies hesitate to adopt base isolation systems. It creates challenges for widespread implementation despite proven safety benefits. Limited awareness among contractors and engineers further slows market penetration. Training programs and demonstrations are often required to build confidence. Governments must provide financial incentives or subsidies to make these solutions more accessible.

Complex Design Requirements and Maintenance Considerations

Designing and installing these systems demands specialized expertise and precise engineering. The Friction Pendulum Bearings market must address concerns about inspection and long-term upkeep. It can be difficult to ensure proper maintenance in remote infrastructure projects. Failure to monitor bearings can lead to reduced performance during seismic events. Regulatory compliance adds complexity, requiring detailed documentation and approvals. Manufacturers must work with stakeholders to simplify design integration and provide reliable support services.

Market Opportunities

Rising Infrastructure Investments and Government Support Programs

The Friction Pendulum Bearings market is positioned to benefit from large-scale infrastructure expansion. Governments are prioritizing seismic safety for bridges, airports, and metro projects. It creates steady demand for advanced base isolation systems in both developed and developing nations. Public funding and international aid programs promote adoption in high-risk zones. Disaster-resilient infrastructure initiatives increase awareness and push project planners to specify these systems. This environment offers suppliers strong long-term growth potential.

Advancements in Smart Bearings and Material Innovation

Innovation in smart sensors and durable materials creates new opportunities for manufacturers. The Friction Pendulum Bearings market gains from digital monitoring that enables predictive maintenance and cost savings. It attracts asset owners looking for lifecycle efficiency and operational reliability. Advanced composites and corrosion-resistant coatings open possibilities in harsh climate applications. Integration with IoT platforms allows data-driven decision-making for infrastructure managers. These trends enhance product value and strengthen competitiveness in global projects.

Market Segmentation Analysis:

By Product Type:

The Friction Pendulum Bearings market is segmented into single concave, double concave, and triple concave designs. Single concave bearings hold a strong share due to their cost-effectiveness and simpler design, making them ideal for small and mid-scale projects. Double concave bearings are gaining popularity for their superior energy dissipation and higher displacement capacity. It allows critical infrastructure such as hospitals, bridges, and government buildings to maintain functionality during strong seismic events. Triple concave bearings serve highly specialized projects where maximum isolation and safety are required. Growing adoption of these advanced designs is supported by stricter seismic codes worldwide.

- For instance, in the “Sliding Isolation Pendulum” for seismic protection by WIT Press / UCSD / University of Armed Forces Munich, devices responded to vertical loads of 2,225 kN, 4,450 kN, and 6,675 kN at friction coefficients of 5%, 4%, and 3% respectively; displacement demands were calculated as ±201 mm.

By Material:

The market is divided into steel, composite materials, and others. Steel remains the most widely used material because of its strength and reliability. It offers proven performance in heavy-duty infrastructure and high-load applications. Composite materials are emerging as a fast-growing segment due to their lighter weight, corrosion resistance, and low maintenance requirements. These materials extend service life in coastal and humid environments where steel can degrade faster. Others include hybrid materials and advanced alloys developed for niche applications. Demand for durable and sustainable materials is expected to shape future innovations in this segment.

- For instance, Hengshui Jingtong Rubber Co., Ltd. supplies a Friction Pendulum Bearing model with rated load capacity 1,000 kN, coefficient of friction 0.05, and maximum displacement of ±100 mm.

By Bearing Type:

The market is categorized into sliding friction pendulum bearings and rolling friction pendulum bearings. Sliding bearings dominate due to their lower cost, simpler design, and widespread use in bridges and public infrastructure. It is favored for its proven ability to reduce seismic forces effectively. Rolling bearings, while more expensive, provide smoother motion and minimal wear, making them suitable for high-value structures where long service life is a priority. Manufacturers are investing in designs that minimize maintenance while improving re-centering performance. The combination of technology innovation and project-specific customization drives strong growth across both bearing types.

Segments:

Based on Product Type:

- Single Concave

- Double Concave

- Triple Concave

Based on Material:

- Steel

- Composite Materials

- Others

Based on Bearing Type:

- Sliding Friction Pendulum Bearing

- Rolling Friction Pendulum Bearing

Based on the Geography:

- North America

- Europe

- UK

- France

- Germany

- Italy

- Spain

- Russia

- Belgium

- Netherlands

- Austria

- Sweden

- Poland

- Denmark

- Switzerland

- Rest of Europe

- Asia Pacific

- China

- Japan

- South Korea

- India

- Australia

- Thailand

- Indonesia

- Vietnam

- Malaysia

- Philippines

- Taiwan

- Rest of Asia Pacific

- Latin America

- Brazil

- Argentina

- Peru

- Chile

- Colombia

- Rest of Latin America

- Middle East

- UAE

- KSA

- Israel

- Turkey

- Iran

- Rest of Middle East

- Africa

- Egypt

- Nigeria

- Algeria

- Morocco

- Rest of Africa

Regional Analysis

North America

North America accounts for 32% of the Friction Pendulum Bearings market, driven by high adoption of seismic isolation technologies in the United States and Canada. The region prioritizes earthquake resilience, especially in states like California, Oregon, and Washington where seismic activity is significant. It benefits from strict building codes such as ASCE 7, which encourage the use of base isolation systems for critical structures. Demand is strong in bridges, hospitals, data centers, and public infrastructure projects. Federal and state government funding supports retrofitting of existing assets with modern bearings to reduce risk. Research institutions and engineering firms in the region contribute to innovation, resulting in the development of high-performance multi-concave bearings. Growing investment in smart city infrastructure and resilient transport systems ensures sustained demand over the forecast period.

Europe

Europe represents 27% of the Friction Pendulum Bearings market, supported by widespread use in countries such as Italy, Greece, Turkey, and the United Kingdom. Seismic activity in Southern Europe creates a strong need for advanced isolation technologies. It is further supported by the enforcement of Eurocode 8 standards, which guide earthquake-resistant design. Governments actively fund infrastructure safety programs, with emphasis on retrofitting schools, cultural monuments, and public buildings. Demand is also increasing in Northern and Western Europe where aging bridges require seismic upgrades. Manufacturers in the region are focusing on corrosion-resistant and long-life materials to meet sustainability requirements. Integration of digital monitoring systems is gaining traction, allowing operators to track bearing performance throughout their service life.

Asia-Pacific

Asia-Pacific holds 30% of the Friction Pendulum Bearings market and is the fastest-growing regional segment. Countries like Japan, China, and India drive major demand due to frequent seismic events and rapid infrastructure development. It benefits from government-mandated seismic codes and major investments in metro rail projects, airports, and industrial facilities. Japan leads in technology adoption, with highly advanced multi-concave bearing systems used in high-rise buildings and nuclear facilities. China’s Belt and Road Initiative and urbanization efforts further create strong demand for resilient bridges and transport infrastructure. Local manufacturers are expanding production capacity to meet domestic needs and supply neighboring markets. Rising awareness of disaster preparedness fuels public and private investments in base-isolated structures across the region.

Middle East & Africa

The Middle East & Africa region accounts for 6% of the Friction Pendulum Bearings market, with demand concentrated in Turkey, Iran, and parts of North Africa. Turkey’s high seismic risk encourages large-scale deployment of base isolation systems in hospitals and public buildings. It is supported by government programs aimed at minimizing earthquake damage and ensuring post-disaster functionality. The Middle East invests in infrastructure resilience for critical projects, including airports, energy facilities, and commercial complexes. Africa shows gradual adoption, with South Africa leading initiatives for bridges and transportation hubs. Rising construction spending and growing awareness of seismic risks create a potential growth market. Partnerships between global suppliers and local contractors are helping improve access to high-quality bearing systems.

Latin America

Latin America contributes 5% of the Friction Pendulum Bearings market, with Chile and Mexico leading adoption due to their high exposure to earthquakes. Both countries have implemented strict seismic codes requiring advanced isolation systems for major infrastructure projects. It supports adoption in hospitals, bridges, and government buildings designed to remain operational after earthquakes. Brazil and Argentina show rising interest as awareness of earthquake risks increases. Regional governments and private developers are exploring cost-effective solutions for retrofitting critical infrastructure. International suppliers are collaborating with local firms to enhance availability and reduce costs. Expansion of transportation networks, including elevated highways and metro systems, drives additional opportunities in the region.

Shape Your Report to Specific Countries or Regions & Enjoy 30% Off!

Key Player Analysis

- Zenith Technologies LLC (ZTech)

- WSP Group

- Mabey Bridge

- Reed Mallik Ltd.

- Zandonini spa

- NSK Ltd.

- Trelleborg AB

- ENEGI

- KELZA Engineering

- FIP Industriale

- WISON Engineering Ltd.

- Lombardi S.r.l.

- VibroAcoustic Consultants Inc.

- S Industrial Minerals

- Furukawa Electric Co., Ltd.

Competitive Analysis

The leading players in the Friction Pendulum Bearings market include Zenith Technologies LLC (ZTech), WSP Group, Mabey Bridge, Reed Mallik Ltd., Zandonini spa, NSK Ltd., Trelleborg AB, ENEGI, KELZA Engineering, FIP Industriale, WISON Engineering Ltd., Lombardi S.r.l., VibroAcoustic Consultants Inc., S Industrial Minerals, and Furukawa Electric Co., Ltd. These companies focus on providing high-performance seismic isolation solutions to meet global infrastructure needs. The market is competitive, with players emphasizing product reliability, multi-concave designs, and compliance with international seismic codes. It is characterized by significant investments in R&D to enhance energy dissipation capacity, durability, and monitoring capabilities. Many players collaborate with engineering firms and government agencies to supply bearings for large-scale projects such as metro systems, hospitals, and bridges. Strategic partnerships and joint ventures help expand presence in emerging economies with growing infrastructure demand. Companies also invest in manufacturing capacity and material innovation to lower costs and improve performance. The shift toward smart bearings with integrated sensors supports differentiation in a competitive market. Overall, competition drives continuous innovation and wider adoption, ensuring that global infrastructure projects meet higher safety and performance standards.

Recent Developments

- In 2024, Mabey Bridge reported a long-span Delta installed in South Lanarkshire, Scotland.

- In 2024, WSP engineers joined a Taiwan earthquake reconnaissance mission after the 7.2 quake

- In 2024, Furukawa Electric opened a laser processing solutions laboratory in Aichi.

Report Coverage

The research report offers an in-depth analysis based on Product Type, Material, Bearing Type and Geography. It details leading market players, providing an overview of their business, product offerings, investments, revenue streams, and key applications. Additionally, the report includes insights into the competitive environment, SWOT analysis, current market trends, as well as the primary drivers and constraints. Furthermore, it discusses various factors that have driven market expansion in recent years. The report also explores market dynamics, regulatory scenarios, and technological advancements that are shaping the industry. It assesses the impact of external factors and global economic changes on market growth. Lastly, it provides strategic recommendations for new entrants and established companies to navigate the complexities of the market.

Future Outlook

- The market is expected to grow steadily driven by rising seismic safety awareness.

- Governments will continue mandating base isolation systems for critical infrastructure projects.

- Adoption of double and triple concave bearings will increase for enhanced energy dissipation.

- Demand for digital monitoring solutions will expand to support predictive maintenance.

- Composite materials and corrosion-resistant alloys will gain share due to durability benefits.

- Infrastructure investments in Asia-Pacific will drive the fastest regional market growth.

- Retrofitting of aging bridges and public buildings will create long-term opportunities.

- Collaboration between global suppliers and local contractors will improve cost efficiency.

- Research will focus on developing smart bearings with real-time data tracking capabilities.

- Growing emphasis on climate resilience will encourage use of sustainable material solutions.